Features of the choice of door insulation

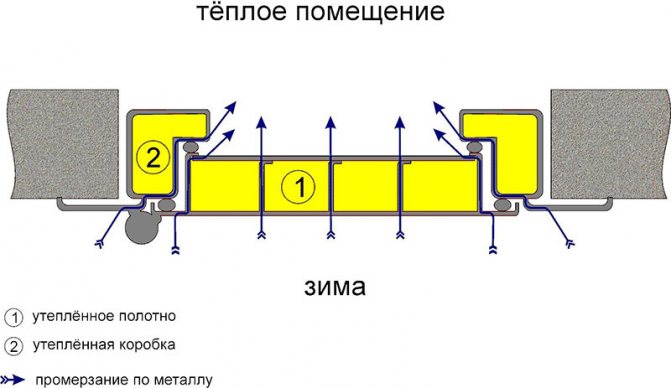

The reasons for heat loss are different: from the skewing of the door leaf and insufficient sealing, to insufficient quality of the material. If the replacement of the door is not included in the plans, then the only correct solution that will help to save 25-30% of heat energy is the door insulation, the nuances of which will be discussed.

You will have to tinker with the insulation of a metal door.

Algorithm for installing heaters on a metal door:

- If the door is collapsible, it is untwisted, after removing it from the hinges and dismantling the locks with handles. In the case of welded seams, they are separated using an angle grinder.

- Laying insulation in an empty box (if necessary, blowing with polyurethane foam).

- Assembling the door frame.

In the case of a wooden door, first align the jamb and reinforce the hinges.

Stages of fixing insulation on a wooden door:

- The doors are removed from the hinges, the fittings are untwisted.

- Lay the canvas on a flat surface, after which a heater is attached to it with liquid nails or glue.

- The upholstery is reinforced with a nail spacing of 30 cm.

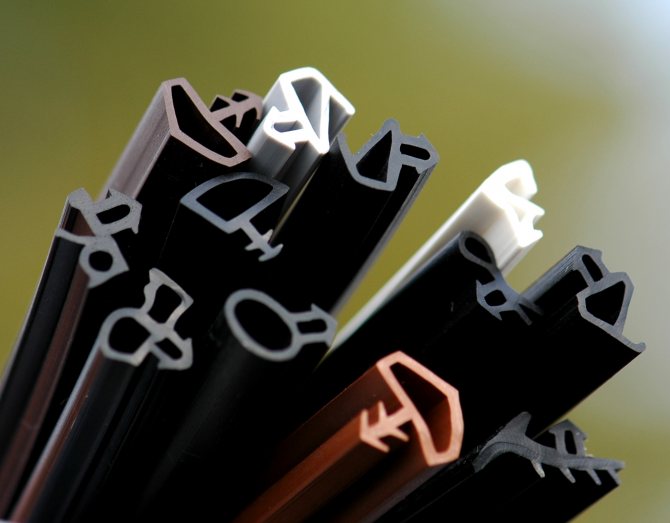

Each material has design and installation criteria that help to choose the insulation correctly.

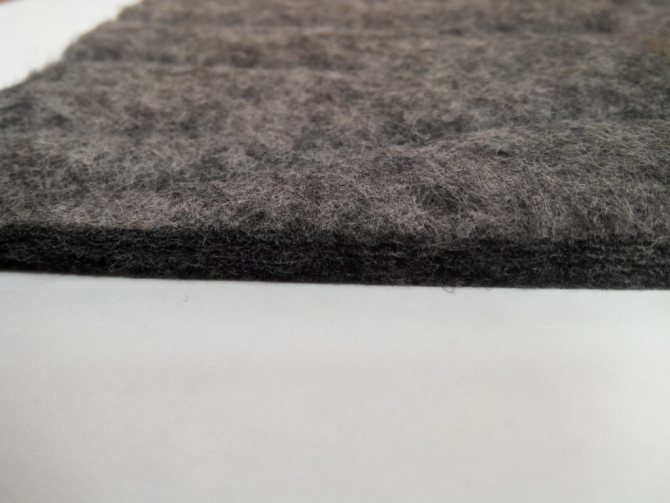

How to attach felt

When this type of seal was used everywhere, and there was no alternative, it was nailed down. Decades have passed since then, and there are more ways of fixing. It is convenient to use a stapler. A paper clip holds the material better than a nail. But the traditional method of fastening with decorative nails has not lost its relevance. Video showing how in a simple and affordable way you can seal the doorway on your own

A wide range of adhesives allows you to choose a brand for fixing both wood and metal surfaces. Felt cannot be fixed on a steel sheet with nails or a stapler, so in this case it is the best option. It is impractical to use double-sided tape. It can be used in exceptional or emergency cases. The bond strength is low and the service life will be poor.

Universal glue "Nairit" with indication of application for felt

The glue method has nuances. The loose and fibrous structure of the felt requires a large amount of composition. A primer is recommended. The prepared strip of insulation is coated with glue and allowed to dry. Do not do it abundantly. Impregnation to a depth of 1 mm is sufficient. After complete drying, a layer of glue is applied, and gluing is carried out according to the technology recommended by the manufacturer in the prescribed mode.

Colored felt

In some cases, felt insulation is used specifically to support the folk style. In wooden houses, baths with deliberately roughly processed surfaces, natural material looks organic, and designers are happy to use this technique. The technology of fiber dyeing has been worked out, and today felt can be purchased in a wide range of colors.

Choosing the optimal insulation

There are several options for insulating the entrance to the house during the cold season, and the most reliable of them is upholstery. For this process, materials such as are used:

- Foam rubber serves as a universal tool to insulate any door: entrance or balcony. Safe for health, does not deteriorate from moisture, a budget option that will last more than one year.For convenience, you can use adhesive strips or plates.

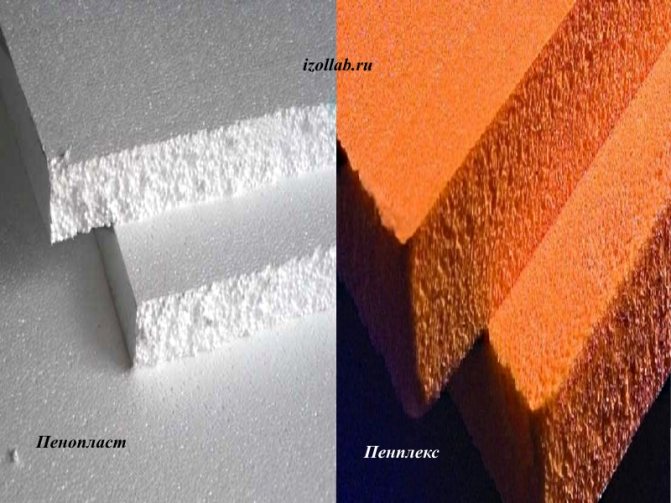

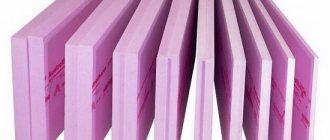

- Polyfoam will serve not only as heat, but also as sound insulation, which is important for residents of apartment buildings. Give preference to the dense look, which usually insulates the facades of knowledge.

- Wool insulation felt will help to reduce harmful vapors contained in the air, is harmless to health, will not lose its qualities, perfectly absorbs moisture, and harmful bacteria will not start in it.

- Mineral wool is non-toxic and resistant to fire, it is produced in the form of pressed panels, ready for use. Does not deteriorate from water, retains heat and serves as good sound insulation. It is not heavy, so it is easy to transport and install, does not shrink. One negative point - it produces phenol, which is dangerous to humans, only when exposed to high temperatures.

- Foamed polyurethane is widely available, comes in rolls, is very light in weight, has excellent sound and heat insulation performance. Not prone to external influence of climatic conditions.

- Corrugated cardboard, perhaps the most economical option, is in demand in the southern regions of the country, since it is not able to protect against severe cold weather.

Door manufacturers, as a rule, use polystyrene directly as insulation, there are many such manufacturers, and they are represented on the market of each city by their own firms, so we will not consider specific representatives.

Warming a house with felt is a harsh reality

Despite all the positive aspects of this material, the complex warming of the house with felt is not possible for a number of reasons:

- it absorbs moisture;

- a mole starts up in it;

- mice feel great in it;

- it is too expensive;

- there is no methodology for such work.

How to insulate a door with felt can be told from two sides:

- insulation of the box (joints);

- complex insulation outside.

Also, this material is used for caulking mezhventsovy slots. In addition, felt insulation for the walls of wooden houses is used as a spacer between the logs (timber) during the installation of the structure. It can be used both in pure form and as part of other materials (jute). It is better to leave attempts to completely insulate the walls of any buildings from any materials. Yes, there is a sturdy yurt felt that has high insulating qualities, but it still won't work. It is not designed to be enclosed by the body of the walls, because you are not going to insulate it without finishing. Felt floor insulation is widely used, but only as a substrate for linoleum. It does not apply to laminate flooring.

Mineral wool

Minvata is made from silicate rocks. High noise and heat insulation characteristics of the product are determined by the fibrous structure. Minvata is environmentally friendly, non-flammable, resistant to moisture penetration, the influence of temperature fluctuations, is not afraid of the effects of chemicals, and besides, it is characterized by a moderate cost.

The main disadvantages of the material are subsidence under its own weight, as a result of which voids are formed. The installation of additional stiffeners that can keep the insulation from slipping helps to avoid this.

Mineral wool

Cotton wool is applied to the entire surface of the door leaf, avoiding gaps, using glue or fasteners, paying attention to insulation around the perimeter. From above it is covered with a decorative coating (leatherette).

Today, this method of door insulation is rarely used in practice due to moral and technological obsolescence.

Material cost from 385 rubles. per package and above. Mineral wool without a binder costs from 35 rubles. for 1 kg.

Warming with other materials

In addition to flax and jute, ordinary heat insulators are very often used when insulating a bath, such as expanded polystyrene, polyurethane foam, mineral wool and dry bulk insulation - expanded clay, brick chips mixed with sawdust, etc. In addition, fiberboard and chipboard are actively used for thermal insulation of the bathhouse walls.

Particular attention should be paid to the vapor barrier of the bath walls. Materials for the vapor barrier layer complement the general heat-saving function of the walls, but at the same time protect them from rotting, mold formation, since the high humidity inside the room can quickly destroy not only the insulation itself, but also the entire building.

Insulation with foam

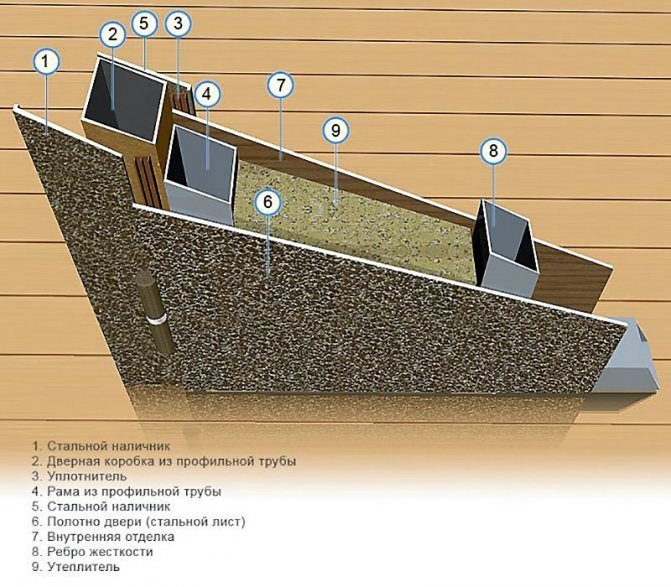

Metal canvases are made from sheet material, which is welded from the sides with corners, while inside there is a void that needs to be filled with something so that the heat does not go away.

The heat saving process is based on the following scheme:

- We remove the dimensions from the door: height and length, in the future they are needed to cut out a part from the fiberboard that will cover the polystyrene layer.

- On a sheet of fiberboard, we display all dimensions accurately, including the location and dimensions of the eye, lock and handles, cut out.

- We apply the cut blank to the canvas to verify the correctness of the cut.

- Cut the foam with a sharp knife for subsequent attachment to the inside of the door. It should be fixed with silicone, which is evenly distributed.

- Next, we proceed to join the polystyrene and the cut-out fiberboard panel. Then screw the blanks to the door leaf with a screwdriver.

- There are also hollow tubes in the canvas, which are designed to increase the strength of the structure; they must be filled with polyurethane foam so that they do not freeze in winter, since a real refrigerator will turn out in the hallway. In order to fill the tube with foam, it is necessary to make a hole through which the filling takes place.

Features and advantages of the material

Felt rags can be found in almost any home, and if not, they can be purchased at a building materials store. At the same time, one should take into account some complexity of installation, because it is not easy to find a sealant that meets the requirements in the retail network (the product range of felt is quite limited). Therefore, the performance of work requires compliance with a number of technological conditions, the availability of certain skills and an individual approach. Often you have to cut the strips of the desired size yourself.

The seal must be sequentially laid along the perimeter of the box at the junction with the sash. Then it must be securely fixed with staples or studs (less often - with superglue) and make sure that the doors fit evenly and tightly to the edge. That's it, drafts are eliminated!

However, it should also be borne in mind that felt is perfect as a natural insulation for the front door leaf. This insulating material keeps heat well and absorbs noise, does not burn and serves for decades without losing its useful qualities. It contains only natural fibers and is therefore harmless.

Be that as it may, during purchase, carefully study the information on the packaging or in the instruction manual.

Felt is 100% wool, while on sale there are products with the same name, but have nothing to do with real felt.

Honeycomb insulation

This material is essentially a standard cardboard, pressed in a factory way into an accordion or in the form of a honeycomb.

The honeycomb filling of the door is considered a cheap option for insulation, but the least effective in terms of insulation from noise or cold air. It is used as a filler that deprives the door of its hollowness.

Fastened as standard, on the entire surface of the door, avoiding obvious gaps.

The cost of the material is from 29 to 125 rubles per sheet.If you buy material in a roll, then the price is 2100-3800 rubles.

How to insulate a concrete floor in a steam room

In the end, you should move on to warming the floors in the steam room. In addition to thermal insulation, you should also take care of the waterproofing of the floors. There are two types of materials editing algorithm. In this paragraph, we will talk about floor insulation in a steam room with a concrete base.

The following algorithm for thermal and waterproofing is simplified, since it is used when laying under tiles.

The work is carried out as follows:

- The base is leveled to a perfectly level state.

- Bituminous mastic is applied on top of it and wait for it to dry completely.

- Then roofing material and polymer film are laid.

- Tiles are mounted on top (read: "").

Better construction for thermal insulation of a concrete floor:

- A plywood sheet is mounted on the rough base.

- Waterproofing is laid on it with a spade on the walls.

- All joints are glued with aluminum tape.

- The gaps are sealed and insulated with a construction hairdryer.

- Reinforcement mesh is laid on the layer and poured with a layer of concrete mortar.

- After the screed hardens, you can start laying the tiles.

When pouring a concrete screed, it is important to take into account the age of the wood used to create the chopped bath. It is important to use material from 2 years old. Otherwise, the structure will shrink, which will cause deformation or destruction of the foundation.

We use foam rubber

If you have a wooden door installed, use this material outside. For this you will need:

- Remove the canvas and place it on a flat surface, preferably on stools. Next, you need to dismantle the locks, handles, peephole and other details.

We insulate the doors with foam rubber

- Now we proceed to the preparation of the rollers, which are needed to fill the space inside the box. If it swings outwards, then it is necessary to mark and cut 3 leatherette strips 140 mm wide, and the length of one strip should coincide with the length of the door, and for the other two, equal to the width of the door. Fasten with small nails along the perimeter of the opening, stepping back 1.5 cm.Only the side on which the hinges are located remains without upholstery. For a door that opens inward, 4 strips are cut: 2 long and 2 short - and nailed on all sides.

- Further, twists of cotton wool are formed in the form of bundles, with a diameter of about 3 cm and are wrapped in leatherette, fixed from below. Everything is rolled up and secured.

- After that, we begin to place the foam rubber sheets along the entire door leaf.

- Cut out one large sheet from the upholstery material, adding 10 cm from 4 sides. Distribute it evenly over the insulation material and nail it in with nails. Please note that the side parts are fixed first and only then the top and bottom.

- We finish the 3 cotton bundles that are needed for the door that opens outward. They are fastened in such a way that the top of the canvas covers the bottom.

- After all the stages, we nail everything over the entire surface, leaving the edge with the hinges for last.

- The last step will be cutting out all the necessary holes for the door fittings in the material: locks, a handle and a peephole. We place the product on the hinges.

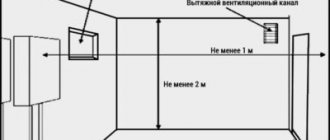

Ventilation gaps

When insulating the walls of a bath building, many owners create a system of ventilation gaps - special spaces located between the insulating material and the outer wall. These are very narrow slots required to drain excess steam and air from the interior. Moreover, such ventilation does not in any way affect the microclimate of the bath from the inside, since excess moisture goes into the ventilation gaps very slowly, gradually, through microscopic pores in the insulating layer of the walls.

Even at a minimum speed and invisibility for the internal atmosphere of the bath, ventilation to a significant extent protects the entire building from premature destruction due to increased dampness, rotting and the formation of mold.Narrow air gaps can be left in the thickness of walls, foundations and ceilings, and can be equipped with special branch pipes.

Thus, using all these nuances - the correct choice of insulation materials, the use of suitable vapor barriers, the creation of a multilayer insulation structure, the abandonment of ventilation spaces - you can create an excellent source for rest, healing and relaxation - a Russian bath.

A Russian bath with a steam room is a guarantee of health and longevity, but in order for the healing procedures to bring maximum benefit, it is necessary to choose the right insulation for different bath designs, taking into account the different functionality, humidity conditions of the premises, the material of individual elements. In addition, it is necessary to know the technology of the insulation process, the observance of which will not only save heat in the bath, but also significantly reduce the consumption of energy fuel. To determine which insulation is best for a bath, you need to know the positive and negative sides of each type of thermal insulation material.

Types of modern heaters

Insulation liquid

Liquid insulators are considered an alternative to bulky frame heaters. They are a mixture similar in consistency to paint, but with the following beneficial properties:

- a high level of thermal conductivity, sound insulation (1 layer of liquid insulation corresponds to a layer of mineral wool 50 cm thick and helps to preserve 30-40% of thermal energy);

- immunity to fire, UV radiation;

- ease of application.

The disadvantage of such materials is not considered an affordable cost for everyone and a lot of fakes on the market.

Liquid insulation is applied with a roller or brush, like paint, after having previously sealed the cracks in the door leaf.

The price for 1 liter of liquid insulator is from 260 rubles. and higher, depending on the brand and the technological nuances of the mixture.

Ecowool

Thermal insulation with ecowool using a mechanized method

The material is made from recyclable materials, which is waste paper, fluffed and treated with fire retardants and antiseptics. Has a gray or light gray color, loose fibrous structure. The advantages of this rather new type of insulation include:

- good heat and sound insulation properties;

- resistance to high temperatures;

- does not support open fire for a long time;

- resists decay processes well; environmentally friendly, if you do not take into account its impregnation with fire retardants and antiseptics. But these substances are low-toxic and non-volatile.

The material can absorb moisture, but it also easily releases it into the surrounding space when a certain level of air dryness is reached. After drying, the thermal insulation properties of ecowool remain at the same level. Before applying ecowool to the surface of the insulated structure, the material must be slightly moistened. The lignin in its composition, under the influence of water, holds the fibers together and adheres well to any surface. It can be used for dry insulation of attic floors. It is not recommended to use it inside the sauna premises, since the material will not have time to dry after each use of the sauna.

Polyurethane foam as insulation

A very effective method of insulation, will help protect the door and further rooms from cold weather. The algorithm of actions in this case is as follows:

- We purchase a pistol and a medium-sized foam canister.

- Glue the door border and the door itself, as well as the walls and frame with mounting tape.

- Carefully, checking for voids, spill foam inside and out. Wait a few minutes for it to take its final shape.

- Remove excess material with a knife or emery tape.

- If necessary, putty the joints and paint.

What is felt insulation for doors

What a pity that this superb, natural material with excellent performance is almost forgotten. Today felt is used to insulate doors and window openings. In ordinary houses, this ends, but if we are talking about wooden structures or a bath from a log house (timber), then it is also used as a mezhventsovy heater and for sealing cracks. And, probably, no one even knows that felt insulation can be different:

- technical fine-haired - manufactured in accordance with GOST No. 288-72;

- technical semi-coarse wool - manufactured in accordance with GOST No. 6308-71;

- technical coarse-haired - manufactured in accordance with GOST No. 6418-81;

- yurt - manufactured in accordance with GOST No. 16221-79;

- Firth - made from the finest fibers of six rabbits and goats.

Felt insulation has a fairly low thermal conductivity, the coefficient is 0.03-0.07 W / m * K and depends on the density of the material. The latter varies in the range from 10 to 400 kg / m. cub.

The material is produced both in panels and in rolls. The dimensions of the panels are 2000 x 2000 mm, rolls are up to 1800 mm wide and up to 200 m long. It is made from both natural and synthetic raw materials. Synthetics is already a trend of modernity, you should not take it seriously, but natural materials deserve attention.

This is a seal for the crowns, 15% made of felt.

Expanded propylene

The main advantages of this insulation are environmental friendliness, light weight, insulation characteristics, resistance to fire, moisture, chemicals and atmospheric agents. Polypropylene foam withstands loads, does not absorb water.

Available in the form of air plates, which can be easily cut to the required dimensions and easily attached to the door using special glue or liquid nails.

The material costs starting at 1100 r and above for 1 package, which differ in size or number of sheets.

Expanded propylene

Production

Felt is produced from sheep wool, which is supplied from the North Caucasus. Thanks to the special felting technology (using steam and water), the material acquires useful performance characteristics. Synthetic felt also has a special production technology. The fibers are twisted, entangled, knocked down and compressed, resulting in a dense fabric, a one-piece fabric.

Felt is characterized by a high degree of strength. It is produced in rolls and sheets, which differ in thickness, density, color scheme and technical parameters.

How to use the gasket correctly

This tool is used to eliminate gaps between the door and the frame. If there is such a hole even when closed, then up to 1/5 of all heat will go through it. To correct the situation, you must:

- Measure the box around the perimeter, this is the length you need to purchase the tape. The width is selected based on the point of contact between the end of the door and the frame. The thickness of the sealing strip must be greater than the gap.

- Remove the protective layer of paper from the sealing tape, and apply the sticky side to the door frame, smooth it carefully to avoid peeling.

So, we have considered all possible types of methods for insulation. But if, nevertheless, the above methods do not help, and the heat still goes away, make sure that the work is done correctly or that the canvas is installed correctly. Also find out if there are any voids in the foam formed during installation.

The main features of felt for thermal insulation

It must be said right away that felt is often used to insulate wood houses. It is in this case that the material demonstrates good efficiency. If we use felt in other conditions, then it will also show itself from a good side, however, there will be some flaws, which we will talk about a little later.

Many builders consider the strong point of felt is the absence of the need for additional surface treatment of the home. This significantly reduces the entire repair process, and also allows you to forget about the integrity of the finish, which can collapse in various situations.

Because this insulation material is relatively inexpensive, it can be stacked in several layers. It will also increase the efficiency of the felt, and at the same time we will save a lot of money by not buying modern thermal insulation materials.

Unfortunately, felt cannot be used in all climatic conditions. You must first find out about this from specialists who offer felt products. In this regard, the material is more demanding than the rest.

Felt insulation

It is considered a classic version of door leaf insulation. Felt seal is traditionally used, but now there is a self-adhesive insulation for doors.

Self-adhesive felt insulation for doors or foam rubber is attached to the pre-cleaned door leaf along the perimeter. At the same time, make sure that the material does not interfere with the tight closing of the door and seals all the cracks.

Self-adhesive for doors costs starting from 30 rubles. per 1 roll, depending on the length and manufacturer of the product.

Advantages of felt seals

Today manufacturers offer a new generation of materials that are easy to install and affordable. The share of felt products is decreasing, but it is too early to abandon the use, since they have a number of special qualities:

- Wear resistance. Natural fibers can withstand significant physical activity without deterioration.

- Life time. Unlike rubber and foam seals, felt does not contain volatile substances, the content of which is steadily decreasing during operation. This leads to the destruction of the material and requires replacement. Felt seals do not lose their properties for many years.

- Soundproofing. The material absorbs vibrations. Both postorenie noises and the sounds of the door when in contact with the box are suppressed.

- Environmental friendliness. Only natural raw materials are used in the production. There is no release of substances harmful to health.

- Fire safety. The density of the wool fibers and their qualities are such that combustion is impossible under normal conditions.

Ready-made felt door seal

Insulation for the steam room bath: 4 layers of insulation

Waterproofing

is aimed at isolating the interior from moisture from the outside. Needed for frame construction and for aerated concrete walls.

IMPORTANT

! You should choose different solutions for waterproofing the steam room and other rooms. Steam baths should be made from materials that can withstand the highest temperatures (for example, Kraft paper).

Warming

steam rooms should be aimed at reducing heat loss and creating a "thermos" effect. Then all the heat will remain inside the steam room, and not warm the environment. Therefore, when choosing a heater for a bath, the steam room requires the utmost attention.

Finishing (finishing) materials

allow to hide flaws during construction, in addition, they provide a beautiful visual appearance of the steam room.

REFERENCE

... The market is mainly represented by finishing materials from such tree species as: pine, linden or aspen. This wood has a low density, so we recommend using narrow boards and placing them horizontally to eliminate the risk of warping. In addition, it is imperative to treat them with oils or other specialized compounds to extend their service life.

We insulate the bath

- Sauna heaters

- Thermal insulation of the floor in the bath

- Summarizing

Bath insulation from the inside: materials

Different requirements are imposed on different premises of the bath, we will focus on the steam room and the washing room, the features of which are high temperature and high humidity. Also, the insulation is selected depending on the material of the walls of the bath.

But, regardless of the material of the walls and the purpose of the room, the insulation should be:

- Non-toxic, so as not to cause poisoning under the influence of high temperature;

- Not hygroscopic so as not to absorb moisture;

- Resistant to high temperatures and steam;

- Non-flammable;

- Retaining shape even after several years of extreme exploitation;

- Resistant to mold and mildew;

- Selling at a reasonable price.

Sauna heaters

| Insulation | In what room is used | Note |

| Natural materials: rolled jute, felt, insulation made of reeds and sawdust, moss, tow, etc. | Dressing room, rest room. | Natural materials ignite at high temperatures and are therefore not suitable for steam rooms and washrooms. But materials from jute and flax are the best insulating materials for a chopped bath. There are excellent modern roll insulation made from natural materials, but they are very expensive, so they are practically not used for bath insulation. |

| Mineral heaters. | They can be used to insulate any room in the bath. Most often, they use easy-to-install plate heaters (mats). | They do not rot, serve up to 30 years, are fire-resistant, inexpensive. It is with these materials that most Russian baths are insulated. |

| Polymer materials | Craftsmen are not recommended for warming the steam room. | Polyfoam is a wonderful heat insulator, but it is flammable, and at high temperatures it releases substances harmful to humans. You cannot use styrofoam in the steam room. ... Extruded polystyrene foam or expanded polystyrene is considered a safe material (it is used to insulate the bathhouse of Russian polar explorers in Antarctica). But the masters do not recommend using this material in the steam room either. |

| Heaters based on aluminum foil. | It is used in accordance with the manufacturer's recommendations for a specific room. | The principle of operation of such heaters is the effect of a thermos, the reflection of heat from the walls and ceiling due to the foil. Some types of foil insulation are made specifically for steam rooms and other rooms with high temperatures, while others, when the temperature rises, begin to emit harmful substances. Foil in the bath is used as a vapor barrier. |

Thermal insulation of the ceiling of the bath from the inside

The bath is insulated from the inside in the following order: ceiling - walls - floor. Most of the heat in the bath goes through the ceiling, therefore

The thickness of the insulation of the ceiling is twice the thickness of the insulation of the walls and is at least 10 cm.

Regardless of the material of the walls of the bath, the ceiling is insulated in the same way.

Foil is used in ceiling insulation without fail.

Insulation of the frame bath from the inside

For insulating a frame bath, roll mineral insulation is most often used.

The thickness of the insulation depends on the type of operation of the bath: if it is supposed to heat it only in the summer, a layer of 5 cm is enough; if you plan to heat the bath all year round, the insulation layer should be 10-15 cm (depending on the climatic zone). To insulate the walls of a frame bath from the inside:

- Insulation is placed in the interbeam space of the structure;

- The next layer is vapor barrier (foil);

- Ventzazor;

- Sheathing.

The foil acts as a vapor barrier, so it is important that even the slightest holes and damage are absent in it, and all joints are well glued with high-quality tape. The tape is always sold with foil, and its quality must be checked in the store (glue the tape to the foil and try to tear it off).

Do-it-yourself bath insulation from the inside: log house

It would be a tragic mistake to insulate a chopped and well-heated bath from the inside. This is not just meaningless and destructive for the walls, it contradicts the very idea of a chopped bath.

Log cabins are made for two reasons:

- To get a classic Russian steam bath, which is heated for a long time and keeps the required level of heat and humidity for a long time. It is the tree that accumulates heat and moisture and gradually "gives up" it. In this case, the bath cannot be sheathed from the inside; you will also have to come to terms with the high consumption of firewood.

- For the image. Not a single bathhouse looks as cool on the outside as a chopped one. But I often don't want to waste time and firewood, I want the bath to be heated in an hour, so insulation, vapor barrier and clapboard cladding are done. The blockhouse works only as an external frame, the meaning of the material is lost. In this case, it is cheaper and more correct to build a frame bath.

It so happens that a person gets a ready-made sauna from a log house, and for various reasons it can be cold. Such a bath can be insulated, but only outside.

The cake looks like this:

- insulation;

- wind protection;

- vertical lathing to create a ventilation gap;

- external cladding.

And from the inside, you can put foil and sheathe it with clapboard, not forgetting about the ventilation gap.

In a chopped bath, only the floor and ceiling are insulated!

If the ceiling of a chopped bath is made of thick boards, it is not necessary to use insulation, but then the following is poured onto the ceiling in a cold attic:

- ash;

- sand;

- expanded clay (it is preferable that the granules were of different sizes);

- clay coating.

Insulation from the inside of a brick bath

Brick is not the most suitable material for building a bath, but if there is a brick factory somewhere nearby, then brick baths begin to grow like mushrooms. Due to the high thermal conductivity of bricks, such a bath needs to be insulated without fail. Warming is carried out only from the inside, and to make the bath look cool from the outside, decorative jointing is done.

Typically, the cake of the insulated wall of a brick bath looks like this:

- brickwork;

- waterproofing,

- insulation;

- vapor barrier;

- sheathing.

Waterproofing between the brickwork and the insulation is optional: if the walls are built correctly and waterproofed from the foundation, they will not dampen. If there is no confidence in the walls, then waterproofing is better done.

Insulation on the brick walls of the bath is attached to the frame.

Thermal insulation of a bath from blocks from the inside

For the construction of a bath, durable and moisture-resistant blocks of expanded clay concrete are preferred. Insulation of such a bath is thought over at the stage of its construction. The most important thing here is to remove the ice block of concrete from the heating circuit. There is a technology promoted by our user ZYBY, which allows you to solve this problem by constructing a frame-wall made of boards indented from the walls of the bath. It is suitable for insulating all stone-walled baths.

To ventilate and dry the space between the frame and the walls, several air vents are made in the walls of the bath, above and below the outside. The vents are closed while people are steaming in the bath, the rest of the time they are open to dry.

Insulation cake for the steam room and washing room using this technology:

- concrete wall with air vents;

- insulation for the frame-wall (with a cover from the concrete wall);

- frame-wall;

- foil;

- finishing with a 50th unedged board (aspen, linden or cedar) to get solid wood into the steam room.

With this approach, you will not have to heat the ice walls. And the insulation will dry out between vapors.

But many owners of a bathhouse made of blocks traditionally insulate it from the inside:

- concrete wall;

- insulation (attached to the frame);

- foil;

- ventilation gap;

- lining.

Such a bath needs insulation outside too.

Thermal insulation of the floor in the bath

The precious heat of the bath also escapes through the floor, so it also needs to be insulated. For warming the floor in the bath, it is recommended to use expanded clay, as the lightest and most environmentally friendly material.

Expanded clay is poured between the layers of the concrete floor as follows:

- the first layer of concrete is poured;

- wait for it to completely freeze;

- expanded clay is poured (layer thickness - 10 cm);

- install a reinforced lattice.

- a layer of concrete is poured;

- make a cement-sand screed.