if you screw drywall, and paste over with ceramic tiles on top? Is this insulation suitable?

There is one more old "GREAT" way.

Flat slate sheet…. As a technologist .. I can say the following. Asbestos is DANGEROUS only in its free state, namely in fibers (raw materials). The "asbestos" canvas in its pure form does not exist. This is a "canvas" departure from the production of slate (installed on a sheet-forming machine). After some "run" - it is changed, and after being taken to a landfill .. it is taken away by enthusiasts for their needs ... In this form, it is also not harmless, asbestos particles in it are with an incredible density per 1 sq. M. When heated, asbestos is dangerous! But the finished product - slate (wavy or flat) is not subject to the release of asbestos, because in slate, it is bonded with cement. And it is completely admitted to installation as a non-combustible material.

BUT! Yet even slate is not entirely shown for installation in residential premises. It is good either as a roofing material or as a fence….

And what prevents you from attaching a 3mm metal sheet to the wall, and already on it place your boiler as you like!

Gas heating remains the best option for organizing heat supply for apartments and houses. To install the equipment, you need to know the current standards, issue a permit in the appropriate service. Of particular difficulty is the installation of a wall-mounted gas boiler in a wooden house with your own hands. The requirements for such buildings are much stricter than for reinforced concrete or brick structures.

Requirements for the premises

The first task is to select the installation site. Basic norms are set out in SNiP on February 31, 2001. Installation in living quarters, bathroom or toilet is prohibited. Installation in a basement room is possible, but not in a basement. Also cannot be mounted in the attic. For powerful equipment over 36 kW, you need to equip a separate boiler room.

It is necessary to take into account the basic requirements - a gas boiler in a wooden house with a capacity of up to 60 kW can be installed in a room with the following parameters:

- The minimum volume is 15 m3. For each kilowatt of energy above the norm, you need to add 1 m?.

- Ceiling height - from 2.5 m and above.

- The presence of forced and natural ventilation.

- Artificial lighting should be complemented by natural lighting.

The place of installation is isolated from the living quarters by a door, if the installation is carried out in a separate boiler room, there must be an exit directly to the street.

Installation of a wall-mounted gas boiler in a wooden house in a separate boiler room is carried out according to the following rules:

- standard requirements for the volume and height of ceilings - 15 m? and 2.5 m;

- interior wall decoration with fire-resistant material with a fire resistance limit of 0.75 hours;

- normal room lighting - artificial and natural;

- the presence of ventilation systems.

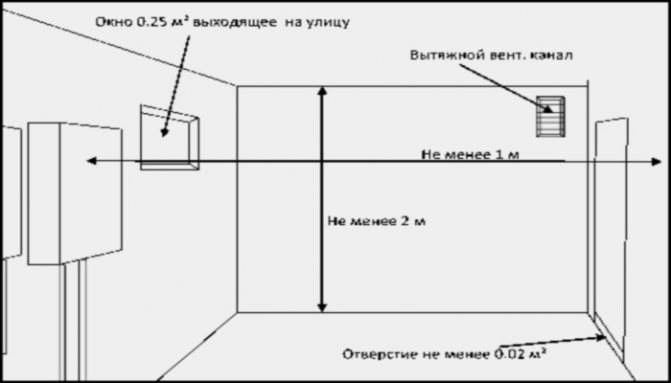

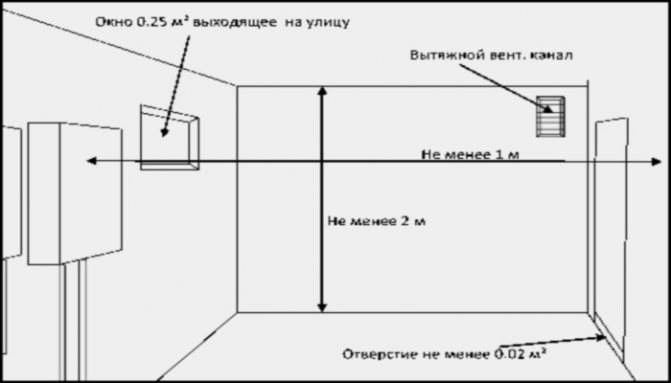

In addition to the door to the street, there may be an additional doorway to the house. It is important that tightness is ensured - combustion products must not enter the building. Ventilation parameters depend on the type of combustion chamber - closed or atmospheric. For the second, the value of air exchange should not be less than 3 volumes of the boiler room per hour. Combustion air consumption is additionally taken into account. This parameter is indicated in the boiler passport. The distance from the heating equipment to the ventilation opening is at least 2 meters. The glazing area depends on the volume of the boiler room. At 1 m? requires 0.03 m? light opening. It is important - this is an indicator of the net inflow of light, excluding the width of the frames and imposts.

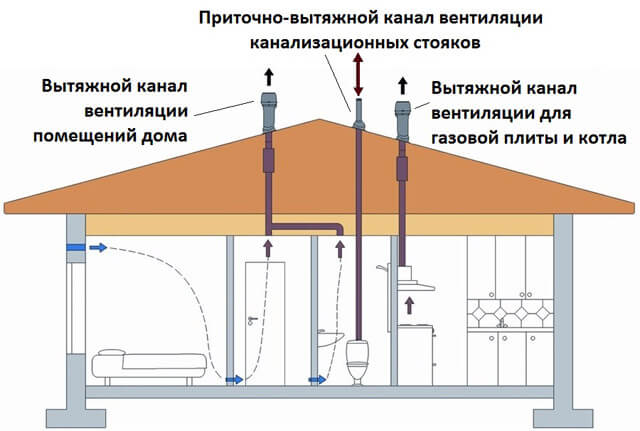

Requirements for ventilation in a private house with a wall-mounted gas boiler

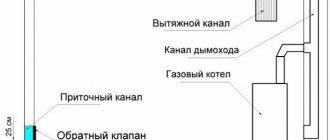

According to the requirements for the boiler room, a separate ventilation outlet must be provided.

The rules for choosing and installing ventilation systems are contained in SNiP 2.04.05 - 1991. Attention is paid to air exchange, which must occur at least 3 times per hour. For a natural inflow, a window must be made in the window opening, and there should be a gap of about 2 cm under the door, or holes are drilled at the bottom of the canvas.

Requirements for ventilation in a gas boiler room:

- smoke extraction and fresh air supply are carried out through isolated channels so that oxygen does not come into contact with combustion products;

- the area of the window for supplying outside air should not be less than 1/30 of the floor area of the boiler room;

- wall-mounted boiler is mounted next to the outlet of the smoke channel and ventilation shaft;

- if a coaxial pipe system is installed, an outlet is made and a technical one is made for repairing and cleaning the chimney.

In a private house, ventilation in the boiler room should always be with open hatches so that air exchange takes place constantly. Before starting heating, gas workers check the laying of sewerage, water supply, heating and the compliance of these systems with the norm. The gas outlet must be insulated, the ceiling height should not be lower than 2.2 m.

Permits documentation

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. The connection to the gas main should only be carried out by certified specialists, but the installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining a technical specification. It indicates the requirements for connecting to the gas main. It is necessary to provide a plan of the house with its characteristics.

- Drawing up a gasification project. This work is carried out by specialized organizations licensed.

- On the basis of the project, a permit is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, gas service representatives must check the building and the pipeline for compliance with the technical conditions and the agreed design. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of subsidiaries of Gorgaz. Their representatives know the nuances of design and the latest changes in the requirements for premises and equipment.

Installation diagrams

After preparing the premises and issuing permits, you can proceed with the installation of the boiler. The equipment installation site is finished with refractory materials. For wall models, it is imperative to use reliable fasteners.

How to hang a gas boiler on a wooden wall, and what standards must be observed? To do this, you need to familiarize yourself with the general rules:

- Drawing up a diagram. The location of the nozzles for connecting to the pipeline, the location of the gas pipeline are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for hot water supply, a circulation pump, an expansion tank and a protection group.

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side slabs this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling is 45 cm.

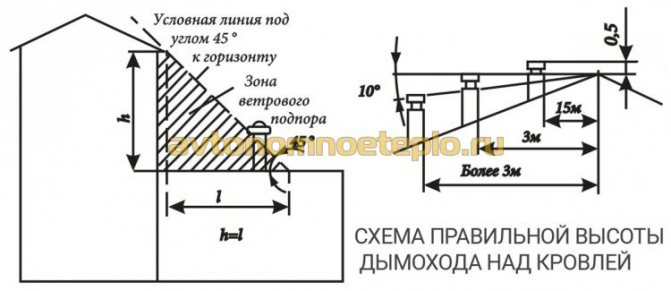

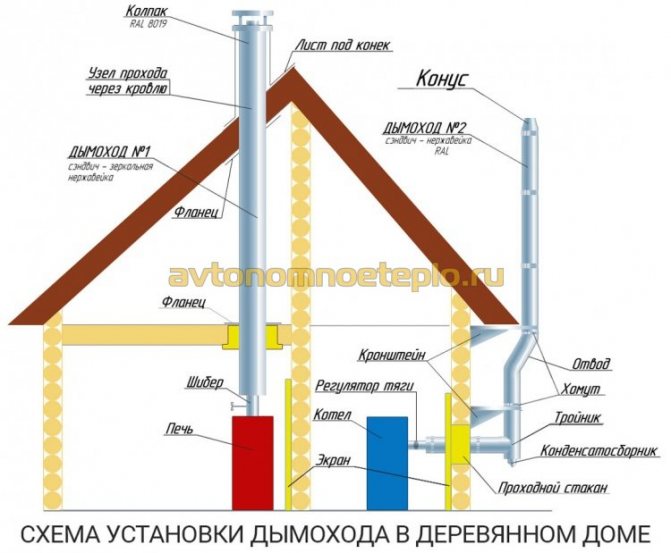

- The opening in the floor or wall for the chimney is protected by a special fireproof sleeve. Its function is to prevent direct contact of the tree with the heated surface of the chimney.

- The use of plastic pipes for heating. To protect the line surface from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

In practice, the same installation of a wood-fired boiler in a wooden house will be easier. But in the future, the cost of heating and maintenance will be higher than for gas heating.

Wall backing material

The main requirement in the decoration of walls, floors and ceilings is fire protection. For this, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process, protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. On a rigid base (metal sheet), a layer with a thickness of 50 mm or more is installed. The density of the cotton wool is maximum.

- Basalt refractory sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

It is forbidden to use polymeric materials - polypropylene, foam. For floor models, special attention is paid to the preparation of the floor surface. It is leveled, fire-resistant material is mounted. In this case, basalt wool is not recommended, as it will be compressed by the mass of the boiler. The way out is to install basalt sheets.

Installing a gas boiler has always been considered a rather difficult task, which must be performed by a specialist with special skills and certificates.

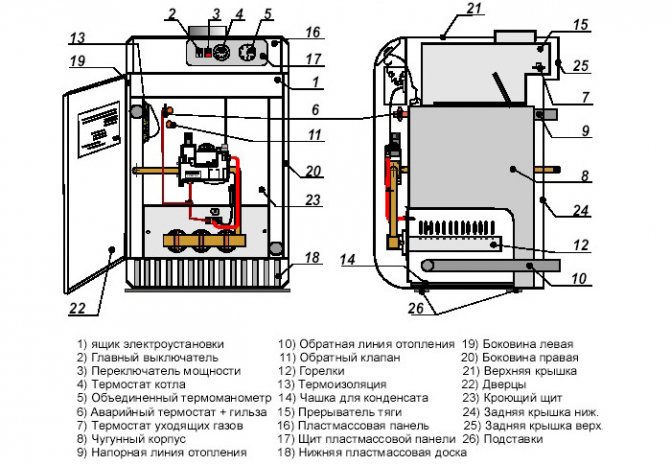

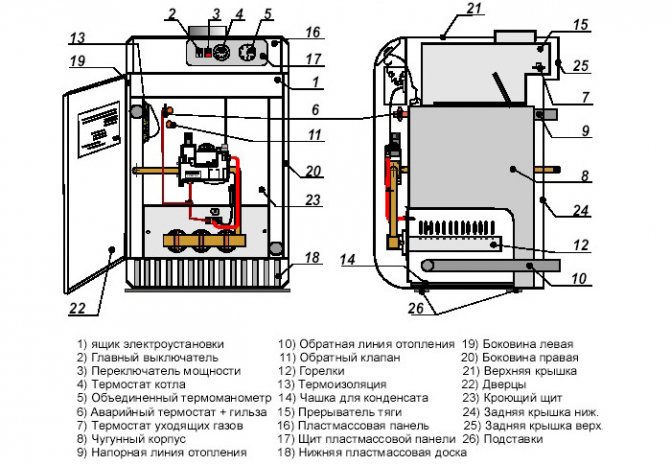

Diagram of the device of a gas floor boiler.

But it should be noted that it is better to entrust the work directly on the gas pipeline to a professional gasman, and you can supply the coolant, water and electricity necessary to connect gas heating yourself.

This will significantly save the family budget.

What you need to know about the placement of a gas boiler

As SNIP says, there are some rules that must be followed if you purchased a gas boiler and want to equip heating in your house with it.

- The area of the room in which the equipment will be located, depending on its capacity, should not be less than 4 sq. M.

- The permissible ceiling height is from 2.5 m.

- The room for heating equipment must necessarily have a free exit, while the width of the doorway cannot be less than 80 cm.

- If you plan to install a suspended boiler, then the wall on which it will be located must be sheathed with refractory materials.

- The floor-standing gas boiler is installed on a special stand, which has a base depth of 30 to 50 cm and is made of cement mortar. Otherwise, the stand must have a sheet steel backing.

- If the boiler is not equipped with a system for removing combustion products, a special chimney must be installed. For equipment with a system, a small hole is sufficient to install the outlet pipe.

- Any electrical or gas appliances must not be placed at a distance of less than 30 cm from the boiler.

- All places of contact between the chimney and the building must be sheathed with refractory materials.

Back to the table of contents

Wall-hung boiler installation

Installation diagram of a wall-mounted gas boiler.

In order to properly install the gas heating equipment, which will be located on the wall, upon purchase, you must carefully check the kit for the presence of all the main fasteners. You should also check the quality certificates certifying the fact that the gas boiler meets all existing standards. In the absence of a certificate, the heating equipment will not be registered by the gas service specialists, and you will not be able to use it. In addition, it is necessary to check the compliance of the number printed on the inner surface of the equipment with the number indicated in the documents.

Before starting the installation of the device, it should be thoroughly rinsed.To do this, remove the plugs and pump a large amount of water under high pressure through the equipment. Then you should check the tubes, which may have gotten debris during manufacture and assembly. After that, you can proceed with the installation.

In order to install heating equipment correctly, you need to stock up on the following tools:

- building level;

- screwdrivers;

- screwdriver;

- pliers;

- filter for the water supply pipe.

The wall on which the boiler will be placed must be sheathed with any fire-resistant material. This is especially true for wood or paper surfaces. The heat-resistant coating layer should not be less than 0.3 cm. Heating equipment must be installed at a distance of 4.5 cm from the wall.

First of all, the mounting strips are mounted. They should be located 0.8 to 1.6 m above the floor. The verticality of the planks is checked using a building level. Then a boiler for heating is attached to the strips, the verticality of which is also checked by the level.

Diagram of a wall-mounted boiler.

In order for the boiler to work correctly, a pre-purchased filter is installed on the water supply pipe, which will help to avoid clogging of the equipment. Stop valves are attached around the filter. With its help, it will be possible to clean or replace the filter without draining the water from the boiler. If the boiler is equipped with a combustion products exhaust system, check the operation of the fan and pass the exhaust pipe through a hole specially prepared for this.

The next step in installing gas heating is connecting the gas. To date, this manipulation is carried out only with the use of a special metal pipe and a squeegee, therefore, the help of a qualified gasman is required to complete it. Only he has the right to check the quality of the installation, compliance with all rules and regulations and authorize the operation of the equipment.

After connecting the gas, the boiler must be connected to the mains. Modern non-volatile boilers for heating are equipped with an automatic protection against short circuits and overheating.

Back to the table of contents

Installation rules for floor-standing boilers

Floor-mounted gas boilers usually have a much higher power than wall-mounted ones and are capable of heating large rooms. Such boilers have a fairly large weight, therefore, the base under them must be reliable and strong.

Floor standing boiler installation diagram.

If the room in which the boiler will be installed for heating has a wooden but solid floor, it is not necessary to pour a concrete screed. It is allowed to lay steel or galvanized iron sheet, the size of which is slightly larger than the size of the boiler base. To position the boiler on the sheet correctly, you need to be guided by the following - the dimensions of the boiler on the sides may coincide with the dimensions of the sheet, but in the back they should be 30 cm or more less.

If the floor is not reliable, a base must be prepared for the boiler. To do this, you should make a concrete screed and cover it with an iron sheet, or build a special stand from a cement mortar. In order for the boiler to work correctly and not to malfunction, after installation, check its verticality using a level. If there are deviations, pieces of hard, non-combustible material can be placed under one of the legs, thereby giving the boiler the desired position.

Then, you should perform all the actions that are performed in order to connect the wall-mounted boiler - lay the pipe for the outlet of combustion products into the hole and connect the boiler to the heating system. The gas boiler must be installed in such a way that it can be removed at any necessary time. To achieve this, it will be correct to place valves on each pipe leaving the boiler. Using the valves, it will be possible to dismantle the boiler without draining the water from the building heating system.

The last stage is connecting to a gas pipe. Here we connect the equipment only in the presence of a gas service specialist. He will check the quality of the installation and sign the commissioning permit for the equipment.

Using this instruction and having certain skills, you can install and connect a gas boiler within a few hours. And when the gasman you have called will sign all the necessary documents and permit the start-up of the equipment, you will fully enjoy not only the warmth in your home, but also the savings in the family budget.

Boiler selection by parameters [X]

Home »Useful information» Installation of Rinnai boilers

We can select and buy a gas wall-mounted boiler Rinnai.

The Rinnai wall-mounted gas double-circuit boiler is designed for heating and hot water supply of residential and industrial buildings.

The boiler can operate both on natural (main) gas - "LNG", and on liquefied gas (propane-butane) "LPG".

For the installation of the boiler, as well as for other wall-mounted boilers, a separate room is not required. The boilers can be installed in rooms with natural ventilation. The use of a coaxial chimney (pipe-in-pipe design) eliminates the need to install a traditional chimney.

When installing and operating the Rinnai boiler, the following safety requirements must be observed:

- The boiler is installed only in a well-ventilated area.

- It is forbidden to place flammable materials in the immediate vicinity of the boiler.

- For normal operation and safety, the Rinnai boiler must be grounded.

- The room in which the Rinnai boiler is installed must be dry and free from high humidity.

- If the boiler does not work for a long time, close the gas cock.

- Hot water is not recommended for cooking or drinking.

- Do not operate a faulty boiler

- It is strictly forbidden to install a boiler operating on liquefied gas in rooms located below ground level and not sealed from them.

- Keep children and unauthorized persons away from the operating boiler.

- If you smell gas:

- turn off the gas with a tap in front of the boiler or at the entrance to the house;

- ventilate the room where the boiler is located;

- call the emergency service or a gas service representative immediately;

- to avoid sparks, do not turn on or off electrical appliances;

- do not use an open flame or smoke in the room where the boiler is located.