Styrofoam characteristics

Before using expanded polystyrene for facade insulation, you need to choose it correctly. Polyfoam used as thermal insulation must necessarily contain flame retardants - substances that prevent it from burning.

Their presence is indicated by the letter "C" in the abbreviation (PSB-S) or the letter "R" if the material is of foreign production. Indicators such as density and thickness are equally important. For insulation of residential buildings outside, plates of five centimeters wide are usually used, no more.

Depending on the type of foam, its density can vary from 15 to 35 units. And since foam is a fairly warm material, its density should not be very high. To insulate the walls of the house, it is enough to take insulation with a compression density of 15 or 25 units. Density 35 is used for floor insulation.

In addition to density, the following qualities and characteristics are characteristic of foam:

Features of the structure of the foam

It is a foamed inhomogeneous cellular structure consisting of granules sintered together under the action of high temperatures, the volume of which is filled with air. The sizes of the cells can be up to 1 cm in diameter, depending on the technical conditions of manufacture. The raw materials for its production are polymers, the composition of which affects the basic properties of the finished material. Foams consist of micro-sized cells and have a large area of contact with air due to the presence of internal thin elastic sealed walls. The bulk of the foam is air up to 98%, which improves its insulating characteristics.

Insulation of a brick wall with foam

You can insulate the walls with foam plastic both inside and outside. However, most often the insulation of a brick wall is carried out outside. External thermal insulation allows you to shift the point of greatest freezing, which prevents the penetration of cold into the house. The walls of the house must be warmed up by internal heating. When installing the foam from the inside, the brick wall will be isolated from the inside, which will interfere with its heating.

As a result, the dew point will shift between the wall and the expanded polystyrene. Moisture will begin to accumulate on the inner surface of the walls under the insulation, soaking the walls and freezing in frosts. As a result, all this will lead not only to freezing of the house, but also to the rapid destruction of the insulation and the brick wall itself.

Therefore, it is advisable to fix the foam insulation slabs on the outside of the façade. But in this case, it is necessary to cover it with a layer of plaster without fail, this will protect the material from the sun's rays, thereby extending its service life, and will also give the structure the necessary strength.

Using foam as insulation

Insulation can be various foam plates. If their density is low, then during insulation it is necessary to make maximum protection against mechanical damage.

Such plates are more often used as insulation for a frame house, that is, in cases where the load falls on the frame and the outer protection of the insulation. If the density of the foam is greater, then protection against mechanical damage can be provided without even installing the frame, but protection should still be there.

In principle, polystyrene as insulation is used for interior and exterior work, for insulation of walls, ceilings, attics, foundations and floors, but it is not very suitable if you need internal insulation of walls if they go outside.

- Such walls must necessarily be warmed up by internal heating.

- If you lay polystyrene from the inside of such a wall, it will be warmed and insulated from heating from the room.

- The dew point will be inside the wall or between the wall and the foam, in both cases, this will dramatically reduce the quality of insulation.

- Moisture will saturate the wall and change its thermal insulation properties for the worse.

If moisture condenses inside the wall, it may freeze at low temperatures. As a result, heat transfer will be disrupted and the wall will gradually collapse. It is better to use it to insulate external walls.

At the same time, even if it has a high density, it is not mechanically strong enough, therefore, it is required to strengthen the foam plates from the outside. If you decide to insulate the foundation with foam, then the slabs need to be protected not only from soil pressure, but also from loads as a result of heaving, it can occur in cold weather.

To strengthen the surface of the foam on the walls, it is enough to use a reinforcing mesh, you also need to apply a layer of plaster. If you are insulating the basement, then the protection should be more serious, you will need brickwork or wooden formwork.

Pros and cons of foam insulation of a wooden house

The question is often asked: "Is it possible to insulate the walls of a wooden house with foam plastic?"

... Among experts on this score, one can find two opposite opinions: some argue that it is possible, others are categorically against it. Let's try to figure it out.

One of the reasons why many speak out against the insulation of a wooden facade with foam is its low vapor permeability, due to which the wood can rot. At the same time, there are many people who took the risk of insulating their wooden house with this material, and are satisfied with the result.

One of the main advantages of wood is its ability to "breathe". This is one of the main advantages of the construction of a suburban wooden house. In order not to lose this quality, the thermal insulation of the facade should be carried out with care. The consequence of improper insulation can be not only insufficient air flow into the room.

The correct technology of thermal insulation implies that the vapor permeability of building materials should increase towards the street, so as not to impede the escape of fumes from the house.

If this rule is violated, moisture will condense on a denser material, which will lead to wetting of the insulation, the formation of condensation and, as a result, wood rot. That is why, when choosing a heater for your wooden facade, pay attention to the vapor permeability of building materials.

As can be seen from the table, the vapor permeability indicators of expanded polystyrene are much lower than those of the walls of a wooden house. Hence, we can conclude that it is undesirable to warm wood with foam, unless you find this material with a higher vapor permeability.

And what does practice tell us? Many people, despite the recommendations or simply not knowing about them, insulate wooden facades with foam and are quite satisfied. The question arises, where does the condensate go.

It should be noted here that the rate of decay directly depends on the amount of moisture evaporating from the house. If the room is equipped with a good ventilation system, then the harm from a small amount of vapors, of course, will be less. However, if you insulate a wooden bath with foam plastic, the result will be obvious within the next few years.

The main reason why polystyrene as insulation is so demanded in recent years is its low cost. That is why, in an effort to save money, many decide to insulate wooden buildings with this material.

Over time, however, these savings can become ruinous. Alternatively, it is better to choose mineral wool.It does not create obstacles in the way of fumes, which perfectly reach the ventilation gap between the insulation and the cladding. The walls "breathe", and you can enjoy life in your wooden house.

The advantages of foam insulation

At the same time, foam has many advantages. It is resistant to moisture and practically does not absorb it, it has good thermal insulation properties. Mold and mildew will not appear on the surface of this material.

It is convenient to mount and cut. It is a lightweight material, which is very positive for any construction work. Another advantage of polystyrene is its low cost, it can be used for a long time and it will not lose its properties.

He is able to withstand extreme heat and frost, he is not afraid of temperature fluctuations during the day. It has good sound insulation performance.

However, this material, like any other, has its drawbacks, its mechanical strength is limited. After installation, you need to make additional protection against mechanical damage.

This material is practically impervious to air. It is easily destroyed when exposed to nitro paints and paints and varnishes that have this base.

In general, this is a good choice of insulation for walls, especially for garages and utility structures. It can also be used for living quarters, but it is advisable to do this in not very cold climates. If you want to save money on repairs and insulation, then foam is the best choice.

In principle, you can do the insulation yourself, but if you are not sure of your capabilities, then you can contact professional specialists

It is important to choose the right material and not save on it, if you try to purchase it at a price below the market price, you will not see any advantages, but there will be many disadvantages, instead of saving you will have to re-insulate and buy the material.

In a word, this is a good option for economical repairs, but it is undesirable to use it everywhere. Before starting work with him, study the maximum amount of information, consult with experts, you need to take the issues of thermal insulation seriously, even if we are talking about non-residential premises.

More information about foam and its use in construction can be found on the construction forum, where you will learn a lot of useful things.

Modern requirements for ensuring the energy efficiency of construction facilities are increasing and therefore it is necessary to use high-quality heat-insulating materials.

One of them is foam insulation. They insulate walls, ceilings, roofs both inside and outside the premises.

Thanks to its heat and sound insulation properties, as well as ease of installation, it has become one of the most demanded materials on the construction market. But is this material really so perfect? Paying attention to polystyrene, one should study not only its basic properties, but also the conditions and requirements for its operation.

Thermal insulation with liquid foam

There is another way of warming - the use of polystyrene foam in liquid form. This type of filling foam is made directly at the construction site and poured into a pre-prepared formwork. Liquid foam can be used to insulate a brick, stone and concrete house.

Thermal insulation technology called "well" masonry is well suited for this material. It provides for a three-layer structure: wall, insulation, additional brickwork. In this case, the insulation is pumped between the two layers.

The advantages of liquid foam include:

- High quality material.

Filling polystyrene foam does not allow cold in winter and heat in summer; - Low price.

Liquid foam saves on stacking and shipping costs.According to experts, wall insulation using this material is almost half the price compared to other insulation materials; - Practicality.

Pouring liquid foam is several times faster than installing conventional insulation. And the principle of pumping thermal insulation allows you to implement new unusual solutions.

Despite the emergence of more and more insulation materials, foam continues to be popular among professional builders and DIYers. What allows this material to maintain its leading position as insulation, and what are the ways to use it?

Is Styrofoam Eco-Friendly?

Since polystyrene is one of the most used heat-insulating materials, the question arises: "Is polystyrene harmful as insulation?" It contains a dangerous substance - styrene. Modern technologies have made it possible to significantly reduce its content in the finished product, so that its amount is absolutely not harmful to health. It is released only when heated above +40 0 С in small quantities. Therefore, it is used to insulate walls from the outside so that the poisonous vapor escapes into the atmosphere. In addition, self-extinguishing foam can be used. In the event of a fire, the foam will be the least toxic compared to other finishing materials.

Specifications

Foam production was started more than eighty years ago. The first block was produced in Germany, after which it began to be applied everywhere in various territories. Polystyrene balls serve as the basis for the insulation boards. Initially, they are elements with a dense structure that do not even remotely resemble foam. At the first stage of production, they are foamed. Next, the base is dried and aged, which is subsequently immersed in a special chamber, where it is sintered with steam at a certain pressure. At the presale stage, the foam is in large blocks that are cut to specification.

The size of a standard sheet that is used for insulation has a length and width of one meter, there are also options for a foam sheet with a half-width smaller. The most popular sheet size is 120 by 60 cm. The difference in types lies not only in size, but also in the density of the material. A density of 25 kg per cubic meter is considered normal for facade insulation. Plates with a density of 15 and 40 kilograms are also produced. This indicator directly affects thermal conductivity. The higher the number, the lower the thermal conductivity and the higher the price for the foam. A denser insulation can withstand heavy loads, so it is often used to insulate the floor.

Due to the fact that the balls undergo preliminary foaming, this saturates them with gas, which determines the low thermal conductivity of the foam. Its indicator is in the range of 0.038 W / (m × K). Typically, the foam is produced in white, but in the process of making polystyrene beads, the manufacturer can add any pigment required to make his products stand out from other options. In some cases, extruded polystyrene foam and expanded polyethylene can also be called foam. These materials differ from polystyrene in the manufacturing method and the underlying material.

Material water absorption

The level of water absorption by a material plays an important role in the construction of objects from materials that cannot withstand the effects of moisture and deteriorate or degrade under their influence.

Note!

Foam plastics are not non-hygroscopic, since with prolonged exposure to water, they are able to absorb only up to 3% of the total volume.

This value depends on the technological features of production and the tightness of the connection of the cells, as well as their sizes. That is, water can only penetrate through the air channels that remain between the cells.Water vapor will also not be absorbed in large quantities, since the diffusion coefficient of the foam is high.

Properties

Based on the characteristics and experience of using foam, it is quite easy to highlight its strengths and weaknesses. The advantages of such an insulator include:

- minimum weight;

- ecological cleanliness;

- low cost;

- the possibility of self-assembly;

- the possibility of insulating various surfaces;

- ease of processing and fitting;

- resistance to biological processes;

- soundproofing properties.

The solids in the foam are only a few percent compared to the total volume of gas contained in the material. This makes it lightweight. Thanks to this, the insulation is perfect for use with frame structures, since it does not exert significant pressure on the foundation and walls. This feature also simplifies the process of lifting the material to a height and self-assembly. Polystyrene is a polymer that, in its structure and composition, does not cause any harm to human health and the environment, if you do not eat it, therefore, you can insulate the structure with foam plastic without fear that, over time, harmful substances will begin to be released from heating. The comparative cost of such a material is low, so it is suitable for low-budget insulation of temporary buildings.

The installation of the material does not cause any particular difficulties, therefore it can be carried out without assistance. Due to its versatility, insulation can be performed on any available surface. At the same time, the foam does not react with most building materials, if you do not take into account organic solvents. Therefore, when laying foam on wooden, brick or concrete surfaces, there are no problems. The insulation can be processed with an ordinary knife or hacksaw, which simplifies the process of adjusting it to various shapes. The material of small thickness can take curvilinear forms, therefore, insulation of semicircular bay windows is available. Polyfoam is an excellent insulation for the basement and foundation. This is due to the fact that it can be in the ground for many years without changing its properties, since it is not subject to decay processes and mold and fungus do not develop on the surface of the foam. The wall insulated with foam acquires additional soundproofing properties, which is also a positive effect.

It is important to know about the disadvantages, which, however, are covered by the existing advantages:

- instability to organic solvents;

- low mechanical strength;

- fire hazard;

- lack of vapor permeability.

It is not recommended to use insulation during painting. Certain types of paints that are diluted with solvents can damage the material by decomposing it. A surface insulated with foam requires additional reinforcement by installing a fiberglass mesh in order to increase its strength, since even a slight mechanical effect can leave a dent in the material. Although fire retardants are added to the insulation during production, this does not make it absolutely fireproof. When exposed to high temperatures, the material melts with the release of carbon dioxide, but is capable of self-extinguishing. Due to the density of the material, air does not pass through it, which provides insulation from moisture, but creates a barrier during its outflow, which can result in the formation of mold under the insulation.

Note! Rodents can get inside the insulation slabs. Mice and rats do not eat it, but simply make passages inside, arranging a dwelling. Poultry also loves to peck on styrofoam, damaging its integrity.

Properties of foam as insulation

To date, there are various types of insulation on sale. or other insulation?

The wide demand for foam plastic is primarily due to its low cost. However, this is not its only advantage. The low weight of the boards, as well as the fact that they are rigid, unlike, for example, mineral wool, ensures simplicity and high speed of installation. Even one person can easily cope with this task without the involvement of any special technical devices, not to mention heavy equipment.

At the same time, the foam is a rather effective heat insulator: its thermal conductivity coefficient is only 0.04 W / m * C (value for grades with an average density).

The technical characteristics of the foam as insulation make this material fragile. Depending on the circumstances, this quality can turn into both an advantage and a disadvantage. For example, due to its low strength, foam plastic lends itself well to processing, it can be cut as you like right during installation. On the other hand, when insulating a building from the outside, the material must be protected with a metal mesh and a layer of plaster. For the same reason, care should be taken during installation, since foam boards of any thickness are very easy to break.

Being completely synthetic in nature, the foam is not subject to decay, however, for some reason, it is very loved by rodents. Having found at least insignificant access to the heat insulator, they quickly gnaw through whole holes in it. But, although interest from rodents is highly undesirable, it is the best evidence of the environmental friendliness of the material.

Another enemy of foam is ultraviolet light. In the absence of protection from solar radiation, the material quickly begins to crumble, becoming unusable. Also, contact with some paints and varnishes contributes to the destruction of the structure of the foam.

Is it worth it to insulate from the inside

The question of insulating a house or other building with foam from the inside causes a lot of controversy, since it is difficult to unequivocally answer this question. It is worth saying that this method of foam insulation exists, but it also has opponents. The main argument is that heat-absorbing materials should be placed inside the room, since they absorb the ambient temperature, and the heat-insulating materials should be left outside so that they prevent the penetration of cold to the building materials. Insulation from the inside with foam is possible if you provide high-quality ventilation of the room, which will remove moisture in a timely manner, which will prevent the formation of mold. It is also important to calculate everything correctly so that the dew point does not shift towards the dwelling. In this case, due to the difference in air temperatures inside and outside, condensation will occur between the insulation and the wall, which will lead to the destruction of the blocks. A video of the process of internal foam insulation is below.

Advantages and disadvantages. An increasing number of homeowners, frightened by the bills for heating fluids, decide to insulate their homes and choose polystyrene as a heat insulator.

- the pros and cons, how not to make a mistake in the choice, the article is devoted to these issues.

We stipulate right away: polystyrene and expanded polystyrene are produced from the same raw materials, but these are different materials. Polyfoam is a brittle, flammable, light-degradable material that does not withstand mechanical stress and is intended for packaging. For insulation, polystyrene foam is used - a denser material with completely different characteristics, but in common parlance, both materials are called the same, which often leads to confusion.

The production process of foamed organic styrene is a technical development in 1951 of the American concern BASF. The insulation, called "styrofoam", consisted of 98% air filling the cellular foam base. The material was characterized by low thermal conductivity, low water absorption and vapor permeability.

As a result of the improvement of technology, extruded polystyrene foam appeared - self-extinguishing foam. Their main difference lies in the structure of the cells: for expanded polystyrene, the structure is open, for extruded material it is closed, due to which water absorption decreases and fire resistance increases.

The quality and technical characteristics of foamed plastics in Russia are declared by GOST 15588-2014 “Foam polystyrene heat-insulating plates. Technical conditions ". For wall insulation in a system with an outer plaster layer, in accordance with this document, it is necessary to use expanded polystyrene with the F-facade marking.

The letter G in the marking of the plates indicates the content of graphite in the composition, which gives a lower thermal conductivity and paints the material in the mass in a silvery-black color.

Resistance of foam to environmental influences

Subject to the operating conditions, the material is able to retain all its properties. It does not decompose and does not shrink, which positively affects its technical characteristics, such as strength and durability. Resistant to salts, weak acids and alkalis. Does not react with building mixtures and materials and therefore can be used in the construction of any facilities. It is not susceptible to the influence of microorganisms, and since it repels water and does not accumulate moisture inside the material. Consequently, sudden changes in temperature will not be able to disrupt its structure.

We're for it"!

So say people who have recently performed foam insulation at home. Indeed, the material has a lot of positive qualities:

- Low weight.

- Low thermal conductivity.

- Excellent sound absorption performance.

- Self-extinguishing property.

- Ease of use.

- Low cost.

Yes, indeed, in terms of thermal conductivity, foam plastic is second only to polyurethane foam, the volumetric weight of the plates is from 10 to 50 kg per 1 m3, while in the best materials made of mineral wool it starts from 30–35 kg / m3, it perfectly dampens noise and fades in 1 second, and any homeowner can work with it.

What to insulate with styrofoam?

- Use as heat and waterproofing material for foundations. This allows you to protect against freezing and temperature extremes.

- Concrete floors, inside of which strong foam plates are installed, and then a leveling layer is poured.

- Insulation of roofs made of materials that do not heat up to temperatures at which styrene will begin to evolve.

- Walls of houses. Moreover, on the inside, a greater effect is obtained, since insulating the walls with foam from the inside means shifting the dew point from the base material to the foam layer and the walls will not be dampened.

Wall insulation

And we are against

This is what people say who insulated the house without taking into account the specifics of the material. Let's list the negative qualities of the material:

- Low vapor permeability.

- Great water absorption.

- Low resistance to mechanical damage.

- Light instability.

- Rodents love.

Due to the low vapor permeability of this material, it is undesirable to insulate the outside of the house from wood - without the device of two ventilated gaps, which is difficult and busy. Moisture absorption of 4% with low quality of work will ensure wetting and loss of heat-insulating qualities by the material after 2 seasons.

When insulating as part of a light plastering system, any accidental blow can lead to the destruction of the protective layer, and the exposed foam will simply crumble under the influence of sunlight. And, finally, the last: this material is preferred by mice for making nests in the thickness of the insulation - it is warm, it is easy to gnaw through the passages.

In wet plaster systems, a metal perforated corner - the starting profile - saves from the invasion of rodents, but when installing a ventilation facade, they easily overcome this obstacle.

Disadvantages of Styrofoam

- Brittleness can cause damage to the plates under mechanical stress and stress.That is, installation on uneven surfaces is significantly difficult. Therefore, you will need to align them or use plywood sheets as a backing. From the outside, the installation of a protective coating will be required.

- Destruction of the structure under the influence of direct sunlight.

- Poor soundproofing level compared to other types of materials.

- Release of harmful substances during combustion.

Warming principle

Where to use Styrofoam?

So why, despite all the negative qualities, polystyrene foam is popular? How to use the best qualities of the material to make your home comfortable and minimize the negative?

Let's consider. A little heat engineering in the tape: for the insulation system to work, it is necessary that the vapor permeability of materials increases from the inside out, and the thermal conductivity of materials, on the contrary, decreases.

That is, the material from the street side should have a higher vapor permeability than the internal material and a lower coefficient of resistance to heat transfer.

Comparing the heat transfer resistance of building materials and foam, we see that this indicator satisfies the requirement, but when comparing the vapor permeability, it turns out that in the case of wood, the foam polystyrene index is lower than that of wood, which means that the dew point will be on the wooden structure, which will lead to the deposition of condensate on it, getting wet and rotting.

When insulating a house made of wood with foam from the inside, the requirement is also not met, since the coefficient of heat transfer resistance of wood is greater than that of insulation.

Thermal insulation properties

Since the foam is filled with air, which is an excellent heat insulator with a thermal conductivity coefficient of 0.026 W / (m * K), depending on the size of the cells, a total thermal conductivity of the material up to 0.043 W / (m * K) can be achieved. One of the closest competitors in this parameter is, but its thermal conductivity is higher and therefore it will be necessary to increase its thickness by about 5-10%, compared to the thickness of the foam. In addition, using polystyrene as insulation, installation of the lathing is not required during installation, and the connecting seam can be made with a minimum gap and high accuracy.

findings

Polyfoam is not suitable for insulating wooden houses, but it will perfectly cope with the task of keeping warm with walls made of bricks or light aerated concrete. When choosing an insulation system, it is better to stay on a wet (plaster) system if the house is located near cultivated areas, where vole mice are a common occurrence.

Considering all of the above and exactly following the instructions of the manufacturers when performing the work, the use of foam for insulation is justified and will last longer than the guaranteed 50 years.

Building materials cannot cope with the task of creating a favorable microclimate in the room, therefore, in construction they cannot do without additional insulation. Builders often use foam as insulation for the roof, ceiling, attic floor, as well as for the foundation and walls. The material has different technical characteristics in terms of thermal conductivity and thickness, which can be used in accordance with the installation site and needs. Another plus is the simplicity of panel cutting and installation.

Polyfoam, or expanded polystyrene, is a cellular mass made of foamed plastic. The characteristic lightness of the material is due to the fact that its main volume consists not of the initial polymer, but of air, which, moreover, is a poor heat conductor.

Marking and density of expanded polystyrene

If the letter C (PSB-C) is added to the marking of the abbreviation in accordance with GOST-15588-86, then this indicates that fire retardants have been added to the foam polymer and such foam belongs to the flammability group G1 or G2. If this letter is absent, then there are no fire retardants and this is G3 or G4. The density of the material shown in the table means the following:

- PSB-S-15 - the number indicates that the panel density is not 15 kg / m 3, but up to this mark. This is the lowest indicator among all brands, therefore PSB-S-15 is used in places that do not bear mechanical stress: insulation of roofs, ceilings, as well as walls and floors under frame cladding. This brand is also used for soundproofing rooms.

- PSB-S-25 - density up to 25 kg / m 3, and such panels have a universal nature of use - they are used more often than other materials. In addition to places that do not bear a mechanical load, this insulation is used for building facades with the application of ordinary and decorative plasters to it.

- PSB-S-35 - panels density up to 35 kg / m 3 allows their use in sandwich panels, in reinforced concrete structures (fixed formwork), as well as for the arrangement of waterproofing. This brand is also used for underground work - insulation and waterproofing of basements and foundations.

- PSB-S-50 is the most durable polystyrene foam and can be used both for places with low mechanical stress and high. It can be used to insulate floors, heated soils and even autobahns.

Operational and technical characteristics

Thermal conductivity diagram of building materials

The most basic quality of expanded polystyrene is low thermal conductivity, this property of foam as a heater in comparison with other building materials is shown in the table above. The effect is achieved due to the uniform distribution of air in the volume of the foamed polymer and its thickness. PSB of any density can be used for indoor and outdoor work with any degree of humidity, as well as with temperature drops (range is from -200ᵒC to + 85ᵒC).

In addition to insulation, expanded polystyrene is used for sound insulation of certain objects, for example, PSB is laid inside plasterboard partitions or under the metal roof of a building. Polyfoam is a chemically neutral substance and has a long service life. Even when a leak is observed, for example, when the roofing material is damaged (corrugated board, slate, etc.), the properties of PSB are not lost, since there is no reaction to moisture.

Styrofoam of different thickness

Foam panels are resistant to weak acids, alkalis and alcohol, which greatly increases the range of applications. PSB is easy to cut and at the same time you can use the simplest tools - a painting knife or a hot string of nichrome. Installation is carried out on glue, on umbrella dowels or between profiles.

Some general information about Styrofoam

This material is obtained by foaming a plastic mass. Gas makes up its main volume, therefore the density of the resulting material is much lower than the density of the polymer.

In everyday life (and not only), we often deal with expanded polystyrene (non-pressed). It is widely used due to its high thermal insulation properties (98% of the material is gas in small cells).

The scope of application is really extensive: in construction for the insulation of various structures, including residential buildings; for the manufacture of all kinds of containers; in instrumentation for thermal insulation (e.g. refrigerators), etc.

Foam technology for thermal insulation

The ease of cutting polystyrene, the simplicity of its installation and low cost contributes to the popularity of the material for private construction. With competent calculations and correct laying of foam plates, it is possible to ensure a normal microclimate in residential and non-residential (household buildings, attics, and so on) premises.

Which side is it better to install the foam

Dew point displacement depending on the location or lack of thermal insulation

When insulating a building, including the attic, the location of the insulation is of great importance, since this shifts the dew point and the effectiveness of the insulating material.If the slab is installed indoors, the wall still remains cold, therefore, it is necessary to increase the thickness of the expanded polystyrene. In addition, the dew point (condensation) most often occurs at the point where the foam meets the wall, which leads to the formation of mold.

If the insulation is mounted outside, then the dew point is shifted to the foam and condensation is not collected due to the lack of moisture inside the foamed polymer. In this case, the wall heats up from the side of the room and dampness does not get there, therefore, the operational resource increases. If thermal insulation occurs under the roofing material, then it is only internal and condensation cannot form at the junction - the dew point is transferred into the attic.

Calculation of the thickness of the foam insulation

The ratio of the coefficient of thermal conductivity and the required thickness of the material. (* Indicates the addition of a factor of 1.15 for buildings with monolithic belts of heavy concrete)

According to SNiP 2.09.84.87-2001, the table shows the minimum coefficient for residential and office buildings. In addition, for each region there is a certain value of thermal resistance - this is a constant value, which is denoted by the letter R. For an indicative calculation, you can take the average indicator R = 2.8 (m2 * K / W).

The calculation formula looks like this: R = R1 + R2

, where R1 is a wall (conditionally brickwork), R2 is a heater (conditionally foam).

The total and individual thickness of materials is calculated by the formula R = p / k

, where p is the layer thickness in meters, k is the thermal coefficient of the building material (W / m * k). For an indicative calculation, a masonry of two bricks and PSB-S-25 foam plastic will be used.

Building insulation with expanded polystyrene

The length of an ordinary brick (coefficient 0.76 (W / m * k)) is 0.25 m, which means that the masonry has a thickness of p = 0.25 * 2 + 0.01 = 0.51 m.The total thermal conductivity of the brickwork will be Rbrick = p / k = 0.51 / 0.76 = 0.67 (m2 * K / W). Therefore, Rfoam = Rtotal-Rbrick = 2.8-0.67 = 2.13 (m 2 * K / W).

For the total thickness of expanded polystyrene, you need to substitute values for the formula Pfoam = Rfoam * kfoam = 2.13 * 0.035 = 0.07455 m. Please note that the calculation is indicative and here neither the thickness of the plaster nor the thickness of the cladding with their thermal coefficient was taken into account. For such walls with decoration (external and internal) and waterproofing, the average thickness of polystyrene foam is usually not 0.07455 m, but 0.5 or 0.6 m.

Cutting technology

For internal and external insulation of premises with expanded polystyrene, a painting knife with a sharp blade is used for cutting it. This factor affects the clarity of the cut - a dull blade tears the foam and as a result, a lot of debris is obtained in the form of small polymer granules. It is very difficult to remove them, as, having a static charge, they stick to all objects.

The panels are cut "under a ruler", which is replaced by a building rule or a long level. For cutting, a wooden plane is used in the form of a plank board, plywood or OSB, so that the blade does not dull so quickly. In this case, the parameters of the cut fragment must exactly match the parameters of the footprint.

Features of installation of PSB under plaster

Installation of PSB on umbrella dowels

The most common type of outdoor installation is the installation of foam plastic on umbrella dowels with additional fixation on glue (Ceresit CM-11 is most often used for this). Such fastening is used under ordinary or decorative plaster, with preliminary sealing of gaps and gluing of a plaster mesh. Considering future mechanical loads, the PSB-S-25 brand is needed here.

For such an installation, a plane without drops is important, so that the panels laid on it also create a relatively flat plane for the front finish. In some cases (as a rule, this happens after the walls have been erected), the surface is first plastered and only after that the panels begin to be fixed.

Installation of PSB insulation under the frame

Installation of PSB under the crate for finishing

In the top photo, you can see the installation of foam with practically no fasteners - here the panels are fixed between the transverse beams, on which the wooden crate is held.Also, such a crate can be attached directly to the wall, but polystyrene foam is still fixed in an identical way, between the beams (boards). If there are gaps between the panels, then polyurethane foam is blown into it.

An identical method is used for drywall interior partitions, where the foam is tightly inserted between the profiles. But here PSB serves not so much for insulation as for soundproofing the room.

Installation of foam on the ceiling under a metal frame

Wood itself is a heater, so mounting panels between the beams is acceptable, but using this method with a metal crate is unacceptable. In such cases, PSB is laid under the frame, whether it be a wall or ceiling, as in the photo above.

First, the brackets are screwed on, on which the metal profiles are held, and then the panels are strung onto these consoles, thus overlapping the entire surface of the wall or ceiling. After that, a metal crate is mounted on top of the foam - this method automatically creates a ventilation gap between the cladding and the foam and moisture from the vapors in the room does not accumulate on the surface of the PSB.

Based on the foregoing, the conclusion suggests itself that the properties of foam as insulation are most acceptable not only for the private sector, but also for industrial construction. And if we talk about roof insulation, then this is the best option, since there is low thermal conductivity and convenient installation due to the stiffness of the panels.

Characteristic of expanded polystyrene

Extruded expanded polystyrene is a material widely used in construction. Outwardly, it looks like a regular foam. Extruded expanded polystyrene is the leader in the market of modern building materials. It is a white substance that consists of air by 98%... The remaining 2% remains on styrene granules, which are filled with gas.

When the mass is heated with steam, polystyrene foam balls are formed, which increase in size by 50 times and sinter together. Next, the process of drying the material begins, the moisture obtained from the steam is removed. The last stage is cutting into blocks. Extruded expanded polystyrene has the following main varieties: teplekst, primaplex, tenonikol, batteplex. Primaplex is used for the reconstruction of buildings.

Wall insulation technology with polystyrene outside

Before proceeding with the insulation of the wall with polystyrene foam, you should dismantle the gutters, decorative elements, clean and prime the wall. Next, insulate the ebb and flow and window slopes.

Now let's talk about the thickness of expanded polystyrene.

NOTE!

Carrying out wall insulation with extruded polystyrene, sheets are used, the thickness of which ranges from 80 to 100 mm and more.

You can use thinner sheets

with a thickness of 30-40 mm, if they are laid in two layers.

Let's start installing insulation on the walls with our own hands:

- at the bottom of the wall, a profile is installed to hold polystyrene foam;

- an adhesive mixture is applied to the wall on the entire area, pointwise and on a sheet of insulation (abundantly on the center and edges of the sheet);

- firmly attach the adhesive sheet to the wall;

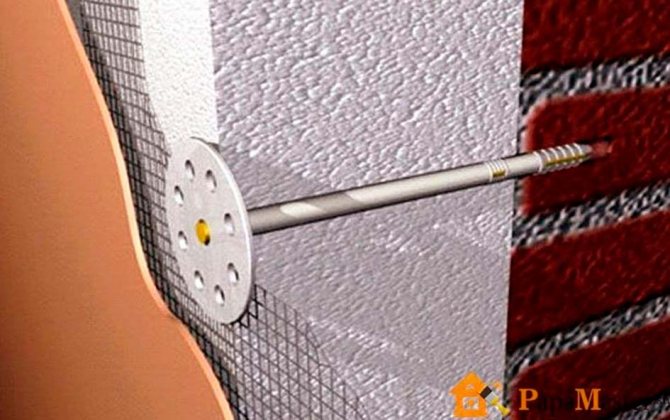

- fix the panel with dowels so that the dowel goes into the wall by at least 50 mm. The dowels are located in the center of the panel and at the joints. It is recommended to use plastic nails;

- if gaps are formed (up to 2 cm), then they are sealed with a mountingfoam

, if there are more gaps, then they are first sealed with pieces of insulation, and then foamed. Excess foam is cut off; - the heads of plastic nails are cleaned and puttyed.

After installing the insulation, a reinforcing mesh is applied to the facade

... Cut strips of mesh at corners and slopes and glue them with a spatula with adhesive. An adhesive composition is applied to the mesh along the wall so that it penetrates 0.1 cm through the mesh onto the expanded polystyrene.If an overlap is formed, separate strips of mesh are applied to it and glued additionally.

Device in razarez

Fastening plates with dowels

Application of assembly glue

After the surface has completely dried, it is leveled with fine-grain emery paper.

Conclusions and useful video on the topic

You can learn about the criteria for choosing extruded polystyrene foam from the following video:

Considering that almost no one pays attention to the weak sound insulation of the insulation, the sensitivity to the effects of ultraviolet radiation is treated by the fact that the material is always protected by a layer of finishing, and low vapor permeability as a minus is excluded by the presence of good ventilation, from the total number of shortcomings there are only "not environmental friendliness" "High cost" of the material, but these shortcomings are also easy to refute.

The very concept of "not environmentally friendly" suggests that

that the material is extremely durable, because over time, especially with proper use, it does not break down into components. Is this not a criterion for considering the "non-environmental friendliness" of a building material as a plus? Well, at the expense of the high cost of EPS, an excellent proverb can be cited: "A miser pays twice." With all the ensuing morals and consequences.

Thinking about using EPS as insulation and want to clarify a couple of nuances of its use after reading our material? Post the remaining questions to our experts below this post - we will try to help you.

If you are professionally engaged in the installation of EPS and want to give useful advice to beginners or supplement the above material with valuable comments, write your comments in the block below.

Some authors of the House Praktika website have already written about how harmful foam is or where it cannot be used. However, as an editor, I received 4 (four) letters in the mail over the last week, reproaching that we should not be considering this material so one-sidedly.

People write that foam as insulation is very good, that it is cheap, that it is irreplaceable in private construction. And in order to stay within the framework of objectivity and present all points of view on our website, I asked two authors from Tver, Anatoly Rudenko and German Shevroshevich, to write a full article, which will consider foam as insulation from all sides and in all respects.

In spite of everything, the foam has every chance to remain the "most popular" insulation.