Requirements for the room for installing a gas boiler - SNiP, diagram, tips

The premises in which the gas boiler will operate are stipulated in SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000 - these documents exclude or minimize any emergencies.

Premises for placing gas boilers fall under the classification of fire and explosives, therefore, when designing, planning, installing and setting up gas heating equipment, all requirements for a room for installing a gas boiler must be strictly observed.

General requirements for the installation of gas appliances

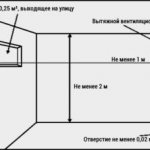

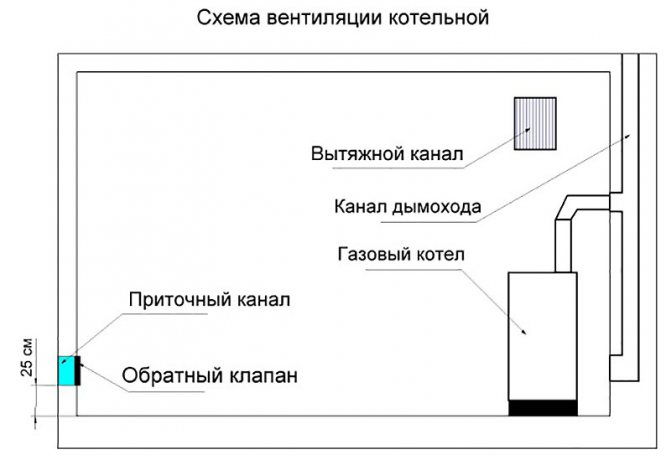

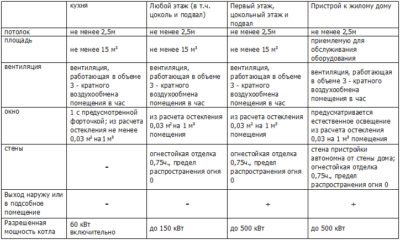

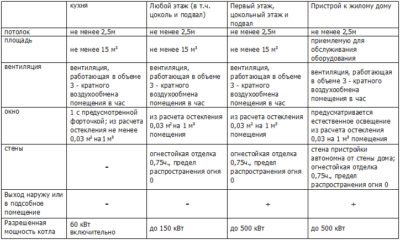

In the room intended for the installation of a gas boiler, according to the above standards, there must be good natural lighting: at least 0.03 m2 of the window opening area must fall on 1 m3 (but not windows - partitions, frames and imposts are not taken into account). It is imperative to equip the room with a supply and exhaust ventilation system according to the following rules: the total volume of forward and reverse air flows per hour, multiplied by 3, is equal to the volume of the entire exhaust device. In addition to a window equipped with a window, a door with access to the street is installed in the room. The table shows the requirements for the volume of the room:

| Gas boiler power | The total volume of the furnace |

| 7.5 m3 | |

| > 30-60 kW | 13.5 m3 |

| > 60-200 kW | Requirements according to the conditions of installation and operation of the boiler on gas, but not less than 15 m3 |

For gas-fired units with a power of more than 6000 W, add 0.2 m3 for each extra unit of power.

Supervisory requirements for the room for the installation of a gas boiler stipulate that it is allowed to operate any appliances for heating an apartment on every floor of a multi-storey building and in any room of an apartment.

Kitchens in multi-storey buildings are also suitable for these requirements, since they are already equipped with appropriate communications.

The only condition is that the total thermal power of all devices for heating water and heating an apartment (boilers, boilers, heating elements, heating radiators, batteries or registers) should not exceed 150 kW in total.

Indoor ceiling heights - 2 meters or more. The room in which the gas boiler will be installed and operated must be separated from the neighboring rooms by capital fireproof walls.

Material for walls or partitions should have a time limit of fire resistance of 0.75 hours (45 minutes).

The boiler room must be planned so that in the event of a fire in operation, there is no possibility for the fire to spread throughout the apartment.

Gas boilers of the TLO brand, operating on the principle of natural circulation of the coolant, can be installed and should be operated only in the basement of the house or in the basement rooms.

- The ceiling is 2 meters or more.

- The total volume of the kitchen is more than 7.5 m3, ventilation is equipped, a window is installed and there is a door opening onto a balcony.

- For air exchange, it is necessary to equip a grate at the bottom of a wall or door that goes into the next room, the area of the grate is at least 0.02 m2.

To install a gas boiler in the kitchen, a permit from the gas service may be required.

Materials (edit)

The main requirement is that the door for the boiler room of a private house must be made of non-combustible material. There cannot be any wooden products in such a room. The ideal material is steel. In addition, the metal must be coated with non-flammable paint.An example is a metal door P-5 on reinforced hinges with a refractory powder coating.

Allowed to use for painting and nitro enamel. Powder coating and nitro enamel are ideal coatings for protection against the spread of fire. They resist ultraviolet light, are not afraid of moisture, do not allow the spread of fungus and rust. All fittings must also be made of non-flammable materials.

Boiler room door ventilation

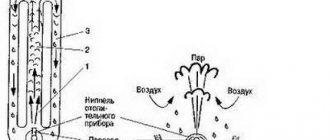

According to safety standards, the door to the boiler / boiler room (especially with gas equipment!) Must have gaps, or supply ventilation. During the combustion of fuel in a closed room, oxygen burns out, so there must be an air flow in it. For this purpose, the door to the boiler room is equipped with a special ventilation grill, which is located in its lower part.

Opening width

According to the norms of SNiP, the minimum width of the doorway should be 800 mm. An example is the TX-9 model with a lower grill. This is necessary so that, in the event of an accident, a stretcher with a wounded person lying on it can be taken out of the boiler room. They must pass freely through the doorway without touching the door frames.

The door to this area should open wide enough so as not to create crowds and to provide maximum freedom of movement in the event of a fire. An example is a TX-16 door with powder coating and ventilation grilles. Opens 180 °.

Requirements for glazing the door to the boiler room of a private house

Special requirements for the door to the boiler room of a private house are also imposed on the method of its glazing. Since the workers of the boiler room must be able to constantly monitor the situation in the working room, the boiler room is equipped with a small window according to the norms. But at least 0.5 m2 is essential for a good view.

Requirements for boiler rooms in public buildings

1.8. * For public buildings, it is allowed to design built-in boiler rooms when using: - hot water boilers with a water heating temperature of up to 115 ° C.

- steam boilers with saturated steam pressure up to 0.07 MPa, satisfying the condition (t - 100) * V ≤ 100 for each boiler, where t is the saturated steam temperature at the design pressure, ° C; V - boiler water volume, m3; The total heat capacity of an individual boiler house should not exceed the heat demand of the building or structure for which it is intended for heat supply, in addition, the heat capacity should not exceed: 3.0 MW - for a roof boiler house and for an integrated boiler house with boilers for liquid and gaseous fuels;

1.5 MW - for a built-in boiler room with solid fuel boilers

It is not allowed to design built-in boiler rooms for buildings of preschool and school institutions, for medical and dormitory buildings of hospitals, clinics, sanatoriums and recreation facilities.

1.10.

It is not allowed to place built-in boiler rooms under public premises (foyers and auditoriums, commercial premises of shops, classrooms and auditoriums of educational institutions, halls of canteens, restaurants, dressing rooms and soap baths, showers, etc.) and under warehouses of combustible materials.

1.18. * The projects of boiler rooms should provide for: For built-in boiler rooms, automated boilers of full factory readiness should be provided.

1.23. * Built-in boiler rooms should be separated from adjacent premises by type 2 fire walls or type 1 fire partitions and type 3 fire ceilings.

Attached boiler rooms must be separated from the main building by a type 2 fire wall.

In this case, the wall of the building, to which the boiler room is attached, must have a fire resistance limit of at least 0.75 hours, and the boiler room overlap must be made of non-combustible materials.

3.10. * Exits from built-in boiler rooms should be provided directly to the outside.

Marches of stairs for built-in boiler rooms are allowed to be located in the dimensions of common staircases, separating these marches from the rest of the staircase with fireproof partitions and ceilings with a fire resistance limit of at least 0.75 hours.

7.14. * The height of the mouth of the chimneys for built-in boiler rooms must be above the boundary of the wind support, but not less than 0.5 m above the roof, and also at least 2 m above the roof of the higher part of the building or the tallest building within a radius of 10 m.

For obvious reasons, I cannot answer specifically. When designing an object for which there are no design standards, it will be necessary to develop STU - special technical conditions.

Dmitry Gorokhov

02/06/2018 at 6:27 pm | #

I have a three storey store. A second fire exit was made from each floor. The exit area of the first floor passes directly under the boiler room (otherwise it does not work), Question - is this a violation?

It is difficult to imagine the architecture of the building without seeing the layout. Intuition suggests that the violation should be sought in the placement of the boiler room on the second floor.

6.9. Requirements for boiler houses

6.9.1 The requirements of this subsection should be observed when designing buildings and structures for boiler houses.

When designing built-in, attached and roof boiler rooms, one should additionally be guided by the requirements of building codes and regulations of those buildings and structures for which they are intended to supply heat.

6.9.2 Stand-alone boiler house buildings in terms of fire resistance, class of constructive fire hazard, building height and floor area within the fire compartment are accepted in accordance with the requirements for industrial buildings.

Buildings of detached, attached and built-in boiler rooms are made of I and II degree of fire resistance of fire hazard class C0; III degree of fire resistance of fire hazard classes C0 and C1.

Buildings of detached boiler houses, belonging to the second category in terms of the reliability of heat supply to consumers, can also be performed with IV degree of fire resistance of fire hazard class C0, C1.

Roof boiler house structures must have a fire resistance level of at least III and belong to the C0 fire hazard class.

6.9.3 Roof boiler rooms are one-story. The roof covering of the building under the roof boiler room and at a distance of 2 m from its walls must be made of NG materials or protected from fire by a concrete screed with a thickness of at least 20 mm.

6.9.4 When blocking a boiler room with a closed storage of solid fuel, the latter must be separated by a type 1 fire wall with a fire resistance limit of at least REI 150.

6.9.5 Attached boiler rooms should be separated from the main building by a type 2 fire wall.

The overlap of the boiler room should be made of NG materials.

6.9.6 Built-in and roof boiler rooms should be separated from adjacent rooms and the attic by type 2 fire walls or type 1 fire walls, type 3 fire ceilings.

It is not allowed to place built-in boiler rooms under living quarters, directly on the ceilings of living quarters adjacent to living quarters, as well as above and below rooms of categories A and B.

6.9.7 The premises of the service personnel built into the building of the boiler room are separated from the production premises by fire-prevention partitions of the 1st type and fire-prevention ceilings of the 3rd type.

6.9.8 The above-bunker fuel supply galleries must be separated from the boiler rooms by partitions (without openings) of the 2nd type. It is allowed, as an exception, to arrange a doorway in the specified partition as an escape exit through the boiler room.

In this case, the communication between the above-bunker gallery and the boiler room must be carried out through the vestibule.The fire resistance limit of the vestibule enclosing structures must be at least REI 45, and the fire resistance limit of doors in the partition and the vestibule must be at least EI 30.

6.9.9 In boiler rooms (but not above boilers or economizers) of detached boiler rooms, it is allowed to provide for the installation of closed liquid fuel supply tanks with a capacity of no more than 5 m3? for fuel oil and 1 m3? for light fuel oil.

6.9.10 For built-in and attached boiler rooms, the total capacity of the supply tanks installed in the rooms of the boiler room should not exceed 0.8 m3.

Source: https://yokvadro.ru/stati/trebovanija-k-kotelnym-obshhestvennyh.html

Valid documents

GOST (state standards)

GOST 5542-2014 “Combustible natural gases for industrial and municipal purposes. Technical conditions »Watch online

GOST R 50831-95 "Boiler installations. Thermal mechanical equipment. General technical requirements »Watch online

GOST R 55173-2012 Boiler installations. General technical requirements »Watch online

GOST R 56777-2015 "Boiler plants. Method for calculating energy consumption and efficiency »Watch online

About licensing of certain types of activities (as amended on December 31, 2020) Watch online

On licensing the operation of explosive and fire hazardous and chemically hazardous production facilities of I, II and III hazard classes (as amended on December 24, 2020) Watch online

On industrial safety of hazardous production facilities (as amended on March 7, 2020) Watch online

On approval of the Rules for the use of gas and the provision of gas supply services in the Russian Federation (as amended on June 19, 2017) View online

About the approval of the Rules for the technical operation of thermal power plants View online

On approval of the Federal norms and rules in the field of industrial safety "Industrial safety rules for hazardous production facilities where equipment operating under excessive pressure is used" View online

Government decrees

Decree of the Government of the Russian Federation No. 1521 of December 26, 2014 "On approval of the list of national standards and sets of rules (parts of such standards and sets of rules), as a result of which, on a mandatory basis, compliance with the requirements is ensured. View online

Resolution of the Government of the Russian Federation No. 87 of February 16, 2008 "On the composition of sections of project documentation and requirements for their content" View online

RD (guidance documents)

RD 10-179-98 "Guidelines for the development of instructions and regime maps for the operation of pre-boiler water treatment plants and for maintaining the water-chemical regime of steam and hot water boilers" View online

RD 10-319-99 "Typical instructions for the safe conduct of work for boiler personnel" View online

RD 24.031.120-91 “Guidelines. Standards for the quality of network and make-up water for hot water boilers, organization of water-chemical regime and chemical control »View online

RD 24.032.01-91 “Guidelines. Standards for the quality of feed water and steam, organization of the water-chemical regime and chemical control of stationary steam waste-heat boilers and energy technology boilers »View online

RD 34.03.233-93 "Typical instruction on labor protection for a boiler operator (stoker)" View online

Organization standards

SO 153-34.02.317-2003 "Methodological recommendations for assessing emissions of pollutants into the atmosphere from auxiliary production of thermal power plants and boiler houses" View online

SP (codes of practice)

SP 131.13330.2012 "Construction climatology" Watch online

SP 22.13330.2011 "Foundations of buildings and structures" Watch online

SP 4.13130.2013 “Fire protection systems.Limiting the spread of fire at the objects of protection. Requirements for space-planning and structural solutions »View online

SP 48.13330.2011 "Organization of construction" Watch online

SP 62.13330.2011 "Gas distribution systems" Watch online

SP 89.13330.2016 "Boiler Plants" Watch online

TR CU (technical regulations of the Customs Union)

TR CU 016/2011 "On the safety of devices operating on gaseous fuel"

Boiler room requirements (planning and design)

Directive of the Moscow Committee for Architecture and Construction of October 23, 2001 No. 39 "Guidelines for the design of autonomous heat supply sources"

Federal Law N116-FZ of 21.07.1997 "On industrial safety of hazardous production facilities" View online

Part of the text from SanPiN 2.2.1 / 2.1.1.1200-03 "Sanitary protection zones and sanitary classification of enterprises, structures and other facilities"

Standards and requirements for a boiler room in a private house

Currently, there is a steady demand for suburban real estate in the immediate suburbs of large and small cities.

Modern technologies in construction make it possible to fulfill an old dream of many people, to live in nature in their home.

The device of a modern heating system is the main question facing the developer.

Large selection of heating systems. A wide range of boiler equipment and automation that ensures stable and safe work in a residential building.

It is better to build a boiler room in a private house for masters of their craft. During construction, it is necessary to know the basic norms and requirements for a boiler room in a private house.

It is forbidden to build a room for a boiler anywhere and anyway.

Types of heating boilers

Fire and gas services have certain requirements for a boiler room in a private house. Guided by the rules and regulations, first of all, it is necessary to decide which boilers will heat the cottage.

- Solid fuel boiler.

- Liquid fuel boiler.

- Gas boiler.

- Combined boiler (Boilers of these types operate on solid fuel, liquid fuel, gas).

- Electric boiler.

Places of installation of heating boilers

- Autonomously built boiler houses (Boiler houses built separately from a residential building)

- Roof boiler rooms (Boiler rooms located on the roof of the house)

- Modular boiler rooms (Boiler rooms placed in containers or block modules)

- Built-in boiler rooms. (Boiler rooms located inside a residential building)

- Attached boiler rooms (Boiler rooms attached close to the cottage)

A large range of heating boilers can be confusing for the developer. For the optimal decision on which boiler to buy, professional advice is needed. If there is no cottage project with all the calculations, where and how everything should be located, then the knowledge of experienced installers will help to avoid mistakes, determining what is the minimum boiler room area in your house.

Gas fired boiler houses

Requirements for gas boilers. Connection of the private sector to the natural gas network without approval and a completed project is not allowed:

- One of the requirements is the entrance to the boiler room. The doors to the boiler room must open to the outside.

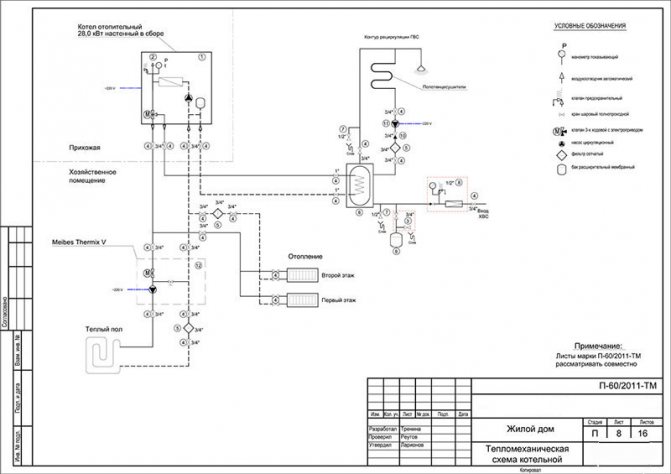

- The dimensions of the boiler room must be built taking into account the power of the boiler. The volume of the boiler room for a private house is required to make a three-fold air exchange. A simple calculation of ventilation is 3 cubic meters per second per square meter.

- To ensure the regulatory requirements, the ventilation in the boiler room of a private house must be three times air exchange. Construction standards, adhered to the SNIP calculation of boiler room ventilation and the size of windows and doors, will ensure the safe operation of the boiler in the house.

- The minimum window size in the boiler room should be 0.5 m2. The norm for calculating windows in the boiler room is as follows: 0.03 square meters per 1 cubic meter of volume.

- The window in the boiler room building must have a window.The window openings in the boiler room work like an explosive valve. In the event of an explosion, due to the increased concentration of gas in the room, windows fly out. The walls remain intact.

The boiler room must be completed

- The walls are brick, concrete or non-combustible.

- The floors are concreted and tiled.

- Door width at least 80 cm.

- Fire door.

- Installation of 2 boilers is allowed.

- Maximum natural light.

- Boiler room ventilation.

Boilers up to 30 kW are allowed to be installed in the kitchen.

Minimum kitchen size:

- Area 7.5 m2.

- The ceiling is 2.5 meters.

- Volume 15 m3.

Preference is given to separately erected boiler houses. One of the conditions for the construction of a boiler house is a separately erected foundation. If the boiler is floor-standing, then a separate foundation and a podium are erected under the boiler.

The chimney, if the boiler equipment is of a non-coaxial type, is built on a specially built foundation under it. The chimney is equipped with a tee for cleaning it. The gas boiler must be serviced at least once a year.

A separate gas boiler room is being installed in the form of a mini-boiler room. You can build such a boiler room with your own hands. A container can be used for placing under the boiler room. Such a boiler room will not take up space in the house. She's safe. There is no small noise from the boiler.

Isoproflex pipes, buried only 60 cm in the ground and excluding heat losses, are perfect for heating mains from the boiler room to the cottage.

Solid fuel boiler houses

The requirements for boiler houses equipped with solid fuel boilers are not as stringent as for gas ones. The range of solid fuel boilers is very wide. The only thing that unites all models of boilers of this type is that they are all floor standing.

Particular attention is paid to the foundation for the boiler and chimney. The approach to the disposal of combustion products is special. The chimney is made with a hole in the lower part to remove combustion products:

- 8 cm2 per 1 kW of boiler power.

- 24 cm2 per 1 kW of boiler output (boiler in the basement).

Installation of the boiler on a concrete base. The construction of the podium is desirable. A sheet of metal is laid on the floor in front of the boiler.

Fire extinguishing means must comply with the SNiP of fire safety. The size of the boiler room for solid fuel boilers must be at least 8 m2.

Supply ventilation in a boiler room with a solid fuel boiler should ensure air exchange in three times. Correctly selected and constructed volume of the boiler room will ensure the safe operation of boiler equipment and the cottage as a whole.

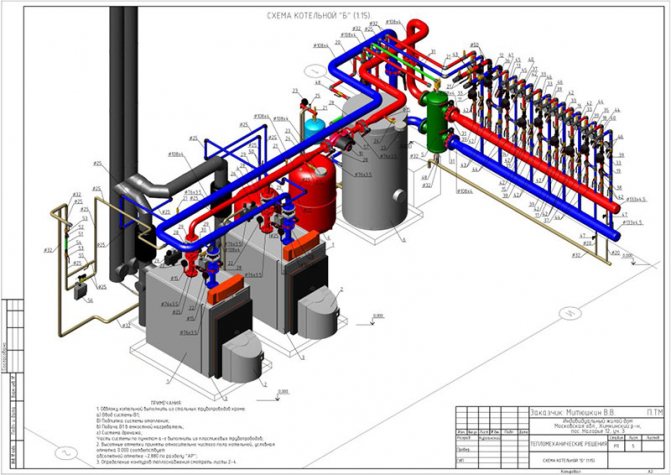

An example of a boiler room with an interesting solution

There is an interesting solution for the construction of a coal-fired boiler house. The boiler house building is being erected right along the border of the site. The boiler room is two-level. Boiler room at an elevation of -2.5 m. The total area is divided into 2 rooms.

In the first, the boiler is directly installed. The second room is equipped for fuel storage. In our case, coal. Both rooms are equipped with a ventilation system corresponding to SNiP. Natural lighting through the windows. The window must have vents.

The fuel storage room is arranged as follows.

A bunker made of sheet steel has been assembled. The hopper is loaded thanks to an inclined chute welded from sheet steel, which leads directly to the hopper. A car with coal is unloaded from the street side by the wall of the boiler room. In an open chute in the wall, the coal flows directly into the hopper.

The physical costs of storing the required volume of coal are minimized. A boiler located at the minus mark performs better. There is no need to install a circulation pump.

The room on the first floor of the boiler room can be used for any auxiliary rooms.It is very good to place such a boiler room on the corner of your site, if there is one.

Oil fired boilers

It is preferable to build a boiler room for liquid fuel boilers separately from the cottage. The construction of a boiler module, standing apart from a residential building, is due to the following considerations:

- No diesel smell.

- Fire safety.

- Convenient fuel injection into fuel tanks.

- Fire — an insulated fuel house separated by a brick wall from the boiler room.

Tanks for diesel fuel in the built-in boiler room can also be placed inside the house. The storage room for diesel fuel should be about 2.5 meters high. The containers take up a lot of space in the cottage.

It is necessary to take into account the dimensions of the fuel tanks during the construction of the boiler house and the methods of refueling them with diesel fuel.

Requirements for a boiler room with an electric boiler

An electric boiler is the safest of all types of boilers. The liquid is heated by electricity. There is no carbon monoxide from it. The electric boiler does not need ventilation. It is not difficult to make a room for a boiler room with your own hands. Here is a list of requirements:

- Make grounding. At home, it is enough to drive three steel corners into the ground 1.5 meters on the street. Connect them together. Checking the quality of grounding is as follows. It is necessary to take the phase from the electrical outlet, zero from ground. If everything is done correctly, then any electrical appliance should work. That is, turn on.

- Installation of machines that cut off electricity.

- Laying a separate cable for connecting an electric boiler.

- Dry room for an electric boiler.

- The premises must be sufficient for connecting heating and water supply pipelines to an electric boiler.

- Natural light with a window area of 0.5 m2 is preferred.

- 12 kW boilers consume three-phase power supply.

Completion

All the above recommendations will help you avoid mistakes when choosing a room for a boiler room in a private house.

A boiler room in a wooden house is no exception.

When designing your cottage, you need to decide on the home heating system. The type and model of boiler equipment, its mode of operation.

In order to avoid gross mistakes, it is advisable to order a project from professionals. The construction of a boiler room in a private house is a serious business and requires special attention.

Source: https://NormaTeh.ru/teplosnabzhenie/trebovaniya-k-pomeshcheniyu-kotelnoj-dome.html

Heating requirements for industrial premises | Heating water supply boiler room

In the cold season, the autonomous heating of the industrial premises provides the employees of the enterprise with comfortable working conditions. Normalization of the temperature regime also has a beneficial effect on the safety of buildings, machines and equipment.

Heating systems, with the unity of the task before them, have technological differences. Some use hot water boilers to heat industrial premises, while others use compact heaters.

Consider the specifics of industrial heating and the effectiveness of the use of various systems.

Requirements for heating industrial premises

At low temperatures, heating of industrial premises, as required by labor protection, should be carried out in cases where the time spent by workers there exceeds 2 hours. The only exceptions are premises in which the constant presence of people is not necessary (for example, rarely visited warehouses). Also, they do not heat structures, being inside which is equivalent to carrying out work outside buildings. However, even here it is necessary to provide for the presence of special devices for heating workers.

Labor protection imposes a number of sanitary and hygienic requirements for heating industrial premises:

- heating the air inside the premises to a comfortable temperature;

- the ability to regulate the temperature due to the amount of heat released;

- inadmissibility of air pollution with harmful gases and unpleasant odors (especially for stove heating of industrial premises);

- the desirability of combining the heating process with ventilation;

- ensuring fire and explosion safety;

- reliability of the heating system during operation and ease of repair.

Outside working hours, the temperature in heated rooms can be reduced, but not lower than +5 ° С. At the same time, industrial heating must have sufficient power in order to have time to restore the normal temperature regime by the beginning of the work shift.

Calculation of autonomous heating of industrial premises

When calculating the autonomous heating of a production room, it is assumed that a constant temperature should be maintained in a workshop, garage or warehouse without strong changes.

For this, a central boiler room is being built, and heating radiators for industrial premises are installed in the working area. However, in some enterprises there is a need to create separate zones with different air temperatures.

For the first of these cases, a calculation is made for the use of a central heating system, and for the second, for the use of local heaters.

In practice, the calculation of the heating system of a production room should be based on the following criteria:

- area and height of the heated building;

- heat loss through walls and roofs, windows and doors;

- heat loss in the ventilation system;

- heat consumption for technological needs;

- thermal power of heating units;

- rationality of using one or another type of fuel;

- conditions for laying pipelines and air ducts.

Based on this, the need for heat energy is determined to maintain the optimal temperature. A more accurate calculation of heating systems for industrial premises is facilitated by the use of special calculation tables. In the absence of data on the thermotechnical properties of the building, the heat consumption has to be determined approximately according to the specific characteristics.

When making a choice among various types of industrial heating systems, one should take into account the specifics of production, heat engineering calculations, cost and availability of fuel - and on this build feasibility studies. The systems of infrared, water, air and electric types correspond most fully to autonomous heating of modern industrial premises.

Infrared heating of industrial premises

To create the necessary thermal comfort at workplaces, infrared heating of industrial premises is often used. Infrared (IR) heat radiators of local action are installed mainly in workshops and warehouses with an area of up to 500 m² and with high ceilings. In each of these devices, a heat generator, a heater and a heat-release surface are structurally combined.

Advantages of infrared heating of industrial premises:

- there is only heating of the floor, walls, workshop equipment and directly people working in the room;

- the air does not heat up, which means that the consumption of thermal energy is reduced;

- dust does not rise into the air, which is especially important for enterprises of the electronic, food industry and precision engineering;

- heating design and installation costs are minimized;

- infrared heaters do not take up useful space.

IR heaters are divided into stationary and portable, and depending on the place of installation, into ceiling, wall and floor. If necessary, impact on individual workplaces, apply directional infrared radiation using small wall heaters.But if you mount infrared film heating on the ceiling of the production room, then the heating will be uniform over the entire area.

Often they also arrange warm floors based on panels with built-in IR heaters, but with such a system, electricity consumption increases.

Options for doors to the furnace or boiler room of a private house:

See also in the catalog: Doors to the boiler room.

The purpose of the front door is clear to everyone, it must be practical, have a long service life, and so on. An additional advantage will be its design, resistance to climatic conditions of the area and a high class of burglary resistance.

When it comes to the door to the boiler room, the degree of responsibility is seriously increased. Both design and installation have a number of specific requirements enshrined in regulatory enactments, therefore, competent expert advice is required.

If you have not yet decided on the choice, see our offers

Powder coated

with MDF coating

For a country house

Tips & Tricks

The experience of operating Russian and foreign heating equipment makes it possible to formulate a number of tips and recommendations, taking into account which will help to avoid additional costs and ensure a comfortable standard of living:

- Installing a voltage stabilizer will protect the electronic boards or the boiler automation from failure due to power surges. Such boards are not subject to repair, and the replacement cost can reach 30% of the price of the entire boiler.

- Sewer drain with a drain in the boiler room floor will help to avoid flooding in the event of a coolant leak or an accident in the water supply circuit

- Installation of a boiler room in a private house with the installation of a heating control system for outside or room temperature brings significant savings in the form of reduced fuel costs. The amount of such savings in a time span of two to three years exceeds the cost of additional costs for the installation of such automation.

- When using antifreeze, remember that not all boiler manufacturers allow it to be used in their products. Using it in boilers of such manufacturers may result in loss of warranty.

- Aluminum and copper form a galvanic pair with each other, which leads to accelerated corrosion of the compounds of these metals. For this reason, contact of aluminum radiators in the boiler room with a copper pipe of the heating circuit should be excluded.

- In the absence of automatic temperature control in individual rooms, it is advisable to install adjustable valves with thermostatic heads on the radiators. This solution automatically maintains the set temperature.

- An important role in the layout of equipment is played by the requirement for its maintainability. Easy and convenient access to all elements when urgent repairs or replacement of equipment in a boiler room in a private house is required - a guarantee of quick and easy troubleshooting and accidents

Read other articles on this topic

| Diesel heating boilers | Electric boilers for heating a private house: features, how to choose, application |

| Combined heating boilers: types, features | Gas boiler room in a private house |

| Modular gas boiler room | Wood boiler for home heating - DIY installation |

| How to choose a gas boiler for heating a private house | How to choose a boiler for home heating |

| Boiler room design standards in a private house | Stand-alone boiler room for a private house |

Services on this subject

| Installation of a boiler room in a private house | Boiler room design |

| Turnkey installation of boiler rooms | Installation of a gas heating boiler |

| Installation of gas boiler houses | Installation of home heating boilers |

| Installation of an electric heating boiler | Installation of a solid fuel boiler |

| Pellet boiler installation | Installation of a diesel boiler |

| Installation of wall-mounted gas boilers | Installing a gas boiler in a private house |

| The cost of installing gas boilers | Installation of floor-standing gas boilers |

Features of boiler doors

- General construction.

The door leaf and frame are made of robust steel profiles. The standards do not set the minimum door width - as a rule, it is determined by the design or ease of use, in particular, the ability to move the boiler equipment. A convenient opening width should be at least 80 cm. The canvas should open outward. Doors can go both outside and inside, but in the latter case, the presence of anti-smoke partitions is required. - Ventilation grates.

One of the main features of boiler doors is the presence of a grate designed to ensure air exchange in the event of a gas leak, as well as to relieve high pressure in the event of a boiler explosion. In addition, the grate provides the additional air flow required for atmospheric boilers. The grate area is calculated using a special formula, which takes into account the power of the boiler, the size of the room and other parameters. - Glazing.

According to the current technical standards, the total glazing area of the boiler room must be at least 0.8 m 2. This ensures efficient deflection of the blast wave. If there is a room without windows or their size is insufficient, then the door with glass allows you to "pick up" the required area. Therefore, models are produced with varying degrees of glazing - from zero to maximum (about 80%). - Fire resistance.

The concepts of "fire resistance" and "fire resistant coating" are often substituted. Doors to the boiler room must have a fire-resistant coating on the side of the boiler room. The most relevant today is powder spraying. Less often, supervisory authorities oblige to install fire doors in the boiler room with a fire resistance limit of at least EL-30. This means that within 30 minutes under the influence of an open fire outside the room, the surface temperature should not exceed 180 ° C. In addition, all structural elements are made of heat-resistant materials.