The boiler is an important component of the heating system, on which the efficiency of its operation depends. Today one of the most common types of heating is hot water, which explains the growing popularity of the use of hot water boilers.

On sale you can see a variety of units, the difference between which is the used coolant, design, installation technology, etc.

Purpose

The hot water boiler is used to heat small buildings, cottages and town houses. Usually, such units are used in the absence of a central heating system or in a situation where it is inexpedient to build a boiler room. In addition to heating, they are used in the hot water supply system.

A hot water boiler is a device for heating water under pressure, i.e. without the possibility of its boiling.

Features of the device and work

The core of almost any electric boiler is a heating element. It consists of internal heating elements, to which automatic units are switched. With their help, the heating agent is heated, which transports heat to the heating circuit. Electricity is supplied from single-phase and three-phase electrical networks. The efficiency of electric boilers is such that they almost completely convert electrical energy into heat: the efficiency of the devices is close to 99%.

For classic boilers, small dimensions are characteristic, which avoids cluttering up the living space. However, in this case, the problem of the lack of hot water is not solved. As you know, only city apartments in multi-storey buildings can boast of centralized hot water supply.

For residents of country cottages, there is an option with manual water heating or the use of an electric instantaneous and storage water heater. Double-circuit electric boilers for heating a house are not much more complicated than their single-circuit counterparts. At the same time, they are able to heat the water with an additional heat exchanger with heating elements.

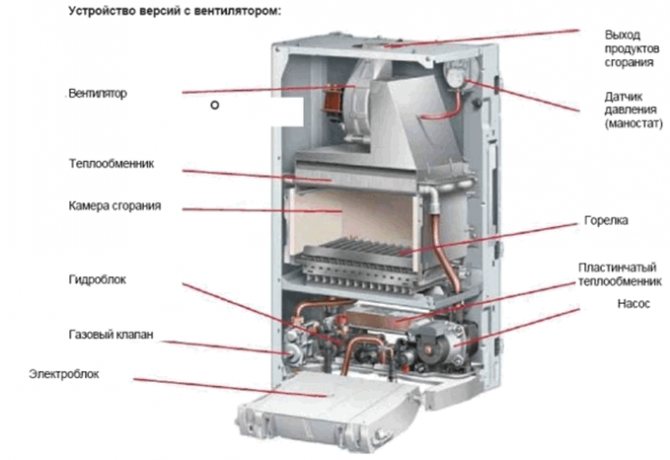

This design consists of the following elements:

- Two heating elements.

- Expansion tank.

- Safety group (sometimes replaced by a safety valve).

- Circulation pump.

The supply heating circuit of the main heating element is switched on according to the set temperature indicators. In this case, the heating element for the DHW circuit is started only after opening the tap with hot water. As for other types of internal arrangement of double-circuit heating boilers, they did not take root in the plumbing equipment market due to imperfect design and a number of weak points. In one of these options, it is assumed that water in the DHW circuit is heated from the heating circuit.

Electric double-circuit boilers for heating and water supply are divided into two groups according to the type of installation:

- Wall mounted.

- Outdoor.

Models for floor mounting differ in greater power: for this reason, they are used to heat large households. There is no need to worry about the loss of living space, because they take up little space and are compact. In a small dwelling, it is recommended to use miniature wall-mounted electric boilers for heating and hot water. Some models of this type are distinguished by good power, which is enough to heat large areas.

The novelty of the boiler equipment market is the so-called. "Energy-saving" double-circuit electric boilers for heating a private house.There are alternative elements in their design. These devices include electrode boilers of the "Scorpion" type. Thanks to the presence of automation, it becomes possible to quickly and inexpensively warm up housing. A characteristic feature of induction appliances is their safety and long service life.

Heat carrier temperature

Allocate the nominal and minimum water temperature at the inlet to the boiler. The nominal temperature is the temperature that the device must provide under normal operating conditions. It usually ranges from 60 to 110 ° C.

The minimum temperature must be observed in order to avoid low-temperature corrosion of the pipeline due to the formation of condensation in it.

The maximum temperature at the outlet of the boiler is such a level at which the heat carrier does not boil. Usually it is 110-115 ° C.

The unit with this indicator is intended for individual use. But there are also products with a higher maximum temperature value. They are used to equip thermal power plants.

Gradient. This is the temperature difference between the water entering and leaving the boiler. Usually its value is 50-55 ° С. The gradient index is influenced by the material from which the equipment is made.

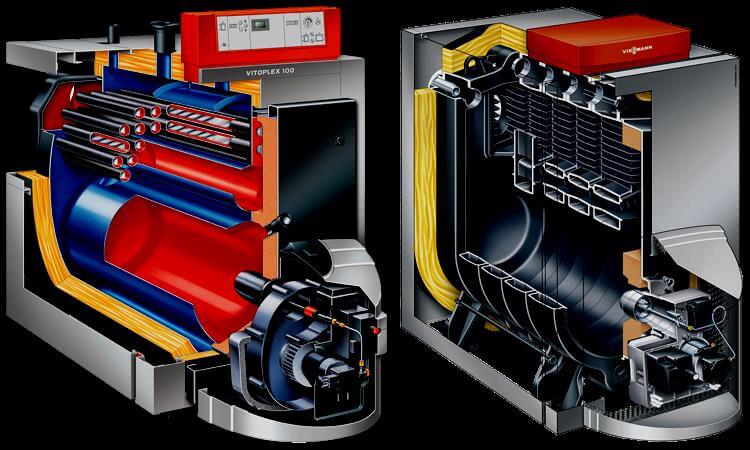

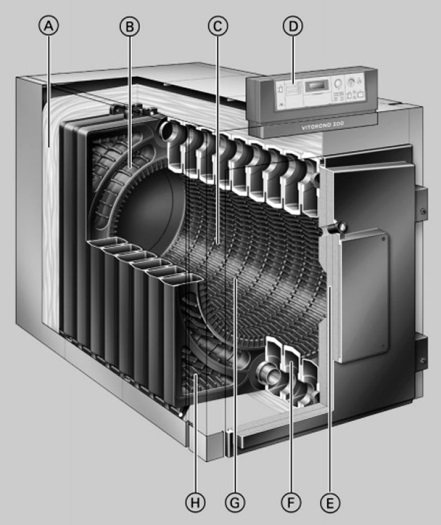

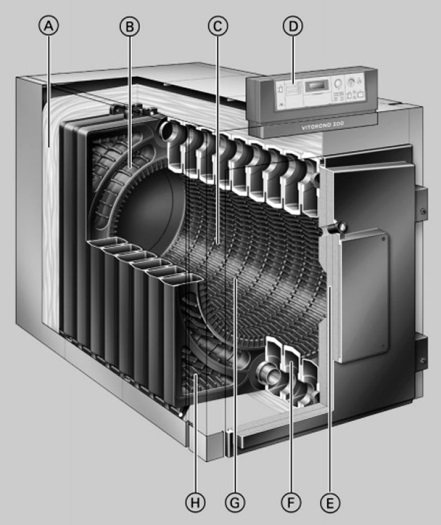

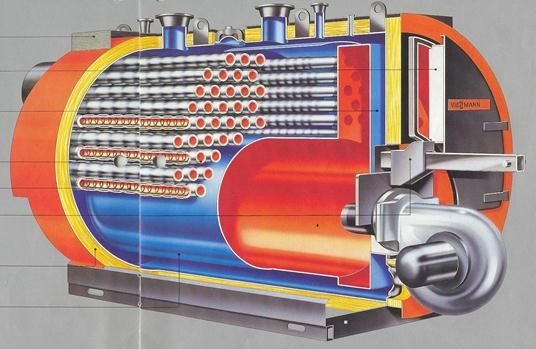

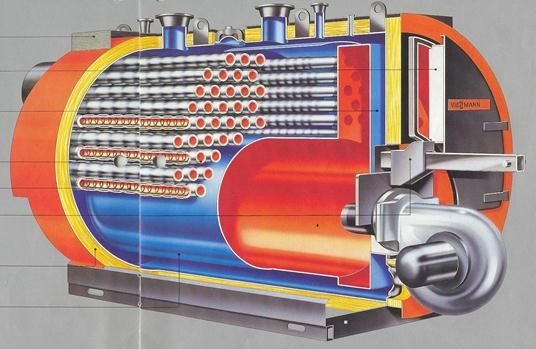

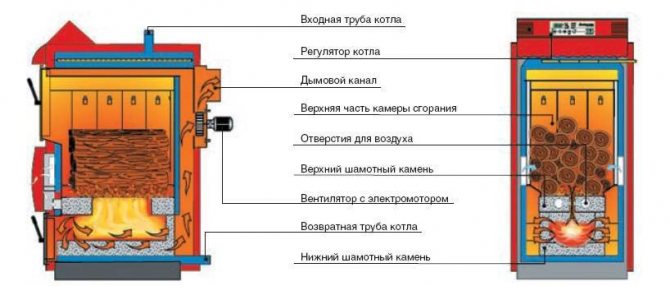

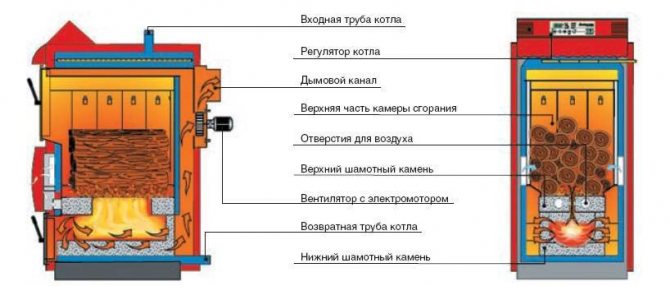

Boilers with flame tube heat exchangers

These hot water gas boilers have a design that provides for the movement of incandescent combustion products through special channels called fire or smoke-fired gas ducts. The bundles of channels are washed from all sides by a circulating coolant, which takes heat from them. At the same time, depending on the design, the flue gases make 2 or 3 passes through the pipes in the forward and backward direction. Accordingly, heaters with such heat exchangers are called two- or three-way. We will consider the device and the principle of operation using the example of a heat generator with three strokes for combustion products.

- A - outer heat-insulating layer;

- B - channels of the second course of gases;

- C - the working area of the furnace;

- D - control unit (controller);

- E - front door with thermal insulation;

- F - smoke tubes of the first stroke in section;

- G - cast iron firebox fins for improved heat exchange;

- H - heat channels of the third course.

This type of unit is combined and can use both methane and diesel fuel as fuel; for the transition, it is enough to replace the burner. When using methane, the principle of operation of a gas hot water boiler is as follows: a modulation burner placed inside the furnace produces a flame torch that heats the cast-iron fins and the entire surface of the channels of the first gas course.

Air is blown into the working area by a fan, it enters the burner structure. However, in order for the combustion products to successfully overcome the resistance of three strokes of the flame tubes, one blower is not enough. Therefore, a second fan is involved here - a smoke exhauster, located at the end of the air duct, at the beginning of the external chimney. As a result, the maximum temperature of the combustion products at the outlet of the fire-tube heat exchanger is 180 ° C, and the fuel combustion efficiency is in the range of 88–94%.

Three-pass heating systems, due to their design, have significant power in relation to the previously considered heaters. They are adopted by the owners of large cottages or industrial buildings. For the same reason, the equipment does not have a secondary circuit for hot water supply, while in previous types of hot water installations a secondary heat exchanger for hot water supply can be installed.

Every methane gas water heater is designed to meet specific operating conditions.Classic units are mainly produced in a non-volatile design and are intended for domestic purposes, that is, heating private houses or apartments. Condensing boilers are more versatile, as they cover a wide range of capacities, some of their models deliver up to 1.5 MW. Two- and three-way installations are not adapted to work with heating systems of small buildings, the value of the initial thermal power in them ranges from 80-100 kW.

Varieties

Modern hot water boilers are arranged in about the same way. They may differ by manufacturer (domestic and foreign) and power characteristics.

Speaking of structural design, all boilers are divided into:

Dignity

One of the main advantages of a gas unit is the ability to convert it to liquid fuel, which can be indispensable in case of emergency shutdown of the gas main.

Also, one cannot fail to note its safety in operation. The built-in flame sensor is responsible for this, which activates the shutdown of the energy supply in the event of a fire dying out. The hot water boiler is supplied with a thermostat, so the system is protected from an emergency in the event that the water temperature rises to a critical level.

With the help of protective electronics, the gas pressure in the network is monitored, since its low values stop the operation of the boiler. According to the same principle, the operation of the device is adjusted in the event of a power outage, when it is turned off, the gas supply valve closes.

Modern equipment is capable of responding to changes in temperature indicators of the air, therefore, heating stops when the set point is reached and resumes after the temperature drops.

Recommendations

There are the following rules for the operation of hot water boilers:

- A hot water boiler requires systematic checks and adjustments, and a specialist is obliged to do this.

- A professional should install and adjust the operation of boiler equipment.

- The boiler needs to be adjusted every three years.

Installation

Taking into account the power, dimensions and increased operating mode, industrial hot water boilers are installed only in annexes or separate buildings. As an exception - the basement of the building, subject to all the requirements for the boiler room. It is prohibited to install special heating heat generators in production premises (workshops).

Almost all industrial boilers are designed for floor installation. But in recent years, compact, high-power wall-mount models have appeared on the market. These new items are more convenient, although taking into account the weight there is a limitation - only for premises in a building made of durable materials. They are not suitable for installation in a light extension, frame and even brick structure. Only reinforced concrete walls are capable of withstanding such a load. As an option - the manufacture of a special frame metal structure for fastening the heating installation.

One of the features of the installation of industrial hot water boilers is the need for a reserve capacity. If problems arise with the water supply system, the supply of liquid to replenish the system will have to be organized from it - the production cycle cannot be stopped.

How does a hot water electric boiler work?

- Indirect heating.

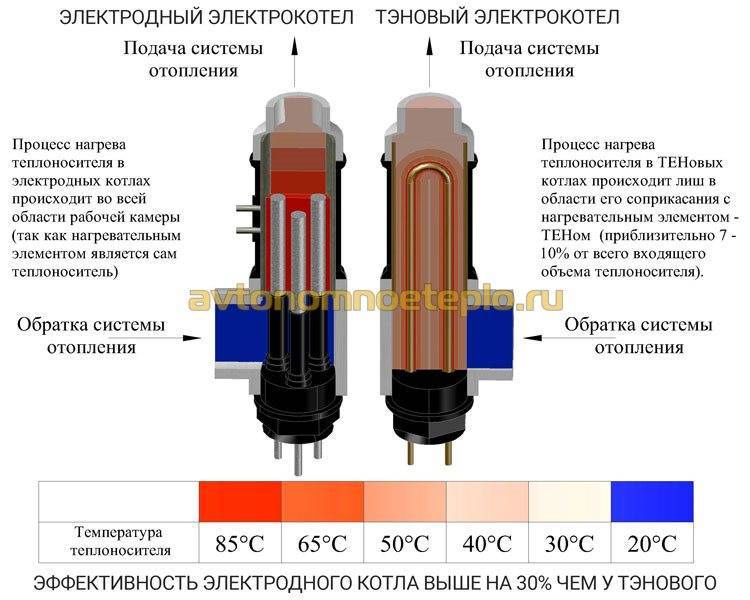

- Direct action on the coolant.

How is the heating medium provided

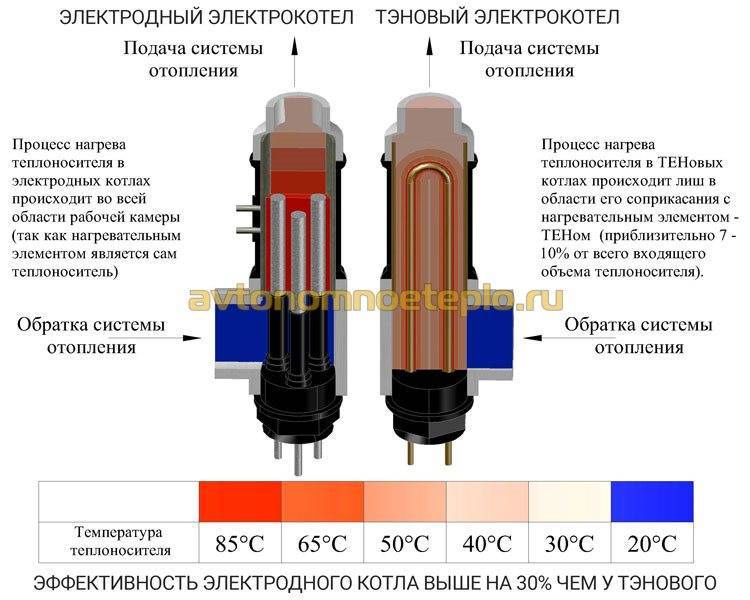

- Indirect heating - this principle of operation, heating elements and induction models are used. In the flask, there is a heater in contact with the coolant surface. Under the influence of electricity, the surface of the heating element or induction rod heats up.Heat is transferred to the heat carrier that surrounds the surface of the heater from all sides. The principle of indirect heating is ineffective. A large amount of thermal energy is spent on heating the heater and is lost during heat transfer. It takes about 10 minutes for the heater to reach operating power after switching on.

- Direct heating is the principle of operation that distinguishes electrode electric boilers. The essence of the method lies in the direct impact on the coolant with an electric current. To provide the required heating intensity, a large volume of salt is added to the heating system fluid. Although, the coolant can be made independently, into the heating system, it is recommended to fill in a special composition made at the factory. Twice a year, you will need to bleed gas from the heating system, which is a product of direct exposure to the coolant by electric current.

All boilers using the principle of indirect and direct heating belong to instantaneous water heating boilers for individual heating systems. For successful and efficient operation, constant circulation of the coolant is required.

The pressure in the boiler is created in a natural and forced way. In the heating element boiler equipment, a circulation pump is installed, which provides the necessary movement of the coolant in the heating system. Electrode boilers operate on the principle of natural circulation, but, if necessary, it is allowed to install a pump on the return pipe of the heating circuit.

Providing hot water temperature

- Heating elements boilers - some modern models of electric boilers using a tubular heater have two circuits: for heating the coolant and connecting to hot water supply. Another heater was added to the boiler design. When you open a hot water tap, a signal is given to turn on the heating element. Hot water starts flowing after a few seconds.

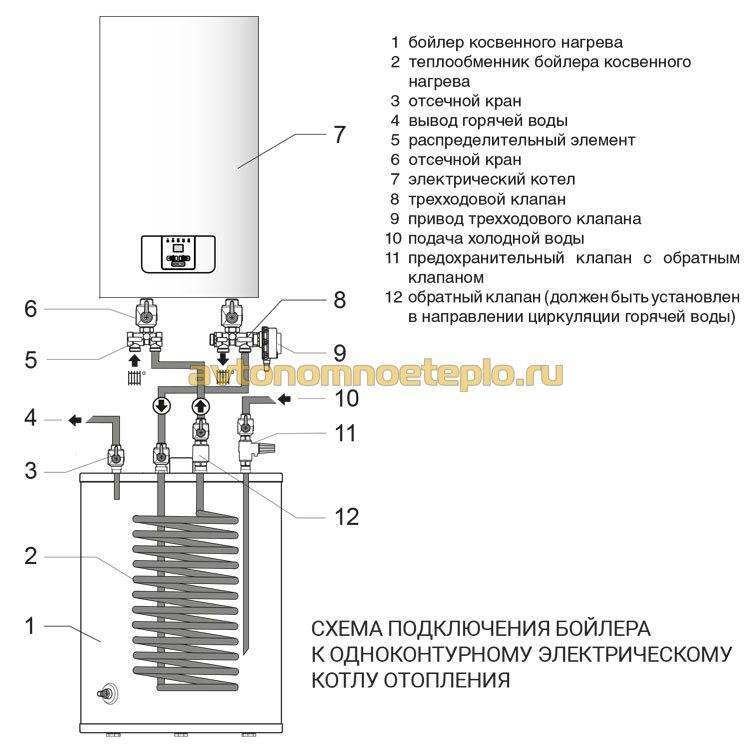

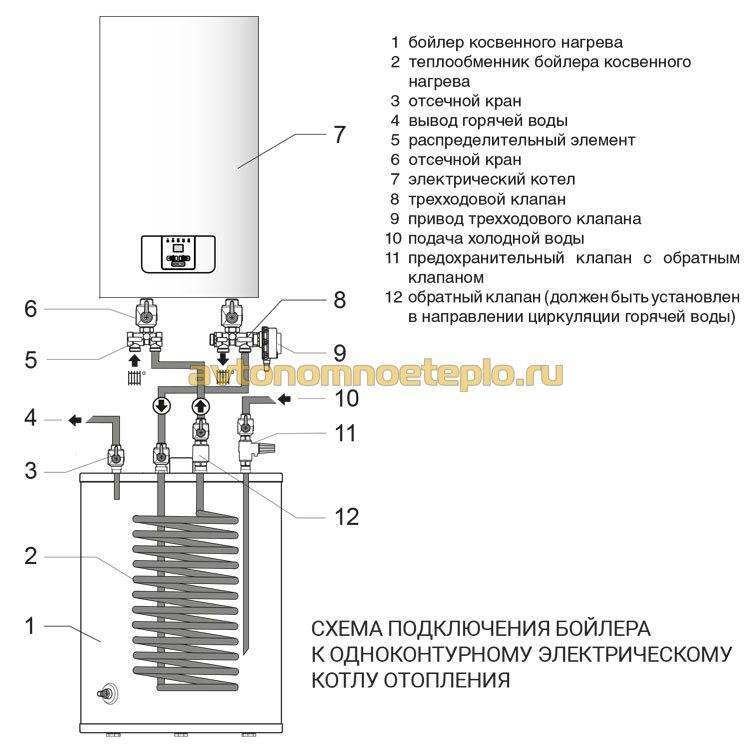

- Induction and electrode boilers - the device does not provide for the possibility of connecting DHW for domestic needs. If there is a demand for hot water, an indirect heating boiler is installed, connecting it to the heating system.

In terms of their energy efficiency, double-circuit heating elements are significantly inferior to schemes using an indirect heating boiler.

Features of the organization of heating

An electric boiler is a convenient option for providing home heating. If the house is not used for permanent residence, then it makes sense to use non-freezing liquid instead of water as a heat carrier. This precaution will prevent the pipes from collapsing in the event of an emergency shutdown of the heating system due to power outages.

Due to the thermal insulation of the housing, the circulating coolant will not cool immediately, so short-term power outages will not affect the operation of the system. But it is impossible to keep the coolant hot for a long time with the power off.

Advice! Antifreeze, 50% ethanol solution or 70% glycerin solution can be used as a heat carrier. These liquids will not freeze even if the temperature drops to 30-40 degrees below zero.

When installing electrical equipment for heating, it is necessary to make a separate connection with autonomous fuses. And when installing a boiler, it is not necessary to do this, this equipment is connected to a common line, since its power is low.

So, boilers running on electricity are the best option for an area in which there is no gas supply. Such equipment can be used for both heating and hot water supply. The heating equipment is distinguished by ease of use, environmental safety and a fairly high efficiency of work.

Selecting the type of instantaneous water heater

When choosing an instantaneous water heater for a bathroom, kitchen or a country house, 4 main factors are taken into account: the type of control, the presence of additional functions, performance and power.

In budget models, there are only basic options. In advanced, you can find the following functions:

- Thermal limiter. A sensor that prevents heat build-up can extend the life of the appliance and protect the user from burns.

- Child lock. The function will prevent the child from using the device, but it can be replaced by a temperature limitation.

- High precision temperature sensor. A useful function that allows you to set the heating to an exact level. Its presence is especially important when the water pressure is unstable.

- Economy mode. With prolonged use, the heater will automatically reduce the water temperature.

- Remote Control. Allows you to switch modes at a distance.

It is highly recommended to consider the electrical safety level. Some models can even fail due to steam.

An important criterion is the type of management. The difference is not only in price: hydraulic devices have several limitations.

- Mechanically controlled devices always start at maximum power, even if the user has set the mode in advance. This can cause burns.

- Another disadvantage is the fixed temperature delta. Most often it is 25 ° C. If ice water is supplied in winter (+ 5 ° C), then at the outlet you will receive cool (+ 30 ° C). This is enough for washing hands, but not for showering.

The cost of devices with electronic control is due to the presence of additional sensors, a microchip and heating elements with multi-stage power control.

They not only add many options, but also provide flexible functionality.

When choosing a pressure device, esthetes should pay attention to the appearance of the body.

Selection by water consumption, performance

When calculating performance, you should consider your own goals and needs.

If the heater will stand in the kitchen and provide you with water for washing dishes, 2-4 l / min will be enough.

For a bath, you will need a more powerful device - 8-10 l / min.

A water heater for a shower stall must have a capacity of 4-8 l / min.

If the device will serve several rooms at the same time, you should select the flow rate for the highest water consumption point and multiply it by 1.5.

By power

The head (indirectly) and heating depend on the power of the device. It is more difficult to calculate the parameter, since the temperature of the supplied water can vary.

In addition, + 40 ° C is considered a comfortable level for a shower, and + 55 ° C for a kitchen sink. This is important for disinfection and grease removal.

With a power of 3.5 kW, it will be possible to take a shower in the summer, but the jet will be thin.

In winter, such a heater for running water will not cope with the task, since the temperature of the supplied liquid at the inlet will be much lower. The difference reaches 20 ° C.

5-7 kW is still not enough for comfort, but a water heater will be able to back up in most emergencies.

In cold areas, the device will not cope with the heating in winter.

Electric water heaters with a capacity of more than 12 kW are suitable for solving any problems.

However, if it is necessary to service several points at the same time, it is better to give preference to more efficient models - from 20 kW.

Typical mistakes when choosing

- Purchase of an instantaneous water heater without temperature control and sensors. In case of drops, a budget device can burn the user.

- Purchase of a device without prior consultation with an electrician. For installation, you need to select a separate line. The main factor to consider is the power allocated to the home.In old buildings with 16 A plugs, it is impossible to install devices with a power exceeding 3.5 kW. In new buildings with traffic jams of 32-40 A, another limitation is 6 kW.

- Lack of accounting for working pressure. If the pressure is weak, the sensors of some models will not respond to the water supply. Most instruments operate at 0.5 bar, but this detail needs to be clarified.

Separation according to the principle of operation

Its functionality depends on the type of device. For example, a portable water heater with a shower head can be taken with you on the road, but such devices are low power and are not able to provide a comfortable pressure.

Gravity flow water heaters

Non-pressure devices are equipped with a separate shower head and are connected to only one point.

This option can be convenient for a summer residence or in the event of an accident.

Non-pressure electric direct-flow water heaters work only with those nozzles that are present in the complete set.

This is important to consider, since after installation you will have 2 watering cans: from the mixer and from the device.

Electric pressure water heater

Pressure devices are more convenient and versatile.

Instantaneous water heaters for a shower can be connected both to one point and to a riser.

This allows hot water to be used throughout the house.

The cost of such devices is higher, so it is advisable to purchase them for frequent or regular use.

For maximum comfort, you should choose an electronically controlled instantaneous water heater.

Hydraulic models are less versatile, therefore not suitable for everyone.

It is advisable to install a separate filter in advance, since the built-in ones do not fully cope with the task.

The cost of pressure devices is quite high (from 10,000), so it is recommended to worry about their durability in advance.

Strengths and weaknesses of electric double-circuit boilers

Electric double-circuit boilers for the home are characterized by significant convenience and practicality. Thanks to this, the owners of country houses get rid of the need to organize hot water supply.

The advantages of the devices are as follows:

- Compactness... In terms of dimensions, electric double-circuit boilers are noticeably inferior to gas heaters.

- No noise... The operation of the devices is not accompanied by hum and noise, which allows them to be mounted in any room.

- Environmental friendliness... During operation, there is no release of harmful substances and carbon dioxide.

- Installation speed... During installation, you have to mess with pipes and other components less.

- Fire safety... There is no danger of gas leakage, fire and explosion.

- Ease of service... All that is required is to brush off the ardor from time to time.

- Can be installed anywhere... In this case, a special boiler room is not needed: the device can be installed in the kitchen, in the closet or in the basement.

- High efficiency (almost 99%).

- The ability to use networks with a voltage of 220 V and 380 V... The output of the boiler used is of decisive importance.

The disadvantages of double-circuit electric boilers for heating a house are usually:

- To connect a powerful device, you will need to lay an autonomous line. First of all, this concerns boilers with a capacity of more than 3 kW. The place for powering such a line is a common electrical panel.

- Expensive compared to gas or solid fuel units.

- High consumption of electrical energy while simultaneously turning on the spirit of the circuits. It is for this reason that an autonomous power line is needed.

- The high cost of consumed electricity. As you know, electricity cannot be called cheap.

The listed disadvantages are not critical, especially in situations where double-circuit electric boilers for heating are the only option for heating residential premises and organizing hot water supply.This primarily concerns the regions where there is no gasification and a stable supply of solid fuel.

Solid fuel boilers

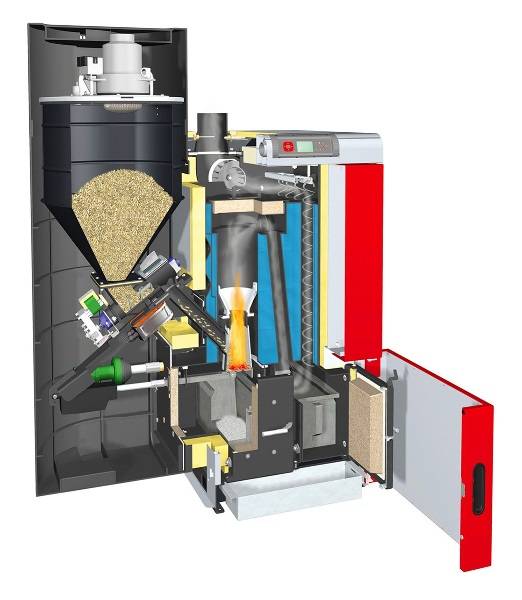

This is a type of boiler that is popular with home owners. It is used for heating in rural areas or in places where firewood, pellets or coal are inexpensive and readily available.

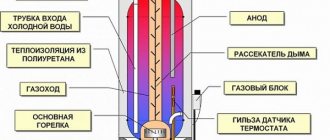

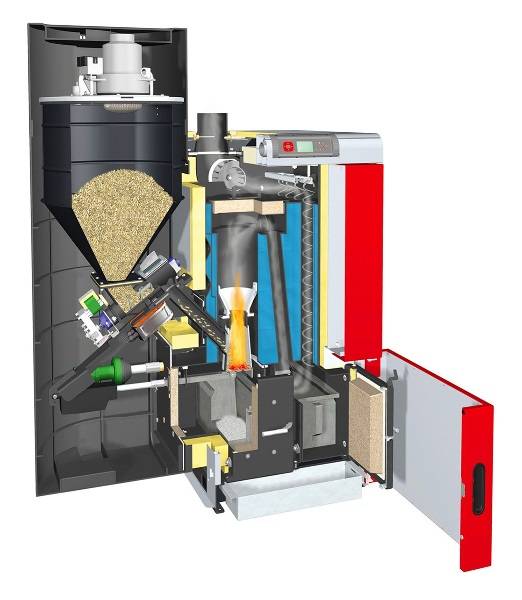

Pellet water heater device

- Fuel type. Wood is used as fuel - wood or pellets, as well as coal. There are mixed boilers with several furnaces.

- Fuel combustion method. Available in classic, long burning and pyrolysis.

Pellet versions are popular, providing a high level of automation with long-term programming of operating modes. These are the most advanced fuel type water heaters in the solid fuel family.

In a classic solid fuel boiler, heat appears due to the banal burning of wood, like in a stove. Hence all the disadvantages of such units - they will have to be cleaned, to monitor the removal of smoke, to constantly throw up firewood and to regulate the force of combustion and traction with a damper, etc. We are not talking about any autonomy in principle. The efficiency does not exceed 75%. The advantage lies in reliability, simplicity of design and piping scheme, independence from electricity and low cost.

Long-burning or top-burning water heaters use a different method of loading fuel - from above. Due to this, complete burnout occurs and efficiency increases.

Pyrolysis boiler device