Recently, among the inhabitants of our country, the fashion for the construction of wooden cottages is gaining momentum. After all, a person sometimes wants to escape from the bustle of the city and be alone with nature. For the construction of such houses, wood materials are very suitable. How does the construction of any building begin, no matter what material is used during its construction? Of course, with the construction of the foundation. The main topic of this article is the insulation of the foundation of a wooden house.

A few words about the strength of the foundation

It is much easier to build a foundation for a house made of wood, because in this case, quite acceptable loads will be applied to the supporting structure.

There are a number of requirements for the walls of the base that relate to strength. To meet them, such materials are used that are capable of withstanding high loads. Indeed, during the operation of the structure, the pressure of structures located above will constantly be exerted on the foundation. For example, floors between floors.

To understand better, imagine a fragile little table. If you put a lot of weight on it, then the tabletop will begin to bend and, in the end, break. With the foundation, everything is about the same. On the base, which is a kind of substrate, pressure is exerted from the side of the structure installed on top. The loads are very significant. This is where the strength requirements follow.

Why is the supporting structure insulated?

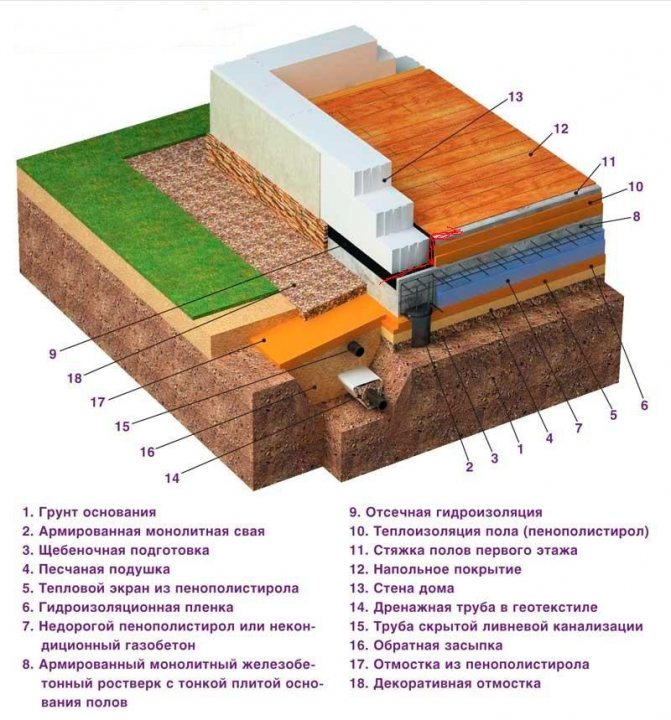

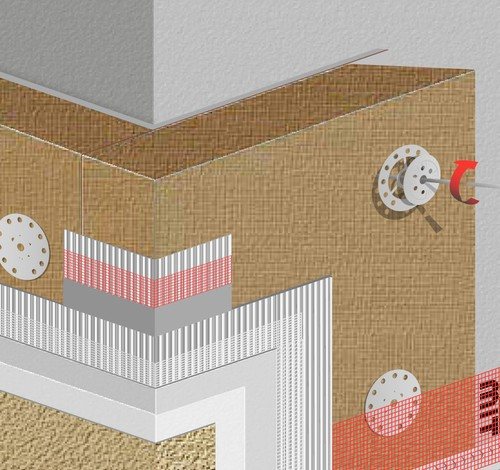

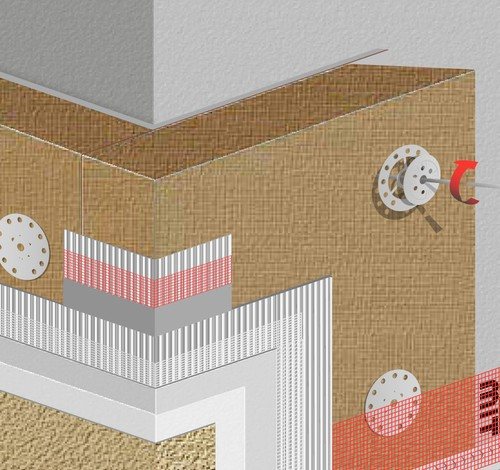

Sectional insulated foundation.

Heat loss is an inevitable drawback that manifests itself after the construction of absolutely any foundation. Sometimes, during the construction of wooden houses, they do without the construction of a supporting structure. This is due to the lightness of wood compared to stone. However, many wooden houses still have an appropriate foundation. You cannot discount such a procedure as thermal insulation of the foundation, even if wood conducts heat much better than stone.

In cold weather, heat loss will be unreasonably high. And it turns out that due to the properties of wood and special insulation materials, the house will be warm, and the lower part will give off cold. In this case, you will have to spend a lot on utilities so that the house is always warm.

How to insulate the base of the house?

According to most experts, polyurethane foam is the best material for insulating the foundations of wooden houses. This material has a very low thermal conductivity, which means that less of it is required for thermal insulation in a wooden house than other heat insulators. The size of the thermal insulation layer depends on the thickness of the base and the thermal insulation material. Usually it is 30, 50 or 100 millimeters.

Of course, polyurethane foam alone is not enough. Insulation is also carried out with foam and expanded clay. However, polyurethane foam copes with the tasks set somewhat more efficiently. He has proven himself to be the best in the construction of many objects. In general, the factors associated with the project directly affect the choice of waterproofing material. Know that polyurethane foam is durable and reliable. But do not give up other materials. Consideration should be given to the requirements of the project. Perhaps foam is the best option for realizing your ideas.

In addition, you can use foam glass, which is also a good heat insulator. It is a foamed glass melt.Silicate glass is heated at a temperature of 1000 degrees, then, while cooling down, it acquires excellent mechanical and thermal insulation properties.

Pile foundation

How to insulate the foundation of a wooden house on piles? For the pile foundation, as well as for the columnar foundation, they construct a pick-up - an imitation of a basement, closing the space between the piles. This alone will to some extent reduce heat loss. For effective thermal insulation of the pile foundation, you need:

- arrange a plinth,

- insulate it from the inside and outside,

- insulate the floor.

You can build a thin brick wall around the perimeter, or you can use slab materials that are attached to the crate. If the option with a brick wall is chosen, you need to fill in a shallow concrete tape 20 cm thick, on which the wall will be built. It is not necessary to use ceramic bricks, you can take foam blocks or foam glass.

Important! Do not make the space under the floor airtight. After the installation of the intake, air vents are necessarily made in it - ventilation holes measuring 10-15 cm. They are placed evenly on all sides of the house so that they fall opposite each other.

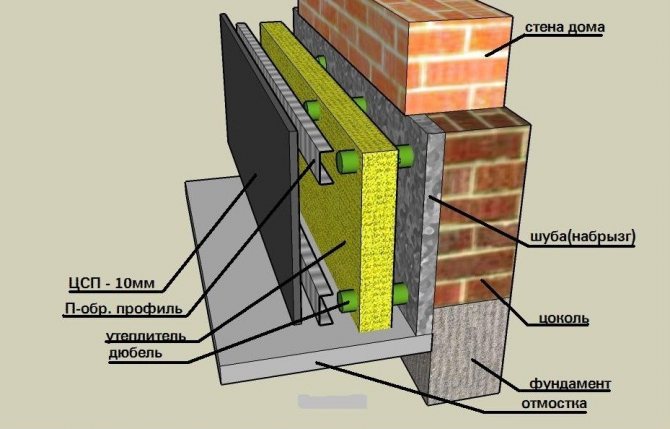

For fixing panels or slabs, a crate is made of a metal profile or wooden bars. As an external cladding, you can use, for example, DSP. There are already insulated facade panels that perform a decorative and heat-insulating function.

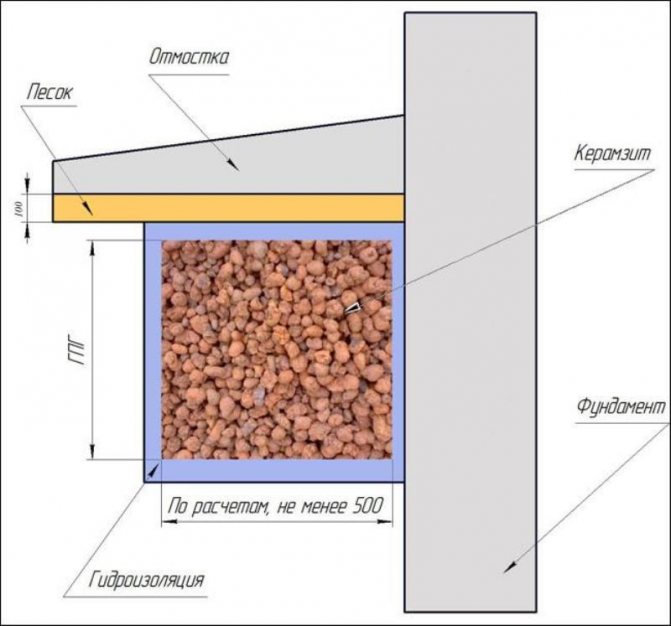

A shallow trench is dug under the cladding, where a layer of sand (2-3 cm) is poured, expanded clay is placed on it, and the trench is covered with earth on top, so that there is no gap between the soil and the cladding.

The video shows the device and insulation of the false base:

To insulate the pile foundation, use

- expanded polystyrene,

- Styrofoam,

- foamed glass in blocks,

- liquid penoizol (urea foam).

The first two options are most often used. Foamed glass is too expensive for a private house, and liquid penoizol requires special equipment or the work of specialists, which is also expensive. It is easier to insulate the foundation in a wooden house with your own hands with polystyrene or expanded polystyrene outside. The main thing is that the material does not absorb water, so mineral wool will not work here. They glue the foam on the foam glue, for reliability, you can use additional wooden strips, which are attached with self-tapping screws to the crate through the foam.

Important! It is advisable to fix the expanded polystyrene or polystyrene on the guides, and not between them. In this case, there will be no gaps and cold bridges, since the thermal conductivity of wood, and even more so of metal, is greater than that of foam.

It is possible to insulate the pile foundation with foam or EPSP from the outside or from the inside. If this is done outside, then the insulation is attached before finishing. If the finish is already attached to the plinth, for example, if these are facade panels or DSP slabs, then the insulation is mounted from the inside.

Floor insulation

To insulate the floor in a wooden house on a pile foundation, I usually use mineral wool, basalt wool, expanded polystyrene, polystyrene, liquid insulation.

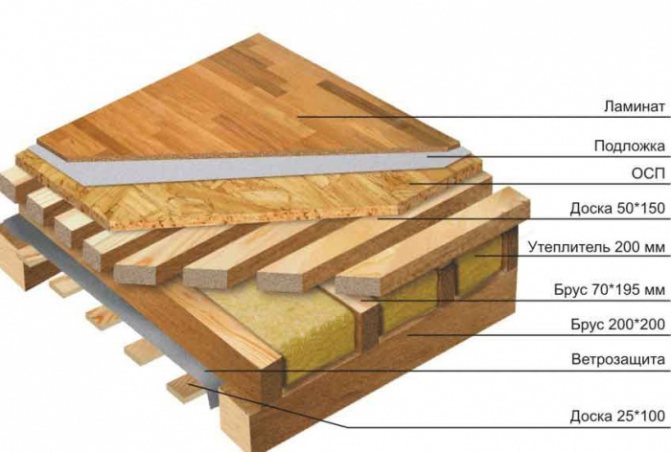

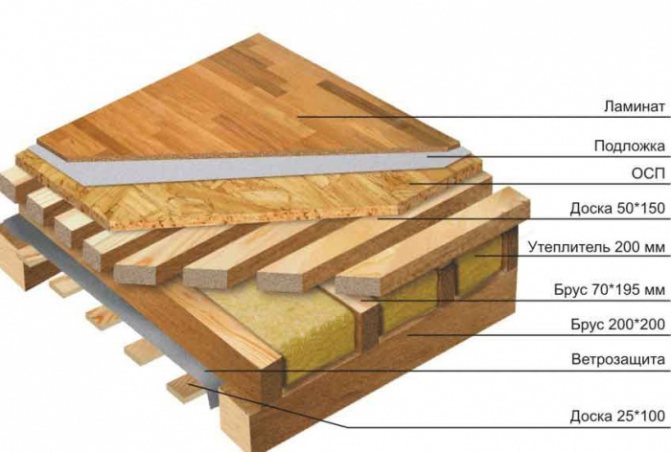

Thermal insulation is done during construction and flooring as follows:

- They make a rough floor on which the insulation will lie.

- A vapor barrier and windproof layer is first placed on the crate.

- Then they put insulation.

- Vapor barrier and waterproofing are placed on top.

- After that, a finishing floor is built.

The layer of mineral wool should be at least 10 cm. If it is necessary to put cotton wool in two or more layers, this is done in a checkerboard pattern (so that the seams do not coincide). The video shows floor insulation in a house on a pile foundation.

For waterproofing, you can use glassine, polyethylene, isospan, wind-moisture protective film. Polyethylene is the cheapest option, but not the best.

Important! In a house made of wood on a pile foundation, it is imperative to treat all wooden floor elements with an antiseptic.

Insulation of a columnar foundation differs little from insulation of a pile foundation, the same materials and techniques are used.

Thermal insulation of the supporting structure of the house made of wood with polyurethane foam

There are only two ways - thermal insulation from the inside or outside. The first option means carrying out work in the basement from the inside of the house, the second - on the street. If you have chosen polyurethane foam, then the insulation is reduced to a simple dusting of this material on the base. Spray guns are great for this job. 35 kg / m3 - this should be the indicator of the density of the material.

You can watch a video showing how to insulate the foundation of a wooden house, as well as the advantages of insulation by spraying polyurethane foam.

https://www.youtube.com/watch?v=3bP6ksK9MNY

It is best to insulate the foundation from the outside. This will save the base from freezing, which has a positive effect on the entire structure. If the house has a basement, then the microclimate in it will improve.

Protect the polyurethane foam from sunlight if it is decided to use it outside the building. Plastering based on a metal or polymer mesh is fine. However, there is another option - fixing porcelain stoneware or stone with a special glue.

Internal and external thermal insulation are practically the same technologies. If you decide to insulate the house from the inside, then you need to cover all walls with polyurethane foam, from floor to ceiling.

Often, when insulating the foundation of a wooden house, not only the walls are insulated, but also the ceiling with the floor - this also has a beneficial effect on the microclimate. The surface that has been sprayed with polyurethane foam is finished with a standard cladding. You can choose any material you like.

Other materials used in thermal insulation

Installation of other heat-insulating elements directly depends on the type of material itself. For example, foam boards are attached to the surface with glue. Expanded clay is filled up, then a layer of waterproofing is created. As a rule, such work is not particularly difficult, but in terms of the simplicity of work with polyurethane foam, they are incomparable.

To insulate a building with polyurethane foam, you just need to use a spray gun. When performing foam insulation, you need to do much more body movements: treat the plates with glue, attach them to the surface, make sure that the layer is even, etc. To do it right, and even with your own hands, is not so easy.

Choice of materials

Insulation of the basement of the house should be carefully planned by the master. This will allow you to purchase the optimal amount of materials. For this, a plan is drawn up. It is necessary to calculate the dimensions of the supporting structure. Most often, the necessary information can be obtained from the design documentation of the building. Experts recommend rechecking the dimensions of the foundation.

To do this, you will need to measure the length of the base. It is worth considering that the result obtained may differ from the perimeter of the walls. Next, you need to measure the foundation in several places and determine its highest place. If the height differences are insignificant, the length of the supporting structure must be multiplied by its height. You will get the total area of the base that will need to be insulated. The result should be rounded up. It is also worth making a small supply of materials.

Insulation of the basement of the house can be done using special materials. They must meet all building requirements. Experts do not recommend saving on the quality of thermal insulation. Otherwise, the work will need to be redone soon.

Insulation must have a minimum level of thermal conductivity. The thickness of the material is chosen in accordance with the characteristics of the climatic zone. Thermal insulation must reliably retain heat inside the structure. The stronger and thicker the insulation, the better it will cope with the responsibilities assigned to it.

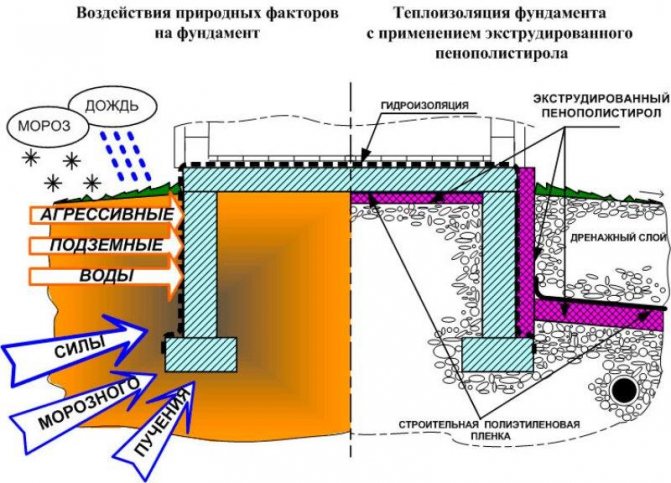

The thermal insulation must not absorb moisture. If such material is saturated with condensation, it will not be able to effectively prevent heat loss. Therefore, materials are chosen that differ in zero water absorption. If you neglect this advice and use a material that absorbs moisture to insulate the support structure, it will deform in severe frost. The water in the structure will expand when it freezes. This will deform the fibers. The material will need to be changed after the first season of operation.

For this reason, mineral wool is not used for such purposes. This material is used only in combination with high-quality waterproofing. This increases the cost of construction work. Therefore, synthetic materials in the form of plates are very popular today. They do not allow moisture to pass through and demonstrate high thermal insulation qualities.

How to insulate a house on a columnar foundation

Another option for insulation in the context.

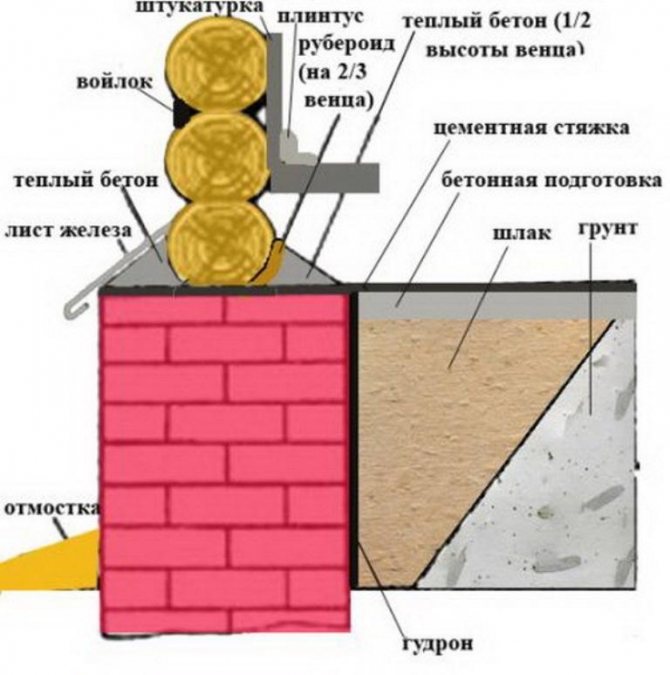

Thermal insulation of a pillar foundation is a process that constantly raises many questions. The pick-up device is the most acceptable option when insulating a columnar foundation.

A pick-up is a kind of partition that fills the space between the foundation piles. It can be made from a variety of building materials. Let's consider them.

- Wooden pick-up. In this case, the pick-up can be made of timber, boards or logs. A trench 30-40 centimeters deep is dug between the pillars. Then a pillow of sand and gravel is placed there, and bars with grooves are attached to the posts, into which 4-6 cm boards are inserted and wooden shields are obtained. After that, the lower part of the filling is covered with expanded clay.

- Brick filling. In this case, a trench is also dug up and the pillow is filled up. Bricks are placed in a row one or two at a time.

- Pick-up from insulation sheets. This method is used when insulating a private house, the length of the foundation pillars of which reaches 0.8 meters. Steel lathing is attached to the posts. Insulation (polystyrene, expanded polystyrene) is attached to it from the inside. Outside - sheets of corrugated board. The space between the insulation and the ground is covered with expanded clay.

For aesthetic beauty, blind areas can be made, which are a waterproof coating (asphalt or concrete strip) that runs along the entire perimeter of the building from the outside. Blind areas will protect the building from flooding and precipitation.

Preparation for insulation

Warming of the basement with expanded polystyrene is carried out according to a certain method. First you need to prepare the materials necessary for the work. Together with expanded polystyrene plates, you will need to purchase a reinforcing PVC mesh. It will need to be purchased 2.5 times more than penoplex. You will also need to purchase special glue for installing the plates. Its quantity is chosen in accordance with the manufacturer's instructions. It is important that organic solvents are not present in the composition. Otherwise, the material will be damaged.

You should also purchase hydro and vapor barrier. If there is no special protrusion on the foundation, you will need to fix the expanded polystyrene to the profile. It must have a "P" cross-section.

You will also need to purchase dowels with a wide head. They will give the structure additional strength. For penoplex with dimensions of 125 × 60 cm, 4 dowels are required. The larger the sheet size, the more “umbrellas” are acquired for fixation. The rod must be made of metal.However, in order to avoid the appearance of cold bridges, such elements of the dowel structure must be completely in a plastic sheath. Also, their caps must have a special insulating material.

Insulation of the basement basement outside with penoplex presupposes finishing. For this, a reinforcing mesh is purchased. A layer of facade putty will be laid on it. Most often, it is sufficient to purchase a fiberglass mesh. However, in some cases, the plaster can have a thickness of 3 cm. In this case, a reinforcing mesh made of metal is acquired.

You should also purchase paint for facade decoration. It must be waterproof. There are special types of materials that can be used for outdoor decoration. It will also additionally protect the material from the effects of sunlight, wind, moisture.

You also need to purchase the necessary tools. You will need a puncher, a set of spatulas, brushes, a building level. To knead the adhesive, putty, you need a container of sufficient volume. Having prepared everything you need, you can start insulating the basement with your own hands.