Principles of operation of combined heating systems

When purchasing a multi-fuel boiler structure, which is an element of combined heating, you need to familiarize yourself with the universal capacity of the boiler device. The area of the building, heating needs are also taken into account here. Consider the most effective and relevant heating combinations, which are based on three principles:

- energy is obtained from all kinds of known sources;

- energy is generated, saved and accumulated, with its subsequent rational use;

- the system is created both during the construction period and in the built house.

Combined heating of a country house is a widely used type of heating, because it is very convenient to switch from one fuel to another by changing the burner included in the general set.

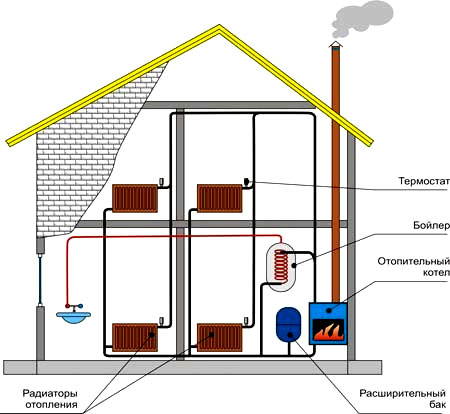

Combined heating option in a private house

At the same time, there are no significant changes in the settings, all issues are resolved using the instructions. The combustion chamber is one for two types of fuel, so the switching process is short-lived. Technically, this option is considered successful, despite the different fuel prices.

How the system works

The principle of operation of this system is based on the physical properties of air.

Exhaust is provided by the mechanical operation of fans installed in bathrooms, kitchens or storerooms. To ensure efficient operation of the fan, the door must have a slot at the bottom of at least 20-25 mm or an installed straightening grid.

With a combined type of ventilation system, axial, centrifugal or multi-zone fans are used. The first type of fans is designed to remove polluted air through a system of air ducts with a length of about 4 meters, which are located in the wall. All models must have a non-return valve to prevent cold air from entering when the fans are turned off.

Exhaust centrifugal fans are usually used to extract air in small spaces. Air discharge is possible through ventilation ducts and air duct system.

Multi-zone fans can be used to extract air from several rooms at the same time. Installation of such devices is carried out on the ceiling, in the wall or in the hemmed area. In addition, such models are economical, efficient and do not require significant installation costs.

Air is supplied directly through passive window or wall air inlets, which significantly reduces energy costs compared to mechanical ventilation.

Uniqueness of designs

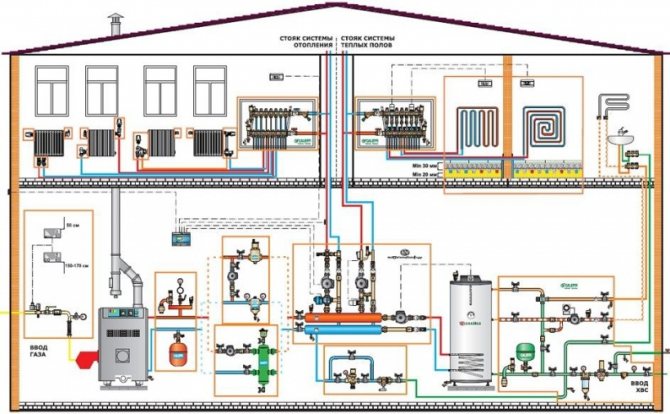

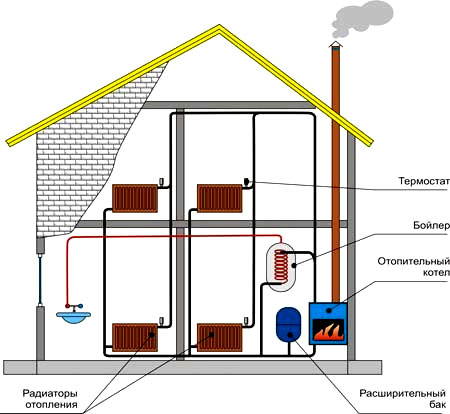

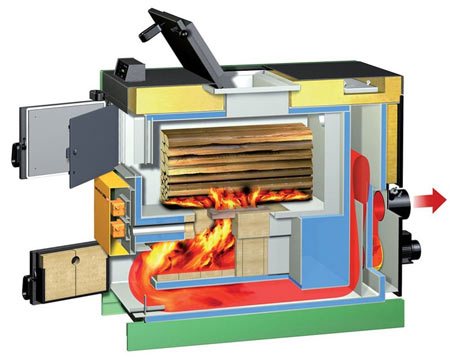

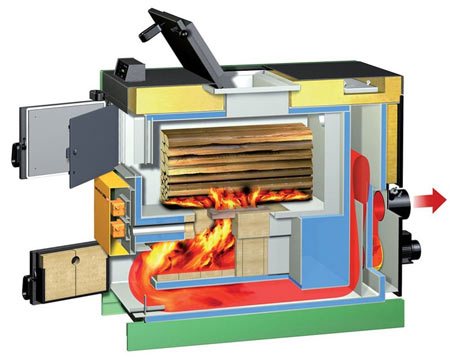

Combined boilers for individual heating of a private house have several fireboxes for different types of fuel. In one of them, solid fuel is burned - wood and coal, in the other - liquid or gaseous in the form of gas or diesel fuel. In such systems, it is possible to connect several autonomous lines and set different temperatures. For example, energy goes from one to the batteries, the other controls underfloor heating.

For heating a two-story house, this is an excellent option, only you need to focus on the presence of individual heat exchangers, they are not available in every combination boiler.

Combined heating scheme for a two-story house

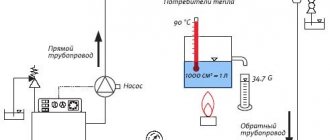

The latest developed representatives have built-in heating elements for operating on existing energy carriers, and there are also burners that allow you to use both gas and diesel fuel, simply by switching the switch to the desired mode. In order to save money and obtain the desired effect of heating a large area, it is worth using a heat accumulator, most importantly in boilers using coal. When using solid fuel, the power of the boiler system is not regulated and the room becomes extremely hot. The present heat accumulator:

- removes excess heat, it is conserved;

- in the event of a lack of heat, hot water is transferred to the hot water supply or to the system.

With this design, the boiler can be turned on less often.

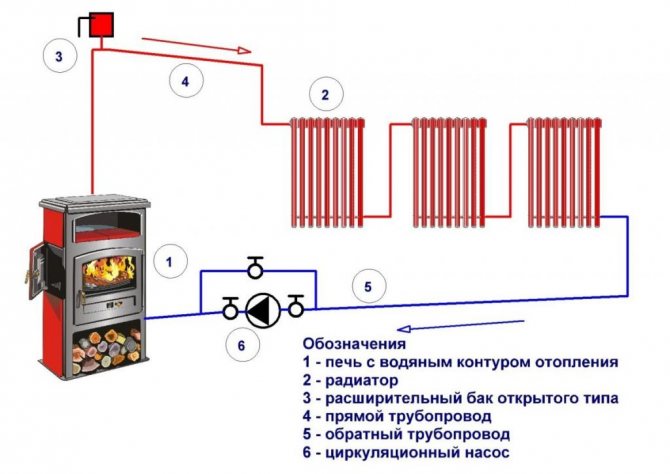

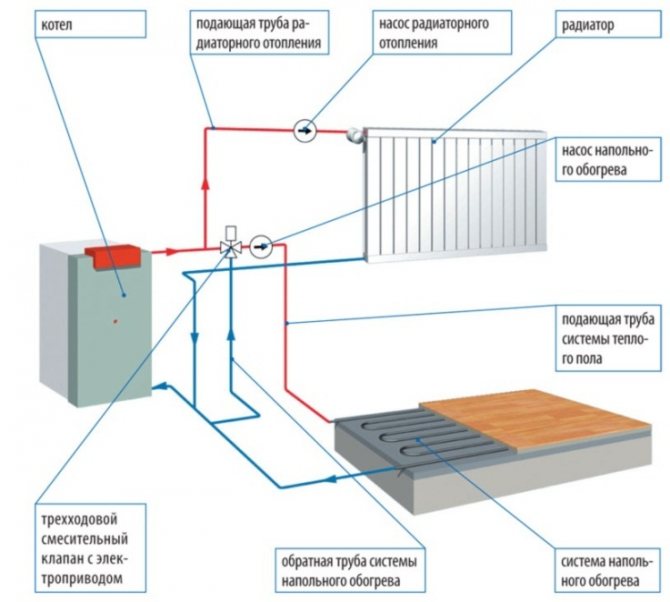

One-pipe system plus underfloor heating

The structure consists of the following elements:

- boiler;

- safety block;

- valves;

- circulation pump;

- expansion tank.

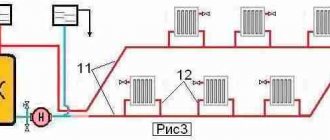

The radiator system is made in the form of two branches, and each branch is regulated by a separate riser located next to the connection to the main riser. Each of the radiators is equipped with two valves on the supply and return.

This is done so that in the event of a radiator failure, it is possible to replace it without shutting down the entire system.

The warm floor is connected to this system as follows:

- from the boiler, the coolant is supplied with a temperature of at least 80 degrees, when it goes back, its temperature is reduced to about 50 degrees. Therefore, the warm floor is connected exactly to the back;

- since the valves are installed both on the supply and on the return, you can turn off the warm floor without stopping the operation of the entire system. For regulation, a bypass is installed on the return pipe, by adjusting which you can direct part or all of the coolant directly into the boiler.

Combined home heating.

This is done when the heat carrier is too hot. The bypass can be closed or opened completely or half, this process you will regulate independently depending on the temperature in the premises.

The disadvantage of such a system can be considered a manual bypass adjustment, but, on the other hand, this option is economical, since buying a mixing unit with automatic valves will cost you quite a lot.

Model selection

When starting the choice of boiler models, you need to know that the size of the power for certain types of fuel will be different for it.

House project with combined heating

This is necessary to determine the main type used for heating purposes. Another information - in foreign boilers, the rated power is indicated, and in Russian - the maximum. This will make a significant difference in performance, so you need to be on the lookout. Combined boilers for a private house have different capacities when changing fuel.

Types of combined heating systems

Gas + diesel boiler

The performance and operation of this combination depends on the performance of the heat exchanger. Such a representative is made of cast iron and steel separately, or in combination. Consumers who use a combined boiler for a private house are convinced that with a nearby gas pipeline, it is possible to use both water heating and a combined system in the form of a combination of diesel fuel and gas. This is a very economical version of the acquisition and further operation of the structure.

Gas + solid fuel

Such a system is an independent combination of gas and solid fuel. A multi-fuel device that operates on wood and coal is suitable here.

Combined heating boiler gas, diesel and solid fuel

This combination is not always effective; the boiler requires the presence of a special automatic technology that controls safety.You need to treat this situation clearly and under the supervision of a specialist, then there will be a return. Despite their complex design, these devices are popular due to their inexpensive cost.

Solid fuel + electricity

Combined boilers for heating a private house with a similar combination are quite often used in practice, mainly in the suburban version. The volume of electricity here is from 220 to 380 volts, the power is 4-9 kilowatts. Potentially, there is a three-phase changeover. Being present in the room, the owners can use solid fuel, and during the departure, the automatics are turned on, and the required temperature regime will be maintained in the building.

The price of such a unit, of course, is rather big, but it is reliable and in the absence of other options, this one will be the best.

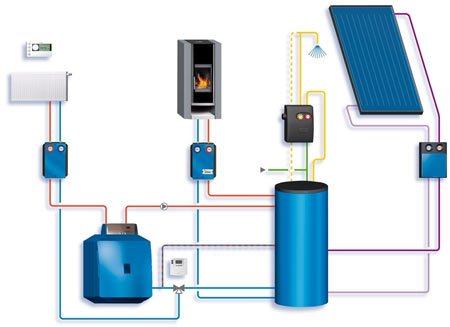

Gas + solid fuel materials + electricity

Consumers who value the ultimate power choose only this heating system, which operates with some fuel sources. Coal, wood, coke, lumber briquettes are used here. A mixed heating system is suitable for different areas located far from the city, but with the presence of a gas pipeline. In the event of a shortage of gas or electricity, there is always a way out - to use wood or other solid fuel.

Pyrolysis + electrodes

This device is suitable for heating a two-story house or heating a summer cottage. The combination of the action of the pyrolysis and electrode boiler will allow you to maintain the required temperature, even when there are no owners.

The scheme is not one multi-fuel mechanism, but two units, and has already gained popularity.

What is a combined heating system

Hello to all my readers! In this publication I will tell you briefly about combined heating systems. They are now quite common and are used everywhere. It may very well be that you also wanted to do this in your home. I will not torment you with long introductions and I'll get down to business immediately!

A combined heating system is a heating system (hereinafter CO), which uses several options for heating a room. For example, this can be heating a room with a stove and electric convectors. The latter are very often used to heat the room after the fuel burns out in the furnace. Instead of the design of the radiators, a heated floor with an electric sample or a climatic device acting on heating can be used. Well, the CO option with a traditional heating boiler and a pump for heating will be quite exotic.

Combined can be considered CO, in which two or more heating devices are used that operate on different fuels. So, for example, in our state, a scheme is popular in which the key gas boiler is duplicated by solid fuel or electric. At the same time, I believe that the solid fuel option is better here. Since light and gas can be an abyss at the same time, and solid fuel can always be nearby for a given occasion. If your CO is forcibly circulating a heat carrier, then you will need an uninterruptible power supply to support the operation of circular pumps and automation.

Well, if you want complete autonomy from the outside world, then here you can create two things:

- Gravitational heating system - the heat carrier in it moves under the influence of gravity.

- Furnace - the room is heated by radiation from the furnace itself, which is made of bricks.

These options have their own pluses and minuses, but we will talk about this separately in the next articles of this blog. And now it is necessary to consider a more common combination of methods for heating a room.

Heating system “heaters plus heated floor”.

It should be said right away that this option is currently used wherever possible. Its fame is explained by the increase in the comfort of living in a private house. You can forget about warm socks and slippers and just walk on a comfortable heated floor.

The essence of such a CO is that the heat losses of the room are divided between heating devices (or other heat supply devices) with underfloor heating. Here, high-temperature and low-temperature heat supply works in pairs. If someone is not in the know, let me remind you that the temperature of the heat carrier in heating devices can reach 90 degrees, then under warm floors it should not be more than 50. This makes it possible to achieve the optimal temperature of the floor surface.

Unfortunately, in our country there are many people who love to do first of all, and only then think ... Well, or never think at all. So, these people connect heated hydraulic floors (EHF) without an independent circulation group (it is also called a mixing unit). As a result, water heated to 70-80 degrees begins to circulate through the pipes, and the floor covering begins to burn the feet. Of course, you will eventually get used to walking around in beach slippers, but it's best to do everything right from the beginning. For a better understanding, I suggest you read the publication about common mistakes when laying underfloor heating.

Apart from ECP, electric heated floors are used. In most cases, it will be much cheaper to put a wire or heating mat in the tie than to drag pipes and make boxes for the manifolds. Only electricity bills will increase, but this can sometimes be reconciled.

Results of the publication.

In the end, it must be stated that it is possible and necessary to use combined heating systems. You need to start here with a project. A properly made project will help reduce installation and operating costs. It's not worth chopping off the shoulder and doing like a neighbor's, otherwise you can "fly through" on payments for electricity, gas or coal. I will interrupt at this! I look forward to your comments and questions

Heating 'target = "_blank"> ’)

The most popular solid fuel boilers

The ranking of the most famous heating systems is topped by Finnish combined boilers. There is an explanation for this:

- The climate of the country is similar to that of Russia; the required capacity of the heating process can be achieved.

- Manufacturing companies already have extensive experience and capabilities in this area.

- The quality of the models is very high.

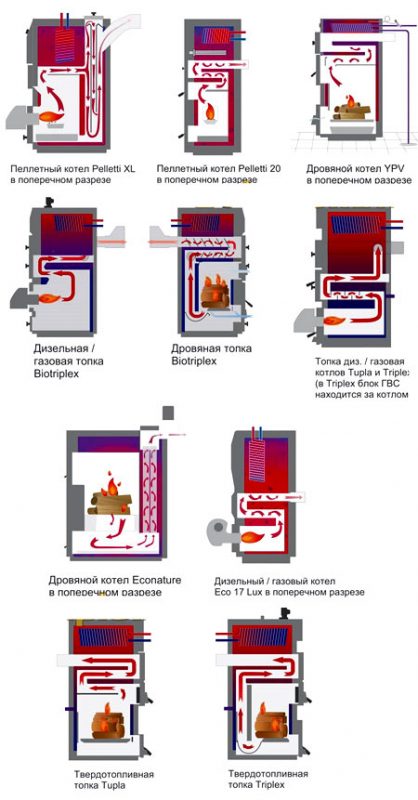

The Jäspi Group is a renowned company specializing in the production of heating equipment. The boilers have good characteristics, they are equipped with heating elements. Another well-known company is Jäspi. Boilers of this representative:

- operate on solid fuel + gas / diesel;

- they have a copper coil and ceramic grates;

- have autonomous fireboxes;

- high efficiency;

Schematic diagram of the Tupla combi boiler from the Jäspi factory - are able to completely burn fuel and are cleaned once a year;

- characterized by small emissions of harmful substances.

The Jäspi Biotriplex range represents the latest model: no switching is required during transitions, the two furnaces exist independently.

The advantages of the combined ventilation system

This ventilation system can be used in regions with cold winters and hot summer months, since the system works effectively in a wide temperature range - from -20 to +40 degrees Celsius. In conditions of low air temperatures, it is possible to accurately control, even with a small air flow, which ensures its even distribution around the perimeter of the entire room.Also, with a combined type of ventilation, you can set a comfortable temperature and humidity level, since the system is equipped with automatic control, which allows you to maintain the set parameters in normal conditions.

The only drawback of this type of ventilation is that it is necessary to constantly check the performance of the fans and, if necessary, replace them.

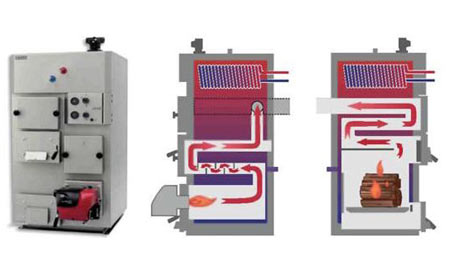

Boilers from other manufacturers

The most demanded in a multi-fuel boiler is the combination: solid fuel + gas.

This is what Zota combined boilers look like.

This allows for excellent heating of cottages, near which gas mains pass. Along with Finnish boilers, there are also Polish ones from Zota. They can combine solid, gaseous and liquid fuels. However, the burner will need to be replaced. The price of a boiler is small, this model is suitable for those who are not going to often change energy carriers.

For those wishing to regularly change the fuel, a combined two-flow boiler from Zota - ECO CK Plus is suitable.

The scheme of work is different here. The main solid fuel runs out, another burner turns on automatically. Everything is fixed in the settings. This is an interesting model of a multivariate boiler, but it also has disadvantages - size and cost. More existing models:

- Finnish Jäspi Triplex and Swedish CTC represent a combination: gas + solid fuel + electricity, and there are also examples: diesel fuel + gas + firewood + coal + electricity;

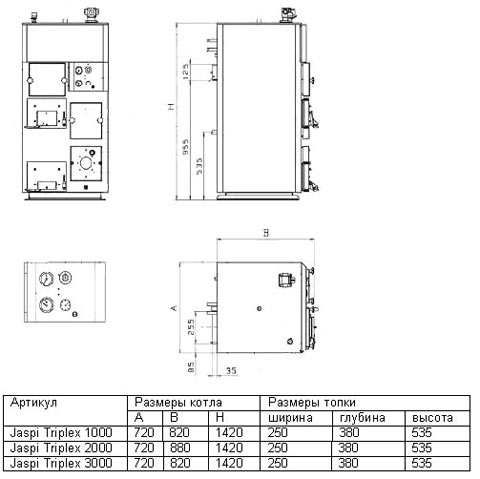

Dimensional drawing of Finnish boilers Jäspi Triplex - Czech cast iron combined boilers DAKON FB operate with pellets;

- Finnish boilers Jäspi VPK operate with pellets, gas, diesel fuel, wood, coal, there is an electric heating element;

- Austrian combined boilers Wirbel Eko Sk Pellet Pus have two furnaces;

- Russian combined boilers "FAX" operate on wood and coal, there is a heating element;

- the combined Russian boiler "Dymok" runs on wood or coal.

Self heating at home

The variety of existing equipment contributes to the arrangement of heating a private house with their own hands, the owner must have the appropriate knowledge. Now living outside the city has become a priority, there is hot water around the clock, heating is turned on at the request of the owners at the right time. But you need to arrange everything competently, otherwise comfortable living will be impossible.

Existing schemes of combined heating boilers

Before equipping the system of any room, especially the heating of a two-story house, a project must be drawn up, which is certified by the relevant organizations. In the case of installing a boiler with gas equipment, you will also have to tinker with documents and connecting the gas line.

An important point is the fact that in private houses, heating systems consist of upper and lower wiring using vertical and horizontal elements. In a one-story house, it is best to use the upper wiring with the presence of a main pipeline in the attic, and for heating a two-story house, the lower one is usually used with a boiler in the basement. Video review of the boiler room of a private house with combined heating.

For the correct installation, you need to stock up on a certain set of tools. Definitely, the combined heating system of a private house is a wonderful discovery for owners who have problems with heat resources. In modern boilers, a variety of fuels can be used - this already depends on individual solutions. Each of the types has its own disadvantages, but with successful combined solutions, you can achieve the desired results and install a suitable and effective heating system for your own home.

The most common are the following combined systems.

Partial frame system, based on a combination of load-bearing walls and a frame that can accommodate all vertical and horizontal loads. The system is used in two versions: with load-bearing outer walls and an inner frame, or with an outer frame and inner walls. The first option is used with increased requirements for the freedom of the planning solution of the building, the second - with the expediency of using non-load-bearing light structures of external walls. The system is used in the design of medium and high rise buildings.

Frame-diaphragm system based on the separation of static functions between wall (tie) and rod elements of load-bearing structures: all or most of the horizontal loads and influences are transferred to the wall elements (vertical stiffening diaphragms), and mainly vertical loads to the rod (frame). The system is most widely used in the construction of frame-panel public buildings of various storeys and multi-storey residential buildings under normal conditions and in earthquake-resistant construction.

Frame-receiver system based on the separation of static functions between the frame, which perceives vertical loads, and the trunk, which perceives horizontal loads and impacts. It is used in the design of multi-storey and high-rise buildings, since with an increase in the number of storeys, horizontal wind loads increase, and, consequently, the requirements for ensuring spatial rigidity and stability, which are effectively implemented by introducing a rigid element - the trunk.

Frame-block system is based on a combination of frame and volumetric blocks, the latter being used in the system as load-bearing or non-load-bearing structures. Non-bearing volumetric blocks are used for floor filling of the frame bearing lattice, additionally providing its property of geometric immutability (spatial rigidity). The load-bearing volumetric blocks are installed on top of each other in three to five tiers on horizontal load-bearing platforms (floors) of the frame located at intervals of three to five floors. The system is useful in buildings over 12 floors. The system allows you to diversify the planning solution and the appearance of the building by tiers due to the variety of combinations of prefabricated elements used - volumetric blocks.

Block-wall (block-panel) system It is based on a combination of load-bearing pillars made of volumetric blocks and load-bearing walls, which are connected to each other by floor disks. They are used in residential buildings up to 9 floors high under normal soil conditions. The system allows you to significantly reduce the time and labor intensity of building construction due to the use of prefabricated spatial elements. The most common in mass construction are floor-by-floor blocks of elevator shafts, plumbing cabins and stairwells.

Barrel-wall system based on a combination of load-bearing walls and trunk (s) with the distribution of vertical and horizontal loads between these elements in different proportions. They are used in the design of buildings above 16 floors. In this case, the role of the trunk as an element of rigidity and stability increases with increasing height of the building.

Barrel-shell systemis based on a combination of an external load-bearing shell and a load-bearing shaft inside the building, working together to absorb vertical and horizontal loads. The joint movement of the trunk and the shell is provided by the horizontal supporting structures of individual grillage floors, which are rarely located along the height of the building.The system is used in the design of high-rise buildings, since it provides a high degree of spatial rigidity and stability while maintaining the flexibility of the planning solution. The system also makes it possible to improve the economic performance of the structure due to the simplification of the floor structures while reducing the span of the elements in comparison with the shell system or to increase the size of the building body due to a simplified floor solution compared to the barrel system with cantilever floors.

Frame and shell systembased on a combination of the outer load-bearing shell of the building with the inner frame when the shell operates on all types of loads and influences, and the frame - mainly on vertical loads. The compatibility of the horizontal movements of the shell and the frame is ensured in the same way as in buildings of the shell-and-barrel system - due to horizontal overlaps - stiffness diaphragms. They are used in the design of high-rise buildings.

Along with the main and combined in the design are used mixed structural systems - combination in a building by its height or length of two or more structural systems. This decision is usually dictated by functional requirements. For example, the transition from a frameless system in standard floors to a frame system in the first or upper ones is associated with the need to move from a fine-mesh planning structure of typical floors to a hall planning structure in atypical floors. Most often, this need arises when arranging large stores on the ground floors of residential buildings or in multi-storey hotels with restaurants and dance halls on the lower and upper floors. It should be borne in mind that such a change in structural systems in height leads to an increase in the cost of building an object.

Mixed structural systems also include a variant of the constructive solution of a high-rise building, in which, along with the same type of reinforced concrete floor disks, horizontal grillage structures of increased rigidity with a height of one storey or more are used, the main purpose of which is to ensure the compatibility and equality of the movements of the vertical load-bearing elements.

In this way, choice of combined or mixed system always has a rationale: constructive compliance with the functional structure of the building, ensuring spatial rigidity and stability, reducing the cost of building a building, taking into account climatic features or the specifics of the construction site.

The concept of "structural system" is a generalized characteristic of building structures, determined by the type of vertical supporting structure and does not depend on the material used and the method of construction.

For example, on the basis of a frameless structural system, a building with wooden chopped, brick, concrete (large-block, panel or monolithic) walls can be designed. In turn, the frame system can be implemented in wooden, steel or reinforced concrete structures, and its main elements - columns - in brick design.