General principles

Beams, they are also logs, are laid parallel to each other between two walls on a layer of concrete screed or on a base plate. Previously, logs were only wooden, but now metal and polymer materials bring variety, which more successfully withstand the deformations and creaks that arise over time on the finished floor boards laid over the boards.

The role of beams can be played by boards of great thickness laid on the edge, but more often it is an ordinary beam, fixed in level in a single plane of the floor. The space between the lags is filled with insulating materials. Sometimes a layer of insulation is located under it. It serves as an additional barrier against high humidity.

Insulation bookmark

The width of the cells for laying mineral wool mats should be 1–2% less than the size of the insulation. Due to the tight fit, excessive floor ventilation is eliminated and the possible shrinkage of the cotton wool over time is compensated. When laying the mats, they must be carefully and evenly squeezed across the plane, put into the cavity and then straightened inside. It is desirable that, after laying, the cotton wool forms a small hump, protruding upward, which will be pressed by the boards. If foil wool is used, it is placed with the reflective surface facing up.

In the case of expanded polystyrene, which is practically not compressible, the formation of minor gaps is possible. They are eliminated by blowing in summer polyurethane foam at the end of filling all the cells. Too thick gaps in order to reduce foam consumption can be eliminated by thin cut-out inserts made of EPS.

To backfill the insulation in the space between the lags, it is necessary to localize the cells by covering the bottom with a vapor-permeable membrane with a fold on wooden beams. In its simplest form, geotextiles or a vapor barrier can be used to protect the roofs. To prevent the membrane from shifting when filling the insulation, it is recommended to shoot it with staples to the wooden elements of the floor system.

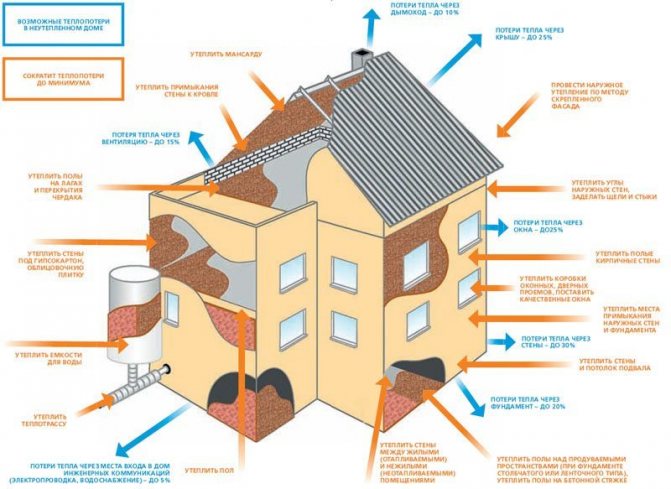

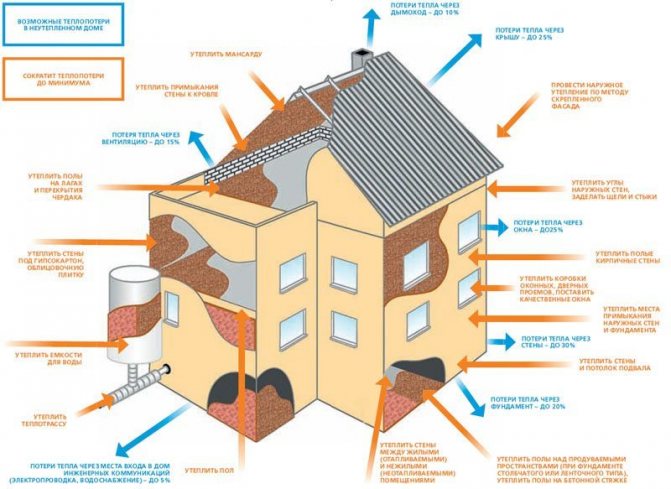

Why insulate a wooden floor

Wood, in comparison with concrete, is a rather warm material, but when building a frame private house or a house from a bar with your own hands, it is not always possible to achieve a rational balance of the thickness of the structure in terms of strength and thermal conductivity. To reduce the consumption of materials on walls and foundations, thermal insulation is necessary. It is possible to carry out insulation work both in the old, long-commissioned building, and in new construction.

Insulating a floor in a wooden house can prevent the following problems:

- the appearance of excessive dampness in the room;

- lowering the temperature in the task;

- condensation, as a result of which mold appears;

- the appearance of a fungus and other microorganisms dangerous to humans;

- increased heating costs;

- destruction of wooden structures from the inside.

Do-it-yourself work can significantly reduce costs. Now there are many materials, the use of which does not require special skills and high qualifications.

Diagram of all heat losses of a wooden house.

Tips: timber floors in a house

11 simple flooring tips from professional builders

During the construction and interior decoration of a log house, many questions arise precisely on the technology of installing the floor covering.Does the floor differ in a log house and a brick (block) cottage? How to make a warm floor in a wooden house? Can ceramic tiles be used? What to consider when choosing materials? There are many questions. We have collected advice from professional builders on installation, insulation, sound insulation and, in general, the technology of laying the floor in country houses.

Do not give up modern and proven technologies when decorating a log house

In a wooden house, it is possible to install any topcoat, lay internal communications, heating circuits. If necessary, a standard floorboard is installed, a base of wood-based panels, a screed is poured - restrictions are only possible on the total weight.

The base of wooden logs is rather a design advantage, the ability to additionally use the internal space, improve thermal insulation and sound insulation (in the interfloor overlap). Are you convinced that a floor in a house from a bar can only be made of wood? Do not believe it, choose any material you like.

What is a rough and final floor in a house from a bar

If the project says "rough floor", then the owner receives an insulated structure with hydro and vapor barrier, prepared for surface finishing. GOOD WOOD uses plywood sheets as a rough finish.

The sub-cover is nailed to the joists and is designed to distribute the weight evenly over the supporting structure. Usually, objects are handed over in this form, if the final finishing is not included in the project, that is, partitions and ceilings are to be decorated.

The finishing floor is laid when ordering the construction of houses on a turnkey basis from glued beams, logs or regular beams. We put tiles, laminate, parquet on the rough surface - any material specified in the specification.

Concrete screed: anti-cracking thickness

If you have chosen a concrete screed, then you should not skimp on layer thickness. Cracks do not form immediately, they are hidden by the topcoat and appear when the destruction reaches a critical point. The surface begins to creak, irregularities, swellings, voids appear, a booming knock from steps.

An additional 1-2 cm of screeds, a reinforcing layer and adherence to technology prevent cracking.

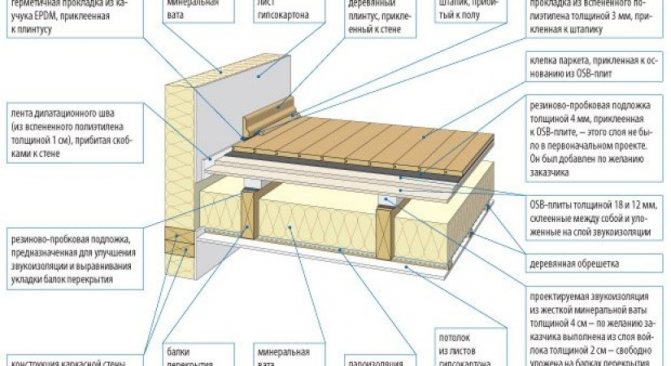

Concrete screed: don't forget about damper strips around the perimeter

Layers of waterproofing and foil insulation separate the concrete slab from the supporting structures from below. A special damper tape should be laid on the sides, which compensates for thermal expansion and completely isolates the base of the floor from the walls. As a result, the appearance of internal stresses during heating is prevented (especially in structures with a warm floor in a country house) and the transmission of vibration to the beams (sound insulation increases).

Not to be confused: waterproofing - from water, vapor barrier - from condensation

The correct arrangement of layers protects the logs of the floor in the house made of timber, the crate and insulation from getting wet, premature wear and freezing. Do not expect that one waterproofing or vapor barrier film is enough - each layer has its own purpose. For full protection, the layers should be correctly positioned, taking into account the direction of the air flow when laying the membranes.

How many layers of insulation are needed

The overlap of the layers eliminates the possible coincidence of the gaps. Usually they use 4 layers of mineral wool 5 cm thick - this "pillow" provides high-quality thermal insulation, dampens extraneous sounds.

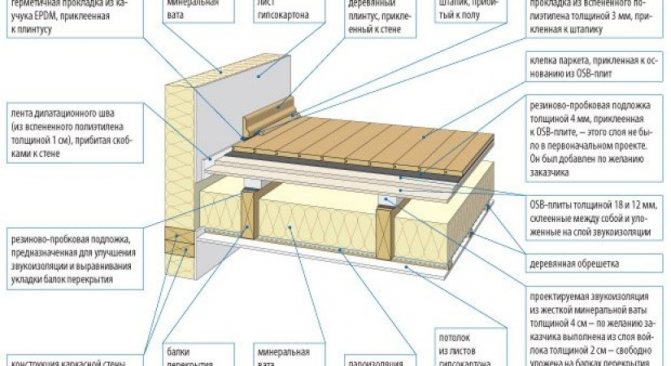

To improve sound insulation, additional rubber gaskets, special fasteners, lining layers for laminate and parquet are used. The linings stop vibrations, the mineral wool fibers muffle the sound. Without such protection, the floor becomes a drum. More details about the construction are described in the section “Rough floors. Soundproofing".

Do you need a warm floor in a house made of timber?

Why not? Warm floor is convenient and comfortable, do not refuse an additional opportunity to make life more pleasant. In private houses, we usually lay a water-heated floor - we connect the pipeline to a separate collector, gently adjust the temperature. At the same time, the rooms are warmed up more evenly, the dependence on the operation of the main radiators decreases.

It is possible to install a warm floor in a bathroom in a house made of timber, a bathroom, a living room, a bedroom, a nursery, in the kitchen - in any room where it is supposed to walk without shoes. With a competent calculation of heating, it is possible to reduce the cost of equipment for the main heating network.

How to choose coverage

If the house is planned to be used constantly, then there are no restrictions on coverage - choose any option. Anything that is used in city apartments with centralized heating will do, including "delicate" materials that deteriorate from temperature and humidity changes. If the house will not be constantly heated, then it is better to give preference to more sustainable materials.

When building a house from glued laminated timber on a turnkey basis, several types of finishing coating and subfloor structures can be used at once. Laminate or parquet for the living room, ceramic tiles for the kitchen and bathroom, combined decoration of the hallway - in a modern wooden house it is possible to use all the design options that you are used to.

Pay attention to the tile adhesive

When choosing an adhesive, we take into account the operating conditions:

- for the street;

- for interior work;

- for laying tiles on a warm floor.

Depending on the purpose, elastic inclusions are added to the glue, which prevent chipping during thermal expansion.

Ceiling: reverse side of the floor

For decorating the ceiling in a wooden house, imitation of a bar is best suited, but sometimes drywall is included in the project (most often in combined houses, when a flat ceiling is better suited in style). In both cases, it is important to follow the installation sequence, to protect the inside of the structure from condensation.

In conclusion - about ventilation

Removing excess moisture is the main requirement for a quality installation. When assembling the floor on the first floor, special attention is paid to waterproofing - moisture is not allowed inside. But high humidity in the space under the floor can destroy any structure, therefore, technological holes are provided in the foundation.

Air vents provide natural ventilation and moisture removal. Make sure that the holes are no further than 90 cm from the corner, 15 cm above the ground level, at a distance of 2-2.5 m from each other. Do not block or cover the air vents with finishing materials.

The floor is an important part of the house, for which a full-fledged section of the project is being developed. Questions about design, heat insulation and sound insulation often arise at GOOD WOOD seminars. Engineers tell about the technology in detail, show samples of materials.

The design options can be seen in the examples of the work performed - photos of houses made of glued laminated timber "turnkey" are in the gallery on our website. In the demonstration houses, you can see options for floor finishes, combinations with wall decorations, examples of materials for different rooms.

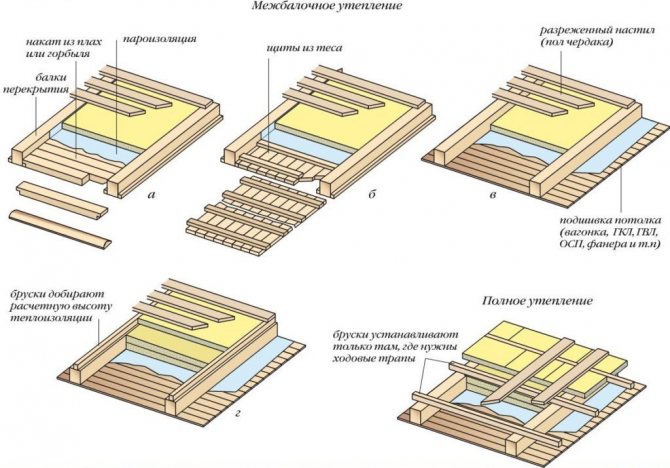

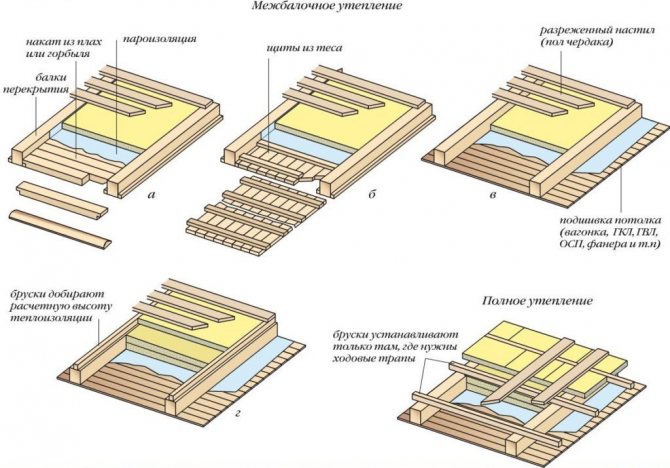

What floors require insulation

The following constructs need protection:

- cold basement overlap pie;

- attic floor;

- construction of interfloor overlap.

In the case of the interfloor version, the material is used as sound insulation. In this case, it is necessary to provide a layer with a thickness of 3-5 cm.

Insulation of the floor of the first floor in a wooden house allows you to provide comfortable living conditions. Most of the heat loss occurs through the ceiling of the upper floor, therefore it is necessary that the thermal insulation is selected and installed correctly.

General requirements for flooring in a house from a bar

To determine what the floor of a wooden house will be, you need to know the conditions, the requirements that must be observed during installation:

- A wooden house is being erected on a lightweight foundation (pile, tape), where, by design, there is a subfloor.

- The floor must have a flooring, a frame without a monolithic surface, where the insulation is laid. If you lay logs on the beams and make a flooring, then centimeters of the height of the house are lost. To avoid this, it is laid on beams.

- When arranging the flooring, a vapor barrier is made from below, which protects the subfloor from decay, and a waterproofing layer is laid on top of the insulation for protection.

- The floor should provide sound insulation between rooms on floors, be warm.

- Under loads, the flooring should not creak, sag, deform. For this, the step of installing the lags (40-70 cm), the thickness of the boards (2.5-4 cm) is selected.

- Materials of construction protect against moisture.

Benefits of wood

Slabs are horizontal structural elements of buildings and structures, dividing them into floors or separating them from technical rooms (attic or basement). Depending on what material the building is built from, the floors can be monolithic, prefabricated reinforced concrete or wooden.

For the construction of a private house, floors on wooden beams are most suitable, since their weight is less than that of structures made of other materials, and building them with your own hands is cheaper and easier.

Wooden interfloor floors can be arranged in houses from any material, with the exception of monolithic reinforced concrete. They are erected simultaneously with the construction of the walls, as the latter are erected to the height of the next floor. In timber frame buildings, floors can be performed simultaneously with the construction of the frame of the entire building, even before it is insulated and cladding.

Preparatory work

When building a private house without a basement floor, a timber floor is considered the best option. The flooring manufacturing process is divided into stages that are interconnected. Violation of technology, a small error in laying may manifest itself in the future as a serious defect. Work should be carried out in compliance with the requirements, and begin with preparatory work.

Tools

The following tools are required to install a wooden floor:

- Circular saw (hacksaw).

- Level, cord.

- Hammer, nails.

- Screws 10-12 cm, screwdriver.

- Grinding device.

House project

The manufacture of floors begins at the time of designing a building from a bar. First, the location of the floor beams is determined, which are mounted when laying the first crown of the structure, connecting with wooden locks.

Then its structure is determined: the distance for waterproofing, insulation. They are planning the device of lags that will be mounted during the construction of the walls.

These points are reflected in the design of the building in order to maintain consistency.

Attention! For lags, floor beams, rectangular beams are used, located with a long vertical edge.

It is also worth thinking about the construction of the foundation, the presence of concrete (brick) posts to support the lags. With such a foundation, the beams are installed between the second, first crowns. When the logs are embedded during the construction of the walls, they have shrunk, then their position is checked with a hydraulic level.

Material handling

The manufactured beams, logs, before their installation, are treated with a special impregnation, which protects the wooden surface from moisture, insects, and endows the wood with fire-resistant properties.

The lower rows of beams are also processed, from which the walls are installed. For a high-quality connection, dovetail locks are used.The installation of lags is carried out at the water level, placing the bars on the same horizontal. After preliminary preparation, they begin to build a floor in the house from a bar.

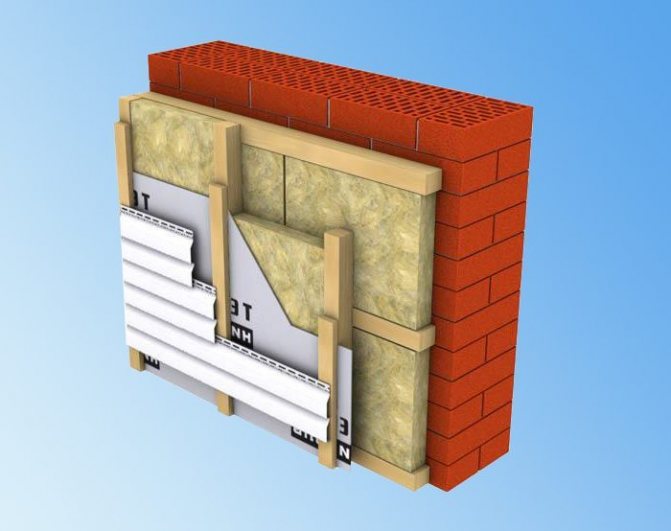

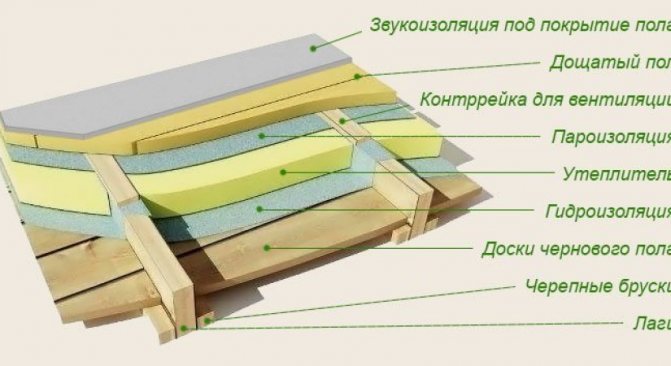

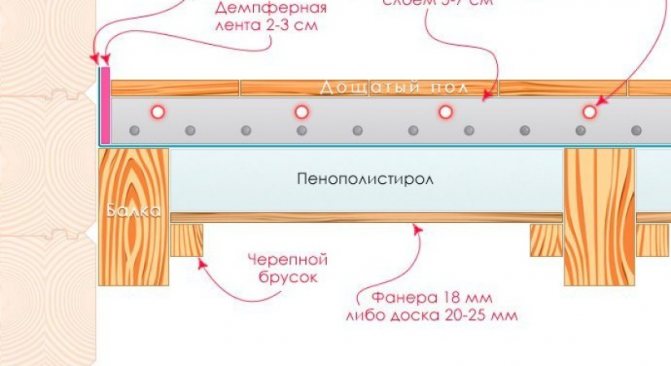

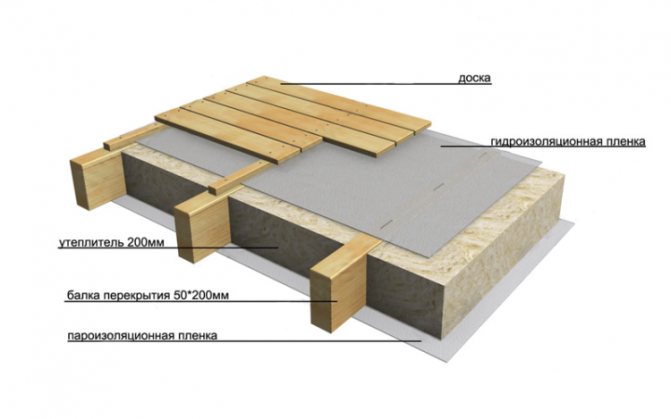

Insulation layers

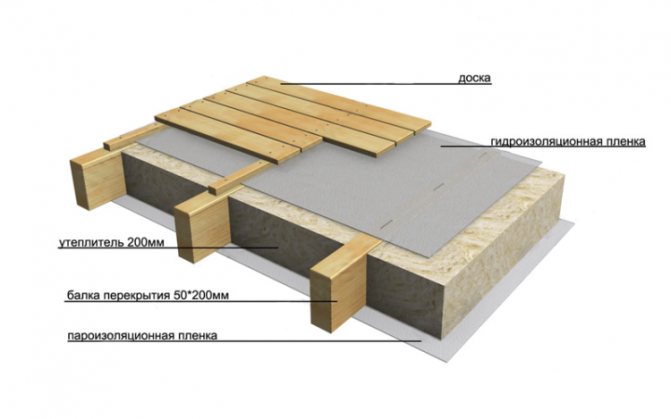

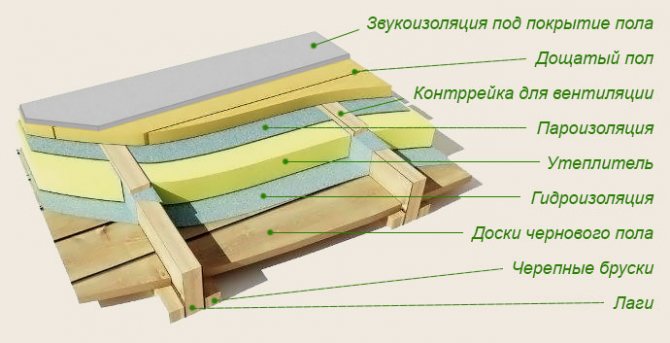

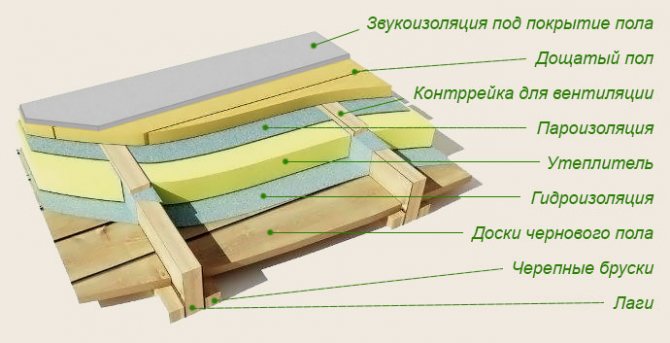

So, if you imagine a cross-sectional insulation cake, it will consist of the following layers:

- floor boards of the upper floor;

- lags;

- vapor barrier of the floor;

- beams with a layer of heat and sound insulation between them;

- vapor barrier of the ceiling;

- ceiling lining.

In multi-storey buildings, the insulation of the interfloor overlap is relevant only if this overlap is made between the basement and the first floor, as well as in the case of overlap between the upper floor and the unheated attic.

If the overlap separates two residential heated floors, then the role of the insulating material for insulation is negligible. In this case, the sound insulation properties of the structure are much more important. Despite the fact that heat and sound insulation materials are included in the same group when classified according to purpose and technological characteristics, their properties may be different.

These differences must be taken into account when using this or that material in a particular interfloor floor.

Why is it impossible to do without floor insulation?

Some believe that if you make a solid foundation, and the floors are equipped with thick materials, then you can do without insulation. But in reality, the floors in such houses - especially in winter - will be cold enough.

Important! The floor is the coldest part of the house, especially the ground floor. After all, cold air, as you know, always goes down, while warm, on the contrary, tends up. Therefore, it is not surprising that the air near the floor is always colder.

The floor is the coldest part of the house, it requires high-quality insulation

We advise you not to save on the purchase of insulation, because without it:

- cold bridges will form;

- you will lose heat resources;

- the temperature in the house in winter will drop dramatically;

- the humidity in the rooms will rise;

- wooden elements will quickly collapse;

- Condensation will build up on the floorboards, leading to the formation of unhealthy mold.

Quality insulation can solve most of these problems. But it is important to choose it correctly and install it in accordance with building codes. Tellingly, with good thermal insulation of the floor, heating costs will be noticeably reduced - by about 30%.

Expert opinion: E.V. Afanasyev

Chief editor of the Stroyday.ru project. Engineer.

By the way, I already talked about the procedure for warming the floor in a frame house. I recommend that you study the detailed instructions with a photo.

Correct floor design

Interfloor floors made of wood are arranged along the beams. They are usually used as a bar. The size of the section depends on the size of the span to be covered, as well as on the expected load on the floor and the types of wood used. Most often, a bar with a section width of 100 mm and a section height of 150-200 mm is used.

Further, the overlap itself is formed by installing the floor boards of the upper floor and hemming the materials of the lower floor ceiling. You can often see that the floor boards are laid directly on the beams, but it is more correct to first mount the logs on the beams, and then make the flooring of the boards along them. The second option is the most preferable, as it will make it possible to produce the correct interfloor insulation on wooden beams.

The fact is that in the cake, to which the filling of the interfloor overlap is so similar, layers of vapor barrier must be present.

They are made of a special membrane with a certain coefficient of vapor permeability, and the upper layer of the membrane allows steam to pass only in one direction - from the insulation into the air. Therefore, an air gap is needed between the membrane and the floor board, which will remove steam from under the boards.Otherwise, the latter will simply start to rot.

In this case, the membrane is laid on the floor beams, and the air gap is formed due to the thickness of the lags, laid perpendicular to the beams.

Steam is removed from under the boards through holes specially cut in the floor or slotted skirting boards used for edging the perimeter of the room.

Note! The bottom layer of the membrane must be made of a material with a very low vapor permeability coefficient.

This is necessary so that moisture from the lower rooms does not seep up through the interfloor ceilings, and also does not linger in the layers of insulation. All air from the floor must be vented to the atmosphere only through ventilation ducts or windows for ventilation.

Warming between lags

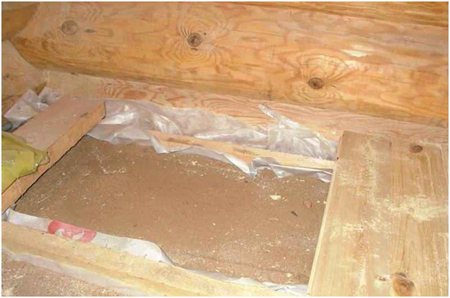

The device is a rough wooden floor (the logs can be replaced with beams or you can place the logs on the beams).

In this case, a lot depends on the design of the foundation. Simplified, the foundation in a log house is a box on which a log house is placed. Such a base of a wooden house can be erected from concrete blocks, cinder blocks, laid out of bricks with pillars in the corners and in the middle, poured with concrete into the formwork. Directly during the construction of the foundation, logs are laid in it under the flooring or places are left for laying them.

There are many options, but the result is the same. There is a rectangular box on the ground with an air cushion between it and the floor. Thus, the base of the house can be formed if the height of the foundation is increased.

If the house is not new and has already stood for a long time, then for greater reliability it is worth completely dismantling the old structure up to replacing the lags. The lack of thermal insulation could not but affect the condition of old materials and the reliability of the structure, even if their appearance is not in doubt.

Replacing the lag should not cause complications.

Unless, of course, they are embedded in the concrete of the foundation, in this case it is better to talk not about replacement, but about restoration. In all other cases, the old structure is disassembled and replaced with a similar one, but made of new material.

When choosing a tree for a lag, you need to pay attention to the degree of its moisture. Freshly cut material should never be used. At least the floor will lead, at the maximum, it will destroy the entire structure and touch the foundation with a plinth. After installation, the logs must be treated with a special emulsion, which will increase the refractory characteristics and protect the tree from pests and fungal formations.

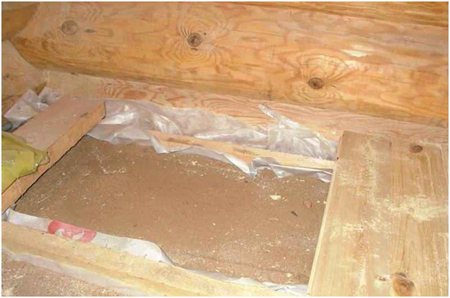

Expanded clay is laid on a plastic wrap overlapped on the walls. The resulting joints are sealed with tape.

After replacing the lag, we measure the space between the lags and the ground. If the distance is up to 200-300 mm, then all this space must be filled with bulk material with low thermal conductivity. Expanded clay will be the best solution to this issue. You can also use coarse expanded polystyrene granules as a primary floor insulation.

Both expanded clay and expanded polystyrene have excellent moisture resistance characteristics, and the thermal conductivity index ranges from 0.07 to 0.082 W / (m • ° C).

The primary insulation is poured to the bottom of the lag with a small, a couple of millimeters, entering the sides, time is given for it to settle down and settle. After settling, it will lie exactly on the lower level of the log.

A waterproofing film is laid between the logs along the entire length of the floor. So that its lateral edges can be attached with a furniture stapler to the supporting joists.

Now the turn has come to the selection and installation of the main insulation for the first floor flooring.

Materials for work

In order to properly insulate the floor in a wooden house, you need to choose a high-quality insulation that has all the necessary properties. Insulation can be carried out both from inside the room and from the cold air side.

For do-it-yourself insulation of the attic floor from the inside or the basement from the bottom, it is better to use light materials that will fix without problems from the bottom to the floor cake. In this case, it will be correct to apply:

- mineral wool in rolls;

- Styrofoam;

- polyurethane foam.

These materials will provide the maximum convenience of work when insulating the ceiling with your own hands.

When insulating a frame house, a house made of timber or logs, work can be carried out from the inside of the room for the floor of the first floor and outside for the last. In this case it is better to carry out floor insulation along logs or beams, since this will prevent the transfer of load to fragile material. For this type of work, you can use the following materials:

More information about insulation with sawdust and expanded clay can be found in the articles "Insulation of floors with expanded clay" and "Insulation of floors with sawdust". These materials have such advantages as natural origin and low cost, so if you need to reduce the cost of construction or insulation in an old building and ensure complete environmental friendliness, it is better to use them. However, they are less technologically advanced than other materials.

Recently, the method of floor insulation with foam (polyurethane foam) is also gaining popularity. This method is good for its low labor intensity and high efficiency.

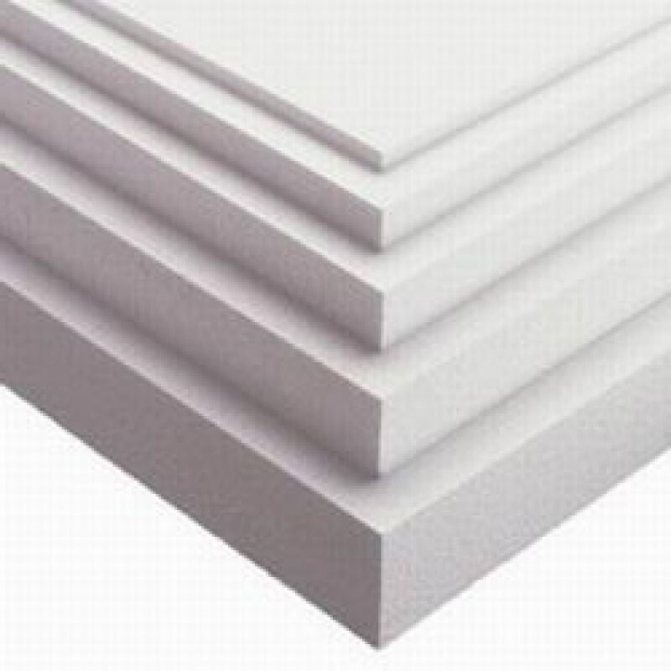

Insulation of the floor with expanded polystyrene also deserves attention due to the relatively low cost of the material and ease of installation. The method of floor insulation with Penoplex (extruded polystyrene foam) is less popular in wooden floors due to the high cost of the material - it is more suitable for insulation under the screed.

Features of insulation and insulation

The next stage of arranging the floor in a timber structure is the installation of insulation. Its layer minimizes heat losses that can occur through the floor. Many people are wondering how to properly insulate a wooden floor in a house from a bar, what kind of insulation to use? Use any available material:

- Mineral wool: made from 3 different types of materials. This is a melt of metal rocks (stone wool), blast furnace slag (slag wool), parts of glass (glass wool). The material is produced in the form of rolls, panels with a thickness of 2-20 cm. In addition, it can be foil on 1 or 2 sides, which increases the effect.

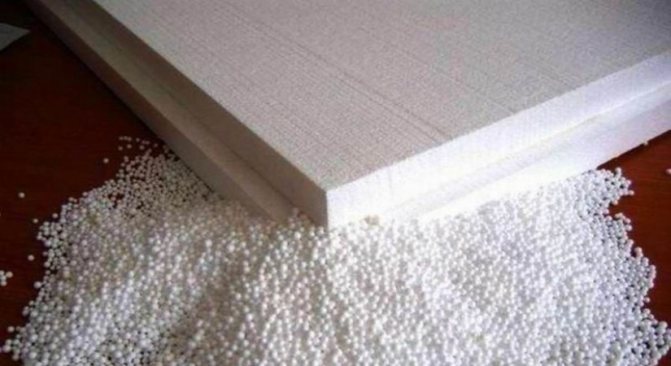

- Polyfoam: it consists of 98% of air, therefore it is the lightest insulation. It is distinguished by its density: maybe 15 kg per cubic meter. meter, and maybe 25. They produce panels with a size of 1 * 1 m with a thickness of 2, 3, 4, 5 10 cm.

- Extruded polystyrene foam: Similar in appearance to polystyrene foam, but made using extrusion. The material has a density of 35, 45 kg per cubic meter. meter, size 1.2 * 0.6 m, thickness 2-10 cm.

- Izolon: used when installing a "warm floor", as a reflector. This is a thin material that is laid with an overlap, connected with tape.

- Expanded clay: a porous, lightweight material formed as a result of firing slate, clay. Used for insulation of concrete, wooden floors, mounted on the ground.

Attention! To form a dry screed, expanded clay sand is used: a pillow is made and covered with fiber cement sheets.

There are no special requirements for the insulation material. You can independently perform floor insulation with any of the listed materials, performing a couple of nuances: loose, mineral insulation does not seal, does not create gaps, and it is advisable to foam the gaps between the foam plates. Lay a layer of insulation on the rough floor between the logs. At the final stage of insulation, an additional layer of waterproofing is laid to protect against moisture from the side of the room.

Materials, their characteristics

In order to decide what is the best way to insulate the floor in a wooden house, it is necessary to carefully study the properties of existing materials. There are different types of heaters on sale that have their own physical and operational qualities. Any of them can be placed under the boardwalk or installed on top of it without removing the old covering. Let's consider the most popular options:

Expanded clay

Loose material in the form of rounded granules. Made from fired clay. It has a porous structure, but the surface of each pellet is covered with a sealed melt film. The main advantage of expanded clay is its durability. The backfill layer can be used several times on different objects, and the material will not lose its qualities. In addition, the advantages of insulation are:

- light weight. Due to the porous structure, the mass of the granules is small. This eliminates unnecessary stress on the supporting structures even when creating a thick layer of insulation;

- low thermal conductivity;

- resistance to temperature changes;

- expanded clay does not burn;

- strength, resistance to mechanical stress;

- installation is not difficult and easily done by hand.

For installation, it is only necessary to fill in a mass of material and level the surface, giving the layer the same thickness. However, to obtain the desired effect, a rather large thickness of the backfill is required - experts recommend laying a layer of insulation of at least 25-30 cm. In addition, it is necessary to monitor the condition of the granules. By themselves, they are sealed and not afraid of moisture, but water that has penetrated into the thickness does not dry out for a long time.

Mineral wool

Popular and demanded insulation used everywhere. Minvata is a collective name for a group of materials, which are:

- stone (basalt) wool;

- glass wool;

- slag, etc.

Basalt wool is most often used, which has the most successful set of qualities. Advantages of mineral wool:

- high heat-insulating qualities;

- light weight;

- resistance to fire or high temperatures;

- there are roll and plate forms of the material, expanding the choice;

- durability.

However, there are also disadvantages:

- the ability to absorb moisture, after which the insulation significantly changes its qualities;

- for installation, supporting structures are required, which complicates the process of insulation.

During installation, the mineral wool has to be cut off on both sides from possible contact with steam or liquid water. For this, a waterproofing film is used. The waterproofing layer creates an additional operation during installation, but it cannot be excluded from the technological process. Soaked mineral wool ceases to be a heat insulator and begins to destroy all structures with which it is in contact.

Penoplex

The technical name of this insulation is extruded polystyrene foam. It is a solidified mass similar in texture to polyurethane foam. Possesses high performance characteristics. Penoplex advantages:

- complete impermeability to moisture in any form;

- low thermal conductivity, the ability to create a thermal cutoff even with a small layer thickness;

- light weight;

- does not support combustion;

- durability.

A distinctive feature of penoplex is rigidity. Installation can be carried out both with additional support elements, and with a continuous canvas. The only drawback is considered to be a relatively high price, although today the cost of penoplex is noticeably lower than a few years ago.

Sawdust

Sawmill waste can be purchased literally for a penny. Often they are given away for nothing, just to take out the surplus. Cheapness attracts some owners of wooden houses who are trying to insulate the floor in this way. However, this option has noticeable disadvantages:

- instability to moisture;

- the ability to rot, rot, the possibility of mold or mildew;

- insects or rodents can start in the sawdust;

- the material cakes and loses its quality.

To compensate for these shortcomings, sawdust is mixed with lime, clay or cement mortar. Installation is simple - a thick layer is poured onto a wooden floor and the surface is leveled. Sometimes slabs are made consisting of cement mortar and a large amount of sawdust. Briquettes are stacked tightly, without cracks and gaps, forming a continuous web. The overall effect of the use of sawdust is low, so in today's practice this option is quite rare.

Styrofoam

This is another type of expanded polystyrene. Unlike penoplex, this insulator consists of individual granules. They are sintered in special autoclaves under the influence of superheated steam. Styrofoam properties:

- light weight. In this respect, the material is the leader among all the alternatives;

- high thermal insulation capabilities;

- ease of installation. Insulation is available in slabs of different thicknesses. You can choose the size you want, or use a pack of several layers;

- resistance to water. The granules are airtight, but there is a slight absorption of moisture into the microscopic cavities between them;

- low price. This is the decisive factor that makes the foam attractive to users.

One of the features of a heat insulator should be considered a complex attitude towards combustion. Manufacturers claim that the foam is non-flammable and does not support combustion. As proof, a video is often shown in which a piece of insulation is unsuccessfully tried to set fire to a lighter. However, in reality the situation is more complicated. The pellets are filled with non-combustion carbon dioxide. But when the polystyrene is completely melted, the gas will escape, and the pool of liquid material will burn well. This point must be taken into account when choosing a heater.

Penofol

It is a roll material made from polyethylene foam. An additional element is an aluminum foil that forms a reflective layer. It directs infrared (heat) rays back into the room, which enhances the effect of the insulator. There are several types of foam, with a reflective layer on one and two sides, and there are types with a sticky layer to facilitate installation. The thickness of such insulation is small, and it can be put on the floor on top of the flooring made of boards, without dismantling the old floor. The layer of material is impervious to moisture and does not allow air to pass through. This has both positive and negative sides. When using such heaters, high-quality ventilation of the premises should be organized, otherwise water vapor will begin to settle on walls and other wooden surfaces.

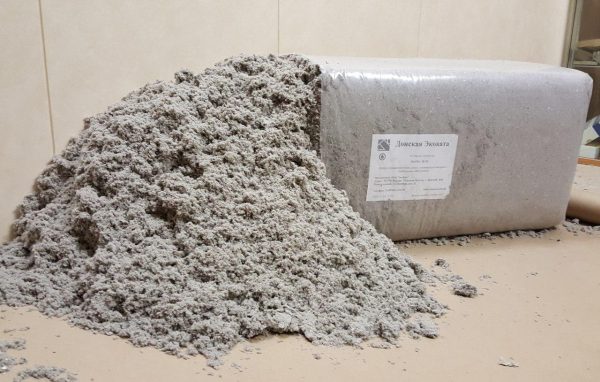

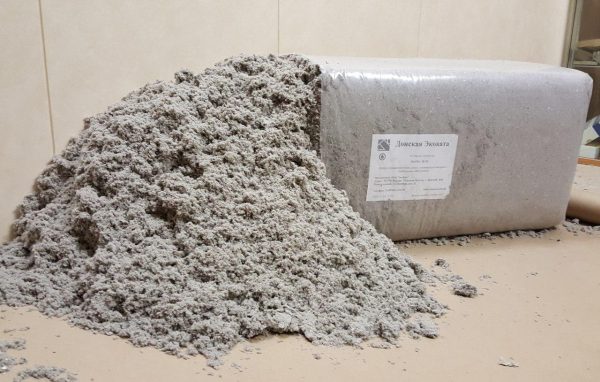

Ecowool

Loose material that is applied by spraying using special equipment. Its peculiarity lies in the fact that the thickness of the spray layer on the wooden floor can be any and depends only on the wishes of the owner. This insulation is a cellulose flake obtained from the processing of waste paper and paper recyclable materials. At the same time, the composition does not contribute to the appearance of rodents. During its manufacture, additives of boric acid and borax are added to it, which scare away rats and prevent the ignition of the backfill layer. The main advantage of this insulation is considered to be high heat-saving qualities. However, the material also has a number of serious drawbacks:

- the ability to absorb moisture, which reduces the performance of the backfill layer;

- the need to use special equipment for styling.

In addition, ecowool is a rather expensive material, which reduces its attractiveness among users.

Foamed polymers

A group of materials, among which types of foamed polyethylene prevail. They have a small thickness, which allows them to be used without opening the sub-floor and without dismantling the flooring. Available in different types and shapes:

- rolls;

- mats;

- harnesses;

- shells (shells) for pipelines.

The scope of application of foamed polymer insulators is wide. They insulate the wooden floor, walls, and other surfaces. With high heat-saving qualities of the material, the layer thickness is small, which favorably distinguishes foamed polymer heat insulators from alternative types. They are convenient for laying under the slab joints, allow you to insulate roof slopes, floors or ceilings, and other surfaces. At the same time, they have not yet received wide distribution among users, since they appeared on sale relatively recently. When deciding how to properly insulate the floor in a wooden house, you can consider this group of insulation. Their prospects are quite large, and their capabilities and properties allow you to get a beneficial effect in any area.

Foam glass

Foam glass insulation was first created in the first half of the last century. However, in our country it is not widespread. The main reason for this was the high cost - in the manufacturing process it is necessary to use heating the glass mass to the melting temperature (1000 °), which increases costs. Insulation has a good set of qualities:

- high strength;

- complete fire safety;

- environmental Safety;

- simple and convenient installation.

The disadvantages are the high weight and high cost of insulation. Foam glass is lighter than wood, but in comparison with other types of insulation, it is noticeably heavier. If it is necessary to install large amounts of material on the floor, an additional load arises on the supporting structures, which are not always ready for this.

Fibrolite

A material representing a sandwich of two layers of thin OSB, between which there is a compressed insulation. It is a composite made up of three main components:

- wood wool (fine fibers);

- cement powder;

- glue (liquid glass).

It is produced in the form of slabs, which makes it easier to install the material on the old flooring (top). A feature of fiberboard is its high ability to absorb moisture. At the same time, if the installation is carried out in several layers, the weight of the insulation increases noticeably. This reduces its operational value. For installation on the floor of the lower floor, this insulation is suitable with restrictions. It is not suitable for ground floors, but can be used on upper floors.

Izolon

This is another type of polyethylene foam equipped with a foil reflector. In terms of its qualities, this insulation is almost a complete analogue of penofol. Many users confuse these materials with each other. There are slight differences in polyethylene grades, layer thickness, roll length and other technological issues. The scope and installation method are no different.

The specificity of the use of materials is also the same - areas requiring complete cut-off from moisture in all types.

How and what to insulate the ceiling on the second floor

Own house made of wood is deservedly considered the most environmentally friendly type of home and is the dream of almost every city dweller.

Nowadays, one-story buildings are a rarity, two-story houses are much more common, where guest or children's rooms, bedrooms and recreation areas are located on the second floor.

In the process of interior decoration of a wooden house, the question of insulating the second floor often arises: it is important to choose the right materials and comply with all the rules for using insulation.

Insulation of the floor of a wooden house is a procedure, the implementation of which is closely related to the design features of the room. It is possible not to make a full-fledged second floor, but to build a simplified version of the superstructure - an attic.

The main difference between the second floor and the attic is the proximity of the roof in the second version. This determines the features of work, the main purpose of which is to preserve heat in the attic:

- due to the wide variety of materials on the modern market, the choice of insulation depends on the preferences and financial capabilities of the customer;

- the walls of the second floor should be insulated from the inside and outside;

- the process of insulating the second floor of a wooden house does not need to be equipped with a vapor barrier system - in contrast to insulating the attic, where it is needed.

In a wooden house above the second floor, there must be an attic space. To prevent the penetration of heat from the first level upwards, the ceiling must be well insulated. The heat insulator layer should consist of several types of insulation materials, which should be laid in a given sequence.

Typically, the insulation "pie" of the floor in a private wooden house consists of the following elements:

- the ceiling of the first floor;

- vapor barrier;

- load-bearing beams made of high-quality timber;

- mineral wool, laid in cells formed by beams;

- waterproofing;

- any floor covering.

This sequence must be strictly observed, otherwise the effectiveness of the thermal and waterproofing of the second floor may suffer significantly. If the second floor will be occupied by a teenager who likes to listen to loud music, or if the house is near the roadway, you should take care of the issue of high-quality sound insulation of the floor and walls of the room.

In addition to the heat-insulating material, two layers of plywood are added to the "pie", which create a sound barrier. When using expanded clay during insulation, a concrete screed should be made from above.

After the overlap of the second floor is insulated, care should be taken to prevent heat loss through the ceiling. The attic is located in close proximity to the roofing.

The role of insulation is played by mineral wool, which is recognized by experts as one of the best materials for insulating an attic. Those who are concerned about environmental friendliness prefer ecowool.

Wool of the selected type is laid in the cells formed by the rafter structure.

Minvata is produced both in rolls and in slabs - its elastic elements quickly and conveniently fit between the rafters. Plates are placed on the ceiling of the upper floor in several ways:

- by pressing mineral wool into the cells of the rafter structure. The thickness of the slabs should be at least 20 cm. This method is the most costly, but it is very popular among builders, since it is distinguished by its simplicity of execution;

- laying insulation boards only under the rafters, which requires additional lathing. The consequence of such insulation will be a decrease in the volume of the attic. Homeowners rarely make such sacrifices;

- installation of mineral wool slabs under the rafters and between them, which requires the installation of additional frame elements. Given the reasonable costs of labor and material, this method has its adherents.

When the ceiling of the second floor is located under the attic, the ceiling should be insulated on both sides. That is, first there should be the floor of the second floor, then the ceiling, then the attic floor.

This approach is due to the lack of heating in the upper level of the building. For this purpose, a vapor barrier is laid on the ceiling of the upper floor, which serves as a barrier for warm air leakage into the attic.

For the purpose of insulation from the inside of the second floor in a wooden house, two technologies can be used:

- internal thermal insulation, carried out by a ventilated method;

- insulation outside, which is done wet or dry.

Internal thermal insulation is justified in the absence of the possibility of performing external work to save heat in the building.

The low popularity of interior decoration at home is due to a number of reasons:

- decrease in the area of the upper floor;

- freezing of the outer side of the walls, which leads to the appearance of condensation and destruction of the material;

- Condensed moisture is the main cause of mold development, which poses a danger to the microclimate in the home.

In the course of wall insulation from the inside, the sequence and the following points should be observed to minimize the above disadvantages:

- preparation of walls, consisting in filling gaps with tow and treating surfaces with antiseptic agents;

- fastening horizontal slats for the purpose of ventilation, which provides air access to the heat-insulating material;

- installation of a vapor barrier membrane;

- installation of vertically arranged racks for further fastening of mineral wool slabs;

- the insulation should be laid between the racks made of an aluminum profile or timber;

- installation of a vapor barrier;

- finishing with plasterboard, chipboard, clapboard, etc.

External wall insulation assumes the same sequence of work, only without installing a ventilation crate. These methods of thermal insulation are carried out "dry", however, in practice, the "wet facade" insulation is more often used.

The facade of a wooden house is insulated with a wet method as follows:

- the walls are prepared and treated with an antiseptic;

- mineral plates are glued to a special composition and additionally fixed by means of umbrella dowels;

- a reinforced mesh is glued to the insulation, the mixture is leveled with a wide spatula;

- a thin layer of glue is applied and finally leveled on the walls;

- the walls are plastered and the facade is painted (if necessary).

Sequence of work:

- bars are installed along the walls of the pediment;

- a distance equal to the thickness of the sheet of heat-insulating material / - 0.5-1 cm must be maintained between the bars;

- the vapor barrier material is laid;

- mineral wool slabs are installed;

- a layer of vapor barrier is laid;

- sheathing is made with finishing material.

For more details about the attic insulation, we write here

Through glass surfaces, windows and doorways, there is an active leakage of heat from the room. Despite the presence of double-glazed windows, the slopes must be additionally insulated. For their insulation, it is recommended to use expanded polystyrene, foam or other cellular material. The loggia is insulated in the same way as the pediment is insulated.

Conclusion

Correctly executed thermal insulation of the walls, floor and ceiling of the attic will provide a comfortable atmosphere in the cold season.

Today, one-story houses are rarely built from wood. Basically, preference is given to two-storey spacious buildings, in which there is a lot of living space, and a large family can freely accommodate. At the finishing stage, the owners often face the question of how to insulate the second floor of a wooden house.

And it is by no means idle, since the process of thermal insulation of the 2nd floor depends on many factors. In particular, this is influenced by the design features of a log house, for example, a heated attic or an unheated attic may be located above the upper floor. Thermal insulation in these two cases will be carried out in different ways. And there can be many such nuances.

Therefore, in the article we will analyze the main issues that arise when insulating this part of the house, and describe in detail the process itself.

We offer you to familiarize yourself with Heating on the second floor of a private house

This indicator plays a decisive role in determining the plan for thermal insulation of the second floor in a private house. Structurally, the room can be:

- A full second floor, above which there is an unheated attic or living room.

- Attic, which is located directly under the roof.

In each case, the principle of insulation will be different. The main difference between an attic and a full-fledged floor is the proximity of the roof, so the main task of insulation is to keep the room warm.

It should be emphasized that thermal insulation of the second floor must be made not only inside, but also outside the house.When insulating a full-fledged floor, it is possible not to equip a vapor barrier layer; vapor barrier is mandatory for the attic. Expanded polystyrene, mineral wool or expanded clay are most often used as insulation.

The work consists of three stages:

- Thermal insulation of the interfloor overlap.

- Heat protection of walls.

- Insulation of the attic of the house.

It is more convenient to carry out the work from the side of the upper floor, the material will be laid on the boards, which are the ceiling of the first floor.

- In order for the insulation to be of high quality and effective, it is necessary to dismantle the floor of the second floor.

- The next stage is the laying of a vapor barrier layer. Above we wrote that the vapor barrier of the second floor can be omitted, but to prevent the accumulation of condensate in the insulation, and to extend its service, it is best to lay a vapor barrier film on the shields and beams.

- Further, the space between the beams is filled with thermal insulation, the material is laid very tightly so that there are no gaps and gaps between the slabs and the ceiling. If expanded clay is used, then all cavities are filled with granules, and then they are well leveled.

- Then the insulation is covered with a waterproof film on which a wooden floor is laid.

If thermal insulation cannot be made from the side of the second floor, then work is carried out from below in the following sequence:

- The ceiling of the first floor is being dismantled.

- Waterproofing is attached to the floors with a stapler.

- Insulation mats are laid between the beams and fixed with wooden slats.

- The structure is closed with a vapor barrier film, which is fixed with a stapler.

- A ceiling covering is mounted, it can be drywall, chipboard, plywood sheets, etc.

Heat protection of walls

Usually, the walls are insulated from the outside. Internal insulation is done in cases where, for some reason, the work cannot be done outside.

Heaters

Various heat-insulating materials can be used as interfloor insulation of a wooden house:

- glass wool;

- basalt wool;

- slag;

- Styrofoam;

- penoplex;

- expanded clay;

- foamed polyurethane;

- shavings, sawdust.

The choice is based on the availability of the material, its cost, characteristics. So, mineral wool and expanded clay are the most acceptable from the point of view of fire safety. At the same time, penoplex does not absorb moisture, does not cake, and has high thermal insulation properties. Sometimes materials are combined, increasing thermal protection.

Different types of cotton wool

Most often, various types of building heat-insulating mineral wool are used to insulate interfloor ceilings. They are made by melting and pulling the fibers of the feedstock. Further, these fibers are intertwined on special machines and formed into mats or rolls. In some cases, such mats or rolls are stitched with synthetic threads to increase the strength of the products.

For glass wool, waste and broken glass production are used as raw materials, for mineral wool and basalt wool, melts of igneous rocks are used. Slag wool is obtained by melting blast-furnace slag.

Different types of cotton wool have different properties. They have different densities, different thermal conductivity. These characteristics depend not only on the type of feedstock, but also on the specified production parameters.

Styrofoam and penoplex

These are two materials similar in properties and method of production. The raw materials for their manufacture are plastics of various compositions. During the production process, they foamed and, when solidified, formed into sheets of the correct geometric shape. The difference lies in the fact that the penoplex is squeezed out during formation through a special device - an extruder.

Both polystyrene and penoplex have closed pores filled with gas in their volume.Only in foam is it ordinary air, and when foaming foam, carbon dioxide is usually used. In terms of the coefficient of thermal conductivity, both materials are almost identical. But due to the fact that in the mass of foam pores are more evenly distributed and they themselves have almost the same size, its strength is much higher.

Very often, when forming sheets of foam, their ends are not made even, but in the form of two or more ledges. When insulating, two adjacent sheets, connecting with each other during installation, provide better insulation, since the joints are not blown out and keep heat well.

Expanded clay

Expanded clay is called a building material, which is a set of oval granules - pellets with an average diameter of 10 to 20 mm. The material of these granules is clay and shale sand. The pellets themselves are obtained by firing pre-prepared semi-finished products in special furnaces. When heated in the volume of expanded clay, pores of different sizes appear, as a result of which it has a very low density. One cubic meter of bulk expanded clay can weigh only 300 kg. For comparison, it can be noted that one cubic meter of pine wood with natural moisture weighs 500-550 kg.

Note! Expanded clay is an environmentally friendly material. It is durable and does not rot or decay.

Polyurethane

Foamed polyurethane is used, as a rule, to insulate basement and attic floors. It is simply applied using special equipment, and later it is foamed in air and takes on a volumetric shape. The advantage of using such a material is that it fills all the leaks and cracks in the structure of the floors, allowing you to make a sealed waterproof and windproof heat protection.

Sawdust

Shavings and sawdust have recently been used much less often, but more recently they have also been used to insulate interfloor floors, filling the name of the cavity between the beams. To prevent such insulation from rotting inside the floors, it is treated with special compounds that kill putrefactive bacteria and woodworms. When laying, shavings or sawdust are mixed with lime.

Vapor barrier

To properly insulate interfloor floors, it is not enough to use only materials with thermal insulation properties. If you do not protect the insulation from the action of moisture in the internal volume of the premises, various microorganisms will multiply in the material, which can subsequently lead to the appearance of mold or mildew. To avoid this phenomenon, it is necessary to make the correct insulation vapor barrier.

Any of the many commercially available options can be used as a vapor barrier. Ready-made protective membranes are widely represented in the building materials market. When building and insulating a private house with your own hands, you can use improvised materials if you know their strength and vapor barrier properties and use them correctly.

As the main layer, the coefficient of vapor permeability of which should be minimal, you can use ordinary polyethylene film or foil. This layer is laid below the insulation, preventing moisture vapor from entering it from the basement or from the lower floor.

As a second layer, which will be on top of the insulation, you can use waxed paper or glassine. These materials are more vapor permeable than foil or polyethylene. They will facilitate the free escape of vapors from the thickness of the insulation upwards.

Features of floor insulation in a log house. Warming on lags

Insulation with polyurethane foam is the most technologically advanced type of insulation. Regardless of the fact that the cost of such insulation is much higher than other methods, it still has a lot of advantages.

- When insulating with polyurethane foam, it is not necessary to make a vapor barrier, since 2 cm of polyurethane foam is already a reliable barrier to moisture and steam, as well as an excellent sound insulator.

- Such thermal insulation has a monolithic structure, increased adhesion to the surface and an extremely low weight, which does not load the floor.

- Work on the arrangement of thermal insulation from polyurethane foam is carried out very quickly with the help of professional equipment.

If the consumer has chosen this type of thermal insulation, then he must take into account the fact that all engineering communications laid in the insulation layer must be carried out and tested in advance, since access to them will be difficult in the future.

Floor insulation technology

It is important to properly lay the insulation in compliance with the correct order of all layers. When insulating the attic floor, the floor of the second floor or the first floor, the cake of the floor has not always noticeable, but significant differences.

Insulation of the floor of the first floor from below

Floor insulation scheme over a cold underground

In this case, when carrying out work with your own hands, the materials should be correctly laid in the following order:

- waterproofing;

- insulation;

- vapor barrier;

- overlap construction.

When building a house from a bar or frame, the material is fixed along the beams. Then the filing is done. Ordinary plastic wrap can be used as protection against moisture and steam. As a second option for waterproofing, waterproof membranes are used. If all the layers are laid correctly, the structure will be reliably and competently protected from the cold from the point of view of heat engineering.

This method is very laborious and is used only if there is no possibility of insulation from the inside.

Also, for insulation from below, the foam insulation method is perfect.

Insulation of the floor of the first floor from the inside

It is quite inconvenient to carry out work under the ceiling, therefore when erecting a frame house or a building from a bar, insulation of the first floor overlap is often performed along the beams from above. In this case, in addition to the previously given materials, you can use bulk materials such as sawdust and expanded clay. When carrying out insulation with your own hands, correctly lay all the layers in the following sequence:

- floor structure;

- waterproofing;

- insulation;

- vapor barrier;

- clean floor.

The vapor barrier must be placed from the inside of the room, so it will work correctly, preventing damage to the floor over the beams from the timber.

Insulation of interfloor overlap

In the first case, the insulation dampens airborne noises: human speech, music, etc. In the second case, the structure is also perfectly insulated from impact noise - steps, jumps, etc.

Competent noise insulation of inter-floor ceilings is a guarantee of a comfortable stay for all family members.

Insulation of the ceiling of the upper floor from the inside

Installation of insulation from the inside does not provide maximum protection of structures, but it can be used as a second option for laying insulation. In this case, the insulation is mounted on the beams from the bottom of the floor. It will be correct to arrange the layers in this order:

- vapor barrier;

- insulation;

- waterproofing;

- overlapping structure on beams.

Insulation of the attic floor

When building and repairing a frame house, a house made of timber or logs, it is better to carry out the attic insulation from above. This method has the following advantages:

- ease of installation;

- the possibility of using inexpensive bulk materials;

- competent thermal protection;

- warming not only the premises, but also the overlapping on the beams of the house from a bar or frame;

- prevention of condensation in the thickness of the floor.

To ensure adequate protection, the layers are stacked in the following order from bottom to top:

- floor structure;

- vapor barrier;

- thermal insulation material;

- waterproofing.

For waterproofing, a plastic film will be enough, but as a second, more serious option, roofing material can be used. When building a house from a bar or in frame construction, you can also read the article "Insulation of the attic floor using wooden beams".

Calculation of the thickness of the insulation

To perform a full-fledged thermal engineering calculation of the structures of a frame house or a building made of timber, it is not necessary to have a construction education. When performing the calculation, it is important to know the thicknesses of all layers of the cake and their thermal conductivity. It is quite easy to find out.

Further on the network you can find the Teremok program, which is freely available.

The calculation will allow you to correctly insulate a house from a bar and prevent overspending of materials. All calculations, taking into account the search for the initial data, are unlikely to take more than half an hour. Usually such layers as waterproofing, vapor barrier are not taken into account.

A competent choice of the method of insulation, the type of material and its thickness can save you from many problems during operation. When building multi-storey residential buildings, the question of insulation does not arise: it is required. The correctness of the selection of the thickness and the availability of measures for thermal protection of the floor, attic floor and walls are checked by an expert examination, which considers these calculations on a par with calculations for strength.

In private housing construction, no one checks the availability of competent insulation, but this does not make it less important.

Work technology

The most effective insulation of the interfloor floor will be if it is carried out during the construction process. It is in this case that you can take into account all the subtleties and apply all available materials.

If the interfloor floor is not yet ready, but only represents a set of wooden beams laid on load-bearing walls, it is necessary to mount a vapor barrier layer on the lower surface, and then hem the ceiling of the lower floor. As a result, if you look at the ceiling from the side of the upper floor, it will be several long boxes formed by the beams and ceiling covering.

It is in these boxes that you need to put insulation. After the material is laid in the space between the beams, it must be covered with a second layer of vapor barrier. Sheets or panels must be overlapped and glued together. Logs are installed immediately along the upper layer of the vapor barrier, on which the floor boards of the upper floor will subsequently be laid.

If we insulate the finished floor, as is often the case during the overhaul of residential buildings, the insulation will have to be mounted on the underside of the floor. For this, from the side of the ceiling of the lower floor or basement, a frame is arranged along wooden bars or metal profiles.

Correctly executed insulation will protect from frost, from heat in summer, and will provide good sound insulation.

We suggest that you familiarize yourself with How to update tiles on the floor

Own house made of wood is deservedly considered the most environmentally friendly type of home and is the dream of almost every city dweller. Nowadays, one-story buildings are a rarity, two-story houses are much more common, where guest or children's rooms, bedrooms and recreation areas are located on the second floor.

After the overlap of the second floor is insulated, care should be taken to prevent heat loss through the ceiling. The attic is located in close proximity to the roofing. The role of insulation is played by mineral wool, which is recognized by experts as one of the best materials for insulating an attic. Those who are concerned about environmental friendliness prefer ecowool. Wool of the selected type is laid in the cells formed by the rafter structure.

- by pressing mineral wool into the cells of the rafter structure. The thickness of the slabs must be at least 20 cm.This method is the most costly, but it is very popular among builders, as it is simple to execute;

- laying insulation boards only under the rafters, which requires additional lathing. The consequence of such insulation will be a decrease in the volume of the attic. Homeowners rarely make such sacrifices;

- installation of mineral wool slabs under the rafters and between them, which requires the installation of additional frame elements. Given the reasonable costs of labor and material, this method has its adherents.

We wrote in detail about the attic insulation here

Correct insulation of the second floor overlap will reliably protect the home from the penetration of cold air. In addition, it will increase noise absorption and provide protection from moisture. Next, we will consider all the nuances of this operation.

Norms and requirements for sound insulation of wooden floors

The above technologies should ensure maximum efficiency of floor insulation. But do not forget that there are norms and requirements for such an indicator as sound insulation. Many insulating materials are good sound insulators. So, the performed thermal insulation can be considered as the carried out soundproofing.

The main requirement for reducing the penetration of noise into the premises of the house from the outside is to reduce them to 45 dB. What can guarantee such an indicator?

- Mineral wool with a density of at least 50 kg / m³, laid with a thickness of at least 100 mm.

- Acoustic mats with a density of 30 kg / m³ and a thickness of 100 mm.

- Construction felt with a density of 20-30 kg / m³ and a thickness of 20-40 mm.

Sand as a soundproofing layer

Sand sound insulation has been used for a long time, because the material has the ability to absorb both low and high sounds. In its mass, it is porous with small cells inside between the particles. It is there, reflected from the walls of the air chamber, that the sound waves are damped.

But sand has several negative characteristics:

- high specific gravity, which requires the construction of floors using powerful beams and a rough base (ceiling);

- high thermal conductivity, insulation of floors with sand is impossible, you will have to add an additional layer of heat-insulating material;

- if you do not assemble a sealed structure, filling up all the cracks and holes, then the sand will penetrate into the premises of the house.

Sand is used as a sound insulation layer in wooden floors

Rating of the best heat insulators for the floor

Here is a small selection of heaters that are most often used for the floor in a wooden house.

# 6. Sawdust

Sawdust

This is a widespread and multifunctional material, it is found in various areas of our life, despite the fact that it is, in fact, only a waste of the woodworking industry. Sawdust is also used for floor insulation.

pros

- cheapness. The material, when compared with other heaters, is very inexpensive, and in some cases it can be obtained for free at all;

- good heat and sound insulation properties;

- naturalness. The material is not hazardous to health.

Minuses

- poor moisture resistance;

- attractiveness to rodents.

Important! Sawdust must be properly processed before laying to protect it from insects and rodents! Often they are mixed with water and cement, or, alternatively, with clay, and only then are they used for floor insulation. The best option for floors on the ground.

Sawdust prices

Sawdust in bags

# 5. Minvata

Minvata

A very famous insulation even among people far from construction. It is not similar to glass wool, but you should not confuse them - these are different materials. Minwata is often used when arranging a floor cake; it is a relatively inexpensive option with good technical characteristics. It is usually sold in rolls, but sometimes it is also found in slabs.

pros

- good sound insulation characteristics;

- low thermal conductivity, good heat saving;

- affordable cost;

- fire safety;

- resistance to rodents, insects, decay processes;

- safety for health (subject to all standards).

Minuses

- loss of properties some time after installation (material cakes, crumples);

- low vapor permeability and, as a result, the accumulation of condensate, which is absorbed into the cotton wool and deteriorates its characteristics.

It is advisable to lay this insulation in several layers, leaving no free space between the lags. The face and hands should be protected during installation - many spiky small fibers will float in the air, which can irritate the mucous membranes and skin.

Prices for mineral wool

Minvata

# 4. Expanded clay

Expanded clay

In addition to construction, expanded clay is also widely used in floriculture / plant growing (when growing plants in pots, it is used as a drainage material). Represents small porous balls, including shale or natural clay.

pros

- resistance to subzero temperatures;

- environmental friendliness, safety for the body;

- muffling various sounds, keeping heat in the house;

- the possibility of using both insulation separately and as part of a cement screed.

Minuses

- over time, the material begins to cake, the balls are pressed, become heavier, which leads to a deterioration in thermal insulation properties.

Important! Expanded clay is undesirable to use for warming the floor of a house built on screw piles - the foundation may sink.

Expanded clay prices

Expanded clay

# 3. Penofol

Penofol

The material appeared on the market relatively recently, and therefore has not yet gained great popularity. It is produced in rolls, has not only a heat-insulating layer (made of foamed polyethylene), but also foil.

pros

- high density;

- ease of installation;

- resistance to mechanical stress.

Minuses

- short service life;

- quite high cost;

- instability to moisture (the material quickly collapses because of it; more precisely, its foil layer).

Penofol prices

penofol

# 2. Styrofoam

Styrofoam

According to its characteristics, it is almost in no way inferior to mineral wool, it is very popular, for many years it has been used in the construction industry. It has good performance properties, but, unlike the same mineral wool, it is resistant to moisture, and retains its original characteristics when wet.

pros

- simplicity and ease of styling;

- good strength;

- not susceptible to decay, mold is almost not formed;

- does not cake and hardly burns;

- resistance to a number of chemical influences, which is very good.

Minuses

- the material is attractive to rodents.

Styrofoam prices

Styrofoam

# 1. Ecowool

Ecowool

It is an environmentally friendly insulation made of cellulose. Consists of gray fibers (sometimes they have a light brown tint), which lie flat and form an even mass. No voids remain during floor insulation, since the material is laid in a semi-liquid form. For work, a special blowing machine is used - ecowool is literally blown out between the logs.

pros

- high-quality vapor barrier, moisture resistance;

- excellent thermal insulation properties;

- resistance to chemical / mechanical stress;

- durability.

Minuses

- the need for special equipment for installation. The material, as we just noted, is blown out by the compressor, but it completely fills all the spaces, thereby eliminating the risk of cold bridges;

- high price.

Nonetheless, the cost of purchasing and installing ecowool is quite justified - often even waterproofing is not necessary. And the insulation itself can last about 20 years!

Installation process

Having decided on the material for thermal insulation, the question arises: how to properly insulate the attic floor? If we talk about mineral wool, then what density should it have and what layer of insulation will be the best?

The choice of layer and density of mineral wool

Mineral wool insulation is best done in two layers

In short, the larger the layer of mineral wool, the better. However, it must be remembered that mineral wool has its own coefficient of specific thermal conductivity. The smaller this coefficient, the higher the thermal insulation properties, and, therefore, you can lay a smaller layer of cotton wool or have a higher insulation efficiency. Often, mineral wool with a thickness of 15-20 centimeters is used, however, to provide increased thermal insulation, a 30-centimeter layer of insulation can also be used. It is also worth noting that with an equal thickness of insulation, two layers of mineral wool are always better than one.

You also need to pay attention to the density of mineral wool, because it can be different: from 30 kg / m3 to 220 kg / m3. Thermal insulation properties practically do not depend on density. A denser insulation is used for facades and screed floors. For the attic floor, a mineral wool with a density of 35 kg / m3 is also suitable, because the insulation will be on a horizontal unloaded surface.

Vapor barrier

Since mineral wool has the ability to absorb moisture, you need to start insulation with the installation of a vapor barrier material.

Vapor barrier - the first layer of insulation

Important! It is best to lay a layer of vapor barrier under wooden beams, otherwise they will be very susceptible to decay. Nevertheless, if it is impossible to put a vapor barrier film under the beams, they must be impregnated with solutions that protect against decay and mold.

The best option is to lay a continuous layer of vapor barrier, but due to the size of the attic this is not always possible, so all joints must be glued with special tape to ensure tightness. The edges of the vapor barrier must be raised above the level of the future insulation and glued with the same tape.

Thermal insulation

You need to work with heat-insulating materials in overalls

This is followed by the installation of insulation. It must be laid in such a way as to completely fill all the space between the timber beams. When it comes to mineral wool, then it does not need to be pressed or squeezed. It must completely cover the space between the beams, leaving no gaps or gaps. The floor beams themselves, too, will not be superfluous to cover with heat-insulating material, because they can serve as a kind of cold bridges.

When laying mineral wool, it is very important to protect yourself, and especially your respiratory tract, from the ingress of insulation fibers. Therefore, you need to use a respirator, as well as gloves, glasses and long-sleeved clothing.

Warming recommendations

The technology for insulating the floor between the floors of a wooden house practically does not differ from standard insulation procedures. However, certain nuances are still present. Therefore, we will consider this process in detail.

Insulation of the interfloor space of a wooden house will reliably keep warm. This procedure consists in laying insulating material between the beams. The simplest option is to do the work on the second floor (that is, to lay the floor). If you do the installation from below, you will have to fix the insulation to the ceiling, which is much more difficult (installation of a canopy takes a lot of effort). First, you need to make preparatory operations:

- We remove the entire floor from the second floor. First, we dismantle the topcoat. If it is plywood or a similar material, then unscrew the sheets with a screwdriver. With laminate, parquet or linoleum, it is even easier - you just need to remove the coating.

- We also disassemble the rough cover. If the house is relatively new and everything is in good condition, then do it carefully so as not to damage anything.Subsequently, you can install everything back.

- As a subfloor for the second floor (if we are talking about a wooden house), as a rule, thick plywood or "forty" (40 mm thick board) is used. If the cover is screwed on, we use a screwdriver, and for the nails you need a pull-out.

- As a result, we have to get to the wooden beams, which serve as a guarantor of the strength of the house. There should be nothing between them, so we remove all the garbage, the remnants of the old insulation (if any), etc.

- The wooden elements of the house need additional protection, so we coat the entire space with antiseptics or similar compounds. This will prevent wood from rotting.

- So that in the process of work you can safely walk on the second floor, we throw several boards along the beams.

So, the space between the floors has been prepared and it remains to insulate. We carry out the work in the following sequence:

- We carefully evaluate the integrity of the coatings - through slots are unacceptable. If there are any, we cover it with a sealant or cement mortar. Even the smallest gaps will promote air circulation, which will lead to heat loss and active condensation.

- After making sure of the integrity of the coating, it is necessary to lay a vapor barrier film. It will protect the heat insulator from condensation (from the 1st floor). In stores, you can find many analogs with different characteristics and, as a result, prices. However, in terms of efficiency, there are few differences, so it makes no sense to purchase expensive models.

- We measure the space between the beams and add 10-15 cm to it. Cut the pieces of the film and glue it to the surface. The material should go a little on the beams (for this, the excess was left).