Do you need to insulate foam concrete? Which insulation is more suitable? How thick should the mine plate be so as not to freeze in winter? How can you decorate a house from foam blocks? What is the insulation cake for a wet facade? How many layers does a curtain wall have? And if you finish with a stone? Why do you need a waterproofing membrane? How to do without a windscreen? How to install a vapor barrier correctly: inside or outside?

Contrary to the assertions of manufacturers that such blocks of foam and aerated concrete do not need additional insulation, in practice it turned out that in the conditions of the Russian climate, a layer of thermal insulation is not superfluous for them. First, let's figure out how these materials differ.

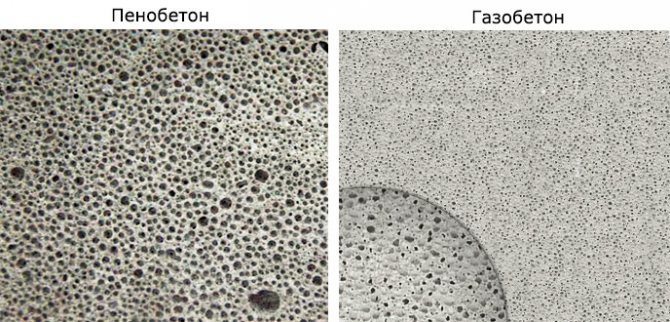

Foam concrete and aerated concrete: what's the difference?

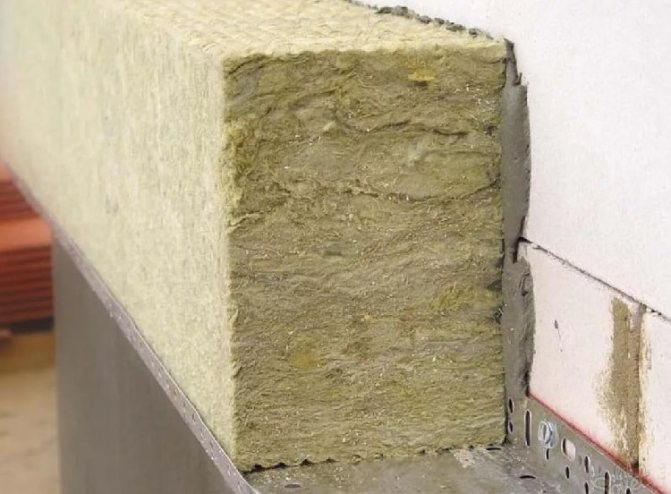

Cellular structure of foam block and aerated block

Both the one and the other material belong to lightweight concrete of the cellular type. The difference lies in the manufacturing method and composition:

- foam concrete is a naturally hardened mixture of sand, water and cement. Cells (bubbles) are formed in it when foaming agents are introduced into the composition;

- aerated concrete has the same composition, but a siliceous binder is additionally included in it. The pores in the blocks are formed after the introduction of aluminum powder into the mixture, which, entering into a chemical reaction with calcium oxide hydrate, promotes the release of hydrogen. Blocks harden at high humidity and temperature.

Aerated concrete is more than 3 times stronger.

Foam concrete and aerated concrete are the same in density, but different in strength. With a density of 500 kg / m³, foam concrete will withstand a load of 9 kg per 1 cm², aerated concrete - 32 kg per 1 cm².

Since the sizes of pores (cells) and their distribution in materials are not the same, the thermal conductivity and moisture permeability of foam and aerated concrete are different:

- under conditions of humidity of 6% D500 foam concrete shows a thermal conductivity coefficient of 0.13-0.16;

- aerated concrete under the same conditions - 0.116;

- pores in foam concrete are unevenly distributed, isolated from each other and unequal in size, therefore they slowly absorb moisture;

- aerated concrete absorbs moisture better, therefore it is not recommended for areas with high humidity.

The advantage of foam concrete is that it absorbs moisture more slowly.

Warming - why is it needed?

A common reason for the need to insulate walls made of foam and aerated concrete is a violation of the rules for laying them: to reduce the cost of construction, ordinary cement mortar is used instead of glue. At the same time, the thermal insulation qualities are reduced due to the numerous "cold bridges".

Using cement instead of glue when laying foam blocks.

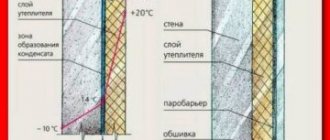

With the help of "thermal fur coat" they extend the life of the house, otherwise, getting into the pores of cellular concrete, moisture freezes in winter, expands and breaks the material. A layer of insulation helps to exclude the appearance of a “dew point” inside the walls, to keep them in a constant zone of positive temperatures and a minimum of humidity.

The process of insulation from the inside will not be considered in this article, since it is not a technologically correct solution and leads to negative consequences for the structure.

When is it worth insulating aerated concrete

If the cost of gas or electricity has risen greatly, and you want to reduce heating costs, then in order to achieve a thermal resistance of 3.2 m2 C ° / W, you will need to insulate the walls of aerated concrete with mineral wool or foam.

The optimal thickness options for aerated concrete with mineral wool:

- D300 (200mm) + mineral wool (50mm)

- D400 (200mm) + mineral wool (100mm)

- D400 (300mm) + mineral wool (50mm)

- D500 (200mm) + mineral wool (150mm)

- D500 (300mm) + mineral wool (100mm)

- D500 (400mm) + mineral wool (50mm)

Recall that the above insulation options are relevant for central Russia. If the construction takes place in colder regions, then the thermal resistance of the walls should be higher.

Choosing a finishing method and insulation

Block house without external finishing.

How to veneer?

With external insulation, they are primarily determined with the type of external decoration. Houses made of foam and aerated concrete blocks are faced with:

- textured vapor-permeable paints and putties;

- thin-layer lightweight plaster designed specifically for aerated concrete (silicone, silicate, lime);

- brick or decorative panels (with mandatory ventilation gaps).

Ordinary cement-sand plasters absorb moisture and do not remove water vapor, and film-forming coloring compositions do not allow air and steam to pass through. They are not suitable for finishing work at home made of foam and aerated concrete.

How to insulate?

It is important to consider the compliance of the insulation with the characteristics of the wall material. It's about again vapor permeability:

For a detailed comparison, see our article "PPP or Mineral Plates?"

- expanded polystyrene - a cheap insulation that does not allow steam and moisture to pass through;

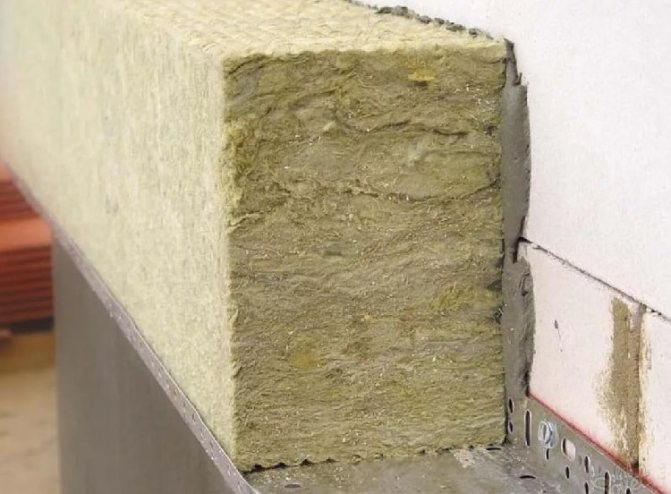

- mineral (stone) wool is an ideal insulation material from the point of view of vapor permeability, but more expensive.

Why is this indicator important? Aerated concrete is good precisely for its vapor permeability. During the operation of the house, moisture is constantly formed inside, which the blocks absorb and remove outside. The process is called "wall breathing" and helps eliminate mold and mildew in your home.

If earlier expanded polystyrene was categorically not recommended for insulating gas and foam blocks, today they talk about the validity of its use if the thickness of the walls from D500 blocks is at least half a meter, and good ventilation is established in the house. The dew point is deep within the material, and condensation will not form on the walls.

Minlabels have a higher vapor permeability than blocks and do not interfere with "breathing".

What is the thickness of the insulation to choose?

Use insulation with a thickness of at least 50 mm.

As for the thickness of the insulation, it makes no sense to use slabs less than 50 mm thick in Russian regions with harsh climatic conditions, strong winds and sudden temperature changes. The best option is 100 mm with a bearing wall thickness of 300-400 mm.

The calculation is approximately as follows: in terms of thermal conductivity, a layer from a block of 300 mm + 50 mm of insulation is approximately equal to a block of 400 mm without insulation. The heat loss of a wall of 400 mm thick + 100 mm of the insulation layer is reduced by 2 times compared to a wall made of blocks of 400 mm, but without insulation, and less than that of a 400 mm block + 50 mm insulation, by 20-25%. Even the increased costs for a layer of insulation of 100 mm will pay off very soon.

Modern technology of thermal insulation of a brick house with aerated concrete D150-D200

User questions

40:04 How to build a wall with minimal risk (from the side of builders)? In parallel, corpulent and aerated block? What are the ligaments? What's the sequence? 42:06 What are the proportions of plaster, lime, cement, perlite? 43:45 Is the house not built of solid bricks, but hollow is indicated on the smart calculator? 43:59 Foam didn't move the masonry? 45:05 Why dry the glue? 46:45 What is the function of the sewer pipes in the greenhouse? 47:08 Is it possible for a D150 100mm gas block to insulate a brick house 6 meters high, without a foundation for the block? To plant the anchors purely on glue 48:02 Is reinforcement of the insulation masonry necessary? 48:18 Was the screed under the underfloor heating, also foamed concrete material, insulated or EPS? 49:09 Why not solid bricks were used? 49:16 Which company is silicate-silicone plaster? 49:28 After insulation with a gas block, the requirements for facade decoration are the same as for a house made of a gas block? 52:51 Was the blind area made before winter? 52:55 Does the gas block rely on PPP? 53:17 If there is no perlite,what can be replaced? 54:16 Do I need to plaster a relatively flat brick wall before insulation? 54:28 Is there enough GB glue or closed loop glue? 55:44 It turns out that the whole gas block will hang? Do you need any support? 56:51 How can floor slabs be supported on such a wall cake? 57:11 Is there a hydrophobic coating? 57:16 Do you apply ordinary GB glue to the D200 gas block? 58:05 Are partitions made of bricks in this case also put on a solution with perlite and plaster with it? 59:15 Are there any peculiarities of fixing / installing GB D200 in the area of doors and windows? 59:25 How to fix the D300 gas block or is it better to support it? 59:54 Considering that the gas block slowly passes water, can we assume that the main moisture exchange occurs through the seams? 1:00:24 I really want to brick it (+ ventilation gap), what advice would you give in this case? 1:00:49 Can I use semi-dry pressed bricks? What are the disadvantages of such a brick? 1:01:50 Did the quarters form in the slopes of the gas block? 1:02:11 Did you use Bonolit or just Aerok? 1:02:40 Is there a minimum thickness for renders to prevent moisture buildup? 1:03:09 How many estimated years before the repair of facade plaster? 1:04:23 If there was a 200 grade gas block, would they build from it? 1:04:43 If the wall has already been made of aerated concrete block for a long time, is it possible to insulate such a wall from the inside with a brick? 1:05:25 Will a similar technology take place in seismic regions? 1:06:46 And if there is no perlite and vermiculite, then what can you add? 1:07:23 If the brickwork at a height of two floors reaches an unevenness of 50-60mm. Could there be a seam of this thickness or do you need to cut the gas block? 1:09:12 While the solution is drying, do you support the gas block with something? 1:10:47 If bricked, then raise the full wall brick + GB + cladding at once? 1:11:06 Was the insulation sanded before finishing? 1:11:42 What are the disadvantages of the wall: GB D600 400mm + D200 200mm + ventilation gap + facing compared to ceramic bricks as a load-bearing material of the wall? 1:13:25 So you can make 2 rows of insulation in a day? 1:16:20 Is the comb on the gas block vertical and horizontal? 1:16:51 Will a brick wall with a width of 250 mm withstand if D150-200 aerated concrete is attached to it? 1:17:14 Does it make sense to insulate D300 instead of D150, provided the thermal resistance is the same? Confused by the low density D150 1:18:44 How long does the filling solution grasp?

Warming "pies"

The layers of the insulating structure differ depending on the method of exterior decoration.

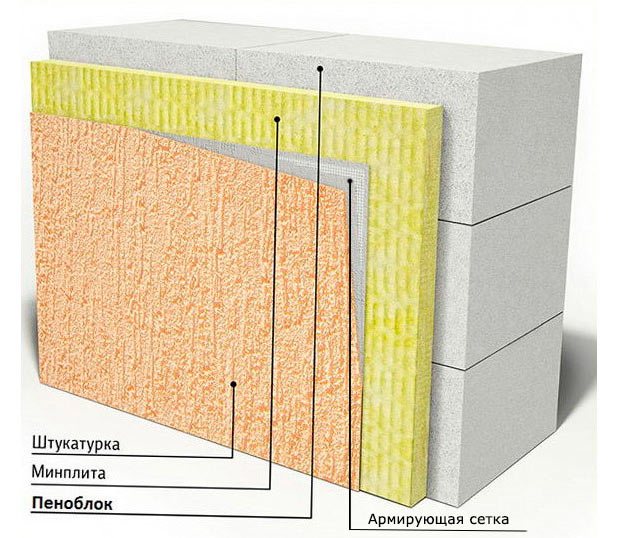

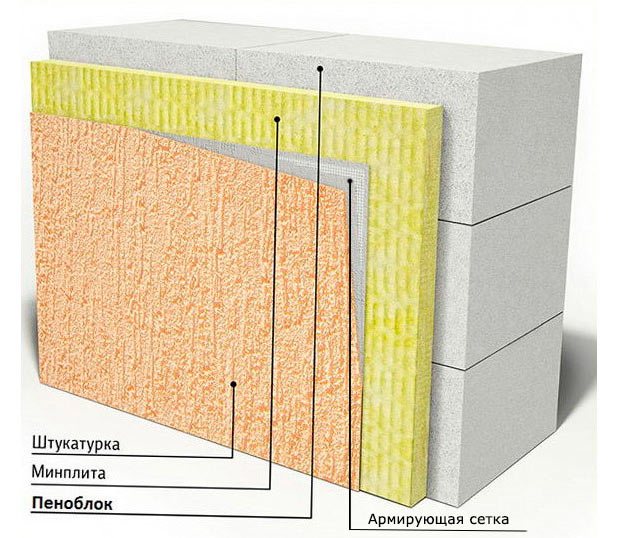

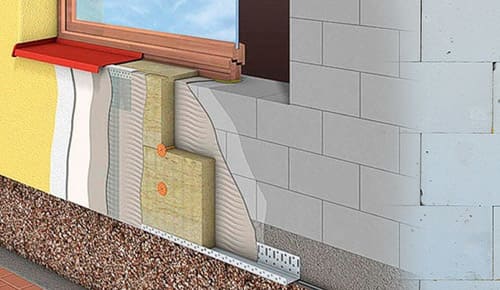

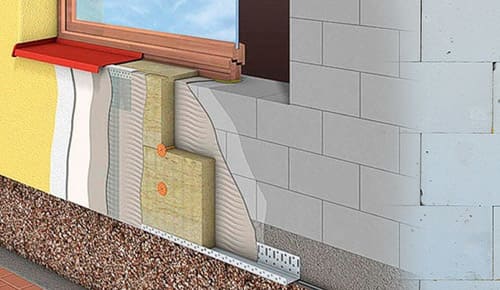

- When choosing Wet technology the insulation is fixed to the wall with glue and dowels, then glue is applied to it, into which the reinforcing mesh (plastic or fiberglass) is embedded, then finished with decorative vapor-permeable plaster, which additionally has a waterproof function.

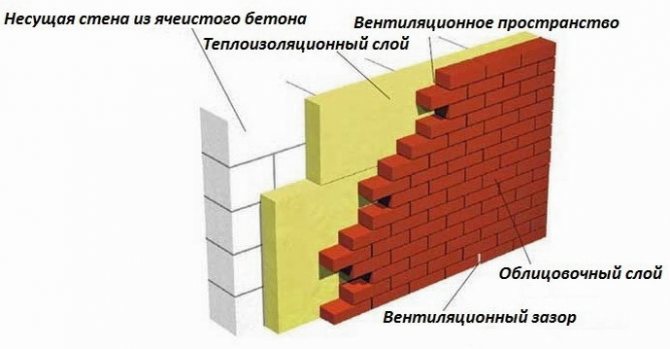

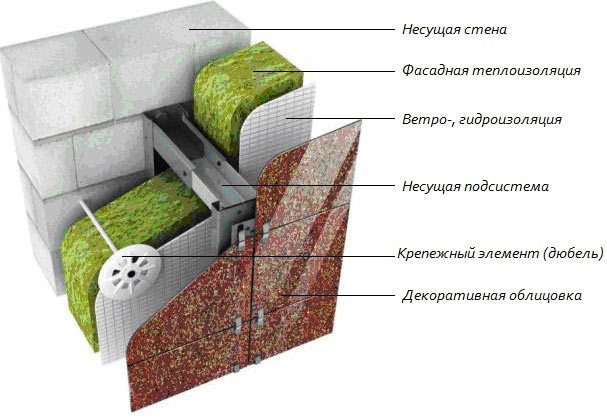

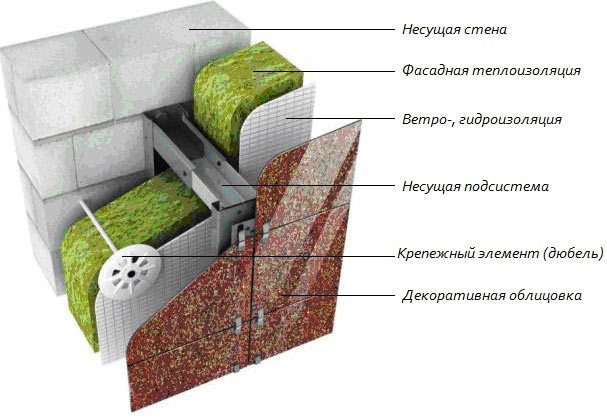

- Warming cake at hinged ventilation facade includes a frame made of wood or metal anchored to the wall; a layer of insulation, fixed with plastic facade dowels; a layer of windproofing - a membrane mounted with an overlap of 15-20 mm at the joints; then the ventilation gap and external decoration - siding or decorative panels, less often - porcelain stoneware slabs.

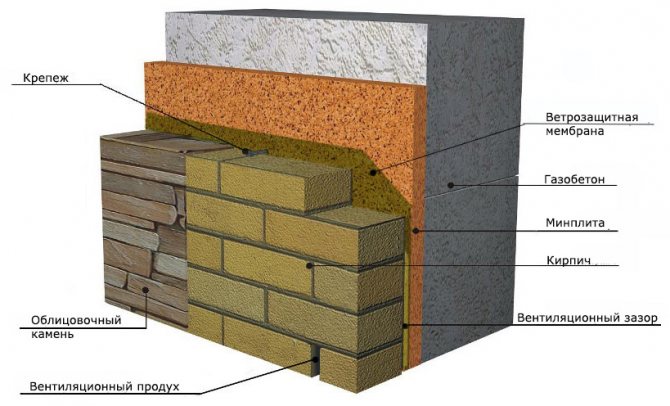

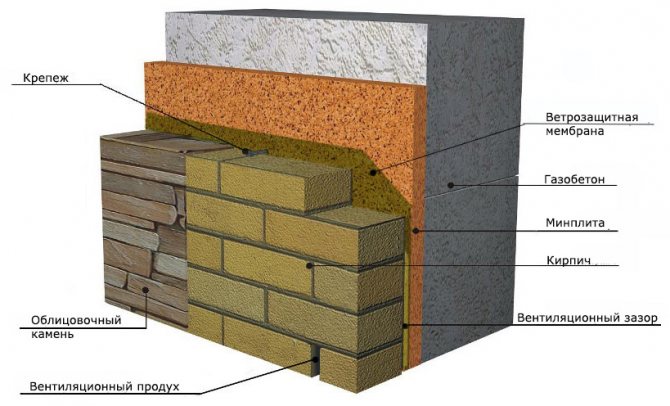

- When facing brick or natural stone the insulation is fixed with dowels to the wall, then a layer of windproof membrane and brickwork (through a ventilation gap of at least 40 mm). This kind of cladding requires additional strengthening of the foundation due to the high load.

Wet facade insulation cake.

Curtain wall insulation scheme

The order of the layers of aerated concrete insulation when facing with brick or stone.

Methods of insulating aerated concrete houses - choice

The choice of insulation methods is influenced only by the parameters of the blocks and the thickness of the walls of the house. It is necessary to take into account the peculiarities of the block structure.

Undoubtedly, aerated concrete houses are easier to build, aerated concrete blocks have precise geometry, they are light, they are easy to process, they have excellent low thermal conductivity.However, aerated concrete blocks are porous material, which means they well absorb moisture from the air (hygroscopicity) and conduct wet vapors through their structures (vapor permeability). Without taking into account these features, house insulation may not improve, but worsen the operation of the house.

For example, using expanded polystyrene for external insulation, without a ventilation device inside the house, you will create a vapor-tight partition on the facade of the house and water will accumulate on the polystyrene plates.

Two popular methods of insulating aerated concrete houses do not create such problems and do not complicate the construction of a house:

- External insulation with mineral wool;

- External insulation of the house with low-density aerated concrete blocks D100 or D200.

House insulation with aerated concrete blocks

This insulation of the facade with low-density blocks D100 (D200) primarily increases the thickness of the machine at home without much stress on the foundation. Partition blocks are glued to the facade of the house, additionally fixing on it with clamping randols (disc dowel). It is important to use a vapor-permeable adhesive and cover the facade with a vapor-permeable finishing material.

Mineral wool insulation

Just like mineral wool is not criticized, it remains a classic in construction. Thermal insulation of a gas silicate house with mineral wool is one of the best options. It can be used in several versions.

- First, to use mineral wool for insulation in the "wet facade" technology;

- Secondly, use the technology of a ventilated facade with mineral wool;

- Third, clad the house with ceramic bricks through a layer of soft mineral wool.