Refusal to use centralized heating and water supply lines, the creation of autonomous heating and hot water supply systems at home is becoming commonplace.

This is convenient for the owners of private houses or apartments, allows you to independently make decisions about the beginning and end of the heating season or heating modes of housing.

Trading networks offer a wide range of gas boilers, on the basis of which the most efficient and economical heating systems are created.

European companies are considered to be confident leaders in the production of heating equipment, but their colleagues from Southeast Asia have achieved considerable success.

Consider the prominent representatives of heating technology from South Korea - gas boilers Arderia (Arderia).

Main types

Arderia brand is owned by South Korean company Daesung... The products of this company are widely known in the world and are in high demand. The main feature of the company is its approach to the production of heating equipment.

Most of the work operations are performed by automated lines, which eliminates miscalculations or negligence. The Arderia brand was created to place gas boilers on the Russian market, which were produced in the following types:

By type of installation:

- wall... Designed for surface mounting indoors (usually in kitchens).

Floor models are not produced, since they require a separate room and are in less demand.

By feature set:

- single-circuit... Designed only for supplying the heating system with hot coolant at a given temperature;

- double-circuit... The units are prepared for simultaneous heating of the heating medium and the supply of hot water;

According to the type of heat exchanger, the following varieties are produced:

- with separate heat exchanger... These are boilers in which the primary unit consists of pure copper (99%), which demonstrates high resistance to temperature changes and the absence of corrosive processes. The secondary heat exchanger is made of stainless steel, has a high heat dissipation capacity and demonstrates noticeable performance;

- with bithermal (combined) heat exchanger... This is a tube-in-tube design. The coolant and water for the DHW line simultaneously pass through it, without mixing with each other. This design allows you to significantly increase and stabilize the hot water supply at home, but requires taking all possible measures to protect against the appearance of scale. The complex cross-section of the heat exchanger tube is very difficult to flush, and replacing a defective unit is too expensive and not always done.

NOTE!

The design of the boilers meets modern requirements for the functionality and efficiency of heating technology. The units have all the necessary certificates and can be used in residential and public premises.

Series and models

Arderia gas boilers are produced in the following series:

Series "B"

Units of the "B" series are manufactured in Russia, at Daesung's own production facilities... The model range consists of two-circuit units with a bithermal heat exchanger made of copper.

The power of the models ranges from 10 to 24 kW, which is suitable for heating rooms from 53 to 250 sq.m.

Basic parameters of models:

- modulating burner;

- ability to work with low gas inlet pressure (up to 4 bar);

- silent circulation pump with a "wet" rotor;

- there is a self-diagnosis and flame control system;

- frost protection;

- the units have been adapted to Russian climatic and technological conditions.

Gas boilers "B" series are reliable and economical... Each unit undergoes a separate inspection by the Quality Control Department. There is a multi-stage protection against operational overloads or freezing.

Series "D"

A series of gas double-circuit boilers with a capacity of 10-24 kW, capable of heating rooms from 53 to 250 sq.m. Equipped with two heat exchangers.

Primary (main) copper, secondary (for hot water supply) - stainless steel. In the manufacture of the used parts and materials from the best manufacturers in Europe, as well as the company's own developments.

Specific features of the units:

- the possibility of reconfiguring to liquefied gas;

- the gas valve is adjusted via the control panel;

- two options for installing the chimney - separate or coaxial;

- the ability to remotely control through the application on a smartphone;

- there are contacts for connecting a room sensor.

The design of boilers of this series is practically no different from the device of the best European models.... At the same time, the prices of Arderia boilers are at least two times lower than those of counterparts from European countries.

This increases the demand for Korean units, increases their importance in the eyes of buyers.

ESR 13-20 kW

The power of boilers of this series is in the range of 16-18.6 kW... It includes two models - ESR 2.13 and ESR 2.20. In terms of the set of functions, they are two-circuit units with a closed-type combustion chamber. Designed for space heating from 65 to 200 sq.m.

Manufactured in South Korea, at their own production facilities.

Possibilities of boilers series ESR 13-20 kW:

- there is a possibility of connection to gas lines with low pressure (up to 5 mbar);

- adjustable turbocharging;

- a circulation pump with a "dry rotor" was used, which allows maintenance without draining the coolant from the system;

- a control panel operating at a distance of up to 40 m is used;

- there is a self-diagnosis system;

- built-in voltage regulator, correcting drops from 156 to 280 V.

Units of the ESR 13-20 kW series are adapted for operation in the conditions of Russia... They are equipped with frost protection

ESR 25-35 kW

The range includes ESR 2.25, ESR 2.30 and ESR 2.35 units. Power range - from 12.2 to 40.7 kW... They are capable of heating areas from 122 to 407 sq.m.

Equipped with copper primary and stainless steel secondary heat exchangers, closed combustion chamber, modulating burner.

main parameters:

- electronic flame ignition system;

- the possibility of readjustment of gas equipment for the consumption of liquefied gas;

- automatic maintenance of the heating medium and hot water supply;

- the presence of an ionization sensor that monitors the presence of a flame;

- adaptation of the boiler to Russian conditions.

The units demonstrate reliability, stable operation, are easy to operate and regulate.... Combined with low prices, these qualities make them competitive in the heating equipment market.

Arderia equipment features

Security and full automation are the main areas of focus for all developers' efforts. That is why several additional protective devices are provided in the design. In general terms, the Arderia boiler has the following design advantages:

- Arderia double-circuit boilers are equipped with two independent heat exchangers. A copper heat exchanger is used for the heating circuit. A stainless steel heat exchanger is installed for the DHW system.

- The installation of a forced draft burner allows the automation to independently control the power of the released thermal energy. This also involves a catch-up fan, which provides the required amount of air for stable combustion.

- Simple and intuitive control of the automation: you can adjust and set the required temperature values for heating and hot water with just a few clicks.

- Connecting a room thermostat allows you to remotely control the boiler operation modes.

- The modern wall-mounted boiler Arderia has an electronic display on which the current values and error codes are displayed in case of a malfunction.

Adaptive design features

In addition, gas boilers of the arderia trademark are fully adapted to the working conditions in Russian systems. To do this, the design of the device provides for the following additional elements:

- The main breakdown of volatile double-circuit boilers is voltage drops, which quite often happens in our country. The manufacturer took this into account and the arderia boiler has a built-in voltage stabilizer. Confident operation of such a stabilizer is maintained at values from 150 to 285 volts.

- Also, the design provides a special gas valve and a reducer, which are able to ensure the operation of the burner when the gas pressure drops to 4 bar.

Such design features were duly appreciated by domestic consumers, which is confirmed by positive reviews on the forums and the official website of the manufacturer.

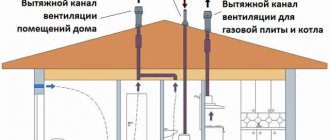

Advice! A transition to liquefied bottled gas is also provided. Safe stable operation on this type of fuel is ensured by a closed combustion chamber and a fan for forced exhaust of combustion products.

Performance characteristics

Let's look at the main technical characteristics indicated by the user manual:

- A closed combustion chamber, in addition to its efficiency, increases the safety of gas equipment, since it is impossible to leak out of combustion products from it.

- The coaxial chimney with a forced fan ensures a stable and reliable exhaust gas evacuation in all weather conditions.

- Overvoltage protection and anti-freeze system.

- A powerful, but at the same time compact circulation pump provides pumping of the coolant through the heating system of any complexity and configuration.

- Electronic system for automatic ignition of the burner. In addition, the electronics provide smooth start-up and flame control.

- The control module has an electronic display, thanks to which the arderia boiler can be easily adjusted to the required comfort indicators.

Advice! To deal with all the nuances of setting up the boiler, detailed instructions will help, which has a Russified section with a high-quality translation.

Specifications

Consider the parameters of gas boilers Arderia:

| Specifications | The values | |||

| Arderia D10 | ESR 2.20 | ARDERIA ESR 2.35 | ||

| Boiler type | Gas heating | |||

| Fuel type | Natural or LPG | Natural or LPG | ||

| Mounting method | Wall | |||

| Thermal power | 10.9 kW | 8.6-23.3 kW | 12.2-40.7 kW | |

| Gas consumption (max) | 1.2 m3 / h | 2.73 m3 / h | 4.49 m3 / h | |

| Power supply | 220V 50Hz | |||

| Dimensions (edit) | 410x652x243 mm | 420x660x200 mm | 460x700x205 mm | |

| The weight | 26.2 kg | 24 Kg | 26 Kg | |

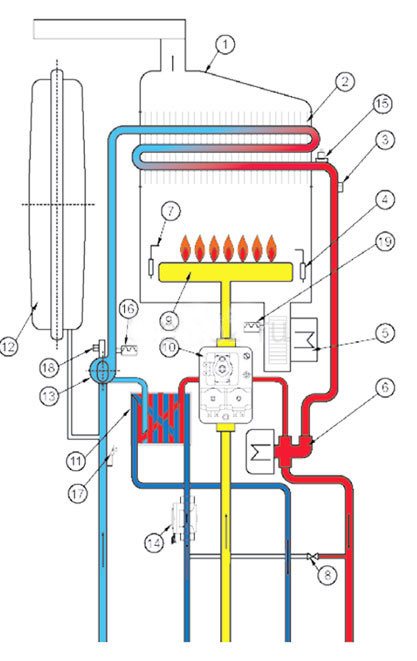

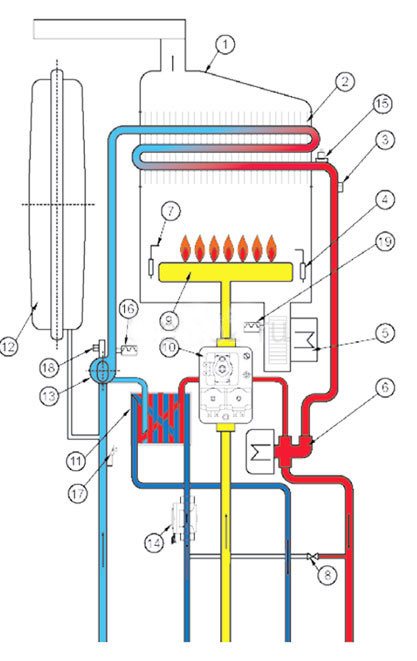

Arderia gas boiler diagram

The device of the Arderiya gas boiler is completely standard, so any user can easily figure out what's what.

The scheme includes:

- Exhaust gas collector.

- Primary heat exchanger.

- Temperature sensor.

- Ionization sensor.

- Ventilating device.

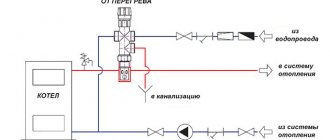

- The crane is 3-way.

- Ignition electrode.

- Feeding device.

- Burner.

- Gas valve.

- Plate heat exchanger.

- Expansion tank.

- Circulation pump.

- Hot water flow sensor.

- Overheat thermostat.

- Liquid pressure sensor.

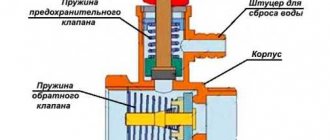

- Pressure relief valve.

- Air vent valve.

- Air pressure sensor.

Arderia gas boiler diagram

Advantages and disadvantages

Dignity:

- efficiency, a good set of performance characteristics;

- the ability to heat the coolant and supply hot water for domestic needs;

- convenient control, there is a remote control and the ability to remotely influence through the Wi-Fi module;

- the presence of a built-in voltage regulator capable of correcting a drop of up to 150 V;

- boilers are designed for operation in difficult Russian conditions;

- a self-diagnosis system continuously monitors emerging problems and notifies the owner about them;

- there is a multi-stage protection against all overloads, freezing of the coolant, voltage drop, etc .;

- the price of the units is much lower than that of the European counterparts of the same quality.

disadvantages:

- the need to connect the power supply. In case of a sudden shutdown in winter frosts, there is a risk of being left without heating;

- the company was founded relatively recently and has not yet managed to create an extensive network of service centers;

- the power of the units is limited and does not allow them to be used in large rooms.

Judging by the demand and high demand, the shortcomings are not critical and are quite surmountable.

CAUTION!

Some users report a high noise level or some time lag when supplying DHW. However, such features are typical for all models of gas boilers from European and Russian manufacturers.

Operation and setup instructions

The initial (basic) setting of gas boilers is carried out at the factory. During installation and the first start-up, it is necessary to correct the factory settings to match the existing operating conditions with the needs of the mechanics and electronics of the boiler. These actions must be carried out by employees of service centers or warranty workshops.

Independent intervention in the design of gas appliances is prohibited.... Operating settings such as temperature control or heating shutdown for the summer are permissible and made by the user.

The operation of the units is not difficult... It is necessary to pay attention to the display readings, if necessary (when an error code appears), call the wizard. To clean the case from dust and dirt, to carry out technical inspection and other procedures in a timely manner. Before starting work, you should carefully study the instructions and follow its instructions.

Error codes

Modern automation and electronics have a self-diagnosis function that displays information about the malfunction in the form of an error code. Let's take a look at these codes and what they mean:

- AA - overheating (boiling) of the boiler.

- AE - chimney blocking.

- A1 - the air pressure sensor is faulty.

- A3 - malfunction of the circulation pump.

- A5 - insufficient pressure in the heating system.

- A6 - ignition error.

- A7 - malfunctions were detected in the gas valve.

- A8 - residual flame on the burner after closing the gas valve.

Advice! If the heating device issues such errors, you should contact the service center for a technical inspection of the equipment. It is not recommended to repair the arderia boiler on your own, as this can lead to the final failure of the equipment of their operation.

In conclusion, it is worth adding that arderia boilers, in addition to high reliability, practicality and durability, have a very attractive price for most consumers. On the forums and the manufacturer's website, grateful users leave positive feedback on the products of the Arderia company.

Major malfunctions

The main malfunctions of Arderia boilers should be considered:

- in case of icing of the outlet, it is possible to disconnect the pressure sensor and blow out the chimney;

- a stop or a drop in fan speed means that foreign objects, particles have entered the working space of the impeller;

- the overheating sensor is triggered when the circulation stops (pump breakdown) or the supply valves are closed;

- the boiler does not ignite. This indicates a failure of the gas equipment (valve) or disconnection of the mains power supply.

All emerging problems are immediately detected by the self-diagnosis system... It issues a special code on the remote control, which indicates a standard situation with a malfunction of one or another sensor, unit, or part.For a complete list of codes, refer to the user manual, which should be kept handy.

Among them, the following designations are most common:

| The code | Decoding | Causes of occurrence |

| A1 | Air pressure sensor malfunction | Short circuit, outlet icing |

| A2 | The rotation speed of the fan axis has dropped | Interference, foreign objects, or debris on the impeller |

| A3 | The pressure sensor worked before the pump was started | Sensor clogged with dirt, needs cleaning |

| A4 | Heating agent overheating sensor | Stopping circulation due to a breakdown of the pump or three-way valve |

| A5 | The coolant pressure has dropped | There is little water, the system is airy, there are leaks |

| A6 | No ignition or blocked chimney | The gas pressure has dropped, the chimney is clogged with soot or ice |

| A7 | Gas valve short circuit | The control unit is out of order |

| A8 | There is a flame on the burner, although there is no gas supply | Problems with the gas valve, control unit. Check grounding. |

| A9 | The coolant is frozen | Lowering the temperature to -5 ° |

| AA | The coolant has boiled | Circulation stopped, valves closed, 3-way valve or pump problem |

| AND YOU | Failure of the thermostat | Breakage, poor contact |

| AE | Chimney blocking | Icing, deformation, ingress of foreign objects |

Repair of a gas boiler Arderia ESR 2.16: elimination of a three-way valve leak

Boiler Arderia ESR 2.16 pleased us with his trouble-free work for 3 years. And the other day, the household noticed a water leak from the unit. And it dripped normally, I even had to substitute the bucket.

I immediately remembered 2 observations that spoke of an imminent disaster:

- the pressure in the system slowly dropped, it was necessary to top up once a week, two times;

- the hot water tasted of rust.

Before calling the gas workers, I decided to try to figure out the topic myself. If the problem is not big - why bother busy people. Yes, and these busy people take for their services, traditionally, not weakly.

Removing the valve

Disconnect the boiler from the 220 socket. Remove the front cover. There are no seals, no secrets, everything is in sight, 2 bolts.

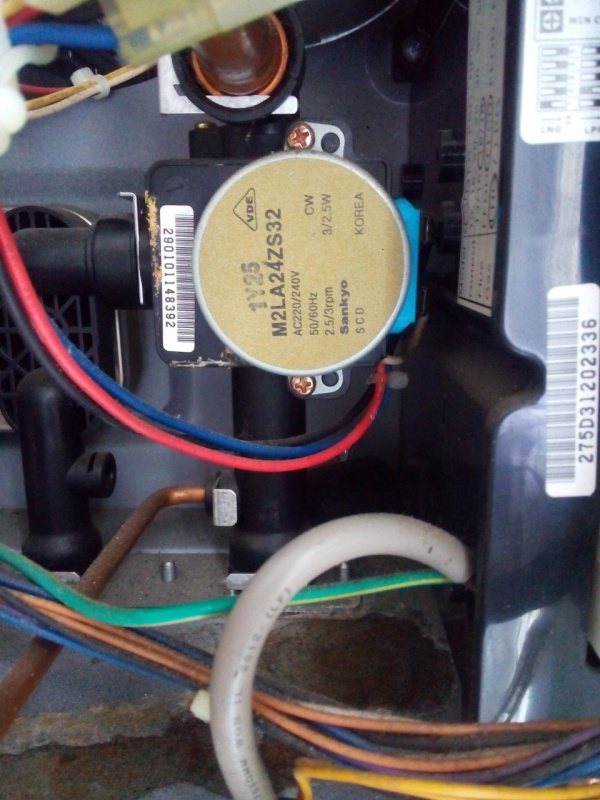

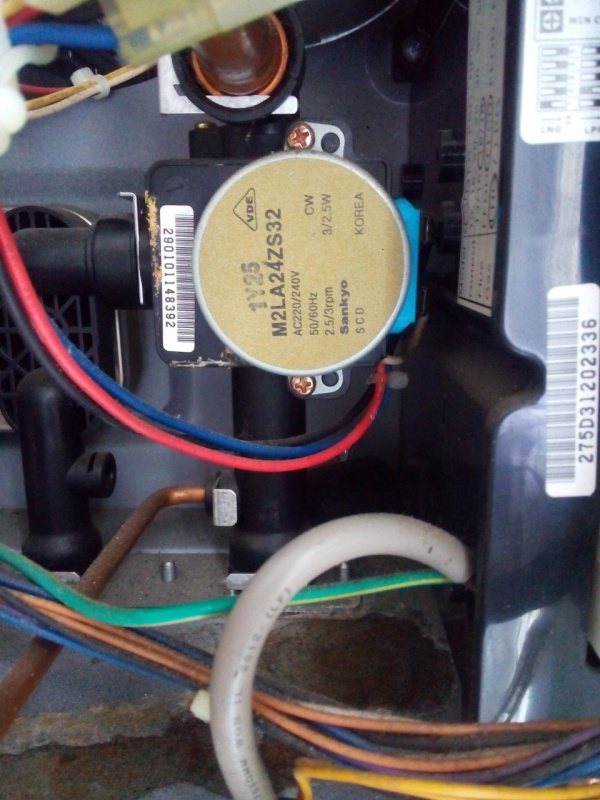

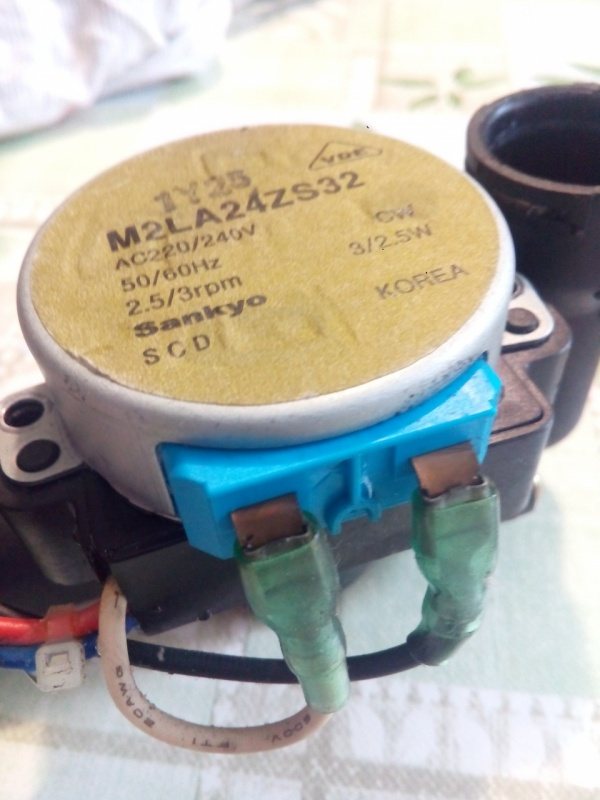

Immediately I saw from where the trickle runs along the boiler body. We read the marking on the mechanism - m2la24zs32.

In the global network we find the name - Arderia three-way valve (2040105).

There is a part on sale, it costs from 3300 to 4400 rubles. in different parts of the country. But there is interest in trying to fix it, if possible. A video with detailed instructions came across on YouTube. 10 minutes, and I'm a master, you can start.

Online help:

The three-way valve in boilers is designed to correctly redirect the heating medium (water). It is a branched adapter with a temperature sensor and an electric drive. It allows double-circuit boilers to quickly warm up liquid for heating systems and hot water supply. The valve is switched according to two main modes: heating the coolant, heating the service water. The principle of operation is as follows: in the first mode, the three-way valve blocks the access of the heat carrier to the second heat exchanger (for heating domestic water), in the second mode, the valve opens the access of hot water from the heating system to the second heat exchanger (the circulation of the heat carrier allows heating water to be supplied to the tap).

First of all, we disconnect from the heating and water supply network (we shut off all 4 taps from the bottom). We drain the water into the bucket through a special tube on the left, and a special tap-valve.

Then we remove the locking valves from all the tubular connections of the problem unit. As well as wires. We are trying to pull out the valve. Caution! water will pour out of the freed pipes again - we catch it with a bucket and rags.

My valve did not want to go out on its own, I had to remove the heated water supply unit on the left with it. Fortunately, he is attached with only one bolt to the heat exchanger.

Wiggle, shake, pull out. I do not recommend using a lot of force.

Repairs

We take the ill-fated three-way valve and settle down at the table, even a kitchen one, like me. It is extremely inconvenient to repair it on the weight and on the knee.

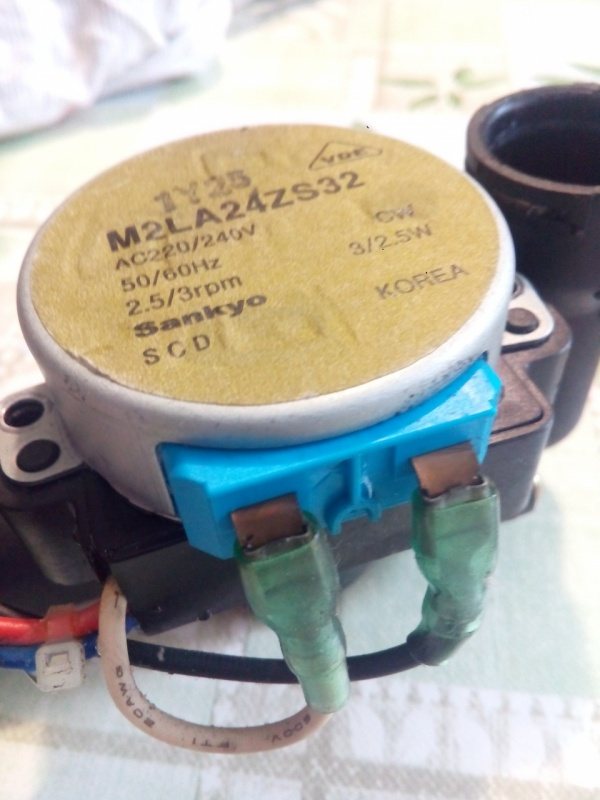

We unscrew the screws, remove the engine, it is unnecessary to disconnect the wires from the terminals:

Remove the plastic wheel from this side of the 3-way valve. He is not allowed contacts. We take out one, with a red wire, the second (double) - we do not completely take out:

We take out the wheel. We remove the cotter pin and the washer along them. Now you can unscrew the 4 screws on the other side of the valve:

And pull out this engineering marvel:

The rubber ball rotates with a motor and switches the flow of water in the pipes - heating or hot water supply. Essentially, it plugs up the holes.

The photo shows the wear of the ball (the surface has become rough), and the silicone rings:

I didn't rush to the store to look for O-rings, took off the dimensions, I'll look on occasion.

Online help:

The main and practically the only reason for the breakdown of a three-way valve is its strong contamination. Constant switching of water flows can lead to deposits of formations on the inner walls of the distributor. The action of a low-quality liquid with numerous additives can even affect a new element of the heating and heating system. Another factor (to which single valves are being modified) is simple wear due to long-term operation.

For the repair, I used FUM tape, cut into thin strips and wound on the seats of the oil seal rings. Naturally, it is not easy to wind such a trifle neatly, but it is possible.

Result. Hopefully not a lot and not a little rewound ribbons.

That's the whole repair. You can collect everything back. It is more convenient to install everything in the boiler also in tandem with plastic pipes from the hot water supply:

For ease of assembly, photographing of the process helps. Sometimes I had to flip through photos on my phone and check myself.

I poured water into the boiler, there is no leak. Started up the heating - bingo! Works and does not drip.

findings

On the Internet, they write that the reason for the failure of this node is dirty water. I cannot agree with this, I think the reason is the lack of design. The rubber ball should press quite hard against the holes, the axis with silicone (or rubber) rings is under heavy stress. Those. the work on the rings is not only to retain water, but also to play the role of a bearing.

I'll see how long my repair will last. I will look for rings for repair. And hopefully the valve is always on sale.

Price range

The cost of Arderia gas boilers is much lower than that of similar European-made devices.

For a Russian buyer, they cost 23-36 thousand rubles.... The price of the unit depends on its power and additional functions. Please note that the chimney and remote control devices, room thermostat, etc. sold separately.

IMPORTANT!

You should not skimp on warranty service. The danger of being left without heating in winter is much more serious than the cost of concluding a warranty agreement.

Arderia gas boilers appeared on the Russian market relatively recently. Most users do not yet know about them, although a considerable number of units are already in operation.

They demonstrate stable performance, efficiency, and resistance to external loads.... Self-diagnosis does not allow the boilers to fail, the built-in voltage stabilizer corrects the drops in the network. The quality and low cost of Arderia boilers allow them to take their rightful place among the alternatives.