2257

In this article, you will learn:

- Why is it necessary to insulate the walls of a wooden house from the inside

- How to choose a material for insulating the walls of a wooden house from the inside

- What are the stages of the procedure for insulating the walls of a wooden house from the inside

- What are the important nuances in the technology of insulating the walls of a wooden house from the inside?

- What are the mistakes when insulating the walls of a wooden house from the inside?

Today more and more people prefer natural materials and products. This also applies to residential buildings. Of course, a house made of wood is endowed with many advantages. But it should be borne in mind that such structures require additional thermal insulation. A special role is played by the insulation of the walls of a wooden house from the inside, which will be the subject of this article.

Why is it necessary to insulate the walls of a wooden house from the inside

The construction of wooden country houses is only gaining popularity. It's not just the fashion for the Russian wooden style, there are also quite practical reasons for its popularity. For example, a dry wood wall holds heat 2.5 times better than brickwork of similar thickness. Wooden walls also release aromatic substances when they dry out gradually, creating a pleasant atmosphere in the room.

Building regulations regulate the requirements for thermal insulation of buildings. A wood house built in compliance with the required standards is subject to shrinkage for about three years after the completion of construction. Its thermal insulation qualities change over time and do not always comply with the norms, why the house is made of wood and needs to be insulated from the outside and from the inside.

Wood itself retains heat well. The thermal insulation properties of wood in regions with a warm climate, as a rule, are sufficient to create comfortable living conditions in the house. In areas with harsh winters, the natural qualities of the tree are not enough. This is another reason for insulating a wooden house from the inside.

Wooden buildings are most often insulated from the outside due to the fact that the temperature surface of the dew point moves from the side of the wooden wall towards the external insulation. As a result, the thickness of the wall remains dry, protected from rotting and fungal attack, and heats up well.

However, it is not always possible to insulate the house from the outside. For example, the status of an old building as an architectural monument, which prohibits changing its original appearance, may hinder. In this case, it is necessary to insulate the walls of a wooden house from the inside.

Recommended reading:

- Options for houses made of laminated veneer lumber for every taste and budget

- Half-timbered house construction technology

- Types of foundations for a private house

The insulation procedure from the inside is optional, provided that the building is well insulated from the outside. But if it is necessary to preserve the appearance of a wooden house and at the same time make the home warm and comfortable, internal thermal insulation becomes necessary.

When insulating a wooden house, walls, floors, ceilings (depending on the number of storeys) and the roof are insulated from the inside. Any interior surface that is not covered with thermal insulation material reduces the overall performance of the insulation. It is more rational to carry out work on thermal insulation from the inside during the construction phase, since it will be much more difficult to insulate an already inhabited interior.

As already mentioned, internal thermal insulation allows you to leave the facade of the building unchanged. Nevertheless, it is recommended to resort to insulation from the inside only if it is practically impossible to insulate the house from the outside.It should also be borne in mind that among all heaters, only jute and felt can be considered 100% environmentally friendly materials. Therefore, if possible, insulate the wooden house from the outside, and if this is not possible, pay close attention to the choice of materials for internal thermal insulation.

The process of insulation from the inside is labor-intensive and technologically complex in itself. In this regard, preliminary planning is necessary for all work that requires a lot of time and effort. To maintain the most healthy microclimate when insulating a building from the inside, only environmentally friendly materials should be selected.

The choice of material for insulating the walls of a wooden house from the inside

Materials used for thermal insulation from the inside must:

- have low thermal conductivity to ensure its main function;

- comply with fire safety requirements for residential premises;

- provide the design mechanical strength both separately and in combination with the building structure;

- be environmentally friendly and safe for living beings, do not emit harmful substances into the environment.

As a result, the method of internal insulation of a wooden house depends on the materials used. Today, the following types of materials are used:

- Basalt mineral wool

Thermal insulation of walls from the inside in a wooden house with mineral wool slabs is the most common method. This material is non-flammable and environmentally friendly, it has excellent thermal insulation and sound insulation. However, mineral wool is hygroscopic and has low strength. This obliges, firstly, to cover it with a layer of vapor barrier material, and secondly, to additionally protect it with an enclosing structure.

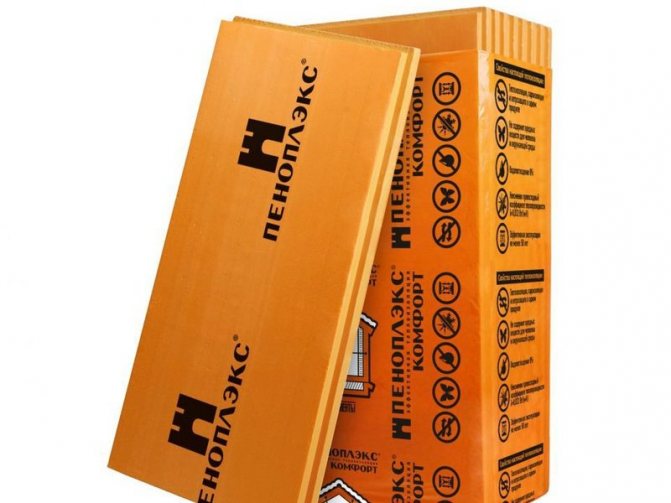

- Expanded polystyrene

The material is used in the form of plates of various modifications: penoplex and polystyrene. Expanded polystyrene does not allow water vapor to pass through, therefore it does not require a vapor barrier, but waterproofing is necessary for it. In comparison with basalt mineral wool, expanded polystyrene retains heat about 1.5 times more efficiently.

Thermal insulation of the walls of a wooden house with foam is actively used by homeowners for thermal insulation from the inside. However, styrene foam can release hazardous substances containing styrene, so this material is not recommended. Much more dangerous compounds (hydrogen cyanide, toluene diisocyanate) are released by non-pressed polystyrene foam during combustion. Therefore, it is allowed to use only an extruded type of expanded polystyrene with a flammability class G1. This material also requires an enclosing structure.

It is better to insulate the walls of a wooden house from the inside with penoplex. Fine-celled polystyrene is more durable and retains heat better than polystyrene foam.

- Glass wool

Glass wool is widely used when performing insulation work. This material is cheaper than basalt mineral wool, while it has a higher thermal conductivity. For insulation from the inside, only a special type of glass wool should be used, which must be covered with a film. Due to the small particles that are hazardous to health, released by glass wool, during installation, you must protect yourself with protective equipment for the skin and respiratory organs. Glass wool insulation should include enclosing elements.

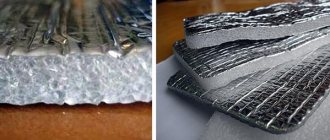

- Penofol

Insulation of the walls of a wooden house from the inside with penofol is a modern type of building insulation. Including it is used in internal work. The material is produced in the form of foamed polyethylene rolls covered with foil on one side. Polyethylene provides thermal insulation, and the foil layer reflects the heat inside the room.Thanks to the foil layer, the strength of the material and its moisture resistance increase, while the flammability of the material also increases, therefore penofol is classified as class G1.

- Izoplat

Isoplat is a modern material consisting of a layer of pressed flax fiber and fiberboard with a thickness of 12-25 mm. It has high strength, which eliminates the need to build enclosing structures. The insulation is environmentally friendly, it can be used to insulate the walls of wooden houses from the inside. However, the thermal conductivity of izoplat is relatively low, and the price is relatively high, in contrast to other types of insulation.

- Polyurethane foam

The modern method of thermal insulation using polyurethane foam is carried out by spraying it from the inside onto the surface. For the performance of work, appropriate equipment is required; building enclosing structures is not required.

- Ecowool

This fairly new material is currently gaining popularity. Among its advantages it is worth noting:

- environmental friendliness (natural wood fibers are the basis);

- vapor permeability;

- fire safety and resistance to biological factors due to the content of special additives;

- low thermal conductivity;

- low price.

With the help of ecowool, horizontal surfaces are also insulated. However, only the ceiling and floor can be insulated on their own, since appropriate equipment is needed to insulate the walls from the inside.

- Warm seam

This technology of insulating the walls of a wooden house from the inside implies sealing joints and seams. It is used when it is necessary to leave a wooden wall without finishing and decoration. In this case, only the joints between logs or beams are insulated with the material, thus reducing the thermal conductivity of the joints and seams.

The insulation material is synthetic sealants based on acrylic, silicone, latex and bitumen, as well as more traditional natural sealants - tow, linen wool and linen rope.

Advantages of the "warm seam" technology:

- simple technology that allows you to independently carry out insulation;

- cost-effective technology;

- improving the thermal insulation properties of a wooden wall without disturbing its original appearance;

- high vapor permeability of the material, due to which a favorable atmosphere is created in the room and the durability of the protective structure increases.

Surface preparation for insulation

Work begins with the preparation of the surface of the walls. Wood is a comfortable natural environment for the development of microorganisms. Therefore, before thermal insulation, it must be treated with bioprotective compounds. Liquid biosecurity can be applied with a brush, roller or spray gun. After that, it is necessary to wait until the applied composition is completely dry.

IMPORTANT! In the process of shrinking the house, gaps may appear between the logs, even if they were originally laid perfectly. In addition, the wood gradually dries out, which is why cracks form in it. So that heat does not go out through the seams, and moisture does not get inside, problem areas need to be sealed with synthetic or natural sealant.

Natural fibrous materials such as tow and jute are laid in cracks and crevices, forming rolls from them. With the help of chisels, the fiber is driven into the hole. And the cracks are closed in a way called "warm seam".

- The protruding cushioning material laid between the logs or a bar during the assembly of the log house is trimmed.

- A polymer sealant is placed in the seam. It comes in the form of a tape (for small cracks) and a cord (for large gaps). Laying the seal is required. In this case, the sealant applied on top of it sticks only to the logs or timber, without adhering to the filler itself.Thanks to this, the structure will be resistant to compression and stretching during further shrinkage of the wood.

- When all problem areas are filled, a synthetic sealant is applied using an assembly gun. The seam is leveled with a spatula, the excess sealing gel is removed.

The procedure for insulating the walls of a wooden house from the inside

Before carrying out work, the walls must be prepared. This is especially true for the insulation from the inside of an old wooden building, when the old insulation has had time to pack during operation. The work at this stage is to eliminate the formed cracks through which cold air enters. The surfaces of the base are preliminarily cleaned of dust and dirt accumulated on the walls.

The wooden blockhouse gradually shrinks, as a result of which cracks can form in the walls. Immediately before insulation from the inside, old walls must be dug up. Jute is usually used for caulking, and if the gaps are wide enough, it is better to use tape tow. Caulking is carried out by hammering the material with a chisel in the gap between the logs or beams. This protects the log house from blowing out and creates additional thermal insulation. It is necessary to hammer the material in the slots until the slots are completely filled with it, until it begins to protrude outward. The quality of insulation of the walls of a wooden house from the inside also depends on high-quality caulking.

Internal insulation is carried out in several stages:

- Antiseptic wall treatment

- Wall waterproofing

- Installation of the frame and thermal insulation

- Vapor barrier

- Exterior wall decoration

First, the strength of the wood is checked, which should not be affected by insects, bacteria and fungus. To prevent future contamination of the tree, it is treated with antiseptics. Additionally, the surfaces of the walls are treated with fire retardants that resist the fire of the tree.

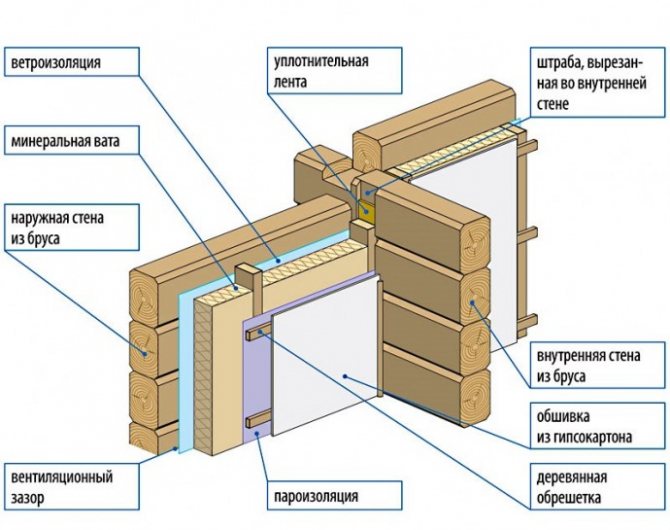

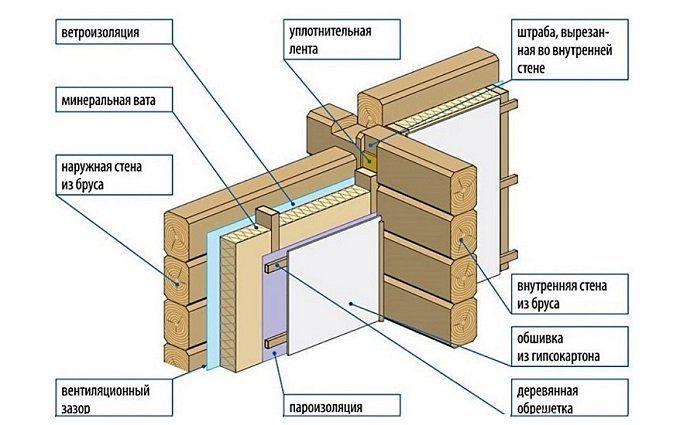

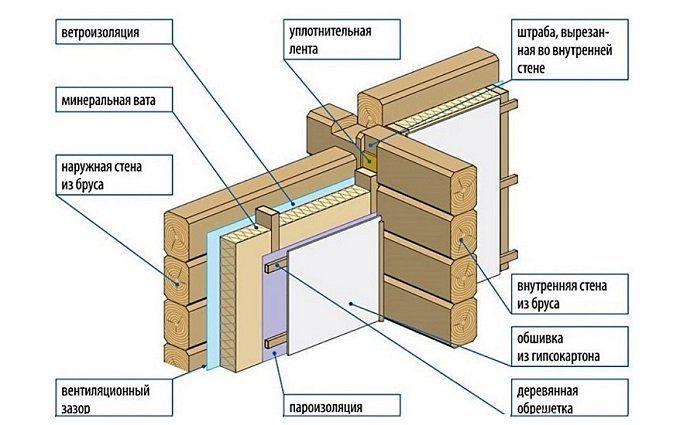

The insulation should be protected from moisture, for which its outer surface is covered with a layer of wind and waterproofing material. As a result, protection against weathering and the ingress of atmospheric water is provided.

Several materials are used for protection, the best of which is a vapor diffusion membrane. It protects against moisture, but at the same time allows air and steam to pass through, allowing the wooden walls to breathe and helping the insulation to get rid of accumulated moisture. Membrane sheets are attached to the wall with a construction stapler, overlapping each other by at least 10 cm. The joints are then glued with tape or construction tape.

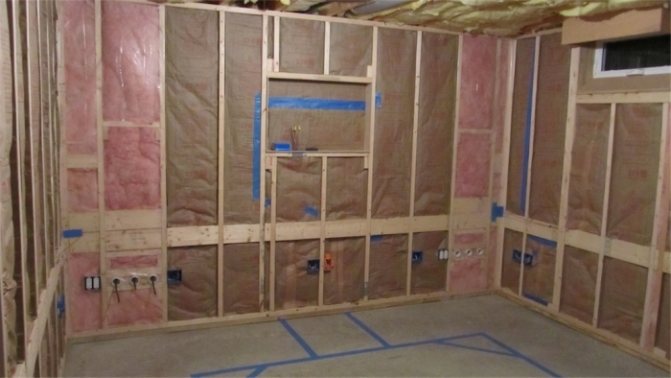

The basis of the insulation is a specially designed frame. Bars with a section of 40x50 or 50x50 mm are suitable for its construction. This section is sufficient to provide the required structural rigidity. The vertical racks of the frame are attached to the floor and ceiling from the inside with profiled plates and self-tapping screws.

To ensure greater rigidity and strength of the structure, it is attached to the walls with large self-tapping screws. To facilitate the installation of insulation, the pitch of the frame racks should be selected in accordance with the dimensions of the insulation sheets - 600 or 800 mm.

If the pitch of the vertical racks is observed, the sheets of insulation do not need to be fixed. They are installed close to the elements of the frame and are held at the edge. At this stage, it is important to fill the entire space between the vertical posts with insulation, otherwise microconvection can occur through the cracks with the formation of cold bridges through the cracks in the insulation.

Vapor barrier is required in the case of using mineral basalt wool, glass wool or expanded polystyrene as an insulation material. The installation of the vapor barrier film is carried out by attaching it with a construction stapler to the ventilation crate. It is required to provide sufficient tension on the film so that a ventilation gap forms between it and the wall surface.The sheets of film are overlapped with each other by at least 10 cm and then fixed with tape and a construction stapler.

If the material for insulation is extruded polystyrene foam, it is not necessary to carry out vapor barrier. This material itself provides reliable protection against moisture.

The metal frame can be the basis not only for insulation, but also for finishing elements. To preserve the wooden interior, you can sheathe the walls with clapboard. If wallpapering is planned, the insulation is closed with sheets of drywall.

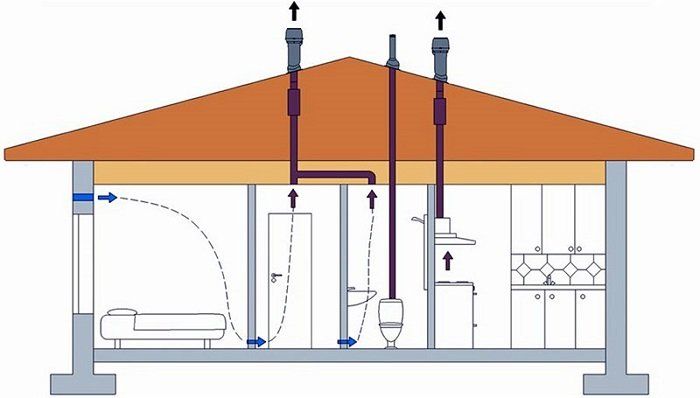

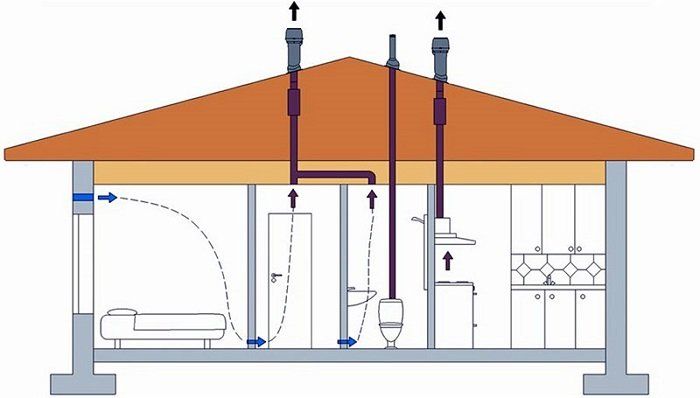

After the completion of the building's thermal insulation from the inside, the air humidity in the premises will increase. Therefore, it will be necessary to install forced ventilation in the house. Using an outdoor hood will result in heat loss, so it is better to use a medium power axial fan. By ventilating the room for 20 minutes, it is possible to get rid of the accumulation of condensation in the room.

When insulating a wooden house on your own, you should not neglect waterproofing in order to avoid problems with the insulation getting wet. When choosing a material for insulation, study its characteristics and do not try to save money at the expense of quality. Follow the advice of the professionals.

Ceiling insulation

Mineral basalt wool, as well as extruded polystyrene foam, are insulation materials for the ceiling of a wooden house.

The technique of technical installation of heat and sound insulation materials is no different from the technique of wall insulation, namely:

- cleaning the surface of the ceiling space from dirt, dust and other elements,

- installation of plastic film,

- fastening wooden lathing, installing insulation,

- second layer of film,

- ceiling sheathing with decorative materials.

When installing thermal insulation, it is necessary to reconsider all options for conducting electrical cables. In places subject to high temperatures (stove or fireplace), ceiling insulation in a wooden house is carried out using special fireproof materials.

Important nuances of the technology of insulating the walls of a wooden house from the inside

When working with insulation, a heat engineering calculation must be performed. In the process of work, it is important to correctly determine the border of the dew point, which should not pass through the thickness of the inner walls and insulation. Thus, the effectiveness of the chosen method of insulation and the method of its installation is proved.

An incorrect dew point determination will lead to high humidity in the dwelling during the autumn-winter period. Despite the fact that the house will remain warm, due to high humidity, mold and fungus will appear, the tree will begin to rot, and the insulation will eventually become unusable. In addition, dampness and mold are fraught with the development of lung diseases in residents.

To insulate the walls of a wooden house from the inside, you should select suitable materials that do not violate the requirements for internal thermal insulation:

- minimum thermal conductivity;

- heat resistance or minimal flammability with the ability to self-extinguish upon ignition;

- high compressive and flexural strength;

- ecological cleanliness;

- chemical and biological safety.

Wall insulation must be carried out over the entire area, even if a relatively small part of it freezes. If heating elements impede access to the wall, it is advisable to use foil plastic, the characteristics of which allow high-quality insulation of the wall. When installed, a sheet of foil plastic is placed with a foil layer towards the room. The aluminum foil will thus serve as a heat reflecting shield.

Greater insulation can be achieved by leaving a gap between the surfaces of the wall and the insulation. The effectiveness of the insulation will increase, and the air gap will help remove excess moisture.However, do not make the gap too wide.

When insulating walls, you need to think about the ventilation of the premises. The ventilation system will relieve the wooden house of excess moisture that appears after the walls are insulated from the inside. To ensure a favorable microclimate in the premises, forced ventilation will be required. It can be created using an axial fan of low or medium power.

The type of insulation is selected depending on the characteristics of the building. With the choice of a suitable option, qualified specialists can help, who for a certain amount will also perform all the necessary work on the thermal insulation of the building. But there is an opportunity to save money and do all the work on your own, subject to the choice of high-quality material and competent performance of the work.

Before starting work, you need to find out the following points:

- The kind of wood from which the house was built.

Each type of wood has its own properties and characteristics, which will affect the overall budget for insulation work.

- Reasons for heat loss.

You should carefully examine wooden walls for cracks and cracks, and existing insulation for defects.

When the shortcomings are identified and the scope of work is formed, you can proceed directly to the insulation of the walls.

If a new wooden house is being insulated, it is not necessary to dismantle the wiring in it. The electrical wiring is laid after the thermal insulation works and the installation of the inner lining have been completed.

In a building in use, the existing external wiring must be removed. Moreover, both open wiring and communications hidden in plastic casings are dismantled.

Consider the differences between external and internal insulation using the example of their advantages and disadvantages

The advantages of insulating wooden walls outside:

- External walls are additionally protected from moisture and solar activity, which increases their service life;

- Removing the dew point outside without the likelihood of condensation;

- Providing highly efficient thermal insulation;

- Preservation of the volume of the room;

- Possibility of sealing external holes and cracks;

Disadvantages:

- Changing the appearance of the building facade;

- high cost of work;

- dependence of work on the season and on weather conditions;

External insulation for siding

Benefits internal insulation:

- low cost;

- the emergence of the possibility of aligning the walls;

- independence of work from the season and weather conditions;

Disadvantages:

- Dew point displacement inside the room and the likelihood of condensation and mold;

- Reducing the volume of the room;

- Possible change in the interior for the worse;

Types of outdoor insulation:

- Strengthening heat insulators on the wall surface using adhesive solutions and plastering;

- Non-ventilated walls in three layers. The insulation material is fixed with a mortar and a single-brick outer wall is installed in compliance with the air gap;

- Ventilated facade. The walls are protected with a waterproofing material, on top of which an insulating material is mounted. Then a windscreen is installed, and the frame is sheathed with clapboard or any other siding. This method allows installation even in winter due to the lack of the need to use adhesive solutions.