In construction, it is permissible to use industrial waste as raw materials for the production of a number of construction works. The construction industry makes the most of the by-products of all kinds of industries.

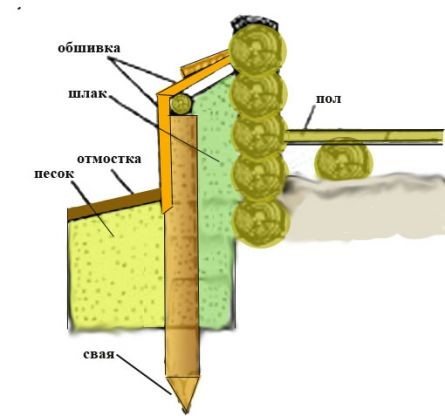

Slag production scheme.

Slag as insulation in the construction of houses is the most affordable material to increase the efficiency and reliability of building operation.

Blast furnace slag is the main resource for the construction industry

After pig iron smelting, blast furnace slag is obtained, which is widely used in construction. It is the main ingredient for producing Portland cement. Slag as an additive improves the performance of the cement. The melt is formed by high temperature from materials such as ore, gas environment and fuel. The composition of blast-furnace slags is characterized by the presence of iron, manganese, and sulfur in them. The chemical composition for the production of building materials is also important, therefore, blast-furnace slags, which have a composition similar to cement, are more often used in construction. Steelmaking slag after cooling has the form of crystals, does not granulate. The open-hearth slag is characterized by a dense consistency, the strength reaches 150 MPa, and is frost-resistant.

Non-ferrous metallurgy slags in construction

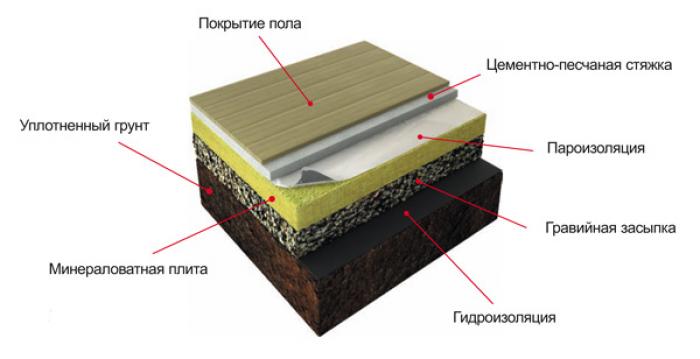

Floor insulation scheme with slag.

Nickel and copper smelting slags are widely used in the construction industry. They do not disintegrate, the strength limit is 120-300 MPa. They are used for the production of mineral wool.

Blast furnace slags of the 1st grade have a coefficient indicating their quality - 1.65, for the 2nd grade - 1.45; grade 3 - 1.2. Slag crystal has become widespread. This material is used in construction for flooring, for cladding a building. When applied, the floors in private houses are of good quality, their service life is improved, and the costs required for thermal insulation are reduced.

Pros and cons of mineral wool and fiberglass

Both types of these materials are available in slabs and rolls. The performance and practical characteristics of mineral wool and fiberglass are almost identical. That is why both of these materials will be considered together.

The main advantage of these materials is their excellent thermal conductivity (about 0.041 W / (m 0C)) and sound insulation. Another indicator should also be noted - fire resistance. Mineral wool and fiberglass practically do not burn and fade out arbitrarily in the absence of open fire.

The structure of fiberglass and mineral wool allows these materials to be laid even on uneven surfaces.

Perhaps the only drawback of these materials is that after getting wet, they almost completely lose their heat-insulating and sound-insulating properties.

Basic requirements for heaters in construction

During the construction of a private house, great attention is paid to the issues of heat preservation in a residential building. Most often, insulation is made for walls, basement space or attic. In brick houses, the requirement for thermal insulation is met by walls with a thickness of 1 m.

Insulation must meet several basic requirements. Special attention is paid to thermal conductivity. With its low parameters, heat remains longer and the consumption of insulation decreases. The thermal conductivity of slags is LSh = 2.3-3.5 W (mK), slightly less than that of metal.Insulation must be able to absorb moisture well. The hydrophobicity of the slag has average properties: the material is safe and stable, has a density of 3471 - 3765 kg / m³. The material is fire resistant. Melting temperature 150 - 200 ° C.

Insulation should be lightweight. The volumetric weight of slag in the placer is 700-1900 kg / m³, in a lump - 700-2900 kg / m³. Insulation must be selected in such a way that it can be easily installed, and the cost of purchasing it was insignificant.

There is no insulation that would meet all the requirements. When used in ceilings, slag with a density of up to 1000 kg / m³ has a thickness of 30 cm.

Characteristics and properties of slag as insulation

Slags are silicates that have been obtained as by-products from the remelting of raw materials, metals, intermediate products, and ore refining and reduction. They include basic, acidic or neutral oxides of silicon, aluminum, zinc, calcium, magnesium or iron.

The main characteristics of the slag are as follows:

- density from 300 to 1000 kg / m 3, depending on the components present in the composition;

- specific gravity from 2.56 to 3.65 g / m 3;

- granule sizes from 0.7 to 20 mm;

- melting temperature up to +1500 0 С;

- compressive strength up to 150 MPa;

- thermal conductivity coefficient from 0.0326 to 0.05 W / mK.

Slag has increased moisture resistance

Insulation of the ceiling with slag is beneficial due to its excellent operational properties:

- resistance to sudden temperature changes;

- natural composition, no toxic substances are emitted during operation;

- chemical and biological resistance;

- no shrinkage, as well as deformation and destruction under the influence of external loads;

- increased moisture resistance.

Scope of fuel slag

The scheme of insulation of the ceiling of a frame house.

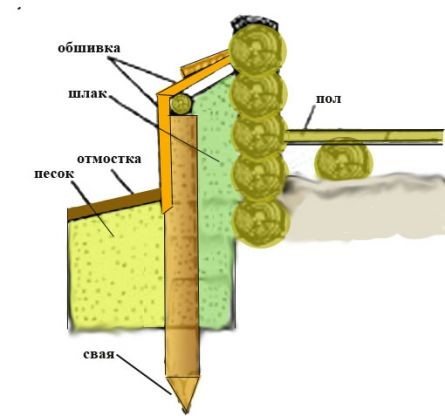

Floor insulation in brick houses is carried out with the help of melt, which is poured under the wooden floor. Particular attention is paid to quality: it should contain as little ash and unburned coal as possible. Impurities reduce the quality of the finished aggregate.

Thermal insulation with fuel slag is used in wooden houses, while not only providing thermal insulation, but also reducing the noise level. In modern construction, slag is used to level the coating under the floor; With the help of cinder-concrete blocks, you can replace expensive bricks and significantly reduce the cost of production. Many developers make the mistake of using fresh slag as insulation, which contains many harmful substances.

Slag building material is obtained after a thorough processing process. Fresh slags are piled and kept for 2-3 months. Such aged slags are protected from destruction. After aging and sprinkling with rains, it is freed from lime, sulfur compounds. Fresh slag is also used for the preparation of concrete mortar.

Advantages and disadvantages

Metallurgical slag is not used in a humid environment due to its tendency to corrosion

Despite the difference in technical characteristics, all types of slags as insulation have similar positive qualities.

The material is different:

- ease of use;

- low cost;

- optimal air exchange;

- resistance to rotting, fungus formation, mold spread;

- the ability to use in any premises;

- mechanical strength and chemical neutrality;

- inaccessibility to damage by rodents and insects;

- good indicators of thermal conductivity compared to monolithic concrete or brick;

- unlimited use time, subject to installation technology;

- fire safety.

The structure of the material imposes restrictions on the application. A high specific weight is taken into account when designing load-bearing structures.

Slags are less effective in relation to modern specialized products for thermal insulation - polystyrene, foam insulation, mineral plates, etc.

Industrial waste is not used to insulate surfaces exposed to precipitation, or concrete screeds are applied over the backfill to protect against waterlogging. Wet slag loses its insulating properties.

Metallurgical type is susceptible to rust in high humidity conditions.

Industrial types of insulation are hidden with a screed or filled into the voids of the brickwork to prevent the ingress of harmful substances into the air of residential premises.

Coal slag in construction

Coal melts are widely used in modern construction. The compound formed between the slag and the binder is called cinder concrete. This new type of building material is several times superior to the heat-shielding properties of ordinary brick. Slag concrete is durable, inexpensive.

Fuel melts are used in the manufacture of slag concrete blocks. They are less durable than metallurgical ones. When anthracite is burned, the highest strength agglomerate is formed. The highest quality melts are obtained by burning brown coal. The chemical composition of the resulting raw material provides for the absence of various impurities in it in the form of clay, ash, unburned particles and earth. In slag, special attention is paid to the quantitative ratio between soft and coarser parts. The use of a fine-grained substance makes it possible to obtain lighter concrete, but they are inferior in strength to heavy ones.

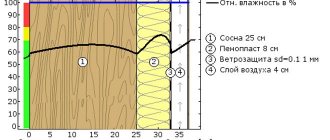

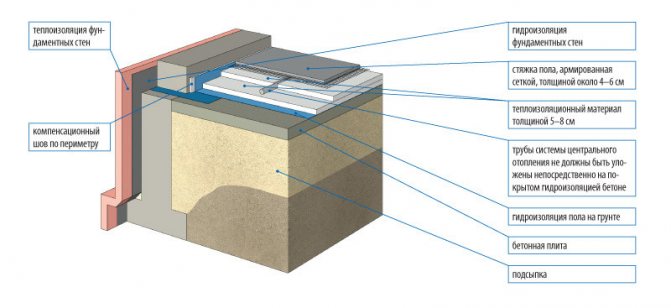

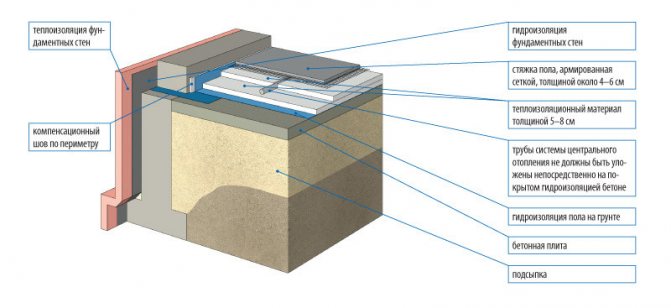

Insulation scheme for the basement of the house.

When building a house for exterior walls, the ratio between large and small parts should be 4: 6. All internal walls are made of fine-grained slag, which provides their strength.

The list of modern materials with which insulation is made is wide, and 90% are insulation made of mineral fibers and plastics. All inorganic materials are made on the basis of raw materials with a mineral composition. Slags belong to this class. Metallurgical slags by means of silicate melt are used to obtain mineral wool.

Slag pumice is widely used as a heater. It provides for the use of a special cooling mode. Astringent properties are completely absent.

Mineral wool insulation scheme

Laying mineral wool or fiberglass should only be done on a previously primed surface. The best option in terms of speed is the so-called "wet" method of laying.

First you need to prepare the surface - remove the existing defects (cracks, chips) and prime. You also need to build a base that will serve as a support for the first base row.

The next step is to prepare the glue. In this case, it is important to follow the instructions on the package. After the glue is prepared, you can proceed with the installation of the insulation.

Please note: the glue must be applied in an even layer to the insulation with a spatula, and not on the wall! During the installation process, you also need to ensure that there are no gaps between the plates.

Thermal insulation is glued in a checkerboard pattern, like brickwork. With a building level, we check the evenness of the masonry. We additionally fix the sheets of thermal insulation to the wall using umbrella dowels. After the mineral wool has covered the entire wall, you need to lay a layer of glue, sinking the reinforcing mesh into it.

Floor insulation using slag

When building a house, proper floor insulation is always in the area of special attention of the developer. The entire heat flux is directed into the residential part of the building through the walls, as well as through a large area of the floor.During construction work, the developer insulates the basement in such a way that the temperature at the base of the floor is at the level of the air temperature in the residential area. It can fluctuate around 2 ° C. For the floor, the coefficient of heat absorption is very low. For flooring and subsequent floor insulation, it is necessary to prepare the necessary tools and materials:

- nail puller;

- ax;

- ticks;

- chisel;

- hacksaw;

- roofing material;

- wooden bars 2-3 cm thick;

- level;

- slats;

- rule;

- antiseptic;

- drill;

- a hammer;

- insulation;

- nails;

- pencil.

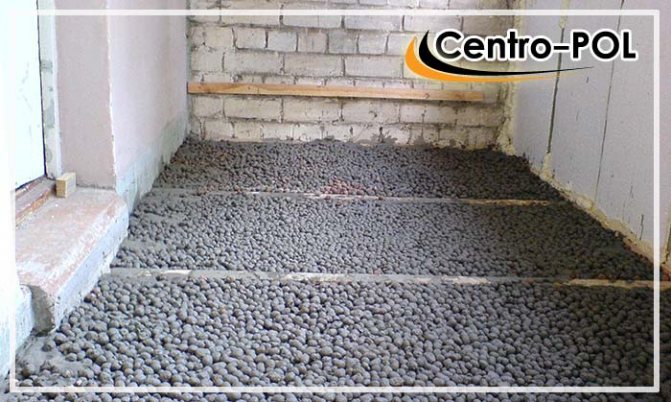

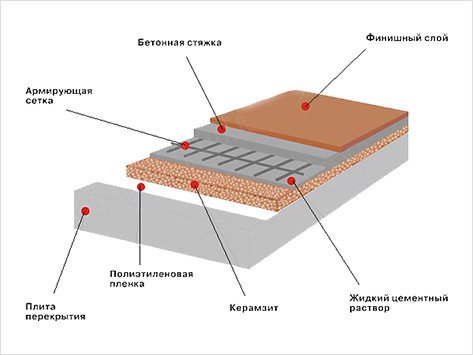

Installation diagram of a dry floor screed.

When carrying out floor insulation, the work is carried out in 3 stages: first, work is carried out with the subfloor, then the insulating material is mounted, and the work ends with the finished floor. It is possible to use a layer of waterproofing, laid before the process of creating the subfloor.

Slag is laid as an insulating material on top of the subfloor. Insulation provides for the creation of a gap of 15 cm from the insulation layer. Insulators must be treated with all responsibility: they must have high performance, be durable, and be well cut to the required size.

Wall insulation with expanded polystyrene

Styrofoam installation is carried out in almost the same way as the installation of mineral wool.

The first stage is surface preparation. Elimination of defects and application of a primer. Further, after preparing the glue solution, we proceed to the installation of insulation sheets.

Important: there should be no gaps or gaps between the plates!

After laying the insulation boards on top of them, you need to fix the reinforcing mesh. Further, this whole cake is carefully primed and putty, after which you can proceed to the final stage - applying a decorative coating.

When the house is insulated from the inside, the internal space of the room is significantly reduced. Nevertheless, this fact is not critical in order to completely abandon the insulation and in the cold season suffer from low temperatures outside the window or throw financial resources into the chimney to heat the house.

Before answering the question of how to properly insulate a house from a cinder block from the inside, you need to deal with the materials offered by construction stores. Today the market offers insulation based on foam and mineral wool. Editing both one and the other does not require any specific skills from the performer.

We insulate the cinder block house with polystyrene foam

The complexity of the installation of this material lies in the preliminary alignment of the walls on which they will be glued. In the case of a brick wall, plastering and puttying will be required. Without fail, wallpaper must be removed from the walls and paint residues must be removed.

Every owner of an apartment or house undoubtedly has a dominant desire to preserve the final result for the longest possible time. That is why the use of a waterproofing substrate, even inside the house, should be indispensable. For what? In order to thus prevent the accumulation of condensate that degrades the foam.

For work you will need:

- five centimeter foam;

- comb or notched trowel;

- glue (usually Ceresit).

Installation work is extremely simple. On the prepared wall, with the help of diluted glue, insulation plates purchased from a building materials store are attached. Then they are thoroughly tapped to remove possible air bubbles from under them. In this matter, an important point is to apply the adhesive mixture directly to the wall and in no case to the foam sheets themselves. They must always be dry.

Further, for optimal insulation of the house, all cracks and loose fit of the material should be treated with polyurethane foam. This must be done in order to isolate the glued layer from changes in humidity in the room.

In the process of fixing foam plates, you can also use special fixing dowels. However, the adhesive solution will suffice. The final step will be the front finishing of the walls and their possible painting.

A fairly quick and practical way. Its most important advantage is the elimination of the pre-leveling stage of the walls. The thing is that mineral wool slabs are installed in a specially created metal structure. Then, in stages, the entire frame is sewn up with plasterboard plates, which will give your wall a perfectly flat surface.

So, a special structure is assembled from metal or wooden profiles - lathing. Plasterboard plates are installed on it. Next, the joints are putty and the wall is either painted or wallpaper is applied to it.

VIDEO: Insulation of internal walls. Installation of insulation on the wall.

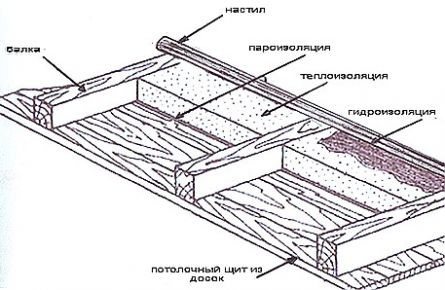

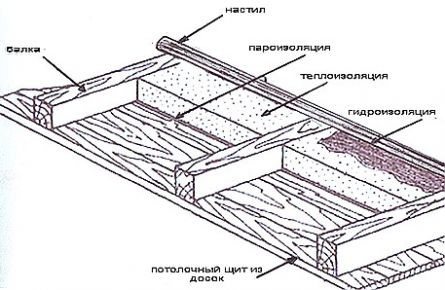

Step-by-step process of floor insulation

Pre-carefully check the plane of the log to determine how smooth they are. They can be trimmed if necessary. Floor insulation should consist of several stages. Insulation is a part of 3 heat-insulating layers: rough filling, heat-insulating material and floor covering.

First, a mesh is mounted to protect against the formation of their nests by rodents. Insulation is attached between pre-installed lags. After the installation of the mesh, slag is backfilled. The method of insulation also directly depends on what kind of foundation a residential building has. With a columnar or strip foundation, the process of warming begins with the filling of granular slag into the underground surface.

A subfloor is mounted on top, and the insulation is again laid. It is possible to lay a layer of slag between the rough and the upper floor, which is additionally lined with insulation on top; on the subfloor, in addition to the slag, a waterproofing layer is laid.

Floor laying scheme on the ground.

If a house is made of timber with a basement and it is necessary to insulate the floor on the ground floor, a double floor is created. First of all, the beams are installed strictly horizontally, at the same distance from each other. Bars 50x50 cm in size are nailed along the bottom of the beams, boards 25 - 50 mm in size (thickness) are taken and the subfloor is equipped. These boards are not attached to previously nailed bars. Then a vapor barrier layer is installed, and the insulation is laid.

At the end of the work, the flooring is laid. The entire space between the beams is filled with slag. It is prepared in advance for insulation: the required amount is mixed with lime so that there are no rodents. Lime is taken in the amount of 10% of the total volume of slag intended for insulation. During the preparation process, it is necessary to thoroughly stir the mixture so that a homogeneous substance is formed. There is no air gap between the slag-like insulation and the vapor barrier layer.

Floor thermal insulation technology

To make high-quality insulation of the floor base, it must first be prepared. Thus, at the stage of filling the granular thermal insulator, there will be no complications:

- When insulating a wooden base, it is necessary to revise the load-bearing structural parts and replace deformed or rotten logs;

- Then you should treat the wooden parts of the structure with antiseptic agents;

- To prevent the accumulation of condensation under the floor, a vapor barrier (roofing felt, plastic wrap, Penofol) is laid before installing the bulk filler.

The process of insulating the floor base with slag depends on what materials the floor itself is made of. To take into account all the nuances of thermal insulation, we will consider each of the options in more detail.

Thermal insulation of a wooden base

How to install slag on wooden floors? To carry out high-quality thermal insulation of the coating, it is necessary to do the following:

- Dismantle old floorboards;

- Replace the rotten parts of the wood floor;

- Fasten the boards from below under the logs;

- Waterproof the base with polyethylene or roofing felt;

- Fill in slag in the section between the logs;

- Cover the filler with plastic wrap;

- Carry out the installation of the topcoat.

Thermal insulation of a concrete base

The concrete floor is insulated only if it is possible to raise the floor base by 15 or even 20 cm. What is the procedure for work?

- The old coating is dismantled, and the concrete base is cleaned;

- The primed floor is waterproofed with a film;

- Beacons are mounted around the perimeter of the room;

- Slag is poured, after which it is carefully leveled;

- For better adhesion to the base, the slag granules are treated with a cement compound;

- After filling the insulation, a finishing concrete screed is made.