Steel radiators have been known to many since Soviet times, when ribbed appliances are installed in apartments with central heating and which gave heat at a decent level. Today, steel heaters have not gone anywhere, but on the contrary, they have developed and are actively used in heating systems. Let's understand in detail.

The main types of radiators

Steel radiators... They are mainly used for heating residential buildings. The appearance is quite aesthetic, the price is above average, decent heat dissipation is why they choose steel radiators for private houses.

Bimetallic radiators... They are widely used in the construction industry. The quality-to-price ratio is acceptable. A distinctive feature is the use of a steel tube in an aluminum casing. Can be used in central heating.

Cast iron radiators... The oldest type of heating radiators. Their form is simple and strict, the facade is smooth, and the design is restrained. They heat up for a long time, but are ideal for systems with central heating. They are durable, inexpensive, last about 50 years.

Aluminum radiators... They stand out for their beautiful external appearance. However, this type of radiator for heating is not the best option for use in living space where there is a central heating system. But in a living space with an autonomous heating system, this type of radiator is considered quite famous. In addition to their elegant external appearance, they are distinguished by reliability and a long service life - about 25 years.

Copper-aluminum radiators... They have high heat dissipation. They are often installed in apartments, offices and similar premises. Resistant to corrosion.

Types of steel batteries

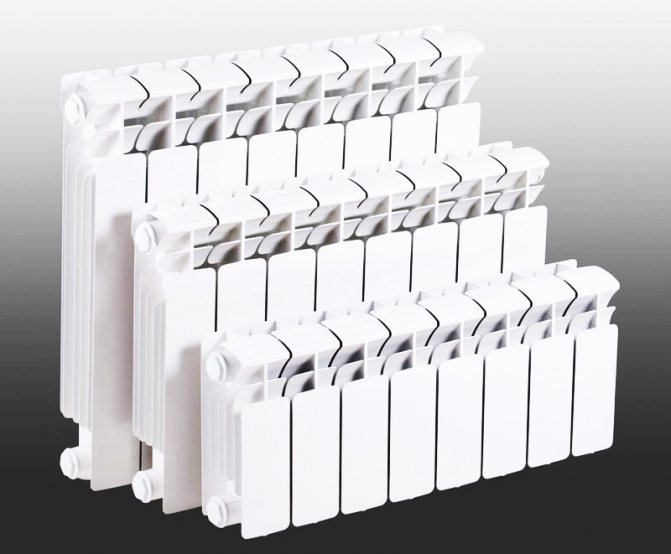

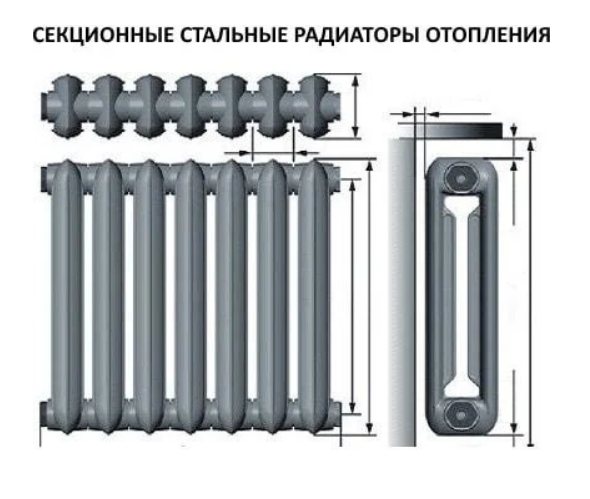

Steel sectional radiator

Wear resistance, flexibility, ductility are inherent qualities of steel. They make it possible to manufacture various types of products.

The main types of steel radiators:

- stamped;

- tubular;

- sectional.

Each has features that are taken into account when buying and operating.

Stamped panel models

Steel panel radiators

In general, the technology for the production of products is simple.

- The metal sheet is stamped by extruding the ribs and giving them a three-dimensional shape.

- The sheets are connected by contact welding to form a kind of closed container.

- To supply the steam-water mixture and remove the cooled heat carrier, two fittings are welded.

The finished product looks like one, two or three panels connected in a single body. Convection plates are installed between the panels, which accelerate heat transfer.

The method of coloring has a great influence on the preservation of an attractive appearance.

Choose products in the characteristics of which the manufacturer has indicated cathodic electrophoresis. It is the most reliable coating used commercially.

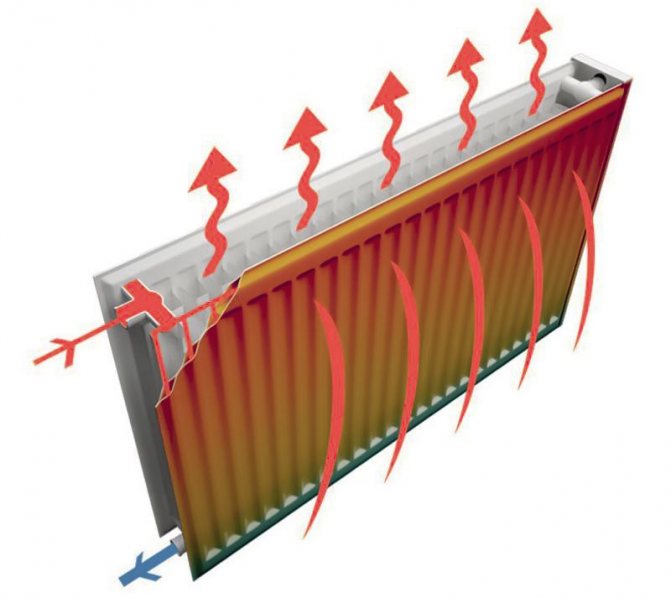

Internal structure of a stamped radiator

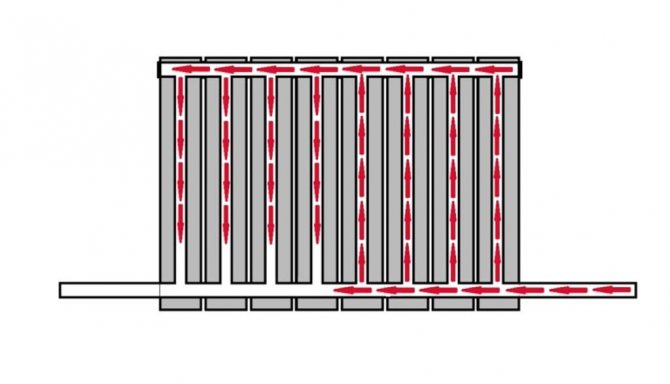

The stamped steel radiator works on two principles:

- radiation into the space of infrared waves (heat);

- convection - the rise of air heated from the panel from the floor to the ceiling.

Advantages of panel metal radiators:

- relatively low price due to manufacturability and minimum materials used;

- attractive appearance, wide range of products;

- the ability to select power depending on the volume of the room;

- quick warm-up after supplying the coolant;

- no need to install a protective or decorative screen;

- low weight makes it easy to transport and install.

At the same time, this type of heat exchanger also has disadvantages. Steel is susceptible to corrosion, especially in the warm season.When there is no circulation of the coolant, cavities filled with air appear in the batteries. In these places, corrosion is more intense.

The same effect is caused by the salt contained in the heating medium of centralized networks. In private houses, this is not so important - you can use special additives or fill the system with antifreeze.

The second drawback is poor resistance to water hammer, so it is not recommended to install flat iron batteries in houses with city heating. If, nevertheless, such a decision is made, it is imperative to install gearboxes that mitigate water hammer.

Inexpensive (600 - 1000 rubles) reducers designed for pressures up to 4.5 atm are intended for private houses. Devices for a pressure of 10 atm, suitable for centralized systems, cost 1.5 - 2 times more than the steel radiators themselves. Thus, it makes no sense to purchase inexpensive radiators. The absence of a gearbox will inevitably lead to rupture of the battery, flooding of neighbors or serious injury from exposure to steam.

The sizes of panel products can be very different. The length is from 40 cm to 3 meters, the height is 0.3-0.9 m. The power of the device also depends on the geometric dimensions. The characteristic can always be found in the passport. Also, heat dissipation depends on the number of rows of panels in the assembly.

Tubular

Steel tubular battery

For products, steel tubes are used, connected in a kind of lattice.

Thick-walled pipes are used, which increases the price. From the inside, the channels are covered with polymeric materials to prevent corrosion.

Thick walls guarantee improved performance in terms of resistance to water hammer. The working pressure for this type of product is set within 15 atm, which allows use in centralized networks.

This is also facilitated by the maximum permissible operating temperature of the coolant - up to 130 degrees.

The dimensions depend on the thickness of the tubes and the calculated value of the output power. Length up to 3, height up to 1 m.

When buying, take into account the presence of taps for side or bottom connection.

In addition, tubular batteries are easy to wipe or wash, since there are no protrusions and bends.

Batteries warm up evenly and have thermal inertia. The effect is achieved due to the thickness of the steel. Products retain heat for some time due to their large mass.

Metal radiators made of pipes often play the role of additional design accessories, therefore, they are relatively expensive.

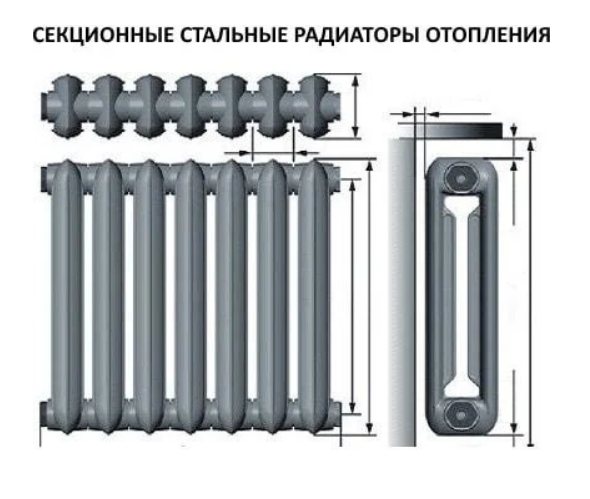

Sectional

Metal batteries assembled from separate sections look very much like cast iron radiators. At the same time, they have significant differences in manufacturing and technical characteristics.

- First, separate sections are made by stamping and resistance welding.

- The next stage is welding the sections into a single piece.

The design is a symbiosis of panel and tubular radiators.

Low corrosion resistance and high price are the main indicators limiting the spread of this type of device.

At the same time, sectional iron batteries can withstand high pressure and can be used for heating in apartment buildings.

The sections are connected by welding, which reduces corrosion at the joints, eliminates leaks between components.

Relative disadvantage in comparison with aluminum and bimetallic products: it is impossible to reduce or increase the number of sections. The product is a whole.

Panel view

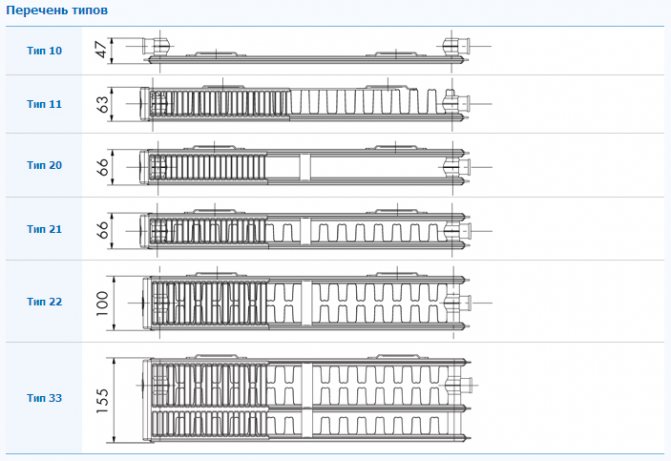

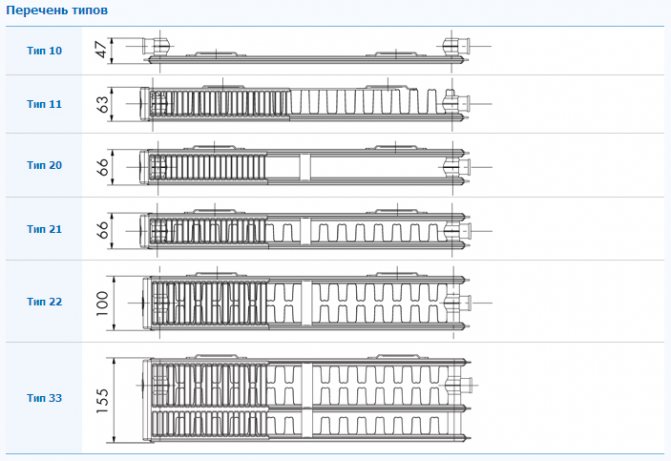

Steel panel radiators are often called convectors. Consists of one / several heating panels, convector fins, connection pipes, heat carrier channels, grate.

Quite an economical choice for use in a private house, it is widely used for rooms with autonomous heat supply.

Types of steel batteries

It is divided into types depending on the number of heating panels, convectors. 11 type - consists of one row of panels, convector, does not have a grate on top. They are often used to equip corridors and toilets. 22 type - has two panels, convectors, casing. With a relatively small size, it has good heat output. Type 33 - three panels, convectors, the casing is closed.

Selection

Heat dissipation varies between 200 and 1800 Watt and more. Depends on the size of the radiator, brand and model. Their inertia is small. They heat up quickly and give off heat to the room. Working pressure is about 7-10 atmospheres. They are highly susceptible to corrosion. Withstand water temperatures up to 120 degrees. The length is about three meters, the height is from 25 to 85 centimeters. The thickness of the steel depends on the manufacturer, usually from 1.1 to 1.2 mm. Durable due to their material, the thicker the walls, the longer the radiator will last. Their installation is quite simple and convenient.

Connection types

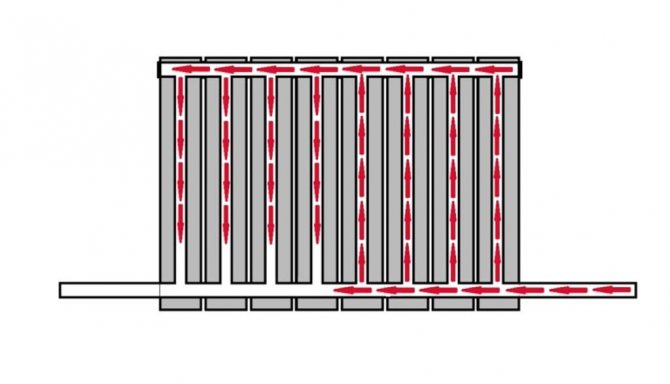

Lower... The coolant flows into the lower part of the radiator. Warm coolants are lighter than cool ones, as a result of which it rises upward, displacing the cooled coolant. Then the cooled one is lowered into the lower horizontal radiator manifold. Heat costs will be approximately 15-20% depending on various factors.

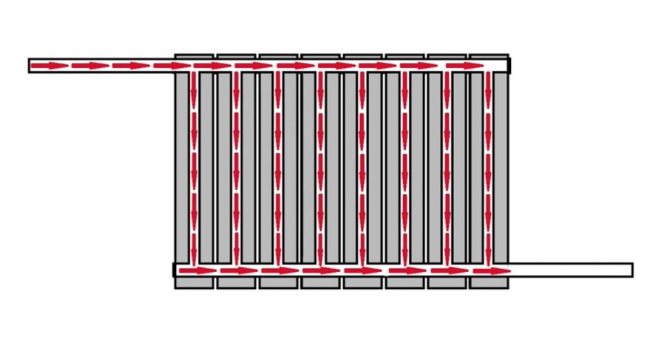

Upper... The coolant moves along the upper part of the radiator, but must go down because of the plug, then go up along the pastel section and flow out of the radiator from the other side. Thus, the coolant flows through the entire structure of the radiator, and it heats up completely.

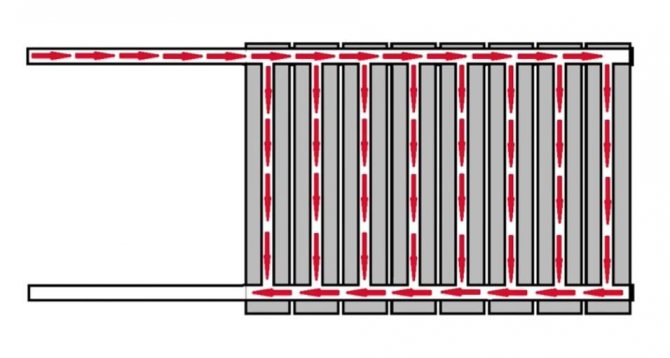

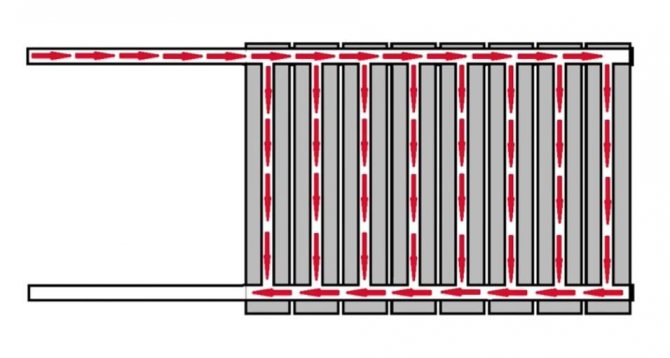

Lateral... With this inclusion, the coolant enters the upper part of the radiator, after which it descends downward along the vertical channel of the radiator and through the lower collector comes out through the side from which the radiator was connected. However, any coolant moves along the path of less resistance. A huge fraction of the coolant will flow through the 1st sections. As a result, the more sections the radiator has, the lower the heating temperature will be in the last sections. This will affect the joint heat loss of the radiator.

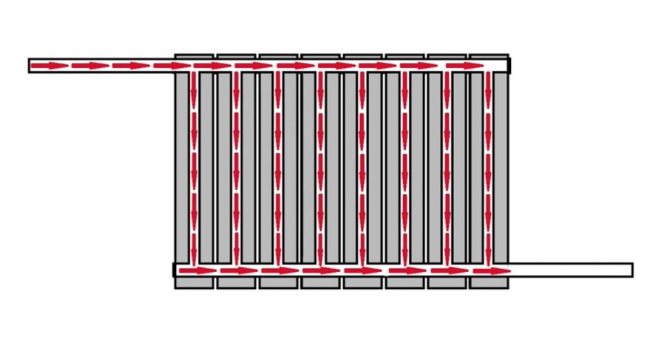

Diagonal connection... The heating medium is supplied through the upper part of the radiator, which is horizontal to the floor. Then it flows downwards along vertical pipes, falls into the bottom of the radiator and goes out in the other direction. So the radiator heats up completely, each section heats up approximately identically well.

Aluminum heat sink design

An aluminum heating radiator consists of separate sections connected to each other at the top and bottom. Inside each section there is a vertical channel for the flow of water or heat carrier.

On the sides of each section there are "feathers" - vertical plates, with the help of which the metal gives off heat. Most aluminum radiators have cut-off plates, located on top of the plates, which remove the heated air inside the room (see Fig.).

Aluminum radiator air cutters.

Advantages and disadvantages

- environmentally friendly, do not harm (thanks to this they can be used in clinics, schools, etc.);

- small volume of coolant and energy consumption;

- high heat transfer;

- aesthetic appearance;

- convenient to mount;

Disadvantages:

- drafts may occur, dust may rise due to convection;

- high risk of damage due to water hammer, use in high-rise buildings is not possible;

- paint may peel off;

- the appearance of corrosion when draining water from the radiator.

- lose in price to many radiators

Tubular view

They look like a standard construction of pipes and steel through which high temperature water flows. Their production costs higher, so the price is more expensive than that of panel radiators. Quite low pH of water - from 8 to 9. Withstands pressures from 9 to 14 bar. The thermal power is 1300 to 1500 Watt.

Tubular steel radiators have similar pros and cons as panel radiators. However, there are two different indicators: they can withstand more pressure and are more expensive.

Main manufacturers

One of the most famous steel panel radiator manufacturers - Kermi, Germany. The quality of the products is high, and special technologies are used during the creation that increase the heat transfer factor. Thanks to the two innovations “Therm X2” and the valve setting, about 10% of the energy is saved in advance. The range includes radiators with bottom and side connections. Available with popular types 11, 22 and 33.

Buderus, Germany. They are used mainly for heating houses, other buildings, where the coolant temperature is not more than 110 degrees. Lengths of executions from 400 to 2900 mm, heights from 350 to 850 mm. Upon delivery, the radiators are completely ready for installation. Can be installed in systems with pressures up to approx. 9 bar.

Korado, Czech Republic. Their main part is a pair of plates, which represent a heating surface. The company has a wide range of models, so a person can easily pick up the steel panel heating radiator he needs. Wall thickness over 1.15 mm. It is used as a coolant for water / water substances with a temperature of up to 109 degrees Celsius. You can install the piping in a hidden way.

DeLonghi, Italy. They operate silently, there are no open heating parts at all, the rooms are heated evenly. The manufacturer guarantees the safety and reliability of the products.

PURMO, Finland. Finnish steel radiators are gaining more and more popularity in our country. Indeed, due to the affordability of prices, domestic creators are not particularly represented on the heating appliance market. The price / quality pleases buyers, a different choice of sizes and types of radiators makes it possible to choose a heating device for your place of residence, office, or other building. Reviews speak of a long service life, a pleasant appearance, high performance of the device. Also a plus is the fact that the manufacturer makes radiators not only in white, but at least in black, red, and so on. You can choose the color to order. Manufactured from mild steel. 4 types of connection are possible - lateral, saddle, diagonal, bottom.

Among the manufacturers of tubular steel radiators, it is worth noting Charleston, Germany. They have a lateral connection, a columnar structure. Made up of several sections that are connected by welding. They are used in closed systems where the radiator does not come into contact with air. It is not applicable for hot water supply. Can be used not only for residential premises, but also for administrative buildings. The thickness of the steel is standard, about 1.2 mm.

Arbonia, Germany. Their appearance is quite minimalistic, you can also choose a color to order. Radiators do not take up large areas due to their small and narrow dimensions - they are tall, but thin. The modern look is perfect for freshening up the design of your area. It doesn't look like traditional batteries.

Steel Heating Radiator Manufacturers

Panel type radiators

In Russia, such radiators are practically not produced - products of foreign production have a very favorable price for the buyer. We can note the manufacturers from Germany - Buderus and Kermi, from the Czech Republic - Korado, from Finland - PURMO, from Italy - DeLonghi. Each company has in its arsenal of radiators that differ in height, length, depth, and, accordingly, power. Therefore, these data must be viewed directly in the passport of a particular radiator model. There are a huge number of models and it is very problematic to present all their technical characteristics within the framework of this material. Therefore, for comparison, we will take a type 22 radiator (it has 2 panels and 2 convector fins), 500/500 mm in size from some manufacturers.

Comparative characteristics of radiators of type 22, 500 mm wide, 500 mm long from popular manufacturers:

| Manufacturers | Working pressure, atm | Max. t coolant, 0С | Power, at 70 0С, W | Water volume | The weight | Connection method |

| Kermi Germany | 10 | 110 | 965 | 2,7 | 17,07 | Lateral - thread 4 x 1/2 "(internal) Bottom - thread 2 x 3/4" (external) |

| Buderus Germany | 10 | 120 | 913 | 3.15 | 14.1 | Side Bottom, with integrated thermostat valve |

| Lidea Belarus | 8,6 | 110 | 1080 | 3,3 | 15,1 | Lateral - 4 connecting pipes with 1/2 ″ internal thread Bottom - 2 connecting pipes with 1/2 ″ internal thread |

| KORADO Radik Czech Republic | 10 | 110 | 914 | 2 | 15,6 | Side - thread 4 x 1/2 "(internal) Bottom - thread 2 x 3/4" (external) |

| PURMO Finland | 10 | 110 | 929 | 2.6 | 13.6 | Side - female thread 1/2 "Bottom - female thread 2 x 1/2" |

| DeLonghi RADEL Italy | 8.7 | 110 | 1079 | 3.1 | 14.9 | Lateral - thread 4x1 / 2 "Bottom - 2 x 1/2" |

* All data are taken from official sources of manufacturers

Tubular radiators

These more expensive products are produced by fewer companies. Perhaps most of them in Germany are Zehnder Charleston, Arbonia, Kermi, Charleston. In Italy, such batteries are made by Israp Tesi. In the city of Kimry, Tver region, there is a KZTO plant, which produces radiators with a working pressure of up to 15 atmospheres. They can even be suitable for an apartment in a multi-storey building, withstanding the instability of pressure in the central heating.

If you notice an error, not a working video or link, please select a piece of text and click Ctrl + Enter.

0