OPERATING MANUAL Introduction …………………… ..

Page 3

- Picture

- Text

3

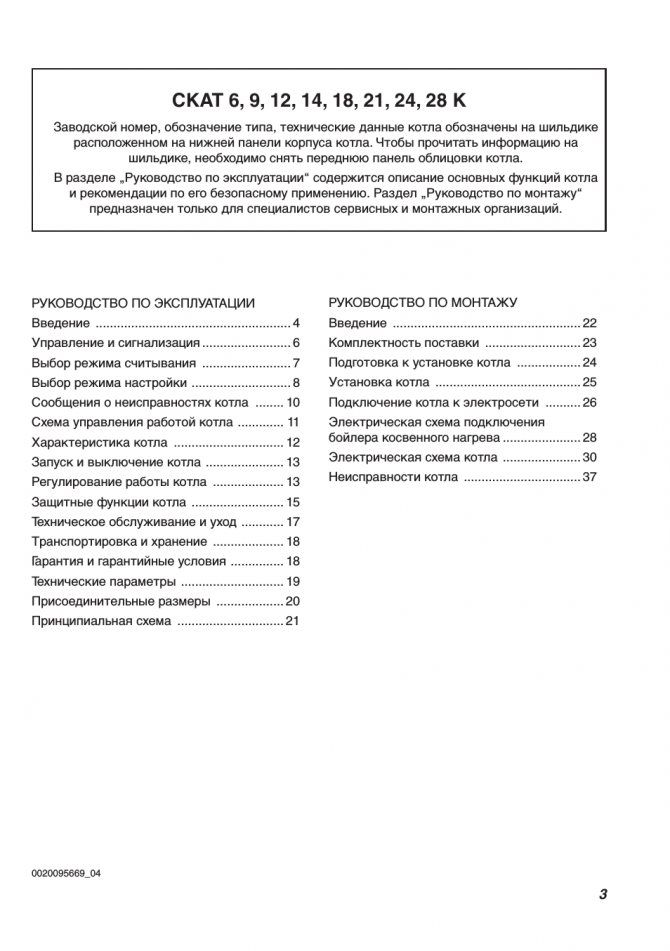

OPERATING MANUAL Introduction ………………………………………………. 4 Control and signaling ……………………. 6 Selecting the reading mode ……………………. 7 Selecting the setting mode ………………………. 8 Boiler malfunction messages …… .. 10 Boiler operation control diagram …………. 11 Boiler characteristics …………………………. 12 Starting up and shutting down the boiler …………………. 13 Boiler operation regulation ……………… .. 13 Boiler safety functions …………………… .. 15 Maintenance and care ………… 17 Transport and storage ……………… .. 18 Warranty and warranty conditions …………… 18 Technical parameters ……………………… .. 19 Connecting dimensions ………………. 20 Schematic diagram ………………………… 21

CKAT 6, 9, 12, 14, 18, 21, 24, 28 K

Serial number, type designation, boiler technical data are indicated on the nameplate

located on the bottom panel of the boiler drum. To read information on

on the nameplate, it is necessary to remove the front panel of the boiler casing.

The section "Operating instructions" contains a description of the main functions of the boiler.

and recommendations for its safe use. Section "Installation instructions"

intended only for specialists of service and installation organizations.

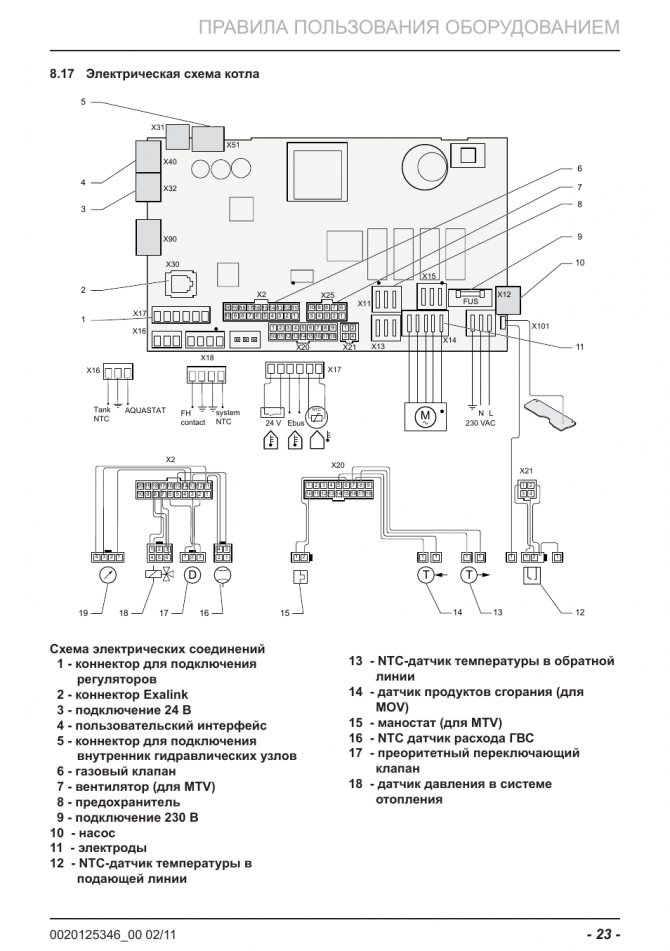

INSTALLATION MANUAL Introduction ……………………… .. ……………………………… .. 25 Connecting the boiler to the power supply network ………. 26 Wiring diagram for connecting an indirect heating boiler …………………. 28 Boiler wiring diagram …………………. 30 Boiler malfunctions …………………………… 37

0020095669_04

Installing and starting up the boiler

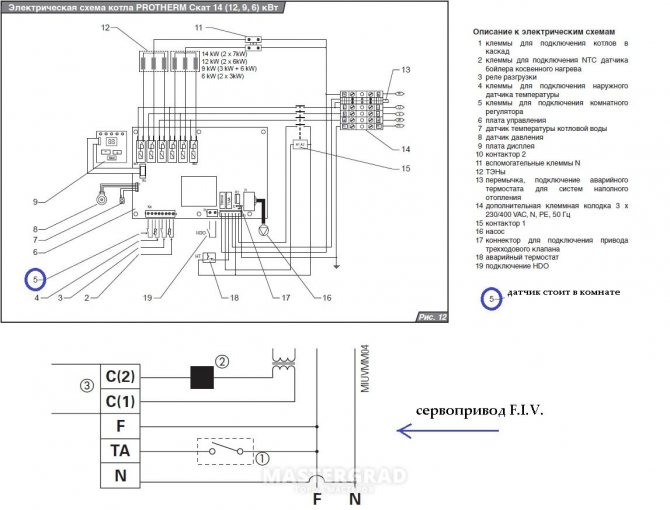

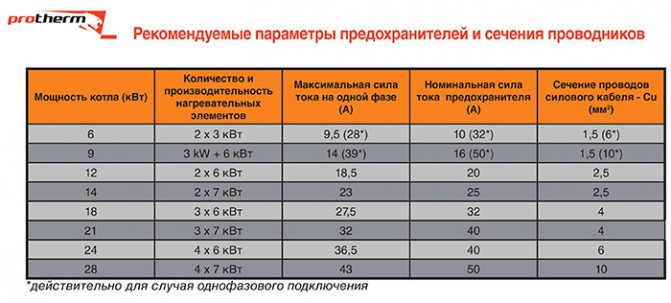

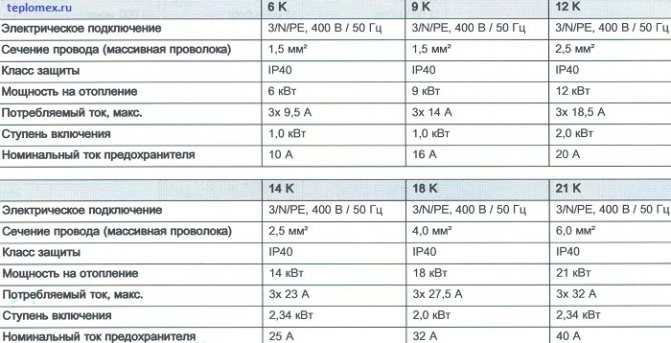

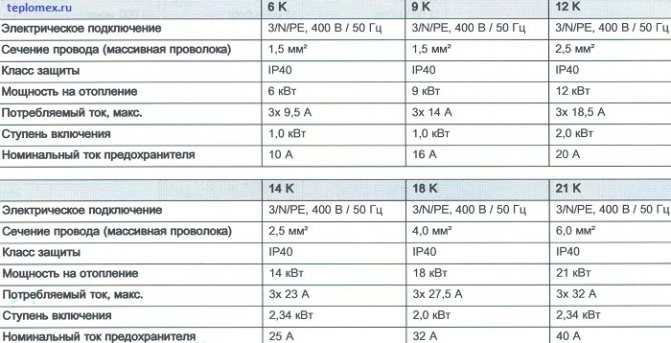

Boilers with a capacity of 6 and 9 kW can be connected to a single-phase network

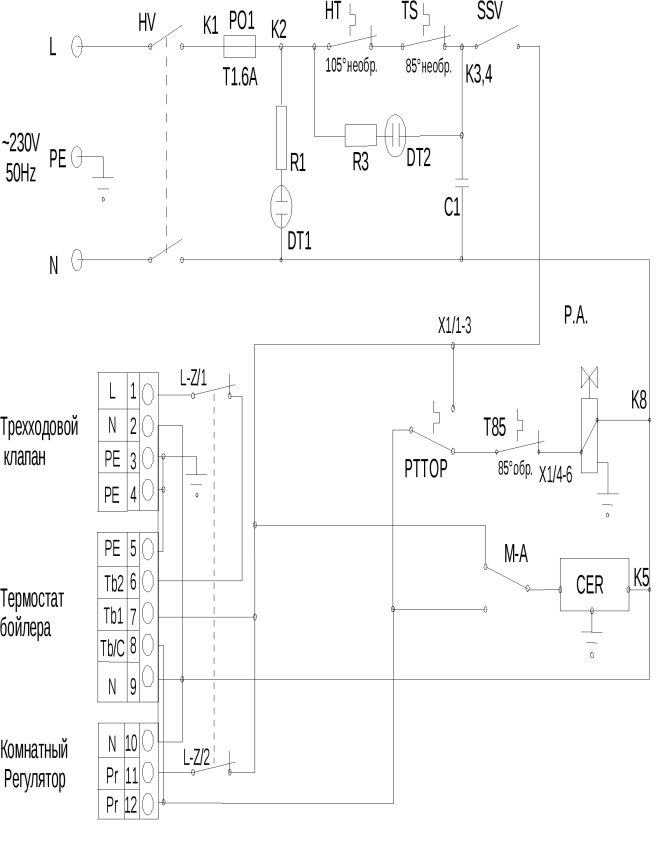

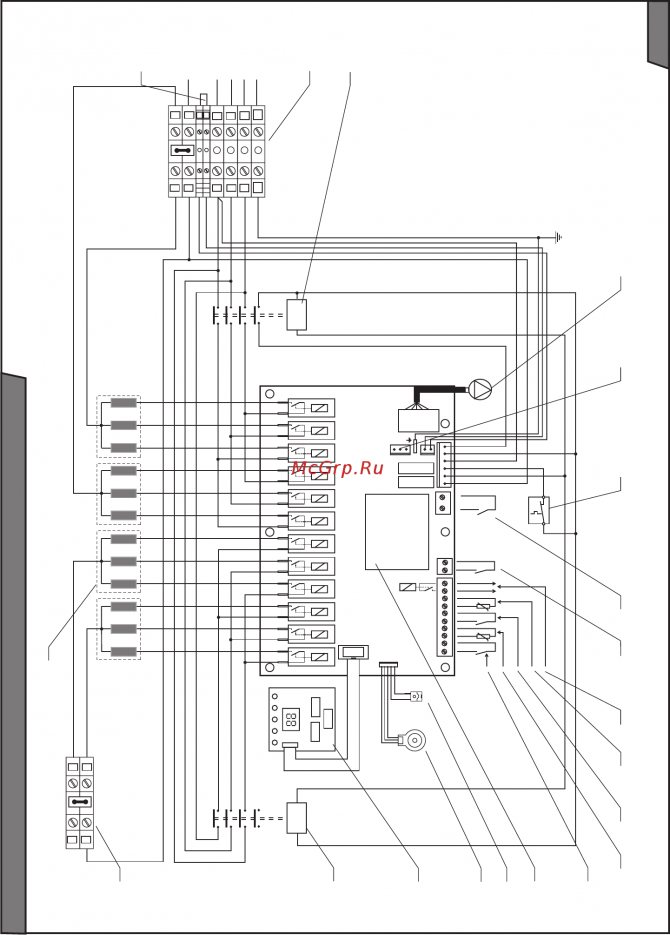

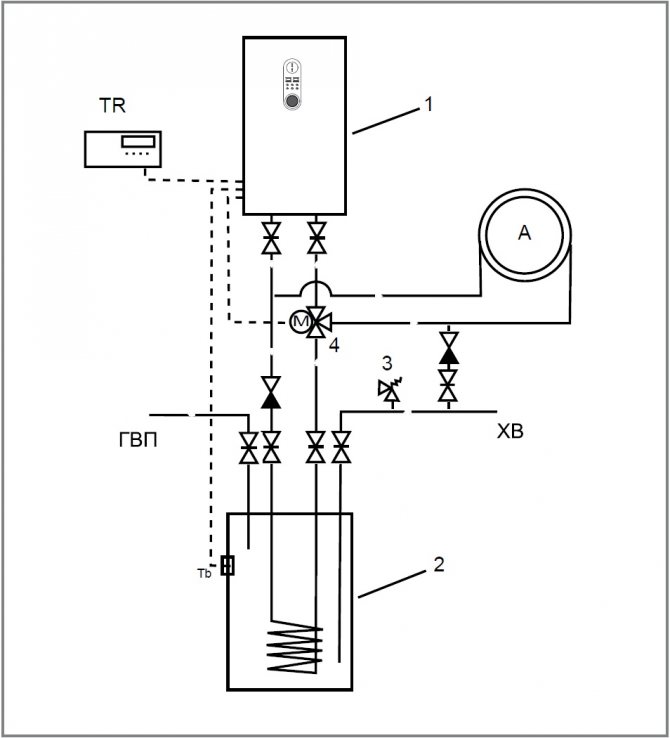

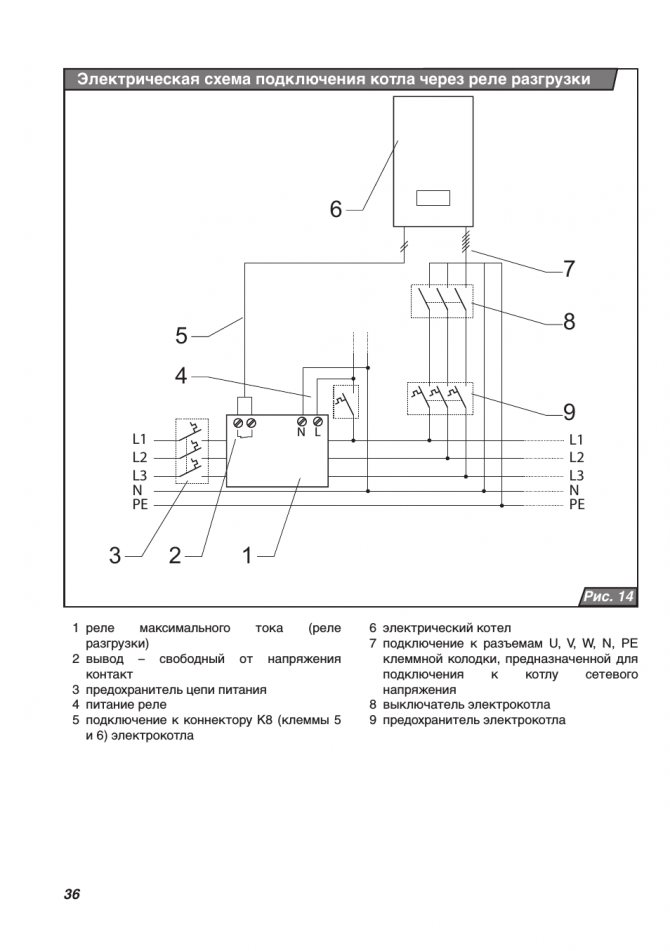

The equipment is hung on the wall with screws. Connect the pipes to the heating pipeline. With additional installation of the boiler, a three-way valve is installed at the point of its connection. They are connected to an electrical network of 380 V. A switch is installed at the input, which interrupts the current supply. A separate power cable is laid for the power supply. All connection points are grounded.

Electric boiler Protherm Skat 9 kW and 6 kW can be connected to a single-phase network using a connecting bridge included in the equipment set. It connects the phases of the wires on the terminal block. To start the unit, open the water supply tap, bring the pressure in the system to 2 atm, the temperature value will appear on the display and the light will turn on.

More details about the operation of the boiler, about setting up various operating modes can be found in the instructions "Installation and operation manual for the Skat Protherm boiler".

Introduction

Page 4

- Picture

- Text

4

You have become the owner of a direct-flow electric boiler for central heating systems with the ability to regulate thermal comfort. We hope that the Skat electric boiler will serve you for a long time and reliably. When installing and maintaining it, certain rules must be followed. Therefore, we ask you to carefully read the contents of this maintenance manual and, when working with the boiler, act in accordance with the recommendations and instructions given therein. We believe that the SKAT electric boiler will help you create a pleasant atmosphere and optimal thermal comfort at home. Please pay attention to the following main points:

1.

The boiler, together with the associated equipment, must be installed and used in accordance with the project documentation, the relevant laws and technical regulations in force, and the manufacturer's instructions.

2. The boiler must only be installed in

specially designed premises.

3. Putting the boiler into operation after

installations can only be carried out

a specialist from a specialized organization certified by Protherm.

4.

The boiler complies with the requirements of standards and regulatory documents in force on the territory of the Russian Federation, which is confirmed by a Certificate of Conformity issued by an authorized body, a Permit for use from the Federal Service for Environmental, Technological and Nuclear Supervision.

5.

In the event of any malfunctions, contact only a specialized service organization - non-professional

Introduction

tampering may affect the warranty of the equipment.

6.

The employee of the service organization putting the boiler into operation is obliged to familiarize the user with safety precautions when servicing equipment and controlling the operation of the boiler; operations that the user has the right to perform independently and operations that only a qualified specialist of the service organization has the right to carry out. If the specified service organization is also a supplier of the boiler, it is obliged to ensure that the original packaging of the boiler is kept in case of possible transportation.

7. Check the integrity and completeness.

delivery.

8. Make sure the type supplied to you is

the boiler according to its input parameters (indicated on the nameplate), is suitable for operation in this region. Input parameters mean: voltage of the electrical network.

9. In the case when you do not have a certain

to be sure of the correctness of your actions on boiler maintenance, find and carefully study the relevant instructions and recommendations contained in this maintenance manual, and act exclusively in accordance with them.

10.

Do not remove or damage the markings or inscriptions on the boiler.

Keep the original boiler packaging in case of possible transportation intact until the boiler is put into operation.

11.

Use only original spare parts for repairs. It is forbidden to interfere with the internal structure of the boiler and make any changes to its structure.

12.

In the event of a prolonged shutdown of the boiler, it is recommended to empty it and disconnect it from the power supply. This recommendation is made taking into account the general

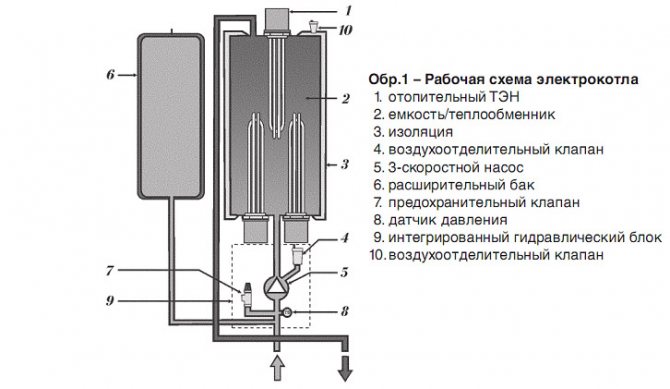

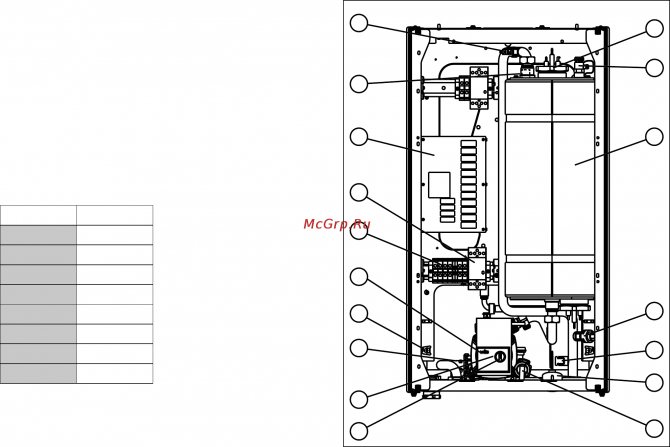

The device of electric boilers Protherm

Electric boilers protherm are a modern high-quality solution for the heating system.

They are produced on the territory of Slovakia and have rather high performance characteristics.

Boiler device:

- cylindrical heat exchanger made of steel;

- heating resistors made of copper.

An innovative element, which is installed in the design of protherm electric boilers, is a pump with an automatic valve for air discharge. The device also has a pressure indicator, a safety valve and a 10 liter expansion tank.

The boilers are equipped with an electrical switching unit that enables easy power regulation. The setting is carried out by means of two switches.

In addition, there is also electronic regulation, which provides the function of power regulation and step switching off. At the same time, a delay in switching on the heating stages is provided, equal to about 20 seconds.

Hot water waste heat boilers are designed to prepare hot water for industrial and household purposes with a maximum design temperature of up to 115 ° C.

Read about what kind of electric hot water boilers are here.

This prevents the occurrence of strong voltage surges when switching the device on and off, which can lead to equipment failure.

Circulation pumps, which are installed in electric heating boilers, are manufactured by well-known companies - Wilo or Grundfoss. Their feature is the work in a special mode, which prevents wear and tear of the device.

After the boiler heating device is turned off, the pump will continue to operate for some time (about two minutes), thereby ensuring circulation in the coolant system.

Electric boilers Proterm Skat

___________________________________________________________________________________________

- Floor standing boilers Bear KLOM, KLZ, TLO, PLO

- Wall-mounted boilers Panther, Cheetah, Jaguar, Leopard, Lynx

He was engaged in the installation of the Proterm Skat 9 kW boiler, a boiler room and a warm floor. Yesterday I refueled the system, gave a pressure of 1.7 bar. Preparing for power supply. The question arose: I measure the pressure with an external pressure gauge - I installed it on the return line. But which one is the pressure gauge in the boiler? He clearly needs to be prepared for work somehow. Apparently you need to bend it back? Otherwise, you will not look at it from below. Please specify how to bend it so as not to break everything or not touch it at all? You don't need to bend anything. Lower mechanical pressure gauge for visual control when the device is not connected to the mains. For operation, the electronic menu of the unit is enough for you. How to switch, read the instructions. Please tell me what is the reason for the requirement of the installation instructions for the electric boiler Proterm Skat 12 kW, which says that the distance to the ceiling from the top of the boiler is 700 mm? The heating elements are pulled up when replacing. Distances of 40-50 cm should be sufficient. Help to understand such a problem. I installed the Protherm Scat 18 kW boiler, through the native Fugas three-way valve and the temperature sensor I connected the Hajdu STA 300 C indirect heating boiler to it. Power, then to Pressure and further in a circle. I cannot set the hot water temperature accordingly. For what reason may the unit not see the boiler? The heating system was started up normally, adjusted, the air was expelled. Radiators heat well, no problem. The device is still operating at 6 kW, the coolant temperature is 55 degrees. The three-way valve is turned on in its position, the sensor is connected, but its wire is extended by 10 meters with a wire with a cross section of 0.7 squares. Maybe this is the problem or something else? The sensor was stuck in the wrong place. Check again. The installation of the heating system is coming to an end, and it will be necessary to start the electric boiler Proterm Skat 6 kW into operation. Tell me what to do with air vents, etc., how and what to unscrew, where to leave what to unscrew? And yet, a black plastic threaded fitting, about which it is written that you need to drain to the street or to the sewer - is it really necessary to do this? Switch on - switch off automatically? In the process of bleeding air, it will probably be necessary to recharge the system to a certain pressure? As I understand it, your system is also propylene, how many degrees maximum do you feed into propylene? Open the air vent on the pump permanently (a couple of turns of the cap). Drain the air from the heat exchanger with a tap through a transparent tube dropped from the bottle. Run the device for 10-20 seconds. Switch off. Bleed the air from the faucet again. Run for a couple of minutes. Stop. Lower again. If antifreeze without bubbles comes out of the tube, you can turn on the boiler permanently and go to expel air from the radiators through the Mayevsky tap. After a day, check that there are still no bubbles in the antifreeze from the tube. After 3-4 days, go through the radiators again, release the air. After a week, repeat again. Never close the air vent on the pump.It may erupt from the fitting when pumping. At least until the system reaches performance indicators - substitute something. Then it is not necessary. On off. automatic, yes. It may and will have to be fed. It depends on how many you initially pump. I have PP pipes, I don't recommend more than 75. But I set the weather so that it was 75 degrees, only starting from -5 outside, and at other temperatures - more benign values. Electric boiler Proterm Skat 14 kW. There is a scheme for the operation of this model on hot water supply through a three-way valve and an NTS sensor. For example, I have an electric boiler of 9-12 kW, I need only 6 kW for heating. I, of course, lower it from the settings panel to the required one. But when switching to DHW heating, how much will it consume? Are the power settings saved for both DHW and heating? Is it possible to supply, for example, also 6 kW for DHW heating? DHW output is not regulated (always full output). Your hot water supply does not always work. And at higher power, the device will heat up the water faster. What is more economical, it takes longer to warm up with a weak device or faster with a powerful one, you have to look. Malfunction of the electric boiler Proterm Skat 28 kW. Error F20 caught fire, climbed to look for a red button, the cap did not slide off it in any way, forged with a screwdriver and short-circuited the sensor terminal, which with the button, to the tenov case, a small spark, the device went out and does not turn on. What are the consequences? See fuses. There are 2.80 mA and 1.6 A. The house is 100 square meters, I plan to install and install an electric boiler Protherm Skat 9 kr-13, I plan to bring 3 phases of 3x5 kW to the house, if one of the phases is cut down (and this is what we have often), then the device will not work on the remaining two? Maybe then connect to one? Phase control relay? Can work on two. But if the phase from which the control is powered is cut off, the unit will of course go out. Well, of course, with two phases, the maximum power will drop by a third. In order for the device not to be extinguished from a power outage of the control board, it is better to power it through a phase selection relay - a kind of ATS. It is better not to record from one phase. Tell me, according to the instructions when installing the Proterm Skat 12K boiler, the free distance from above should be at least 800 mm. In my case, it turns out 400. It will be a backup, the main apparatus is gas. What is the risk of violation of the free distance? To replace the heating elements, the boiler will need to be dismantled. Does it make sense to power the circuit pumps from the pump activation line through the power relays? To clarify my doubts: the Protherm Skat 6 kW electric boiler is controlled via Zont by the temperature in the boiler room - the initial version of home ownership. And the pumps of the circuits (warm floor, heating radiators) - work continuously. FUGAS is already connected to the external pump control contacts. Is it possible (using power relays) to reconfigure the operation of the pumps on the comb from the algorithm of the built-in pump? The pump has stopped - “the circuit pumps have frozen”. And vice versa. As far as I understand the problem, the power of the contacts that control the operation of the built-in pump is not enough to control additional pumps? If so, connect a contactor (relay) instead of the built-in pump. And hang on it everything that should be turned on / off at the same time. Help to figure out the problem with the electric boiler Skat 14 kr-13. The display shows 4.5 bar, while the mechanical pressure gauge is 1.1 - 1.2. A couple of times it already happened, I corrected it by restarting the unit. This issue did not work yesterday. The device is the 3rd month in operation. What to do and how to proceed? What is the reason? There are two ways: if the installation and start-up were carried out officially, then file a claim with the seller or the installer. If everything was done independently, then the field of possibilities is much wider: Do not worry. After all, there is a mechanical pressure gauge and a safety valve. Check the quality of the power supply. Maybe some interference introduces errors in the measurements. Replace the sensor, if it does not help - the board (it may periodically fail, incorrectly processing the data received from the sensor). Invite ASC for diagnostics.Independent start-up, even under the terms of the guarantee, is not yet the final verdict. The boiler Proterm Skat 18 kW is in operation. Works on radiators and underfloor heating of the 1st floor. I have two questions for specialists. An external temperature sensor and a room one are connected to the device, we have been working normally for the second year. For this winter, I assembled and connected a remote control, which in our absence supports about 10C and, if necessary, we turn the device into normal mode in advance. In addition, the system tries to take into account the night rate. Everything would be good, but I want more - feedback. That is, monitoring power, water temperature, pressure and possible error messages in operation. Actually the question is - where can I get the schematic diagrams of the control board and the main board (I don’t know how it is called correctly)? Very necessary. Judging by the description, when connecting a warm floor, it is necessary to connect an emergency thermostat to the device. In fact, I see a jumper on the necessary contacts of the electric boiler. What do you advise? All that comes to my mind is to limit the temperature of the coolant. Now it is limited to 60C, which naturally has a negative effect on the heating rate of the premises. And is it possible to install this thermostat without disassembling the floors? Where is it generally installed, and what temperature of the coolant for the floor is considered critical? I installed an electric boiler Protherm Skat 9 kW, in the process of studying the Instructions for the installation and operation of the boiler, I found information that there should be a minimum distance to the ceiling above the boiler - 800 mm. What is the reason, why such a gap? I did not find such a requirement in the instructions for the gas unit. Is this the specificity of an electric boiler? In fact, I get about 400 mm. Is this a big problem? 800 mm is required to replace the heating element, if you have 400 mm, then to replace the heating element you will have to remove the device, this will not affect its operation in any way. Electric boiler Protherm Skat 12 kr-13 is in operation. Thermostat Evan ZONT H-2 as a room thermostat. Several sensors in different areas of the house. The thermostat also supports the ability to connect an outdoor sensor and work depending on the weather (weather-dependent automation). At the same time, the unit itself also has an output for connecting an outdoor temperature sensor, for example, S010075. The logic of the boiler, which has both a room thermostat and an outdoor sensor connected at the same time, is not clear to me. I am trying to find the best solution. The PZA algorithms in the umbrella are still grossly incomplete. In the boiler, the PZA works perfectly and in a slightly different way. The umbrella pulls the power supply of the apparatus to simulate the PZA, and the apparatus modulates its power in accordance with its own PZA. That is, the principle of the PZA is completely different: the umbrella is on / off. it at full capacity to maintain the coolant temperature, the unit simply changes its current coolant temperature in the menu, while adapting the power. I have been using the Protherm Skat 6 kW electric boiler for the second season in night mode and over the last month I received a slightly higher electricity bill than for the past time cycles. By turning off all email. consumers, besides him, found out that he consumes 6.5 kilowatts. Maybe someone knows what the problem is? Well, if he consumes 6.5, then he is giving 6.5. In fact, most likely, the clue is in the increased voltage in your outlet. Installed in a house (150 sq. M.) And connected to the heating system, an electric boiler Proterm Skat 14K. After two weeks of operation, the value 14 disappeared in the power selection menu (kW), that is, I can select 2,4,7,9. Of course, this is not critical, we do not use the full power (it is turned on up to a maximum of 9 kW), but I would like to understand what this is connected with. Visually, the board is whole and the wiring contacts of the heating elements, too. The device has been working for 2.5 months from the moment of installation, and I came across it by accident. During installation, the wizard showed how to use the menu and set 9 kW, and just after two weeks I tried to switch the power myself. I did not see indication 14 after installation.He called the master and said that he had not specifically set a restriction. I sit and think, or he accidentally set a restriction, because after your answer, I realized that this is real and it is possible to reconfigure the boiler or something has broken. I disconnected the unit from the network, it did not help. Hopefully, the problem is not serious. I haven't installed the unload relay yet, but I'm thinking about it, since 15 kW comes to the house and when using powerful consumers such as a boiler and a boiler, it is necessary. It's just that in the service menu you can set the maximum boiler power, above which it will not be possible to set it through the usual menu later. Are you sure that after the visit of the installer, the device gave you 14 kW? I just don't remember that the electric boiler excluded the power of the heating elements from the menu in case of damage. Try turning it off in the dashboard automatically (when it will not heat up) and turn it back on. I started the electric boiler Proterm Skat 9 kW and forgot about the drain hose with a gray turntable on the container with the heating elements, it boiled for a long time (about 20 minutes), but he heated the water in the BKN in the normal mode, and then I also started the heating circuit, like everything is also normal mode. Now the question is tormenting: did I set fire to the heating elements, or was it all right? Well, one, two, three, all the heating elements will either close or vice versa will be in a cliff. Or part will close, part will be in the gap. It will manifest itself either in a short circuit or in a decrease in the heating rate. Or maybe you're lucky, everything will work out. Can you tell me whether it is possible to increase the power of the Skat electric boiler from 12 kW to 18 kW by replacing the heating elements, or do you still need to change something in the control of the unit? The contact to the external room thermostat stopped working. Recently, I pulled out the wire from the thermostat to the device in order to connect the thermostat to a diesel boiler. When I put the wire back in, the electric boiler stopped responding to it - it turns on in any case, regardless of whether the circuit going to the thermostat is open or closed. Moreover, if you remove the block from the board, into which the wire from the thermostat is actually stuck, it still turns on, as if a jumper is inserted. Although, in theory, in this case, everything is open, and it should not turn on. Electric boiler Proterm Skat 6K is in operation. The area is about 50 sq. m. with a corridor, bathroom and second floor. Bimetallic radiators. Two heating circuits depart from the apparatus separately: the first floor, the kitchen, the bathroom (4 radiators) and the second circuit to the corridor, the second floor (4 radiators). Each circuit can be disabled, each radiator can be shut off. Propylene pipe 32. What worries: When heating one circuit, no matter what - everything works fine. When connecting the second circuit (second floor and corridor), the water temperature does not warm up above 54 degrees, even if I shut off all radiators on the second floor. What's wrong? The pump is hot, is this normal? Is the pump constantly running at its fastest speed, is this normal? Does it make sense to adjust the pump speed? I got to the inclusion of pump adjustments, it shows 0, and then what to do to reach 16 and then what? So someone didn’t have an instruction to the end. Help connect the room thermostat, just literally, where to stick what. I figured it out on the unit, but even electricians cannot tell with the regulator. How much should it be? The heat removal of the radiators should be 10 percent more than the maximum power, I don't see any problems, perhaps the 2nd floor is not sufficiently insulated. Take a pyrometer, measure the supply / return branches, the thing is necessary and is not as expensive as a thermal imager. It may be worth considering installing a hydraulic arrow and connecting your own pump to each branch. Yes, it's normal, it has a wet rotor, it should have a return temperature. Climb the wrong place. Pump speed point 19. Download the service manual and read it carefully. Cling to dry contacts, this is terminal 1 and 0, a multimeter to check to help you. Do not connect to 220 under any circumstances. Electric boiler Protherm Skat 12 kr-13 is in operation (purchased and installed a month and a half ago).The power limit is 10 kW, the coolant temperature is limited to 65 degrees. Works only for heating (heated area 115 sq. M). The coolant can be heated to a maximum of 48 degrees and that's it. Working at 10 kW (according to the display), it actually consumes about 7 kW (according to the electricity meter). The unit was checked, everything is in order with it. The neighbors have the same problem, but a different device. Electricians said that the problem in the power grid was low voltage (174-200v, and not uniform in phases). It was recommended to install a powerful voltage regulator. The question is - if I put a voltage regulator, will it really allow to increase the heating temperature? And which version of the stabilizer is better: one three-phase, or three single-phase? In fact, the electric boiler will not be able to exceed the power allocated to the house, since at this voltage, and the power is proportional to the square of the voltage, the unit produces half of the rated power and even less. You were given the correct advice, the 12 kW mode will allow you to remove a little more heat from it. But the installation of stabilizers will not completely solve the issue, since at low voltage, the actual power that you can take from the network is much less than that limited by the input automaton. If the heating system cannot establish normal voltage in the network, then let it allow increasing the rating of the machine. In this case, it will make sense to install stabilizers (or change the heating elements for more powerful ones). Boiler malfunction Proterm Skat 6 kr-13. After switching on, it turns off after 5 seconds. What is the problem? In the burnt / burnt element of the heating element. Other options are unlikely, unless, of course, this happens in idle mode. I started the boiler Proterm Skat 9 kr-13, I was just going to buy Instat-2, but it was taken out of production. What do you recommend in return? Take a closer look at Termolink S and SD 2000. I installed and connected an electric boiler Protherm Skat 12 kW, started it myself, everything was according to the instructions, the air was bleed off before starting. The radiators heat up, everything is as expected, the temperature is kept. But after turning it on, it starts to buzz strongly, you can hear it in the house very well. I checked the air, bleed it again, it was not much. Question to those who have the same device, is the buzzing normal? How does it work for you? Yes, the impression is that the pump itself is humming. Most likely the pump, and if its speed is set too high for your system, then it may make sense to lower the speed. When the system is too clamped, the coolant can cross the sound threshold and a characteristic sound begins in the pipes. Electric boiler Proterm skat 9K. Is it possible to operate it painlessly from a generator using a single-phase switching scheme? Models 6K and 9K can operate from a network with a voltage of both 380V and 220V, others only from 380V. If it does not make it difficult, you can outline the nuances of the scheme of your boiler piping. In the near future I am going to install an electric boiler Protherm skat 6K, now I am collecting information on piping. It is better to place the lower edge of the device on the same level with the boiler so that the display is at eye level. I used an ordinary PPR pipe for feeding the VTP collectors - the road to the device is open for oxygen. Installed and connected electric boiler Protherm Skat 9k. When the temperature of the coolant drops to 30-35 degrees, the pressure drops below 0.6 and the boiler, accordingly, stops with an error F22. The system is closed, one floor, there is no circulation pump in the system (only in the apparatus). With the boiler off, pump the expansion tank to 0.8, then feed the system to 1 bar through the return line, turn it on? Can't do without a circulation pump? We turn off the unit and drain the water from it, only then pump it (the drain valve is open). And why a circulation pump? If you pump them in the absence of a water supply system, then it will not lift more than 0.6. Something happened to the Skat 12K boiler. The machine gun was knocked out. I did not show any errors on the display before, well, at least they did not see them. We tried to turn it on. At first, he started to turn on and immediately turned off.And now in the morning he clicks, the red lights under the lid are blinking. It does not turn on, the display does not light up, the indicators on the displays do not light up. Then it turned out that the cable from the display fell off. They put it in place, the display worked. We turn it on, it starts working, and then cuts down phase 0. Is it connected through an automatic machine (maybe you need to use a bus)? In the block of heating elements, there is a breakdown to the case or short circuit, most likely a breakdown and you have a differential. machine. Use an indicator screwdriver to check the presence of a phase on the case. Take a Megohmmeter (or a very good multimeter), disconnect the heating elements from the board and ring. On short circuit / breakdown. Tell me, if you drain the water from the pipes, then there will be no water left in the Protherm Skat 14 kW electric boiler? Are we planning to turn off the heating for a year, store the device in a warm room or can it be stored in an unheated one? Most likely, the water will remain in the elbow that leads from the boiler tank to the pump. It can be emptied by removing it. It should drain from the rest of the place. Installed electric boiler Proterm Skat 18 kW for radiators and underfloor heating. I would like to learn from afar about the temperature of the coolant and whether the unit is working at all (are there any power outages). What do you advise? I am looking towards Micro Line GSM-Climate ZONT H-1, but suddenly there are alternatives? And is it worth installing a thermolink with, is there really any benefit from it in terms of saving electricity? The following problem was formed with the electric boiler Proterm Skat 24 kW. After 4 months of normal operation, the following malfunction appeared. I turn it on, diagnostics take place, the pump starts, the heating elements turn on gradually up to 24 kW, the temperature starts to rise, after thirty minutes the heating elements are suddenly turned off 24-22-20 ... -0, while the error number does not light up, after which the unit tries to turn on the heating elements again , but immediately disables them and so continues to try to start. If you turn it off from the mains and let it stand and cool for about 30 minutes, it can work for a while in normal mode and then turn off again. The pressure in the system is 1.5, the temperature sensor dropped from the tube no effect, the emergency thermostat reset to zero, the system is clean, water is poured. I turned to the service center - they refused under the guarantee, since there was no commissioning work, they did not even bother to look at the boiler for a factory defect, they simply unsubscribed and offered to make repairs with replacing the board with installation for half the cost. Maybe someone has encountered a similar problem or there are guesses that you can still see. Malfunctions and errors of the electric boiler Proterm Skat Stuck relay - In such cases, the HDO LED will start blinking on the control panel. The device will try to unstick the relay on its own, and in case of failure, the error message F41 will appear on the display. The appliance will start operating at minimum power. If, after switching off and on again, it starts to work in normal mode, but the HDO LED continues to flash on the display, you need to contact a specialized service organization. Check: When the command to heat heating water is canceled - at the end of the heating cycle of the heating water (opening the RT circuit) or hot water supply (the water temperature in the storage tank has reached the set value). When the "programmable temperature limiter" is activated, i. E. in case of exceeding the set temperature by 5 C. This function is activated in cases when the device is in standby mode (that is, there are no commands). The function starts when the detector is activated. If the device operates with a jumper and an external temperature sensor without heating the hot water supply, then a similar problem with the relay can be ignored until the temperature of the water in the system calculated by the equithermal regulation unit exceeds 5 C. Checking the sticking of the relay does not depend on the operating mode. It is linked to the current state of the heating function. While the latter is disconnected, and the relay status is checked. The unit is in a similar state whenever the heating elements stop working, i.e.after canceling the commands for heating the heating water and preparing the hot water supply, activating the anti-freeze protection system - heating. When the programmable temperature limiter is activated - setpoint + 5 C. In the event of a detector triggering (for example, in case of an accidental closure of a relay contact), the function is activated. In addition, the function is activated in the following cases: DHW - cases 1 and 2 may occur, ОВ - room thermostat - 1 and 2, ОВ - jumper and external temperature sensor. Decrease in water pressure in the heating system - When the heating water pressure in the system drops below 0.8 bar, the indicator bar will flash. The electric boiler will continue to operate, but at the same time it is necessary to increase the pressure of the water circulating in the heating system to 1-2 bar by means of its replenishment. After reaching the required level of water pressure in the heating system, it will automatically return to normal operation. If the malfunction cannot be eliminated, you need to contact a specialist. Error codes for Protherm boilers Slope and their meaning Error F00 - Opening of the NTC sensor circuit at the extract air outlet. The malfunction is indicated in case of open circuit of the NTC sensor installed on the OB terminal. The message will be automatically cleared after reconnecting the NTC sensor. Opening of the NTC sensor circuit occurs when the voltage rises above 4.75 V. Error F10 - Short circuit of the NTC sensor at the OB terminal. The malfunction is indicated in the event of a short circuit of the NTC sensor installed on the OB terminal. The message will be automatically cleared after reconnecting the NTC sensor. A short circuit of the NTC sensor is detected if the voltage in its circuit is below 0.45 V. Error F13 - Short circuit of the NTC sensor of the external DHW storage tank. The malfunction is indicated on the display in the event of a short circuit in the NTC sensor of the external DHW storage tank. The message will be automatically cleared after reconnecting the NTC sensor. A short circuit of the NTC sensor is detected if the voltage in its circuit is below 0.45 V. Error F19 - Short circuit of the outside temperature sensor. Fault is indicated when the outside temperature sensor is short-circuited. The message will be automatically cleared after reconnecting the NTC sensor. A short circuit of the NTC sensor is detected if the voltage in its circuit falls below 0.45 V. The error is not indicated if the equithermal regulation function (E-) is inactive. In this case, the device continues to operate in normal heating mode (without equithermal regulation). Error F20 - Unit overheating. Fault is indicated in case of activation of the emergency thermostat as a result of overheating of the device. The message will be automatically cleared after manually resetting the emergency thermostat. Error F22 - Loss of water - insufficient water pressure in the heating system. A malfunction is indicated when the water pressure in the heating system drops below 0.6 bar. The message will be automatically deleted after the heating water pressure in the system rises above 0.6 bar - as a result of adding water to the heating system. An error message will not appear if the pressure sensor is faulty. Error F41 - "Sticky" relay. This message will appear in case of a 5-fold unsuccessful attempt of the boiler to "unstuck" the relay. The message will disappear when you turn it on and off again. The presence of a problem with the "sticky" relay after the device is switched on again continues to be signaled by the blinking of the HDO LED. The message will disappear after updating the unit's factory settings stored in the EEPROM (code d96). Error F63 - EEPROM memory error. This message will appear in the event of a problem with the data stored in the EEPROM memory or an error in the EEPROM communication. The message will disappear after updating the factory settings of the boiler from the EEPROM (code d96). Error F73 - Short circuit (signal - GND) or open circuit of the pressure sensor.The message will appear in case of short circuit (signal - GND) or open circuit of the pressure sensor. The message will be automatically cleared after reconnecting the pressure sensor to the appropriate location. A short circuit or an interruption in the sensor circuit is identified if the voltage drops below 1 V. Error F74 - Short circuit (signal - +5 V) of the extract air pressure sensor. This message will appear in the event of a short circuit (signal - +5 V) or an open circuit of the extract air pressure sensor. The message will be automatically cleared after reconnecting the pressure sensor to the appropriate location. A short circuit of the sensor with a +5 V signal is detected if the voltage rises above 4 V. Error F85 - Freezing of water in the device. This message will appear if the temperature displayed by the NTC sensor at the extract air outlet falls below 3 C. The message will be automatically deleted when the water temperature displayed by the NTC sensor at the extract air inlet rises above 4C. The message will not appear if there is a failure of the NTC sensor at the output. Error F86 - Freezing water in the DHW storage tank. This message will appear when the water temperature indicated by the NTC sensor in the storage tank drops below 3 C. The message will be automatically cleared after the water temperature indicated by the NTC sensor in the storage tank rises above 4C. The message will not appear if the NTC sensor of the storage tank is faulty, or the function of heating the water in the storage tank is disabled - the value of the function is set to o.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alpha Calor, Thermotechnik. Adjustment of gas automatics Eurosit 630. Replacement of the thermocouple and maintenance of the ignition burner.

Malfunctions and repairs of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Gas heating boilers Bosch Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Options for setting functions and modes.

Repair recommendation Navien Models Deluxe Coaxial, Deluxe Plus, GA. Errors and malfunctions. Work with remote control Ksital. System control. Setting work on temperature and pressure.

Floor standing boilers Buderus Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vilant boilers Turbotec Atmotec pro / plus VU / VUW INT models. Components and work functions. Adjustment programs. Gas system. Installation and assembly. Maintenance and prevention.

Floor standing boilers Protherm Repair of the Bear models KLOM, KLZ, TLO, PLO with a capacity of 20 to 50 kW. Breakdowns and malfunctions. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and settings Models of gas floor boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automatic equipment Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted coppers of Protherm Repair of the Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repair and adjustment Repair and operation of boilers Ciao, City, Novella, Exclusive. Wall and floor models. Malfunctions and error codes. Working functions and setting of service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of an automatic pellet burner APG-25, 36, 42. Settings of operating modes.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting of service parameters. Maintenance.

Heating boilers Alfatherm Description of Beta floor-standing boilers and Sigma wall-hung gas boilers. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - malfunctions and repairs The Wolf boiler is installed. I noticed that over time, the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks but found nothing. What else to check?

Gas boilers Junkers After 7 years of operation, the gas boiler Junkers ZW-23-KE has the following problems. When DHW starts working, it either turns off or stops working ...

Repair of boilers Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, no matter what the temperature is. To make sure that this is so, he raised the temperature in ...

Price ↑

The price of electric boilers depends on the level of their power and varies in different retail outlets within the following limits:

- Skat 6 kW: 490-580 €.

- Skat 9 kW: 500-610 €.

- Skat 12 kW: 510-620 €.

- Skat 14 kW: 570-690 €.

- Skat 18 kW: 590-720 €.

- Skat 21 kW: 620-750 €.

- Skat 24 kW: 630-770 €.

- Skat 28 kW: 650-795 €.

Electric boilers are significantly cheaper, starting from 350 €. For comparison, a Kospel boiler with a capacity of 8 kW, similar in parameters and quality, costs about 550 €. But, having studied its characteristics, you can pay attention to the fact, for example, that it does not have an expansion tank. The latter will need to be purchased separately and installed, which significantly increases costs.

Brief operating instructions

Competent setting of gas boilers Protherm provides optimal temperature conditions in rooms of different purpose and area. Among other things, the regulation of the automation of such equipment contributes to an increase in the efficiency of the unit, and also makes its operation reliable and safe. Modern automation solves problems:

- opening and closing fittings in the gas supply system;

- the process of starting the unit in automatic mode;

- installed or emergency shutdown of boiler equipment;

- regulation of the flame level in the burner by means of a temperature sensor;

- displaying air temperature indicators, heating agent heating level and other parameters on the screen.

Instructions for setting up a gas boiler:

- connecting the thermostat to a temperature sensor fixed in the room and setting the required values allow you to get a comfortable temperature regime for heating;

- the installation of a thermostatic valve on the supply pipes in front of the heating radiators helps to change the cross-sectional area of the pipe and easily carry out the process of regulating the temperature of the heat carrier;

- the first start-up of the system at the limiting temperature allows the used coolant to freely enter the tank, which contributes to its maximum filling;

- the efficiency increase is facilitated by the timely removal of scale and soot, as well as control of the lack of air in the system and the installation of a draft limiter;

- regulation of pressure indicators is carried out using special valve regulators, and in order to increase the pressure, a circulation pump is installed;

- the reduction of the boiler burner power is carried out automatically through the service menu, and the power control for increase is carried out by installing additional radiators or replacing the existing ones with the most powerful models;

- many units are characterized by full performance at a pressure of 1.5 atm., and normally this value is 0.3 atm. lower than the indicators in the heating system;

- a slight decrease in the pressure level in the unit is restored during a standard restart;

- automatic selection of the operating mode of the gas boiler helps to maintain the desired temperature level even with a long absence of consumers in the room.

The process of switching on the boiler for the first time is accompanied by its short and energetic operation after the unit is fully connected to the heating system, due to which it is easy to check the correctness of the installation of the boiler equipment and the full functioning of the heating.