External insulation of facades

Insulation of the walls of the house can be both internal and external. The most preferable is the external insulation of the facade, since it is under this condition that full-fledged protection of the walls from external atmospheric and temperature influences can be provided.

External thermal insulation of facades prevents the appearance of dampness due to the formation of condensation. As a result, the problems of freezing of walls and the appearance of mold, which are the main reasons for reducing the life of buildings, are solved.

The advantages of facade thermal insulation are obvious: they are preserving heat inside the building, reducing the cost of heating the room, removing condensate formed on the walls and, in general, increasing the service life of the building.

There are various ways of external insulation of facades. These are siding (insulation is located between the lathing bars), a hinged ventilated facade (there is a ventilation gap between the insulation layer and the cladding), facades with a thick plaster layer and light plaster facades.

Recently, liquid ultra-thin thermal insulation is gaining more and more popularity.

Liquid ultra-thin thermal insulation

Liquid insulation is a thermal insulation coating consisting of a polymer binder and hollow glass microspheres. The consistency of the material resembles ordinary paint, which makes it possible to apply thermal insulation and process structures of any shape, where traditional thermal insulation materials are difficult to apply.

And thanks to the unique properties of hollow glass spheres, the effectiveness of liquid thermal insulation is several times higher than that of traditional insulation (such as polymer foam or mineral fiber).

After drying, the material forms a durable and light elastic heat-reflecting coating with unique heat-insulating and energy-saving properties.

Liquid ultra-thin thermal insulation belongs to this class of innovative energy-saving materials. Teplocor-Facade

.

Glass replacement

A panoramic balcony is not as easy as it might seem at first glance. In addition to the fact that there are difficulties with installation, and in general with the arrangement, you need to pay attention to the glass. Be prepared for the fact that from the street you can see absolutely everything that is happening in the room.

Therefore, for a comfortable stay in rooms with panoramic windows, special glasses are installed:

- having a mirror coating on the outside;

- tinted;

- electrochromic.

If, during the first installation, they did not pay attention to such moments, the glasses are replaced. But when ordering products, be sure to check what material the new package is made of. It is desirable that it be tempered glass with a thickness of 6 mm.

All fittings must be made of durable and reliable material in order to protect apartment residents or office workers from accidents.

Liquid insulation for walls and facades

Liquid insulation of walls Teplocor-Facade

Is a heat-insulating material, which is a composition based on acrylic polymers, hollow glass-ceramic microspheres, pigments and auxiliary substances.

The thermal insulation coating is resistant to weathering, temperature extremes, ultraviolet radiation, aging, cracking and destruction.

Heat-saving coating Teplocor-Facade

it is used in the field of construction and housing and communal services to reduce heat losses, eliminate fungus, condensate, icing. In this case, the following tasks are solved:

- insulation of building walls (internal and external ultra-thin insulation);

- effective increase in energy saving;

- combating freezing of the walls of residential premises;

- lower costs for external finishing during the reconstruction of houses;

- aesthetic appearance of the treated surface.

As a result, the use of liquid insulation Teplocor-Facade

allows you to reduce the weight of building structures, reduce the consumption of building materials, reduce energy consumption for heating buildings and improve indoor comfort.

Scope of liquid thermal insulation

Energy saving coating Teplocor-Facade

has the widest application in the field of construction and renovation:

- thermal insulation of the facade of the house, basement, foundation and blind area;

- basement insulation (including from the inside of the basement walls);

- insulation of the walls of the house from the inside and outside;

- insulation of balconies, loggias, attics, window slopes;

- roof insulation from the inside and outside to reduce heat losses in winter and reduce the cost of air conditioning in summer;

- processing of interpanel seams allows you to combine the process of hydro and thermal insulation;

- processing of the ends of monolithic floors in frame construction, etc.

Facade insulation is used for processing concrete, reinforced concrete, plaster, brick, slate, wood during work both inside buildings and structures, and for structures in the open air.

It is recommended to insulate the outer walls of the house at a positive ambient temperature, preferably in the range from + 15 ° C to + 70 ° C.

The choice of liquid facade insulation

On the site krasko.ru You will find all the necessary materials for durable protection and insulation of facades. By calling or writing to us, you will receive professional advice from our technologists on the choice of coating specifically for your facade.

Liquid insulation offered by us Teplocor-Facade

designed to create a heat-insulating coating on surfaces of any shape, including in hard-to-reach places.

Liquid insulation can be applied to both new and previously treated surfaces. The heat insulator is versatile and can be used in combination with common building materials.

Effective external thermal insulation will minimize the cost of heating the premises. Thermal insulation of the exterior walls of the house and facades with the help of a highly efficient liquid heat insulator will eliminate heat loss.

More information about liquid ultra-thin insulation (wall insulation from the inside and outside, heat-insulating materials and coatings, liquid facade insulation) can be found on our website.

Glass exterior walls look nice and respectable. But if they cannot cope with the loss of heat, the penetration of dampness, draft, dust, noise into the room, then the structure requires insulation of the glass facade. The costs of this work will quickly pay off by reducing heating bills.

Our company performs thermal insulation of glazed surfaces outside high-rise buildings using the industrial mountaineering method. Climbers have the right equipment, gear, skills. All work is carried out quickly, within the time frame specified in the contract.

| Name of works | Price from |

| Thermal insulation of facades | from 1500 rub. - sq.m. |

Get a free consultation from our specialist

We will answer all your questions

Insulation of external glazed facades

There are several ways to reduce heat loss from glass surfaces. These include:

- installation of energy-saving double-glazed windows;

- partial replacement of the frame of the facade elements with the fixing of the heat-insulating material;

- additional installation of the circuit inside or outside the building.

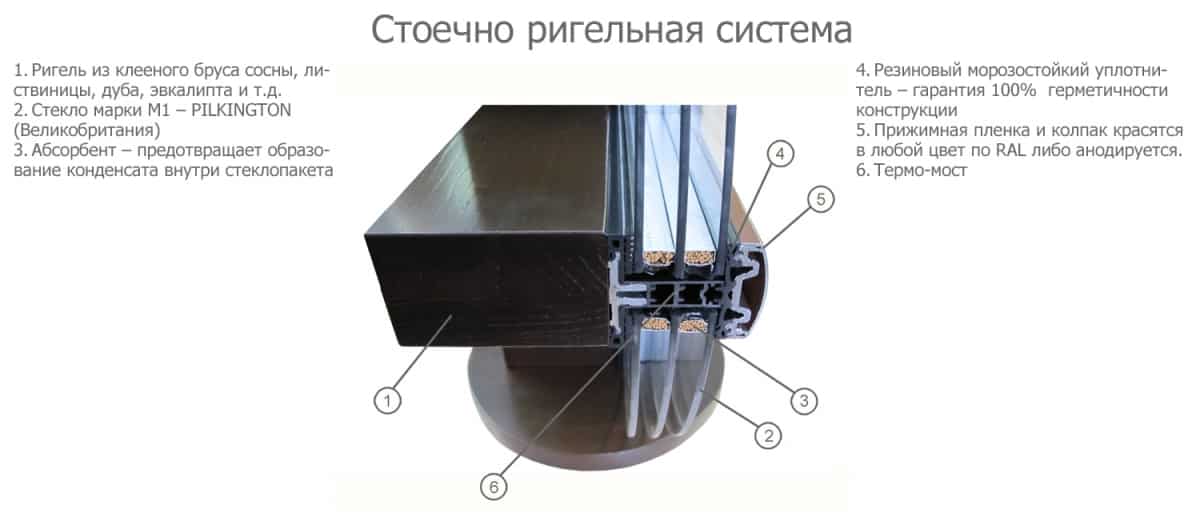

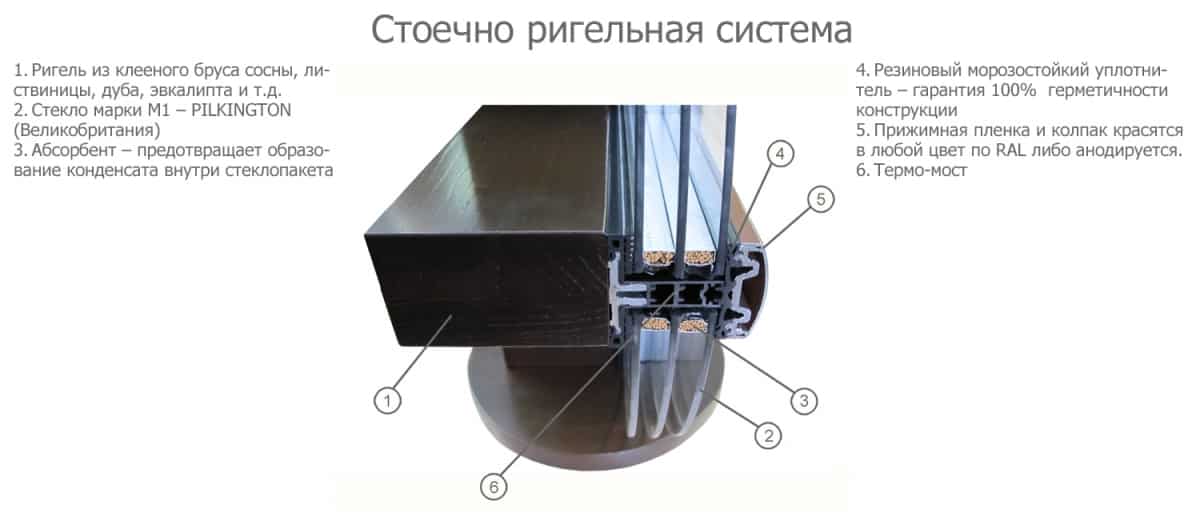

When insulating a stained-glass facade, the tight fit of the frame to the surface, as well as the design of the glass unit, is important. The more glasses there are, the farther the distance between them, the more efficient the heat saving. Additionally, the space between the panes can be filled with an inert gas.

In addition to reducing heat losses, the level of noise from the street will decrease in the room, while maintaining the level of insolation. The building will maintain a favorable microclimate, mold and mildew will not form, and the exterior glass facades of the building will retain an elegant overall appearance.

Thermal insulation of a panoramic balcony

If the owner of the house has decided to glaze the balcony from ceiling to floor, and this is what a panoramic balcony looks like, then you need to prepare for a laborious and lengthy process. This type of decoration is suitable for structures that protrude beyond the overall vertical of the building.

In addition, a panoramic balcony should be chosen if there is a beautiful landscape outside the window, pleasing to the eye, both in summer and in winter. The main difficulties of the arrangement are as follows:

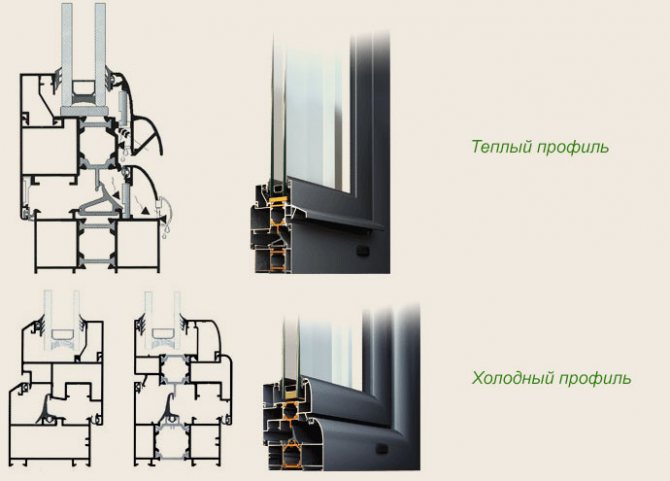

- The need to use plastic or metal profiles with a thermal break.

- Installation of warmer double-glazed windows, consisting of three chambers and filled with inert gas.

- Involvement of professional workers, both for the manufacture of the glazing system and for its installation.

All these points require significant financial investments, in addition, panoramic balconies often require changes in the design of the main structure. If this is not a private building, but an apartment building, then you will have to go to certain authorities in order to obtain permission for constructive changes.

Technology

Previously, it was believed that such facade decoration is the prerogative of exclusively shopping or business centers, but every year more and more owners use this technology to build a country house. In addition to beauty, front cold and warm glazing has many advantages:

- The speed of work processes. It can be done much faster than facade plastering or natural stone finishing. Plastic partitions are erected literally in a matter of days, this allows you to cover even large areas in a short time;

- Excellent thermal insulation performance. Glazing is often used to insulate balconies, loggias and doorways. Plastic and glass, which can be used during the installation process, retain heat well inside the room and do not let drafts through;

- Plastic stained glass windows are very durable. They do not rust and are practically indestructible under the influence of aggressive chemical compounds.

Video: Technology of facade glazing of buildings (element facade)

But along with this, facades made of glass and transparent plastic have some disadvantages. First, they are quite fragile. Under shock loads or vibrations, they easily break and crack. Secondly, plastic glazing requires certain building skills.

Facade glazing example

Facade glazing of buildings is classified according to the principle of installation (a transom system or walls can be used), materials and type of insulation. Consider the proposed technical options:

- False. It is used for a house whose walls require major repairs. In this type of arrangement, the walls themselves are used as a load-bearing base. Guides are installed on them, on which translucent plastic sheets are then mounted. This can significantly reduce the operating time, but, at the same time, it does not solve the problem of overhaul. In other words, only the impression of the fundamental nature of the building is created;

- Panoramic or structural glazing is a fully framed building façade. Due to the presence of the frame, they are provided not only with a beautiful exterior, but also with additional strengthening of the walls.This technology is used when working on complex facades, as well as if insulation of the house is required, since a certain distance remains between the frame, the cladding and the building, in which the insulation is subsequently installed. This type of glazing is more expensive than false;

- Frameless "spider" mount. Ideal for finishing small areas (balconies or loggias). It has no vertical posts; it is secured with brackets and special awnings. Panel sizes can be any: from 2 to 5;

Spider fastening For many meters to modern houses and country cottages, the front continuous glazing of the jumbo type is used. Large glasses are used for it, the width and height of which often exceeds 6 meters. Thanks to such impressive dimensions, they allow you to create a coating without seams. Due to the large weight of facing materials, it is rarely used on high-rise buildings, but on the other hand, it is ideal for decorating various shops and private buildings.

Jumbo dripping

According to the materials from which the facade is made, double-glazed windows (translucent plastic), plastic panels and real glass are used.

Consider the features of each coating:

- Glass is considered the most expensive and of the highest quality, since it is it that transmits light best. But, on the other hand, this material is very fragile and heavy. They mainly work with glass at low altitudes;

- PVC. Plastic panels help provide great styling and can be of any color or shape. These sheets are used for any exterior decoration of houses. They differ in affordable cost and low weight. But they have a much worse light transmission than glass;

How much will it cost?

The cost of these works is quite high. The total amount will include:

- profile (metal is more expensive than plastic);

- double-glazed window;

- sealant;

- Additional materials;

- installation work.

The manufacturing company will also affect the cost. If this is a domestic manufacturer, then there is a chance to cut the budget a little. Adding all the data, it turns out that the price per square meter of facade glazing starts from 5500 rubles for domestic companies and from 8 thousand rubles for foreign companies.

Installation

Work begins with the creation of drawings. To do this, you can use the services of professionals or draw the facade yourself, for example, in the AutoCAD program (dwg drawing format). As the experience of numerous craftsmen shows, a ready-made sketch and drawing, as well as a technological map, are the key to success.

Step-by-step instructions and a diagram of how to glaze a facade using a frame technique (GOST 30673-99):

- By means of measurements, the side of the dominant winds is calculated. Separately, it should be noted that it is better not to place the opening panels on this side. This data can also be obtained at the meteorological station - their specialists will help to carry out quick and accurate measurements of the wind rose;

Frame

Finished frame

Fastening a double-glazed window

Similarly to the installation, individual panels are repaired or cold facade glazing is replaced with warm one. A separate glass unit is simply removed, and a new one is attached in its place.

Insulation of facade glazing.

In addition to installing plastic windows, it offers insulation of cold glazing without dismantling the supporting aluminum structures and leaving the original appearance and color (this is mainly true for the outer part of structures). It is possible to change the opening configuration of the sash to a more convenient one, and to make the previously closed parts transparent to create a panoramic stained-glass window.

Replacement of cold glazing on loggias with "Nice Windows" is:

Free measurement and consultation

We are working on further recommendations.

Focus on quality and service

Only high-quality designs and installation in accordance with GOST.

5 years general warranty

Truly workable multi-year warranty

Lowest prices

We will make the most favorable price offer for you.

High thermal insulation

Heat transfer resistance 0.8 m2 ° C / W with reinforcement

Maximum noise reduction

Increase in noise insulation of the room by 25-30dB.

Quality control

Quality control of each object by our technician

Payment upon delivery

Payment on the fact of a high-quality result.

Insulation of cold glazing - this is an increase in the heat transfer resistance of the structure (about 0.70-0.80 m2 ° C / W, compared to 0.1 m2 ° C / W with standard glazing). and an increase in the noise insulation of the room by 25-30 dB.