Ventilation of the boiler room of a private house: requirements

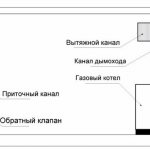

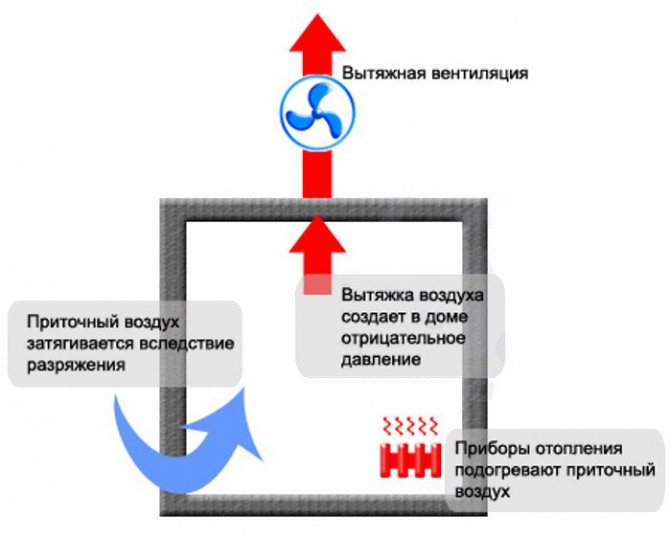

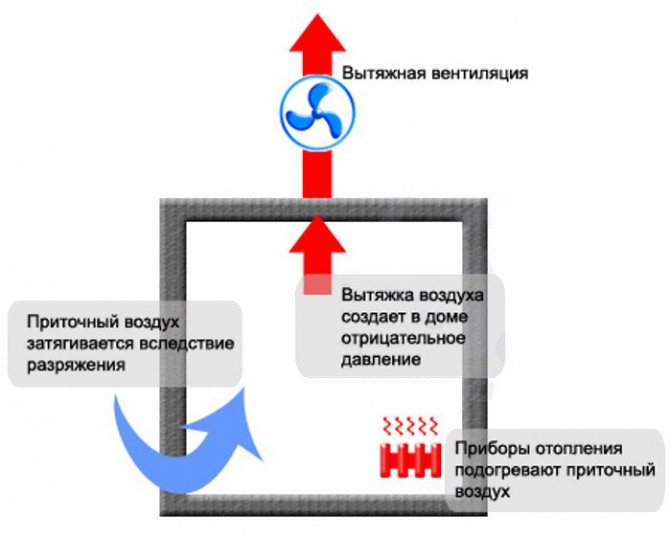

The presence of ventilation prevents the appearance of reverse draft, leading to the spread of combustion products in an individual house. The air circulation pattern in the boiler room is determined by the type of heating equipment.

Requirements for ventilation of a boiler room in a private house.

- Air is supplied to the boiler room through special channels or openings.

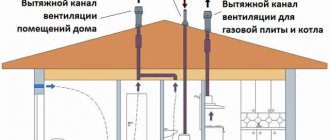

- The boiler room is part of the general ventilation system of an individual house. The air outlet is through the ceiling or the upper part of the wall of the room where the boiler is located.

- For 1 kW of power of the heating unit, fresh air is required through openings with a cross section of 30 cm2 when it is supplied from the inside and at least 8 cm2 if the draft is carried out outside.

- There should be two horizontal channels on the hood: one for the ventilation chimney, and the other (0.25-0.35 m lower) for cleaning it.

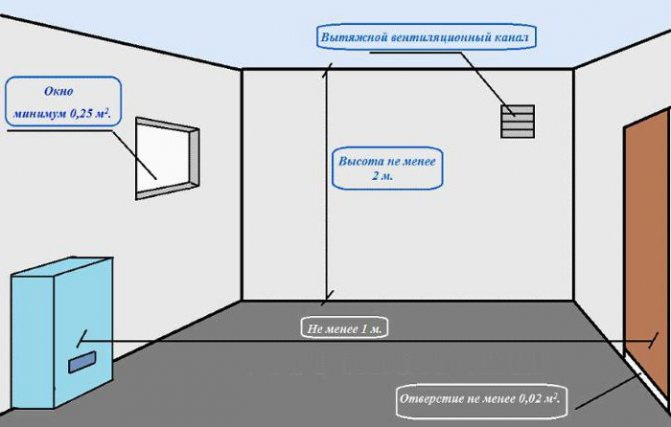

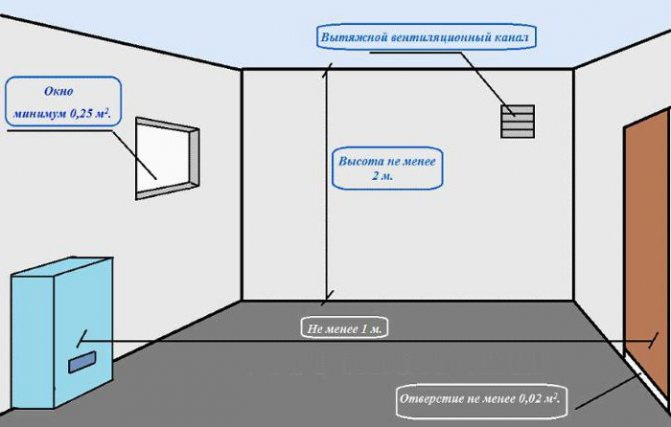

- The distance of the boiler equipment from the walls should not be less than 0.1 m.

- Exhaust and air supply are located on opposite sides of the room.

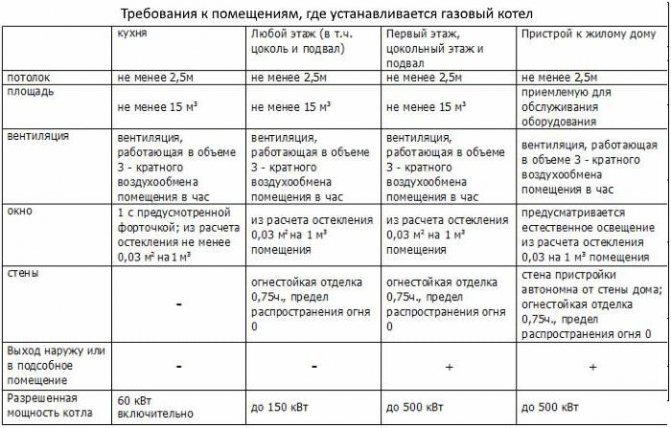

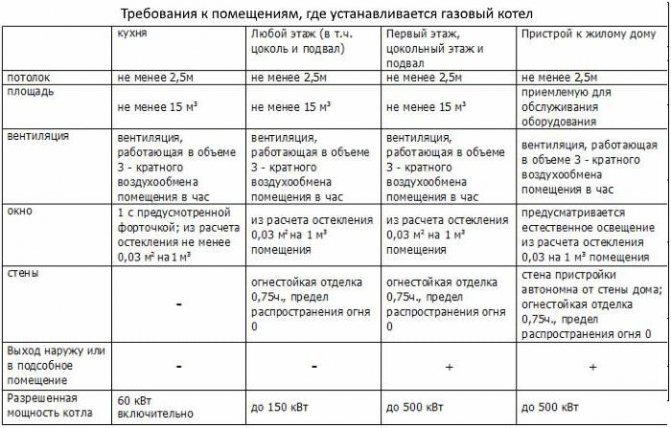

In accordance with SNiP, ventilation of a gas boiler room in a private house must perform three times air exchange per hour. Its quantity to support combustion is not taken into account.

In accordance with the accepted requirements and norms, the boiler room is created in several versions.

- Separate building.

- Extension to the house.

- Built-in room inside the house.

- Indoors at home, such as the kitchen.

- System in the attic.

- Block-modular system - container with equipment.

The choice of premises is determined by the performance and dimensions of the equipment.

Gas boilers up to 30 kW can be installed in the kitchen. A basement or basement is not suitable for LPG. Fuel has a higher specific gravity than air. Gas may accumulate in the lower rooms if it leaks, which is unacceptable.

Requirements for the boiler room:

- floor area not less than 15 m2;

- room height from 2.2 m;

- the presence of a window with an area of 3 cm2 per 1 m3 of the boiler room volume;

- the window must open or have a window.

Pros and cons of the two systems

Natural ventilation

You don't need any special skills to equip such a hood yourself, while it has a number of advantages:

- The absence of mechanisms makes such air exchange reliable and durable.

- There is no need to spend money on purchasing devices.

- Ease of use.

- Silence during operation.

At one time, such a hood fully met its requirements, but with the advent of new gas equipment, the view on this has changed.

At the same time, the following significant disadvantages were discovered:

- Dependence of the optimal air circulation on the season and climatic conditions.

- Inability to regulate the air flow.

- Penetration of foreign particles through the system.

We recommend that you familiarize yourself with: An overview of 5 hoods built into the structure of a suspended kitchen cabinet

And also with a decrease in air intake, there is a possibility of an increase in humidity in the room.

Artificial ventilation

Artificial hood is the best option when installing gas boiler houses, since:

- There is a possibility of self-regulation of the air supply.

- The importance of this ventilation in confined spaces.

- Nice microclimate in the room.

- The ability to regulate air exchange using the remote control.

- Independence from weather conditions.

If there is a boiler with a coaxial outlet in the house, then the built-in fan in it automatically creates a favorable atmosphere for human living.

The only drawback of such a system is the rather high cost of this installation.

Natural ventilation

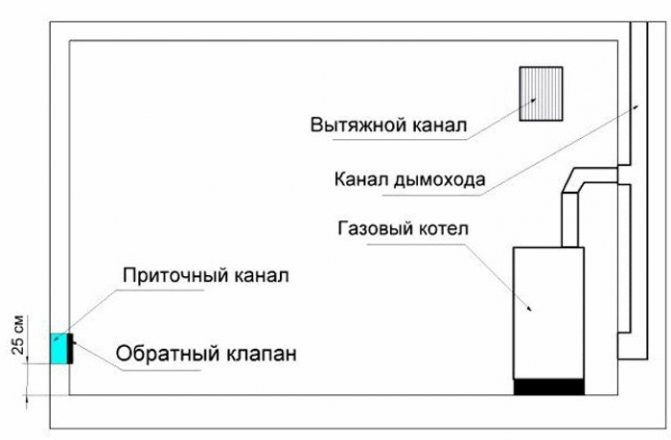

Ventilation in a boiler room in a private house is mainly done on natural draft. Air can flow under doors or through channels in walls. The supply air with a boiler power of up to 30 kW is made with a diameter of no more than 15 cm and is located no higher than the working area of the boiler. It contains a plastic pipe, which is closed from the outside with a mesh, and inside it is equipped with a check valve that prevents air from entering outside.

The exhaust outlet is located above the boiler, at the top of the room and can be equipped with a non-return valve. Then the air will not enter the room from the outside. The pipe is easy to install with your own hands. A metal umbrella from precipitation is attached to it from above.

A big drawback is the lack of control over air exchange, which also depends on the ambient temperature, wind strength and atmospheric pressure.

Diagram of a boiler room with a solid fuel boiler

The room in which you place the heating equipment may be located:

- …inside the house. This option is suitable for low power gas and electric boilers. As for solid fuel models, it is recommended to take them out of the residential premises.

- … In the annex. This is a separate building, built right next to one of the walls of the cottage. At the same time, it is important that the distance from the walls of the attached boiler room to the windows and doors of the house is at least 1 meter. The furnace should have a separate foundation and four, not three walls.

- … In a separate building. In this case, the boiler room is located not far from the cottage and is connected to the living quarters by utilities. A detached boiler room with a solid fuel boiler is the safest and most convenient option for owners of private houses.

In the furnace room, it is necessary to allocate space for the following mandatory elements of the heating system:

- Solid fuel boiler;

- Boiler with heat carrier;

- Boiler piping - expansion tanks, pump, sump, etc .;

- Distribution manifold for directing water along the circuits;

- Boiler safety group for removing air from the system;

- Boiler automation to control the operation of the entire system;

- Equipment for extinguishing fires.

An additional indirect heating boiler can also be located in the combustion room, which provides hot water to the house if a single-circuit device is used as heating equipment.

Forced ventilation

For powerful boiler rooms, forced draft ventilation systems are installed. Fans with characteristics corresponding to the cross-sections are installed in the ducts. The power of the hood is taken with a margin of 25-30% in relation to the maximum load. The duct length, cross-section and number of bends are also taken into account.

The casing in which the fan is installed must be reliably protected from corrosion and fire. For this, reliable coatings, aluminum or copper alloys are used.

Forced draft is expensive in terms of equipment and energy costs. Energy consumption can be reduced by using only blower or exhaust. But a truly ventilation system is only effective when the fans are pumping and extracting air.

An automation system is required in the boiler room. It not only ensures safe operation of the equipment, but also reduces gas consumption, reducing gas consumption when it is not needed.

Boiler room ventilation in a private house: rules and regulations

The basic rules related to boiler room ventilation are as follows.

- The location of the exhaust duct inlet is at the top.

- The presence of an additional channel for cleaning the exhaust pipe.

- Ensuring the supply of fresh air through the ventilation duct or under the doors.

- If air is supplied from the street, the size of the airflow per 1 kW of power is at least 8 cm2, and for inflow from other rooms - from 30 cm2.

Indoor installation

Gas ventilation in the boiler room can be of both exhaust and supply type. Consider the installation process for each type.

Exhaust ventilation

For a device of this type of ventilation, the following sequence of actions must be observed:

- mark the air duct outlet. It is made according to the size of the pipe diameter with a margin of about 1 cm.When choosing a place for laying the pipe for the exhaust, it should be noted that its outlet should be at least one meter to the gas boiler so that cold air does not affect the operation of the device,

- drill a hole

- install the chimney in the drilled opening with a slight slope from the gas boiler towards the street,

- use polyurethane foam to fill the gaps and remove excess foam only when it hardens,

- install a flap with which the size of the through hole is adjusted,

- install an exhaust fan,

- attach a ventilation grill at the outlet. It will protect housing from insects and street dust, and will also give the system a finished look.

Supply type ventilation

Installation of supply ventilation is carried out in the same way, with only one difference: instead of an exhaust fan, a supply-type device is installed. It takes in the flow of air, cools it or warms it, and then redirects it into the room. For the boiler room of a private house, you can use a simple model of such an installation, a supply fan. Watch the installation video:

Test and check

Checking the efficiency of the gas boiler exhaust is carried out with the front door closed and the window open in the boiler room. A regular paper towel is applied to the inlet of the ventilation duct. During normal operation of ventilation, it will be attracted to the hole, in case of clogging of the channel or improper installation, the napkin will fall to the floor.

Ventilation requirements for the boiler

Gas ventilation must meet the following requirements:

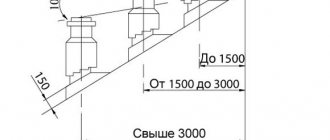

- permissible angle of inclination of individual elements of the chimney - no more than 30º,

- length of the maximum branch - 1 m,

- the maximum permissible number of bends in the chimney - 3 pcs.,

- there must be no ledges or narrowing of the cross-section in the system,

- the structure should include devices for revision and a drip,

- turning points are equipped with a cleaning hatch,

- for the arrangement of ventilation, only ideally smooth products from the inside are used,

- the distance between the air ducts and the surface of the ceiling and walls made of flammable materials must be at least 0.25 m. It is allowed to reduce this distance to 5 cm for structural elements made of non-combustible materials,

- the minimum size of the ventilation inlet for air supply from the street is 8 cm² per 1 kW of the rated power of the gas unit, for the air supply from the inside - 30 cm² per 1 kW.

Ventilation system calculation

3-fold air exchange per hour is achieved in a boiler room with an optimal height of 6 m. Due to the fact that it is difficult to provide it in a private house, air exchange is increased by 25% for each meter of height decrease.

A simplified calculation of boiler room ventilation includes the following parameters:

- volume v = b * l * h, where b is the width, l is the length, h is the height of the room;

- air flow speed w = 1 m / s;

- coefficient of increasing the frequency of air exchange k = (6-h) * 0.25 + 3.

Calculation example

The dimensions of the boiler room are 3x4x3.5 m.

Determine v = 3 * 4 * 3.5 = 42 m3; k = (6 - 3.5) * 0.25 + 3 = 3.6.

For 1 hour, natural ventilation ensures the passage of air in the amount of V = 3.6 * 42 = 151 m3.

The cross-sectional area of the chimney channel will be S = V / (v * t) = 151 / (1 * 3600) = 0.042 m2.

According to this indicator, you can select the closest inner diameter of the hood from the standard range d = 200 mm. The inlet must have the same section.

When the ventilation shaft is installed, when its flow area is less than the design one, forced ventilation is made to compensate for the lack of capacity.

Features of installation of the ventilation system

With natural ventilation, the air ducts are placed only vertically, not lower than 3 m. For forced ventilation, horizontal sections can be installed, but without turns.

Any homeowner is interested in the question of how to make ventilation in the boiler room of a private house better? The best option includes both ventilation methods. When one of them fails, the other can be applied. In both cases, it is necessary that the incoming air volume be equal to the outgoing one, which is ensured by the operation of the fans and dampers. But here it is important that the required system performance is provided.

The location of equipment must be carried out in accordance with SNiP. When using solid fuel boilers, additional fans should be installed in the place where soot appears.

How to choose the material for the hood

Manufacturing material can be different.

Let's consider some of them.

- Brick. This material is used for the construction of an exhaust duct in solid fuel boilers. Cleaning of such channels is very time consuming, but their service life is significant. In gas boilers, a brick air duct is not an optimal option, since they have a low temperature and condensation may appear in the pipe that can destroy the brick;

- Ceramics. For use in a solid fuel boiler room, high-temperature ceramics (up to 650 ° C) are used. In gas boiler rooms, ordinary ceramics can be used, but with the possibility of condensate drainage. The pipe must be insulated with heat-insulating materials;

- Metal. Steel exhaust ducts can be used in both solid fuel and gas boilers. The only difference is the use of thicker-walled metal for solid fuel boilers. The metal must be heat resistant. Among the disadvantages are the high price and shorter service life compared to brick ones.

The requirements for corrosion resistance and interaction with soot will help to determine the material of the exhaust duct. It is also important to take into account what pressure is created by forced ventilation, the amount of condensate, the temperature of the gases. If it is necessary to restore the exhaust duct from brick in the conditions of gas equipment operation, metal air ducts can be placed inside the old duct.

Installation of forced ventilation

The presence of a fan significantly improves system performance. Supply ventilation is easy to install.

- A hole is made in the wall with a diamond bit or perforator with a slope towards the street.

- A pipe is installed in the hole. The crevices are foaming.

- The duct fan is being installed.

- Wiring is laid and connected to power the fan motor.

- Sensors, noise absorber and filter are installed.

- Grilles are attached to both ends of the pipe.

Exhaust ventilation is installed in the same way, only the air must be extracted, not forced.