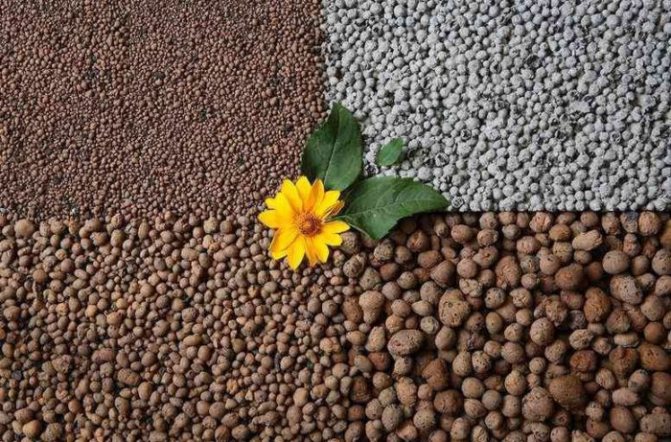

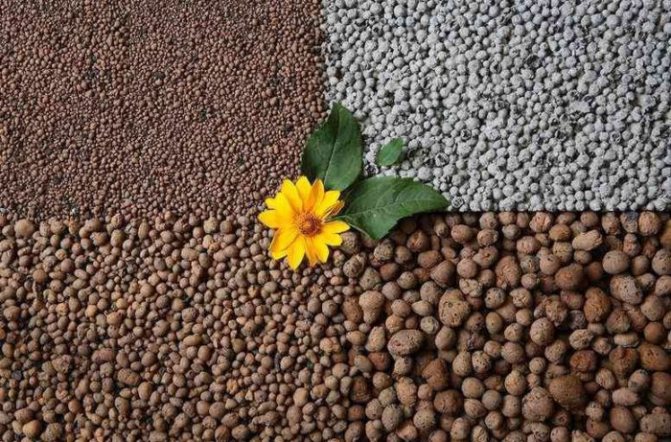

Thermal insulator classification by fractions

The type of material is due to the size of the fraction, i.e. size of granulates:

- Small. In terms of parameters, it is 0.1-5.0 mm. Used as a free-flowing backfill mixture. Also used in the production of concrete blocks.

- Average. Reaches a size of 10-20 mm, called gravel. Construction experts consider this fraction of expanded clay to be better for insulating ceilings, floors and floors of buildings.

- Big. Sizes range from 20-40 mm. Expanded clay of this fraction is used to insulate the roof, basements and basements, as well as floors in the garage and cellar.

Today the building materials market offers about ten grades of expanded clay. The distribution of material types is carried out due to the density of the filling level. So, expanded clay of a coarse fraction has a lower density. Thus, the lower the grade and density of the granulate, the higher the quality.

Reviews of expanded clay

Alexander, 42 years old, Volgograd: “I used expanded clay for floor screed in the bathroom and toilet. Waterproofing "Osnovit", a layer of 7 cm was poured with cement milk, on top of a cement-sand screed and tiles. Normal, warm. "

Alexey, 38 years old, Saratov: “I covered the roof of the old house with expanded clay with a layer of 20 cm. It became warmer, and the rain was not so audible”.

I propose to compare such heaters as expanded clay and mineral wool. These heaters are not the most expensive. And today, the cost is the first thing customers pay for when building and choosing building materials. These materials are different in structure and have different application possibilities. Thermal conductivity is also different for them.

| against |

| ? ? ? ? |

Insulation of the roof with penofol

Penofol is a modern rolled synthetic material. Despite its small thickness (only a few millimeters), penofol has excellent thermal insulation properties due to its low thermal conductivity coefficient.

The surface of penofol is covered with a thin layer of aluminum foil, which also affects its thermal insulation characteristics. Moreover, the foil gives the material water and vapor barrier properties.

This allows you to replace conventional vapor and waterproofing materials with penofol.

Due to the above properties, penofl is perfect for insulating roofs and attics, both in residential buildings and in saunas, garages and other buildings. The small thickness of the material allows you to forget about the restrictions regarding the thickness of the rafters. Convenient form of release provides ease of installation.

Penofol is used as an additional insulating material. It is mounted between the layer of insulation and the outer finish of the roof / ceiling

When installing, it is important to leave small closed air pockets between the layers of materials

Their thermal resistance, reinforced by the reflective foam insulation, is comparable to the resistance of a 50 mm thick mineral insulation slab or brickwork of one and a half bricks.

Reflective material as an added plus

The use of reflective material penofol for insulation of the roof or attic floor will allow you to refuse an additional layer of vapor barrier. The low vapor permeability coefficient of the penofol material makes additional layers unnecessary.

Penofol allows you to protect the structure from moisture, minimize heat loss. At the same time, it does not affect the volume of the insulation layer. The material goes well with any insulation, but it can also be used independently.

To insulate the roof of a country house, a "cold" attic in a bathhouse or agricultural buildings, it is enough just to "hang" penofol on the rafters.

Roof insulation with foam

Due to its unpretentiousness, Penoplex can be used in different conditions. Click on the photo to enlarge.

- Low moisture permeability.

- Resistant to strong temperature changes.

- Biological neutrality.

- Resistant to fire and high temperatures.

- High rates of heat and sound insulation coefficients.

- Environmental friendliness, non-toxicity, safety for human health.

All this makes penoplex a popular and demanded material for roof insulation. Penoplex is easy to install, it can be cut with an ordinary knife. At the same time, it is resistant to mechanical stress and has a low weight, which makes it popular for insulating floors and flat operated roofs.

Penoplex plates are made of high quality expanded polystyrene by extrusion. During the production process, airtight air cavities are formed in the raw materials.

After hardening, the penoplex acquires a cellular homogeneous structure. Thanks to her, the material has high thermal insulation characteristics, as well as mechanical strength.

Where is it possible to use Penoplex?

Extruded polystyrene foam is allowed for use in all climatic zones.

Its use can significantly reduce the cost of materials during construction and for the further operation of the building. After all, a five-centimeter layer of foam is not inferior in characteristics to brickwork, 153 mm thick.

Roof insulation with foam foam can be made using any type of material. Most often, the following types of extruded polystyrene foam can be found on sale:

- Penoplex 31 Standard.

- Penoplex 35.

- Penoplex 45.

Penoplex 35 is most often used to insulate the roof in a private house. It perfectly protects the waterproofing of the roof from sudden temperature jumps and other destructive factors.

It is used to insulate a pitched roof from the inside of an attic or flat roof using the "rolling ceiling" method. In the second case, gravel or paving slabs are covered over the roof insulation. This will help protect the material from the wind, improve the fire safety of the roof.

Expanded polystyrene

Low values of thermal conductivity of heaters made on the basis of polystyrene (foam) justify their advantages. Equipped with an extruded or foamed type of polystyrene, floors in private homes provide excellent protection against heat loss and moisture penetration. Due to the low weight, it is not required to strengthen the base if there is a basement under it, and this is a great advantage. Let's be consistent and highlight the factors that give the foam plastic advantage and priority when choosing:

- Polyfoam and its extruded modification are not subject to soil moisture absorption, which conducts heat well, which significantly reduces the insulation performance of heaters.

- Expanded polystyrene is a chemically neutral material, and therefore resistant to various biologically and chemically harmful influences.

- Building materials from the subgroup "polystyrene" are an ideal solution for floor insulation, since, in addition to their main purpose, they provide protection against moisture and its vapors. And therefore, floor insulation in a house on the ground is very often the only possible non-alternative way to solve the problem.

- The structure and technical parameters do not change during operation, and moisture and high temperature for the foam is not a problem at all.

- One square meter of expanded polystyrene withstands a load of up to 400 kg, and its structure does not collapse. Plus, it can be safely used when arranging underfloor heating (water and electric).

Note! Material availability in terms of price is another key advantage.This material has such a democratic price (with excellent characteristics) that it is available to homeowners with an average and lower income.

Varieties of expanded polystyrene

Heat insulators made of this material are divided into three groups, which differ in the method of production, technical characteristics and method of application:

- Extruded the insulation is produced by foaming the material with CO2 gas, and then the resulting mass is passed through the extruder head under pressure. Sheets of the required size are cut from the solidified mass, resembling a sponge. The extruded analogue of the foam is ahead of it both in terms of performance and price.

- Styrofoam is formed when a special substance is foamed, as a result, granules are formed, which are then attached to further sintering. These granules have a weightless structure and an impermeable shell, which, when pressed, makes it possible to obtain plates with unique thermal insulation characteristics.

- Expanded polystyrene foam It is sold in liquid form and requires special sawing equipment to use it. This material is applied to the floor in a uniform layer, and when interacting with air, this material begins to increase in volume, thereby filling the empty space of the floor with a porous, heat and moisture resistant structure.

Foamed polystyrene foam is great for floor insulation in a private house with a basement. In this case, it is possible not to remove the floor covering, but to insulate the cellar / basement ceiling, of course, if the dimensions of the underground room contribute to this. This heat insulator is not afraid of moisture, rodents and mold - its scope is unlimited.

What is expanded clay

Expanded clay is a heat-insulating material made by firing natural clay that can be foamed. This is a clean, ecological material that can be purchased in any city at a very low price.

Expanded clay sand (up to 5 mm in diameter) is used in filling and in the lower layers for insulation. Fractions from 5 to 40 mm are used to create an insulating “pie” on roofs, attic floors, floors, foundations, blind areas and even walls.

Benefits:

- environmental friendliness - the material, even over time, does not lend itself to decay, rotting and decomposition;

- does not release toxic substances into the air;

- resistant to temperature extremes, frost-resistant;

- does not support combustion;

- rodents do not live in it;

- affordable price;

- expanded clay sand perfectly fills all depressions and cavities;

- easy process of roof insulation with expanded clay.

Disadvantages:

- the material is fragile, and broken granules lose a significant part of their thermal insulation qualities;

- the cellular structure of the fractions allows them to be filled with water when heated, which somewhat reduces the ability to maintain the mixing of cold and warm air.

A little about the choice

Today there are 10 grades of expanded clay: from 250 to 1000, depending on the density of the fill. This or that number indicates the number of kilograms of material per 1 m³ of volume. One cubic meter contains about 20 buckets of expanded clay.

What brand of expanded clay is used for roof insulation? It depends on the climatic conditions and the strength of the attic floor. In addition, when insulating an attic, more than 1 grade of material is used.

Insulation technology

Insulation of the roof with expanded clay in a wooden house begins with an inspection of the attic floor and removing all debris. What needs repair - you need to fix the problem immediately.

Further, the algorithm is approximately the same as when using other heaters.

We make waterproofing

The floor of the attic must be covered with waterproofing with an obligatory overlap of strips (by 200-300 mm) and gluing the seams with reinforced tape.

Many people prefer roofing material or parchment. Previously, people with a lack of finance used ordinary cardboard. The waterproofing should extend 15 cm to the walls and floor beams. If the budget allows, the beams can be completely covered with foil.

This is how waterproofing is done for expanded clay

What should be the thickness of expanded clay?

It is better to make the lower layer of fine expanded clay sand, and for the upper layer, use fractions of 10-30 mm. Many people immediately purchase a mixture of granules of different sizes. The material is poured between the beams, but not above their upper edge.

Expanded clay backfill is carefully compacted and leveled by the rule.

Expanded clay must be leveled

You can already finish the work at this stage, but if you are going to somehow use the attic (storing things, drying vegetables and herbs), you better organize flooring in the room.

To do this, lay another layer of vapor barrier on top of expanded clay and install wooden flooring / plywood / chipboard.

If there is a need to fully use the under-roof space, concrete pouring is performed on the attic floor. To do this, a reinforced mesh is laid on top of expanded clay and poured with a screed. After complete drying, the floor covering is mounted.

Useful video below - be sure to watch.

https://youtube.com/watch?v=W7CNaXfxy4w

Insulation of a concrete floor

The lowest layer should be film materials, mastics, liquid primers. They should go up the walls by about a couple of tens of centimeters. At a distance of about half a meter, a wooden beam is laid, which should be treated with a moisture protective agent.

The gaps should be filled with insulation (of your choice). The top layer is strong plywood (boards, chipboard, OSB) And the last layer is the floor covering (carpet, linoleum, etc.). To extend the service life, each layer should be treated with moisture-proof compounds.

Pros and cons of thermal insulation with expanded clay

Insulation of the ceiling with expanded clay has a number of advantages:

- The heat insulator has a long service life.

- Fire safety, because the material is not subject to combustion and, when heated, does not emit toxic substances hazardous to humans, animals and nature.

- Due to the porous structure of the insulator, the weight of the insulation is much less than its counterparts.

- Does not attract insects, rodents and bacteria that contribute to the formation of mold and mildew.

- The low price tag allows the use of expanded clay on any construction site.

- High-level thermal insulation, coupled with sound insulation, ensures an optimal microclimate in a private house.

- Absorption of moisture without increasing its own weight and without loss of performance.

- Crumbs or crushed stone from expanded clay are not allergens. This is due to the natural origin of the material.

- Ease of use of bulk heat insulator.

- The fractional shape of the material creates a barrier to air outlet, which further increases heat insulation and allows natural convection.

Along with positive features, the material has disadvantages:

- The effectiveness of expanded clay as a heat insulator depends on the thickness of the layer, i.e. filling to a depth of 20-40 cm is meaningless.

- It is necessary to protect the material from the effects of precipitation.

- The best application is the application of overlapping to concrete products. This is due to the fact that monolithic beams are able to withstand high loads, and delay the granulate from spilling onto the second floor.

- When planning work on insulation of the ceiling in a wooden house, it is necessary to ensure the protection of expanded clay with a vapor barrier film. In this case, the PVC film is placed at the bottom and top of the heat insulator. Thus, protection against the effects of atmospheric precipitation is created.

Construction industry experts advise against using expanded clay insulation on a suspended ceiling hemmed with beams from the lower side (first floor).

Given the weight load, material volume and structure, there is a high likelihood of a breakthrough in such a structure. In this case, the collapse occurs inside the room.

Expanded clay or ecowool: which is better?

Since expanded clay is made from clay, it is considered environmentally friendly. If you need to protect the ceiling, expanded clay insulation is optimal for the attic floor. As you know, clay does not burn, does not emit toxins. The density of the material varies, but it is best to buy granules ranging in size from 4 to 10 mm.

Among other advantages of expanded clay:

- No dust.

- Does not cause allergic reactions.

- Long service life.

- High temperature resistance.

The coefficient of thermal conductivity of expanded clay is slightly worse than that of ecowool, but the vapor permeability is lower. However, clay insulation has been used for a long time and is gradually being replaced by other materials. If we take into account the modern methods of insulating the ceiling from the outside, ecowool is out of competition. Increasingly, it is used to insulate walls and floors of houses. The main component is cellulose fibers, the laying is done "dry" or "wet".

In more detail: "Insulation of the ceiling with expanded clay"

In the first case, the material is simply scattered on fixed logs and rammed between the beams, in the second, ecowool is mixed with an adhesive composition. The wet material is evenly distributed over the entire surface under pressure.

And here is a list of the advantages of ecowool:

- If you are worried about the issue of environmental friendliness, and you do not know how ceilings are insulated, pay attention to ecowool. It does not contain toxic substances, so it can be used on the ceiling.

- You will not have any questions about how to fix the insulation to the ceiling, because the ecowool layer can be of any thickness.

- Long service life without loss of qualities.

- Any ceiling insulation "preserves", that is, protects against the formation of mold.

- If the ceiling is insulated with eco-friendly cotton wool, it will "breathe" and will protect the room well from the summer heat and winter cold.

If we compare expanded clay and the second type of material, ecowool wins in the category of the best insulation.

The use of expanded clay for insulation of the roof of the house

Roof insulation scheme with expanded clay.

Roof insulation can be organized on your own, you do not need to hire specialists for this. Before insulating it, you need to know what expanded clay is and why it is so highly valued for thermal insulation of buildings and structures. Expanded clay is a natural material. It has high strength and can last a long time, unlike synthetic insulation. It is based on clay. Due to all this, it does not rot, it can withstand very low temperatures, which is especially appreciated in cold climatic conditions. It has a crumbly and porous structure. The porosity promotes heat retention. The great advantage of this material is its fire resistance.

Insulation is most often carried out with expanded clay gravel, sand or crushed stone. In addition to all of the above, expanded clay is a fairly light material, which simplifies the work. Today, many synthetic materials are not environmentally friendly, which cannot be said about expanded clay. It is absolutely safe for humans during operation. Expanded clay is water-resistant, so there is no need to make an additional waterproofing layer. Its prime cost is low, which is of great importance in the consumer market. In addition, it provides a minimum load on the entire house and the roof itself. The main disadvantage is its fragility.

Roof insulation technology with expanded clay

Single-layer attic insulation scheme.

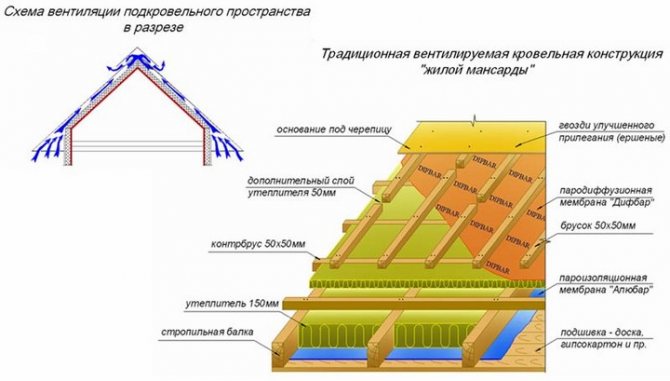

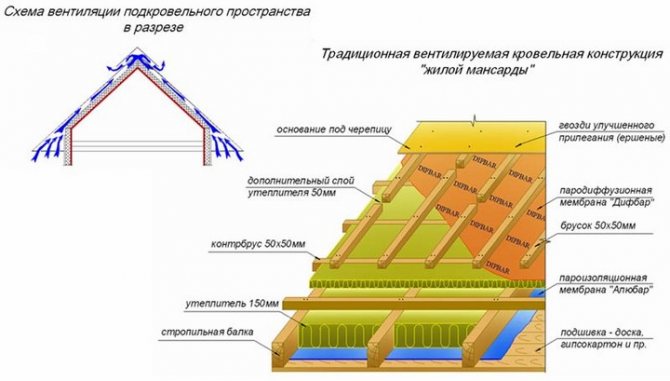

Before insulating the roof with expanded clay, you need to know some of the features of this work. First of all, in order to obtain a good effect, it is advisable to take into account the peculiarities of the house, its structure, walls, roof slope when insulating the roof. Modern technology of roof (roof) insulation includes several main stages: interior cladding, vapor barrier, laying a layer of insulation and surface finishing (laying slabs or other coating).

Warming with expanded clay is no different from the standard.If there is a reinforced concrete overlap with slabs of the upper floor of the house, then the work is somewhat easier.

This will ensure a more complete and thorough filling of all voids and irregularities. The layer thickness should be 25 cm. Expanded clay gravel is leveled and tamped. This can be done manually or using a special machine. It is recommended to screed over the first layer. This will give the structure greater strength and rigidity, a smoother surface. It is advisable to arrange several ventilation ducts between the inner and outer layers so that it is possible to remove excess moisture and ventilate the space. Roofing material is placed on top of the insulation layer

It is important that the rolls overlap and there are no gaps. On top of it - roof tiles or tiles

List of tools and equipment

Roof insulation will require a whole range of tools and materials. It includes: insulation (expanded clay gravel or crushed stone), a shovel, buckets, a log or a tamping stick, a rail for leveling a layer of expanded clay, a waterproofing film, a roll material (roofing material), a knife, tiles or shingles. Based on the foregoing, it can be concluded that roof insulation with expanded clay is an effective and simple way

This material is fireproof, lightweight, durable, resistant to low temperatures and moisture, which is especially important for our country. In addition to its heat-insulating properties, it has an inherent noise-shielding effect due to its physicochemical characteristics.

It is durable, which is why it is so widespread. Expanded clay is used not only to insulate the roof (roof), it is perfect for insulating floors, hangars, that is, any horizontal structures.

It has 1 drawback - it's fragility, so you need to work with it very carefully. Filling of expanded clay on the roof is carried out quickly, no complicated equipment is needed for this

It is only important to comply with the basic requirements (layer thickness, organization of ventilation holes, etc.)

The thickness of the expanded clay layer directly depends on the strength of the roof. A thick layer can be very stressful. It is advisable to combine loose expanded clay materials, for example, with foam crumbs for the best effect. The seams when laying roll material must be tight, for this they are glued with construction tape or mastic based on bitumen and rubber, which is more optimal.

Ceiling insulation - which insulation to choose. Insulation of the floor with expanded clay or mineral wool

Which insulation is better for the ceiling: mineral wool, expanded clay or expanded polystyrene

With an increase in the cost of heating the house, the owner comes to the conclusion about the need for additional insulation. In this case, the thermal insulation of the ceiling is very important, because the most intense heat is lost precisely through the ceiling, if it does not have a heat-reflecting screen. Warm air, according to the laws of physics, rises up. Therefore, insulated walls, reliable double-glazed windows, thick doors cannot provide effective heat retention inside the room if the ceiling is not able to retain heat inside the space. But which insulation is better for the ceiling: mineral wool, polystyrene, expanded clay? To answer this question, you need to familiarize yourself with the information on the properties of insulation and how to insulate the ceiling.

Insulation scheme for attic floors and ceilings.

Ceiling insulation: indoors or outdoors

Before choosing a material for thermal insulation, you should decide on the method of insulation. Ceiling insulation is possible from the side of the room or from the outside - from the side of the attic.

Ceiling insulation from the inside is usually practiced during construction or renovation.

If a decision is made to insulate a room that does not require repair from the inside, then the repair will still become a necessary final stage of the thermal insulation work.

Diagram of a ceiling device with insulation.

Thermal insulation of an attic floor is a traditional way of insulating a house. In this case, our ancestors used dry, bulky materials - wood sawdust, shavings, dry leaves, reeds, dried grass as insulation on the ceiling. These are natural materials that have some disadvantages: they are highly flammable, attract rodents, are a favorable breeding ground for microorganisms, and are significantly inferior in their thermal insulation properties to modern heaters. Over time, an alternative material for insulating the floor of the attic space has become a light, porous material, expanded clay (clay is the basis for its manufacture).

Expanded clay has a number of advantages over the above-mentioned natural materials - it is fireproof, absolutely uninteresting to rodents and microorganisms, and has low thermal conductivity. At the same time, the effectiveness of expanded clay insulation depends on the thickness of the layer of insulating material - from 20 cm to 40 cm.The thermal insulating properties of expanded clay are significantly inferior to modern materials, for example, mineral wool - inexpensive, fireproof, simple

pilorama-chita.ru

Insulation of the roof with a layer of expanded clay

Roof insulation is most often performed using the following types of expanded clay:

Expanded clay crushed stone. It is a large material. The size of its granules does not exceed 4 centimeters. Well suited not only for roof insulation, but also for wall and floor insulation in the house;

Expanded clay gravel. This material is also coarse. Its granules are angular and do not exceed 4 centimeters in size;

Expanded clay sand. It is a finely dispersed material. Particle size - up to 5 millimeters. When using this material as insulation, the layer thickness should not be more than 5 centimeters.

As mentioned above, it is quite possible to perform thermal insulation with expanded clay with your own hands.

Before starting thermal insulation work, you need to study certain subtleties of the insulation process

First of all, you need to pay attention to the structural features of the building.

Insulation of the roof of a house with expanded clay includes the following stages:

Internal cladding;

Laying a vapor barrier layer;

Insulation laying;

Surface finishing.

Detailed description of works:

- The thickness of the expanded clay layer when insulating the roof should be 25 centimeters. It should be poured directly onto the vapor barrier material. This work must be done quickly and very carefully so as not to damage the granules of the material.

- To improve noise and heat insulation, it is desirable to make the expanded clay layer thicker. However, you should remember about the maximum load that the roof of the house can withstand. In this case, it is best to choose the middle ground.

- Next, you need to properly level and tamp the expanded clay layer. Then there will be fewer voids between the particles of the material, and the thermal insulation will be better. You need to tamp the expanded clay with your hands or with a special machine. Further, it is recommended to apply a screed over the first layer. Due to this, the structure will become more durable and rigid, and the surface will be smoother.

- It is also necessary to make several channels between the inner and outer layers. Moisture will be removed through these channels, as well as air will circulate.

- At the next stage, roofing material is laid on top of the heat-insulating layer. It must be overlapped.In order for the seams of the roofing material to be airtight, they are insulated with bitumen mastic or construction tape.

- At the final stage, the installation of tiles or shingles is carried out.

- Features of thermal insulation

- Advantages and disadvantages

- Insulation technology

- Training

- Flat roof

- Pitched roof

Roof insulation with expanded clay is the oldest and most frequently used method of thermal protection at home. The comfort of living depends on the reliability of the roof, and this material helps to ensure this reliability for a long time. Today we will tell you how to use expanded clay for roofing.

Expanded clay as insulation

Classifying such a heater by the method of production and the size of the granules, there are several of its varieties:

- gravel;

- crushed stone;

- sand.

The first one is round grains 2-4 cm in size, having a porous structure, covered with a strong shell. It is the presence of closed cells containing air that makes it possible to use expanded clay gravel as a heater. It is obtained by swelling light types of clay. This fraction is characterized by the best thermal insulation properties.

Expanded clay crushed stone is a product of crushing expanded soft clay into fractions of 1-2 cm in size. As a result, elements are formed that have an irregular, often angular shape. If only grains of this type are included in the composition of the insulation, then the thermal conductivity of expanded clay will be slightly higher.

A by-product resulting from the production of the two main fractions is expanded clay sand, which is a grain size of 0.5-1 cm. It has the worst thermal insulation properties in comparison with gravel and crushed stone. This type is used mainly as a porous filler that is part of a concrete screed.

Influence of bulk density and layer thickness on total thermal conductivity

Provided that equal thermal insulation properties are achieved, the layer of expanded clay gravel will have a smaller thickness in comparison with crushed stone. The floor load in the first case is lower - this is due to the difference in the bulk density. This parameter characterizes the ratio of the total mass of granules (in this case, expanded clay) to their total volume without taking into account the gaps between them and inevitably emerging chips.

The density of expanded clay takes values from 250 to 800 kg / m3.

In practice, a mixture of three fractions is used as a heater: gravel, crushed stone, sand. In this way, the greatest rigidity and the smallest layer thickness are achieved, and the convection movement of heated air through the formed voids between the granules is prevented. Therefore, when calculating the height of the expanded clay layer, it will be more correct to be guided by the value of the true density, which is 1.5-2 times higher than the bulk density. Its recommended thickness when laying on the ground is 25-30 cm. When insulating a concrete floor, it should not be less than 10 cm.

Comparison with mineral wool and foam

Polyfoam has good insulation properties, which are expressed in a specific value - 0.047 W / (m * K). It is widely used for the decoration of apartment or private houses, office buildings. But, despite the seemingly great efficiency of the foam plate (relative to the expanded clay layer), this is far from always the case.

Where it is required to arrange surfaces that are exposed to frequent mechanical stress, significant loads, it is better to use a mixture of gravel and crushed stone. However, with thermal insulation of walls, the floor of the attic, polystyrene foam will be more effective. In addition, it has a low weight, is characterized by a smaller thickness compared to other heaters. All this allows it to be used where excessive floor loads are unacceptable.

When insulating with foam, no additional waterproofing device is required. However, like most polymeric materials, it is flammable.

Mineral wool is also widely used to protect housing from cold weather. But even in this case, it is not worth comparing the thermal conductivity of mineral wool and expanded clay, even though its value in the first case is much lower (0.048-0.07 W / (m * K)). Such heaters are used in different cases. So, for cladding walls, ceilings in private houses from the inside of the room, neither gravel, nor crushed stone, nor, moreover, expanded clay sand is absolutely not suitable. Minvata will be practically irreplaceable here.

However, it is a rather voluminous insulation material. Any attempts to compress it will lead to a decrease in the volume of air contained in the mineral wool, and therefore to a decrease in efficiency. In addition, the use of mineral wool should be extremely careful. This type of insulation has a negative effect on the human body. This characteristic suggests that all installation work should be done only with the use of personal protective equipment.

Nowadays, the cost of heating housing and premises in general is constantly increasing. At the same time, for some reason, salaries remain almost in place - a bad tendency, but one has to reckon with it. In such conditions, almost every owner of a house or apartment begins to worry about the issue of saving energy. Today, walls, floors, ceilings, slopes are massively insulated - such measures allow the most efficient distribution of heat throughout the room due to the fact that the level of heat transfer of the building is reduced.

This article will touch upon such a difficult issue as floor insulation - let's figure out what is better for this: mineral wool or expanded clay. In principle, foam is also often used, but this is not the best option, because the possibility of ventilation, airing the ceiling practically disappears. Although, undoubtedly, the thermal insulation characteristics of the foam are at a height.

So, mineral wool and expanded clay, which is better - you can start with a review of the first material and compare everything on specific properties.

This insulation is a soft coarse fiber board or rolls. This material is made on the basis of waste from metal and carbon alloys of various minerals such as basalt. In structure, it resembles glass wool, only the latter is much worse in terms of thermal insulation characteristics. In principle, mineral wool is widely used in construction, and it is especially popular when insulating facades. However, the facade is not floor insulation - there are still different specifics.

The main advantages of this insulation are considered to be several points.

- Durability.

A rather controversial property, since in order for the insulation to last a really long time, it is necessary to ensure that there is no moisture in the space where it is installed. Weak resistance to moisture is the main drawback of the material, because if the mineral wool gets wet, then in this place all thermal insulation qualities are instantly excluded. Of course, manufacturers have now learned how to process rolls with various moisture-proof compounds, but this does not always work effectively.

In addition, mats and rolls are afraid of mechanical damage, that is, simply speaking, they can break even due to the activity of mice. Therefore, the issue of durability is still mostly dubious. It is difficult to 100% protect such insulation.

- Fast installation.

This is true, however, it is also controversial - which is easier - to roll out the rolls on a plane or fill the space with expanded clay? There is not much difference in complexity. Therefore, in comparison with working with expanded clay, this quality is definitely not an advantage.

- Fire resistance.

Likewise, expanded clay is also not afraid of fire.

- Air permeability.

That is, that is - the basalt roll has good vapor permeability, due to which steam, in theory, will not accumulate in the floor space. However, if the same quality is applied to expanded clay, then the same situation is visible here - steam passes perfectly between the scattered granules of the material and, accordingly, the vapor permeability is also at a height.

It turns out that while the roll insulator "loses" to expanded clay due to the fact that it is afraid of moisture and is not too tear-resistant.

Now it's time to consider the structure of expanded clay.

Roof insulation with expanded clay technology and nuances

To carry out the work, you will need the following materials and tools:

- Vapor barrier layer;

- Waterproofing layer;

- Rack (will be needed for tamping and leveling);

- Shovel;

- Several buckets;

- A knife with a sharp blade;

- Expanded clay.

Before the insulation procedure, it is worth doing some preparation work. They will consist in cleaning and leveling the surface that needs to be insulated. In addition, all cracks and crevices will need to be repaired.

The subtleties of laying bulk insulation

The technology of roof insulation using expanded clay has a number of rules that must be taken into account when carrying out work. If they are not taken into account, the results of labor will not only not please, but there is also a risk that the insulation layer will have to be redone again.

When the angle of inclination is more than 5 °, the space between the rafters will need to be filled in the same way as the walls of frame houses are backfilled using bulk insulation. This is done gradually, in small portions. At the same time, the wall is sheathed in parallel.

All types of work must be done from the outside. In this case, weather conditions can become an important factor. In the process of warming, it is unacceptable to work in rain or fog, as well as other factors that provoke significant air humidity.

The backfill will need to be protected as much as possible from the possibility of moisture ingress. For this, a waterproofing layer is laid on the outside of the building, and a vapor barrier is installed from the inside, preventing the ingress of water vapor from the dwelling. Tightness can be ensured by laying the film with an overlap, the joints are additionally sealed with tape or bitumen mastic.

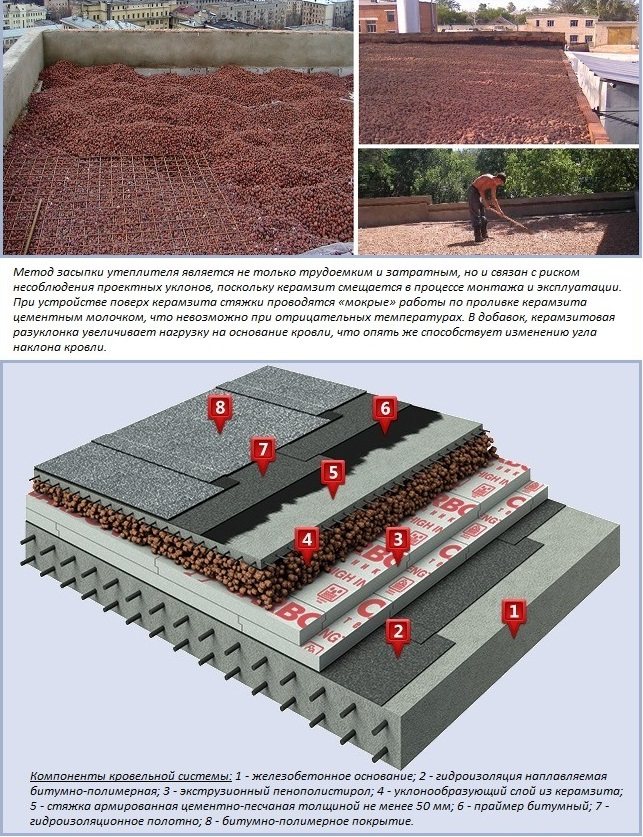

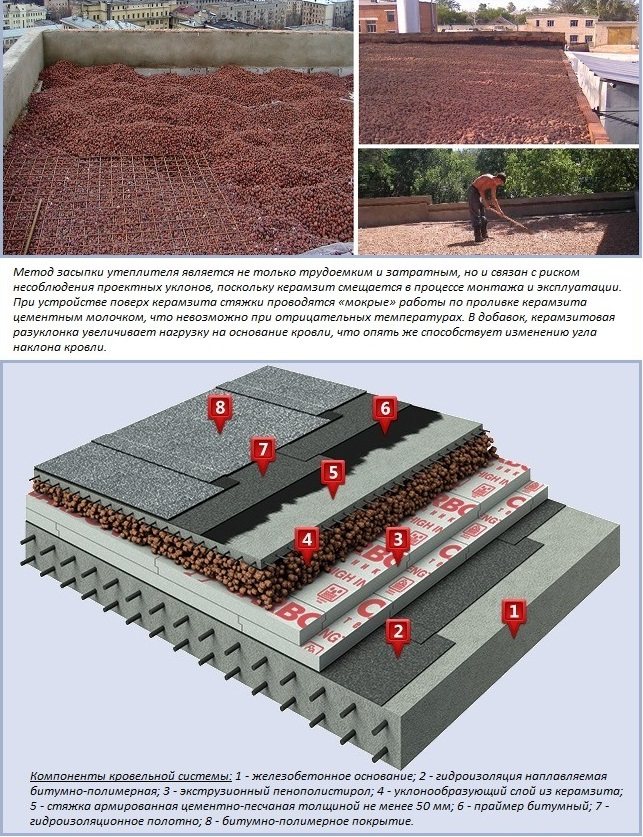

Since a sufficient layer of insulation has a significant mass, the roof structure must be distinguished by high strength indicators. It will be best if the flooring material is a reinforced concrete slab (if a flat roof is being installed).

Thermal insulation of a flat roof

Basically, expanded clay is used for insulating flat roofs. It is easy and convenient to work on a horizontal surface, which allows you to fully appreciate all the advantages of this type of insulation.

First, you need to clean the work surface of debris, paying special attention to the presence of small stones with sharp edges. If not removed, they can damage the vapor barrier. The vapor barrier layer must be distributed over the entire surface area requiring insulation

You can use high density plastic wrap for this. To make the protection highly durable, you can cover the surface in two layers. The key stage of thermal insulation is the backfill process itself. It is recommended to calculate the required thickness of the insulating layer in advance, taking into account all the nuances of a particular construction site. This will make it possible to carry out all stages of work in a short time. The most common thickness of expanded clay insulation backfill varies from 30 to 40 centimeters. If during operation it turns out that this layer is not enough, after the first winter you need to insulate the ceiling from the inside of the house using mineral wool or foam. After that, a screed is made using reinforcement.This technique allows you to carry out routine roof maintenance work without risks. The final stage includes laying one or two waterproofing layers. To give the roof a beautiful finished look, the roof covering is installed. For this, ceramic or soft tiles, sheets of slate or painted corrugated board, etc. can be used. materials.

Roof insulation with slopes

It will be more difficult to install thermal insulation if the roof is pitched

It is extremely important to achieve uniformity of the layer of backfill insulation in the inter-rafter space

When the space between the rafters is completely filled, a layer of waterproofing is laid on top of the sheathing and the final roof covering is installed. The vapor barrier is fixed from the side of the room, not forgetting about the tightness standards, using overlapping panels and carefully gluing their joints.

Expanded clay, although not a material with which it is easy and simple to work, but this is covered by its versatility. The main thing is to follow all the rules for working with this material, and then it will perfectly perform its functions as a heater for various roofing structures.

The choice of insulation, advantages and disadvantages

There are several ways to insulate the floor: foam, expanded polystyrene, expanded clay, ecowool or mineral wool, penoplex, chipboard, sawdust and other organic materials:

- Styrofoam - a product of foamed plastics, consists of 90% air. It is used not only for internal, but also for external insulation. Advantages of foam insulation: ease of installation and use, excellent moisture resistance, which means that it will not grow overgrown with fungi and mold, perfectly retains heat and does not lose shape throughout its entire service life. Of the minuses - low fire resistance, when burning, it emits poisonous vapors and an unpleasant odor.

- Expanded polystyrene - also works great at retaining heat, does not absorb moisture, similar in properties to foam. But it has the same disadvantage - flammability. When heated, it emits poisonous vapor, so it is better not to use such material. It costs about twice as much as polystyrene.

- Expanded clay - one of the types of clay, which undergoes heat treatment at high temperatures, is widely used not only in insulation works. It is fire resistant, easy to use, environmentally friendly, does not react to temperature changes, provides sound insulation and is relatively inexpensive. But there are also disadvantages - expanded clay is very fragile and quickly absorbs moisture.

- Ecowool - costs about the same as glass wool. It has many acceptable properties: it is made of cellulose, which means that it is environmentally friendly and non-toxic. But do not forget that this is still cotton wool, because it also absorbs moisture and is highly flammable.

- Mineral wool - a product of melted rocks, with the addition of a connecting component. Now it has become very popular in the construction market. Minvata is environmentally friendly, it has excellent fire resistance, moderate moisture absorption, and also, it does not settle during operation. Of the shortcomings - it can get heavy from a large amount of moisture, a low level of hygroscopicity, difficulties may also arise during installation, so a specialist should do this.

- Penplex - heat insulating material for various designs. Consists of expanded polyesterol. Of the properties - low thermal conductivity, good noise insulation and moisture resistance. When using penoplex, you can be sure of its durability. It can serve as a great alternative to Styrofoam.

- Chipboard, sawdust and other organic materials are not refractory and are far from ideal as a heat-insulating material, although they do not emit toxic gases during combustion.

Thermal insulation of the floor with mineral wool

Expanded clay

It is a lightweight material, the structure of which includes many pores, which determines its high thermal insulation properties.It is produced by firing shale or clay itself at a high temperature (1000-1300 degrees) for quite a long time (20-40 minutes). Depending on the type of feedstock and processing technology, the density of the resulting expanded clay can range from 0.35 to 0.6 g / cm3.

There are the following types of it (depending on the shape of the fragments):

Expanded clay gravel. Consists of streamlined oval honeycomb elements, their size varies from 5 to 40 mm in diameter. Usually this type is used when there is a need to create a layer of insulation over 5 centimeters.

Expanded clay crushed stone. The size of the pieces is approximately the same as expanded clay gravel, but their shape is more like a cube, the edges and corners of which are sharply protruding. The technology for its production is reduced to crushing larger fragments of expanded clay.

Expanded clay sand. The particle size is approximately 14 to 50 millimeters. The peculiarity of this type of building material makes it possible to create a layer of thermal insulation less than 5 centimeters thick without losing its insulating qualities. In addition, it is used in the range of 14-50 millimeters. Small dimensions allow the use of expanded clay sand with a thickness of the insulating layer not exceeding 5 centimeters. It is also used as a filler for concrete or other mortar.

Advantages of expanded clay

This material for thermal insulation is very economical. When using expanded clay, you can carry out sound and heat insulation of the home with the least investment of finance. The material has a high rate of fire safety and a high degree of environmental friendliness, since various types of clay are used for its production. It also has a significant service life. This is due to the fact that the material does not condense moisture.

Any material used for construction must meet environmental safety requirements. Expanded clay is made exclusively from pure clay, which does not contain various chemical additives. Therefore, it is completely harmless to human health. In the production of oval varieties of expanded clay, clay is fired.

Expanded clay gravel allows filling various types of voids. In this way, the thermal insulation of the roof is carried out. Often, during the installation of insulation, expanded clay gravel is mixed with foam crumbs, which increases the thermal insulation properties of the layer.

Material disadvantages for roof insulation

One of the important disadvantages of expanded clay is considered its increased fragility. This point must be taken into account when carrying out work, and carefully handle the building material. When the material is poured into the cavity, some of its elements may be damaged, which leads to a partial loss of their properties.

Expanded clay should only be used as a dry backfill material. It is impractical to mix it into cement or mortar.

Nevertheless, even without being a professional builder, you can still use expanded clay. Everyone will be able to produce high-quality insulation of the building, while spending a minimum of time on the process.

Mineral heaters

These include mineral wool, expanded clay, cement-based mixtures.

Mineral wool is considered one of the most popular materials for floor insulation. Most often it is used to insulate floors on the ground floors or attics. The material is durable and will justify the funds spent on it. In its composition, cotton wool contains rocks, slag or glass. Depending on the raw material, it is subdivided into glass wool, basalt (stone) and slag.

Minvata is produced in the form:

- Slabs

- Rolls

- Matov

These forms of material greatly simplify the work of insulating floors. Insulation placed on a concrete base, covered with a layer vapor barrier material... A wooden or artificial floor is mounted on top.

Among the advantages mineral wool- its incombustibility. It prevents the spread of fire, thereby increasing the fire safety of the entire room.Mineral wool has high thermal insulation properties and excellent sound insulation. She does not freeze and does not deform from temperature changes, not susceptible to mold and mildew, vapor tight.

The disadvantages of a heat insulator are considered to be impressive layer height and the need for additional waterproofing, since not all types of cotton wool are moisture resistant. Glass wool is the most resistant to moisture, but it is not very convenient when laying because of the flowability of small fragments of glass. The presence of formaldehyde in the composition of cotton wool raises doubts among those who seek to create an environmentally friendly space in their home. However, contact with undesirable chemical elements can be avoided with competent work with the material.

Expanded clay- granular clay based insulation. At cost, it is considered one of the most affordable. Expanded clay backfill for thermal insulation increases the height of the subfloor by at least 12-15 cm, so it is carried out during construction work or major repairs.

Expanded clay has good thermal insulation and strength... It is environmentally friendly, resistant to low and high temperatures. The material is considered an excellent sound insulator. Among the disadvantages of insulation are its fragility and high moisture permeability, which in some cases is absolutely undesirable.

Expanded clay can be used with cement mortar. In this case, the floor is poured with a mixture consisting of 1 bag of cement, 2 bags of sand and 3 bags of expanded clay. Such expanded clay cement screed is strong enough and provides good thermal insulation of the floor in the apartment.

The use of expanded clay for the insulation of the roof at home

The scheme expanded clay roof insulation.

You can organize on their own, without the need to hire professionals to do so. Before you insulate it, you need to know what the concrete block and why it is so highly prized for thermal insulation of buildings and structures. Expanded clay is a natural material. It has high strength and can last for a long time, unlike synthetic insulation. At the heart of it - clay. For all these reasons it does not rot, it can withstand very low temperatures, which is especially appreciated in cold climates. It is crumbly and porous structure. Porosity contributes to the conservation of heat. The great advantage of this material is its fire resistance.

Warming of the most frequently performed expanded clay gravel, sand or gravel. In addition to the above, concrete block - pretty light material, making it easier to carry out works. Today, many plastics are not environmentally friendly, which is not about the concrete block. It is completely safe for humans when operating. Expanded clay waterproof, so do not need to do additional waterproofing layer. Cost of it is low, which is important in the consumer market. In addition, it provides a minimum load on the house and the roof itself. The main disadvantage is its fragility.

The technology of expanded clay roof insulation

Driving a single-layer insulation of the attic.

Before you insulate roofs expanded clay, you need to know some features of this work. In the first place, to obtain good effect when it is advisable to take into account the particular roof insulation the house, its structure, walls and a sloping roof. Modern (Roof) includes several basic steps: the inner lining, vapor barrier, laying down a layer of insulation and finishing work on the surface (stacking plates or other coating).

is no different from the standard. If there is a reinforced concrete ceiling slabs of the upper floor of the house, the work somewhat easier.

This will provide a more complete and thorough filling all voids and irregularities. The layer thickness should be 25 cm. clay gravel leveled and compacted. This can be done manually or using a special machine. It is recommended to make a screed on top of the first layer. This construction will give greater strength and rigidity, a flat surface. It is advisable to organize some ventilation ducts between the inner and outer layers to be able to remove excess moisture and ventilation space. On top of the layer of insulation roofing material is placed. It is important that coils overlapping fit and there are no gaps. Above him - shingles or tiles.

List of tools and equipment

Thermal insulation of the roof will require a whole set of tools and materials. It includes: insulation (expanded clay gravel or crushed stone), a shovel, a bucket, a log or stick to ram, rail to align the expanded clay layer, a waterproof film web material (roofing material), Knife, tiles or shingles. Based on the above we can conclude that the insulation of the roof with the help of expanded clay - effective and simple way. This material is different fire safety, lightness, strength, resistance to low temperatures and humidity, which is especially important for our country. In addition to thermal performance, it is inherent in the soundproofing effect due to the physico-chemical characteristics. It is durable, so found a wide circulation. Expanded clay is used not only to insulate the roof (the roof), it is perfect for warming the floor, hangars, ie all horizontal designs.

Thermal insulation of beam and concrete floors with expanded clay

Insulation of the attic with expanded clay in a house with beamed ceilings.

Insulation of the attic with expanded clay and the floor differs very little by technology if the work is carried out in a house with beamed ceilings. In houses where a concrete slab acts as a floor, the insulation technology is somewhat different. Therefore, we will consider how to insulate the ceiling with expanded clay from two angles:

- in a house with beamed ceilings;

- in a house with concrete floors.

In a home with beamed ceilings, there is space between the subfloor and final floor, or the ceiling and the second floor. The height of the buffer zone is equal to the cross-section of the bearing beams. Expanded clay for insulation of the ceiling or floor is poured there. The three components of an insulating cake:

- expanded clay;

- diffusion membrane;

- vapor barrier.

The main thing is not to mix up the films. The vapor barrier must be placed between the insulation and the heat source. Waterproofing is laid between expanded clay and an unheated room.

That is, when insulating the attic with expanded clay, the vapor barrier is laid from below, and when insulating the floor - from above. Naturally, the joints of both layers of the films must be airtight. When insulating the ceiling of a bath with expanded clay, Penofol should be used as a vapor barrier - this is a reflective insulation, which consists of two layers. The first layer is a pillow made of expanded polyethylene with a thickness of several millimeters to a centimeter.The second layer - foil, which beats off infrared rays, is laid with the shiny side to the heated room. An important condition is the presence of an air gap between the finishing and the reflective surface of 1.5 cm or more.

In houses with concrete floors, expanded clay insulation is carried out under the screed. There is nothing complicated in the technique, the main thing is to lay a plastic wrap between concrete and expanded clay and glue the damper tape around the perimeter of the room. The screed is poured over the beacons.

(, be the first)

Styrofoam or polyurethane foam?

Alas, the disadvantages of foam are much more than advantages, although it has been used for more than 50 years. Insulation of the ceiling in an apartment with expanded polystyrene is in demand due to its low price and low thermal conductivity. However, the thickness of the insulation for the ceiling “picks up” the height, expanded polystyrene is very flammable, and releases incredibly toxic smoke during combustion. If you are interested in how to insulate a ceiling from the inside with a non-toxic material, foam is clearly not your favorite.

In more detail: "Ceiling insulation with foam"

The sprayed material, which is applied using special equipment, is polyurethane foam. This heat insulator is applied in 2-3 layers. It has proven itself in harsh climatic conditions. When applied, polyurethane foam fills in overlaps, cracks and even small gaps. The hardened mount has a high density. You can easily walk on it without fear of cracks and dents. After the polyurethane foam has been applied from the inside with your own hands and hardened properly, the excess material is easily removed with a knife.

How much will it cost to insulate the walls with expanded clay

The costs of creating expanded clay insulation are largely related to the height and perimeter of the building, the number of floors and the selected material. The amount also depends on the method of insulating the walls with expanded clay - the optimal three-row, lightweight or combined. In most cases, the width of the expanded clay concrete layer is about 300–400 mm, of the expanded clay cement layer - 100 mm, which corresponds to a brick enclosing structure with a thickness of one meter.

With an average cost of 1 cubic meter of expanded clay about 2000 rubles, and expanded clay concrete about 3500 rubles. it is easy to calculate that for a wall, the inner layer of which is 250 mm thick and the average one is 100 mm, the costs will be approximately as follows:

- for 1 sq. m of the wall will be 0.4 cubic meters. m of expanded clay concrete blocks costing about 1400 rubles;

- the same area contains 0.1 cubic meters. m of expanded clay for 200 rubles;

- for a building with a height of 3 m and a perimeter of 32 m (for example, 8 x 8 m), the costs only for expanded clay concrete and expanded clay for wall insulation will be: 3 x 32 x (1400 + 200) = 153.6 thousand rubles.

The cost of cement depends on the selected proportion, but in any case, it is several times less than the cost of expanded clay.

The price of the outer layer, which is taken as facing brick or wood, may differ significantly depending on the chosen finishing option. Sometimes it is comparable in cost to insulation (from 1000 to 1600 rubles / sq. M), but it can be several times higher than the cost of expanded clay and expanded clay concrete, reaching 3000-6000 rubles. for 1 "square".

How to insulate the surface with basalt wool, polystyrene foam, expanded polystyrene?

Since it is best to insulate the ceiling in an apartment from the inside with glue, we will try to choose the most optimal substance. Suitable also "liquid nails" and polyurethane foam, and even a special glue on a cement basis. The substance is dotted on the slabs with a trowel, polyurethane foam is applied with a gun.

Next, you press the insulation panel against the surface above your head and hold it with a little effort for a few seconds. For additional fixation, "mushrooms" fasteners are used. How can you fill the gaps that have formed between the slabs? For these purposes, it is best to use polyurethane foam.