We will send the material by mail

The foundation for the house is the foundation. Its laying is a crucial stage of construction. But before starting the construction of the foundation structure, it is necessary to prepare a base under it, which is called a pillow. Therefore, the purpose of our article is to determine which pillow for the foundation: sand or crushed stone is better.

Why is a pillow needed

Probably, it is incorrect to pose the question of which bedding under the foundation is better: sand or crushed stone. But it arises all the time when a suburban developer starts building a house.

The bottom line is that the base under the house must meet certain requirements:

- be strong and tight;

- groundwater should not accumulate under it;

- even if repeated wetting and drying occurs, the base should not lose its strength characteristics;

- under the foundation there should not be a layer in which active organic inclusions are present, because they will not only negatively begin to affect the quality of the foundation, but also rot;

- the bedding should not change during frosty heaving of the soil;

- and it should not allow uneven shrinkage, which leads to deformations of the foundation structure.

It is understood that the soil at the construction site may not meet the requirements stated above. That is, it will be difficult to select materials for the pillow without knowing the type of soil. Therefore, many developers work, so to speak, with what is available upon availability.

But in any case, it is necessary to understand that under the foundation you need a layer that at least approximates in its characteristics to the above-indicated requirements. What materials are used today to form the foundation cushion:

- sand;

- crushed stone;

- gravel;

- Sand and gravel;

- gravel in the form of crushed rock, which is called grit;

- skinny concrete layer.

Each of the designated materials has its own properties and characteristics, therefore, they are selected for the pillow, taking into account the characteristics of the soil at the construction site. But it should also be noted that the main task of the pillow is to adjust the performance of the soil under the foundation. Therefore, this building element is an optional structural part of the house. For example, on firm clay soils, a pillow is often not formed.

But if such is included in the project, then first the type of foundation for the ground is selected, and then the pillow.

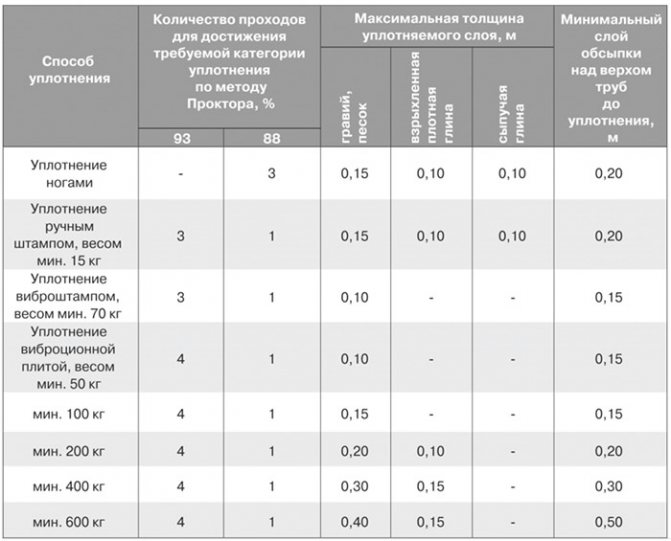

Coefficient of compaction of soil and sand

What is the coefficient of compaction of sand (Purchase) is known not only by specialists working in design organizations, but also by operators, whose main activity is construction. It is calculated in order to compare the actual density in a certain area, with the value prescribed by the regulations. The compaction ratio of bulk materials is an important criterion by which the quality of preparation for the main types of work on construction sites is assessed.

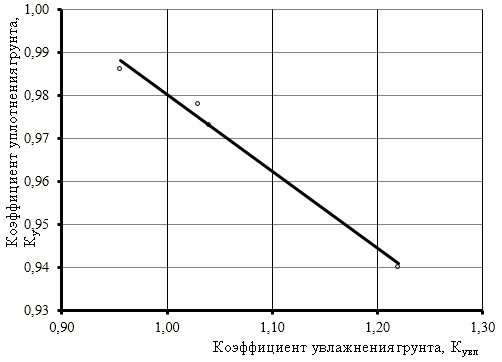

The purchase characterizes the density that the soil has in a particular area, refers to the same indicator of the material that has undergone standard compaction in the laboratory. It is this figure that is used to assess the quality of the work performed. This coefficient determines how the soil on the site meets the requirements of GOST 8736-93 and 25100-95.

In different jobs, sand can have a different density index. All these norms are spelled out in SNiP 2.05.02-85, table 22.They are also usually indicated in project documents, in most cases this figure ranges from 0.95 to 0.98.

What causes the density coefficient to change

If you do not understand what sand ramming is, then it is practically impossible to calculate the correct amount of material during construction. After all, you need to clearly know how various manipulations have affected the soil. What ratio of the relative compaction of sand we get in the end can depend on many factors:

- from the method of transportation;

- how long the route was;

- whether there is any damage of a mechanical nature;

- the presence of extraneous inclusions;

- moisture ingress.

Naturally, if you ordered sand, then you simply have to check it on the spot, because late claims will be completely inappropriate.

Why Consider Relative Factor When Building Roads

This indicator for a sand cushion must be calculated, and this is due to an ordinary physical phenomenon that is familiar to any person. To understand this, remember how the loosened soil behaves. At first, it is loose and voluminous. But after a couple of days it will settle and become much denser.

The same fate awaits any other bulk material. After all, its density increases in the warehouse under the pressure of its own weight. Then, during loading, it is loosened, and already directly on the construction site, the sand is again tamped with its own weight. In addition, moisture affects the soil. The sand cushion will be compacted in any type of work, whether it is road construction or backfilling of the foundation. For all these factors, the corresponding GOST (8736-93 and 25100-95) were calculated.

How to use a relative indicator

For any construction work, one of the most important stages is the preparation of an estimate and calculation of coefficients. This is necessary in order to correctly draw up a project. If it is important to find out how strongly the sand will be compacted during transportation in a dump truck or railway carriage, it is enough to find the required indicator in GOST 8735-88 and divide the required volume by it.

It is also necessary to take into account what kind of work lies ahead. Either you are going to make a sand cushion under the roadway, or backfill the foundation. In each situation, the ramming will proceed differently.

For example, when sand is backfilled, an excavated pit is filled. Tamping is done using various equipment. Sometimes compaction is done with a vibrating plate, but in some cases a roller is required. Accordingly, the indicators will be different. Keep in mind that the soil changes its properties during excavation. So the amount of backfill must be considered taking into account the relative indicator.

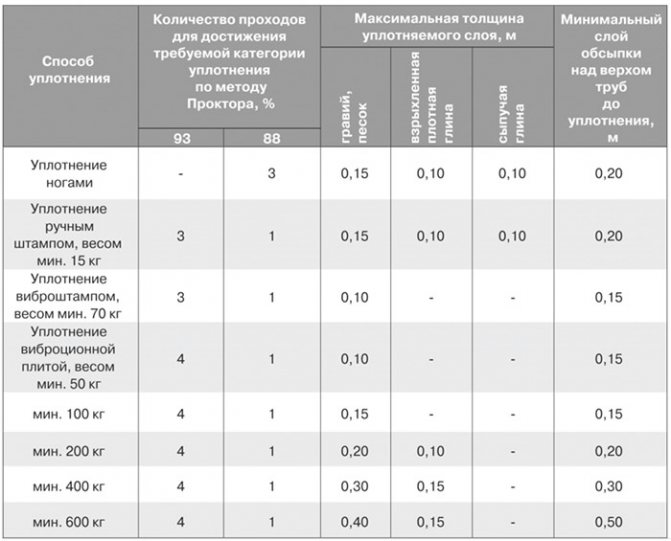

The table of values of the compaction coefficients depending on the purpose of the sand.

Varieties of foundation pillows

To begin with, the ideal cushion is a poured concrete layer. Sand, crushed stone and other materials indicated above are just an opportunity to reduce the cost of building a house. But among them the best is compacted sand. And there are several reasons for this:

- A well-compacted sand cushion has the same strength characteristics as dense soil.

- It evens out the uneven bottom of the foundation pit or trench more easily than other materials.

- Sand is an excellent drainage material that helps to drain melt and rainwater from the foundation structure.

- The formation of the pillow itself does not require the use of special techniques.

But it should be noted that the sandy layer has its drawbacks. First, the material is quickly washed away by groundwater. Second, it has poor transverse strength, especially if the load is pointwise.

For backfilling, it is better to use coarse-grained or medium-sized sand. A prerequisite is the minimum amount of clay inclusions.The thickness of the layer is 10-70 cm. It is possible to tamp in one pass a layer up to 5 cm thick, therefore the process of forming a sand cushion is long and laborious.

On our website you can get acquainted with the most popular projects of brick houses - from construction companies presented at the exhibition of houses "Low-rise Country".

Sand ramming is carried out with moistening. And here it is very important to catch the amount of water. If you overdo it with this, then the sand will begin to disperse from the place of ramming. That is, there will be a decrease in the thickness of the layer and a decrease in its density, which cannot be allowed.

The easiest way to determine the exact amount of water is to prevent it from appearing on the surface of the pad as it is tamped. And the required density of the compacted sand is determined by walking on it. There should simply be no traces on the surface.

So, having figured out why a sand cushion is needed for the foundation, as well as with the technical characteristics of the layer, we turn to crushed stone.

Rubble pillow

More recently, in private housing construction, one method was used to form a cushion from rubble. It was simply interfered with the bottom of a foundation pit or trench, and then rammed. It turned out a good quality pillow, which had one serious drawback - under the influence of groundwater, the earth was gradually washed away, only rubble remained. That is, the strength of the layer itself decreased.

Which crushed stone is better to use for the foundation cushion. To form this element at home today, crushed stone of a large and medium fraction is used. But this building material is used only if it is necessary to ensure the maximum possible throughput of the layer in terms of its drainage characteristics. At the same time, a drainage system must be formed around the house, and under it.

In all other cases, either a lean concrete solution is laid using crushed stone, or a mixture of sand and crushed stone. The latter, while seemingly inconsistent in terms of strength, has its own advantages over other materials:

- high drainage qualities that do not allow water to accumulate in the pillow;

- sufficient strength to speak of the ability to withstand the loads of a house of three floors;

- resistance to erosion.

Of course, even a mixture of two materials is a layer that absorbs water well. Therefore, there is a high probability that the cement milk, which is part of the concrete solution poured into the formwork, will leave the concrete, weakening it.

What the builders offer in this case. There is only one way out - to waterproof the bottom of the trench or foundation pit. But, as practice shows, it is often more expensive than pouring lean concrete.

How to tamp sand properly

Compacted sand is a material that is perfectly capable of resisting both stretching and compression. Accordingly, such a process as compacting sand should be given special attention. In order for an unburied foundation to turn out to be of high quality and durable, before starting work such as arranging a sand cushion, you should make careful calculations, determine how much sand is required, and determine what thickness the cushion should have in your particular case.

To complete the work, you will need a building level and an ordinary tape measure. The first step is to make a markup and dig a trench or foundation pit.

The bottom must be leveled very carefully, and the soil must be carefully tamped.

After that, you can proceed to the very process of the pillow device. To do everything correctly, you need to pour a layer of sand, the thickness of which corresponds to the technology of laying a particular type of foundation. The material must be pre-wetted with water.This is necessary so that the density of the sand during the compaction process is as high as possible.

In some cases, it is allowed to use not pure sand, but mixed with gravel.

In this case, the thickness of the layer should not change. The easiest way to achieve tamping material is to walk on a layer of sand in your shoes and stomp it thoroughly. Alternatively, a hand held vibrator can be used. From a special technique, you can use a vibrating plate. This will significantly speed up the process.

The thickness of each layer of sand should be no more than 200 mm. In this case, the minimum thickness cannot be less than 100 mm. And in this case, the pad is used to level the base.

The maximum thickness of the sand cushion under the foundation is usually calculated based on the width of the foundation strip itself.

What material to give preference

Let's start with the question - what material is better for a pillow under a strip foundation: sand or crushed stone. The tape structure is most often used in private housing construction, hence this question.

It is necessary to approach it like this. If the foundation will be constructed from ready-made concrete blocks, then the best option is sand, because it more efficiently distributes the load from the foundation structure. Plus: it is easier for them to level uneven surfaces. But there is one nuance - the sand layer is rammed with special units, which are called vibrating plates. If they fit in the trench, then sand can be used. If not, then it is better to ditch this material in favor of lean concrete.

As for the slab foundation, the situation is the same here. You just need to understand that sand is often used only because it is cheaper. And, as practice shows, it is often necessary to level the bottom of the pit by forming a sufficiently thick bedding layer. In this regard, both crushed stone and concrete solution increase costs several times.

But for the pile foundation, it is better to use crushed stone. Because the main function of the pillow in this case is groundwater drainage. And, as an addition, protection of the foundation structure from the negative effects of organic impurities in the soil.

The subtleties of the foundation device: in what cases is a crushed stone pillow required

If you want to sleep peacefully, choose the right pillow. Especially if you are going to sleep in your house, and the pillow is the underlying layer under its foundation. Let's say right away: for a serious building, a cottage of any number of storeys, the pillow should be made of rubble. It is under a shed or light shield house, you can spread sand. A massive structure requires a more solid foundation.

The soil can act as a cushion only if, when digging a foundation pit, you have reached the natural crushed stone layer of the required thickness. In other cases, it must be organized independently.

A crushed stone cushion has a higher strength than a sand cushion and is used for massive structures

Why do you need a pillow under the foundation

A crushed stone pillow performs several tasks:

- evenly redistributes the load from the foundation;

- significantly reduces point ground pressure;

- helps to level the bottom of the pit;

- significantly reduces the likelihood of soil shrinkage;

- protects the base of the foundation from groundwater.

Crushed stone is a product of crushing natural materials. Depending on the original breed, it can be of several types:

- Limestone. It has the lowest strength, but it is also relatively inexpensive and shows good frost resistance.

- Crushed gravel. It has high strength and is most often used in construction.

- Granite crushed stone. It is used in the construction of massive buildings, in the production of reinforced concrete blocks, it is characterized by increased strength characteristics.

Pillow shaping technology

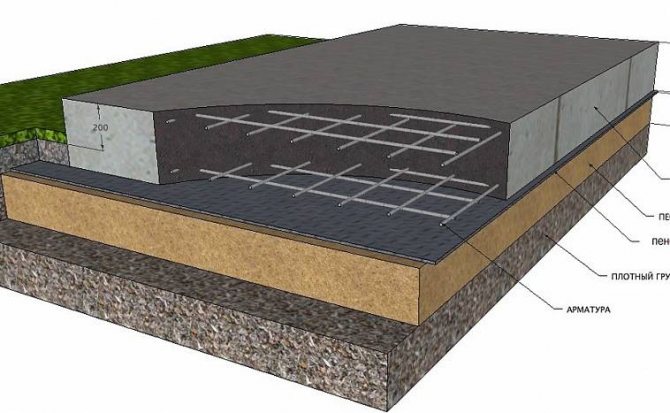

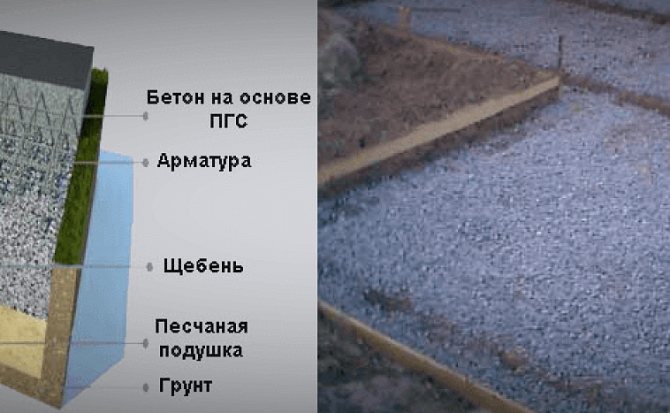

So, let's figure out the topic - how to properly make a pillow under the foundation of sand and rubble:

- Sand is poured into the bottom of the trench.It is rammed until the layer height is 10-15 cm.

- Next, crushed stone is poured. The material is also rammed until the height of the common layer is 40 cm.

Of course, you need to understand that the thickness of the pillow is selected taking into account the type of soil at the construction site. The softer the soil, the thicker the layer of the materials to be laid. It should be borne in mind that the width of the backfill should be 15-20 cm greater than the width of the foundation on each side. And the crushed stone must form a horizontal surface.

As for the question of what fraction of crushed stone is needed for a pillow under the foundation, this has already been mentioned above. Just a reminder once again - within 20-40 mm.

Monolithic sand cushion and its purpose

When using a sand cushion, the costs are minimal, and the effect is quite good.

By creating a sand cushion, the cost of building materials is significantly reduced. At the same time, private developers have an excellent opportunity to easily and simply replace low-quality soil in and at the same time make a general and uniform rise in the level of the entire floor. Despite the small material costs and simplicity of technology, such a monolithic slab perfectly copes with all the tasks assigned to it.

Sand base pillow: its advantages

- It becomes possible to create high-quality according to the permissible load standards.

- There is a guaranteed protection of the entire base of the structure from destructive destruction by groundwater.

- There is an excellent opportunity to level the entire site under the foundation of the structure being erected.

- And most importantly, this is a relatively low-cost construction stage compared to its importance for the entire structure.

When is a sand cushion needed under the foundation?

It is far from always required to make such an arrangement for the foundation of the structure being erected. Therefore, experts recommend that it is imperative to conduct a detailed analysis of the soil on the site where the house will be built. And already on the basis of these data, decide: is such a plate required in a particular case? But most often, a sand pillow is necessary to create a reliable and strong house, as well as to protect it from groundwater, flood waters, freezing and thawing of the soil.

Conditions under which it is necessary to install such a layer:

- If, according to analyzes, the site where the house will be built is problem soil. In this case, it is more expedient to compact such soil with sand.

- Be sure to ram the heaving soil with sand, since during freezing and thawing of the soil it is strongly deformed.

- The sand layer is an intermediate link between the base soil and the foundation itself, due to which the settlement of the entire structure in the future is significantly reduced.

To make a flat basement area near a dug pit or trench, experts most often use sand, since a thin layer of sand gives an excellent opportunity to align the bottom of the excavation or trench along a horizontal line. At the same time, you can eliminate all, even minor irregularities of any surface.

A building material such as sand is able to actively resist the natural compression process. Therefore, it is necessary to replace the surface layers of the soil with sand in order to avoid settling of the entire structure, as well as to protect its walls and foundation from dampness and moisture during many years of operation.

Sand cushion dimensions:

- The thickness of the layer of the sand bed itself is determined based on certain conditions. Usually, the pillow is laid in a layer of up to 20 cm, thanks to this, you can significantly save on the consumption of cement under the foundation.

- As for its shape, it is better to lay a trapezoidal sand pillow, which should taper towards the bottom. The taper angle should be 30 °.

- In this case, the created monolithic slab should not exceed the width of the foundation itself by more than 3 times in thickness.

Back to the table of contents

Briefly about the main thing

As you can see, the two materials indicated above can be used for the foundation cushion, either individually or in mixed form. Do not compare them categorically, that is, sand is better or crushed stone. In each case, one factor must be taken into account - the type of soil.

At the initial stage of construction, when the earthworks are completed, they proceed to the preparation of the base of the base of the foundation. At the bottom of dug trenches or a foundation pit, a pillow is made under the foundation. For small objects, it is better to form a pillow from sand. The question arises, how to choose the right sand for the foundation cushion?

Stages of work on the device and selection of material

Tamping sand under the foundation begins with marking the future foundation using a tape measure and a building level. Then, according to the project and the measurements made, a trench or foundation pit of the required depth and width is dug. If the digging was carried out by an excavator, then the bottom of the trench must be leveled, and then carefully tamped.

Then sand is poured into the pit, each layer of which is moistened with water so that the pillow becomes more dense, and tamped well. To determine if this is done correctly, the simplest method is used: they pass over the compacted layer in boots or boots. If there are no traces left, then the pillow has acquired the required density.

Sand under the foundation is rammed manually using a manual vibrator or a homemade bar with handles, or with a special device - a vibrating plate, which significantly speeds up the process of erecting a sand cushion. The use of a particular ramming method depends on the size of the structure and the amount of work.

Device for compaction of sand under the foundation

The sand is laid and rammed in several layers, each layer having a thickness of at least 20 mm. And they switch to the filling of the next layer after the previous layer has been compacted tightly. In this case, you should constantly monitor the evenness of the base using the building level.

The most optimal choice for a foundation cushion is considered to be coarse gravelly sand. It is undesirable to use fine-grained material, since it has low resistance to compression, which can lead to significant shrinkage of the erected building. Often, ordinary river sand with medium fractions is used for backfilling.

To improve performance, sand can be mixed with gravel or crushed stone, or each type of these materials can be used to create a foundation cushion.

Sand classification

Sand is a versatile natural building material. It is a sedimentary rock composed of grains of the mineral quartz.

Grade 1 sand

The breed is subdivided into several modules of the grain size of the breed:

- Large - from 2.5 to 3.5 mm;

- Medium - from 2 to 2.5 mm;

- Small - from 1.5 to 2 mm;

- Very small - from 1.5 to 0.7 mm.

The current legislation in Russia obliges all manufacturers of building materials, including sand minerals, to certify their products. The building material is divided into three classes:

- Grade 1 combines sands with compressive strength up to 30 MPa. They are used for the manufacture of concrete and reinforced concrete structures;

- The 2nd class includes material with a compressive strength of up to 20 MPa. Used for the manufacture of concrete and reinforced concrete products and other structures;

- The special grade 3 sandstone has a compressive strength of up to 40 MPa. It is used for the production of reinforced concrete products with a high bearing capacity.

Sands by their natural origin and methods of its extraction are of several types:

Quarry sand

The mineral is mined in quarries in a mechanized way.This rock contains many inclusions in the form of stones and clay. Without additional processing, it can be used as a bedding under the foundation. The quarry mineral is sieved or washed. Foreign impurities in the form of stones and clay particles are screened out through a special sieve.

The rock is washed with a large amount of water, washing out clay and other inclusions. Alluvial sandy rock contains fine particles of about 0.6 mm. It can be used for plastering work.

River sand

I extract the river mineral with floating dredges from the bottom of the river. This breed is better than other types of sand in terms of its quality characteristics. The high quality and purity of the sand is due to the natural purification by the waters of the river.

As with sea pebbles, the shape of river sand grains is also rounded. Therefore, when using river sand as a foundation cushion, reinforced compaction of the sand layer will be required.

Sea sand

To use sea sand as a building material, it is subjected to double processing. First, during the extraction of sand, foreign impurities are removed from it, then the rock is subjected to hydromechanical treatment.

The sea mineral is considered one of the highest quality minerals. They use it in all areas of construction.

Crushed sand

Crushed sand is mined by crushing rocks with mechanical mills. Its cost is quite high, which is reflected in the price of the material.

The advantage of the material is the irregular shape of the grains of sand. This ensures a tight connection of the rock particles with each other. When compaction of the sand bed of the foundation, there is a slight decrease in the volume of backfill, which reduces the consumption of sand.

Which sand is best to use to create a pillow

Gravel sand is used to create the foundation cushion.

For the construction of a high-quality sand cushion, experts recommend using coarse gravel sand. At the same time, it is categorically not advised to use a thin and fine fraction, because such material negatively affects the resistance to compression, and this fact in the future threatens with severe shrinkage of the entire structure. In order for a reliable monolithic slab to be installed in accordance with all the requirements, it is advisable to use clean river sand of the middle fraction.

As a last resort, you can use quarry sand. But in order for the sand layer to serve for many years, not to be destroyed and washed by groundwater, before filling a trench or foundation pit, an insulating material should be laid - geotextile. Why is this needed? This precaution will effectively prevent sand and soil from mixing in the future.

Materials and tools used:

- pegs and rope;

- sand;

- insulating material - geotextile;

- level and tape measure;

- an excavator for digging a hole or a shovel for the manual method;

- dump truck for sand delivery;

- vibrating plate, manual vibrator or large round bar with handles.

Sand pillow

The underlying layer of the foundation sole is multifunctional in its intended purpose:

- Backfilling under the base of the foundation levels the soil base of the trench or foundation pit. It is imperative to arrange a sandy underlayment under the precast concrete foundation blocks.

- The sand layer helps to prevent the foundation from moving on weak heaving soils. Due to the filling, the bearing capacity of the soil base increases.

- When the thickness of the sandy litter is more than 30 cm, the possibility of capillary penetration of moisture from the soil to the base of the building is interrupted.

- Sandy rock removes water better than other building materials, thereby protecting the base structure from soil heaving. Without an additional drainage device, the mineral can become silted. Before starting construction, it is necessary to determine which drainage is better for the underlying layer of the foundation.

For the construction of the underlying layer, they try to use only coarse and medium-sized sand. The sand layer protects against siltation by groundwater with waterproofing. When silting up, the underlying layer can turn into a heaving base.

Geotextile for cushion insulation

To avoid this, roofing material is laid in two layers, polymer material, geotextile or other waterproof material, on the ground in dug trenches under a monolithic tape, at the bottom of a pit for a reinforced concrete slab. What type of waterproofing to use is up to the developer.

If the embankment is of great height, then sand under the foundation is poured in layers 200 mm high. Each layer is moistened to increase the adhesion of the grains of sand.

Compaction of the next layer of sand is obligatory. For this purpose, both an electromechanical vibrating plate and a rammer made of improvised material are used.

Tamping cushions

The manual rammer is easy to manufacture. A double-sided handle is nailed to the upper part of the block, and a wide board 25-30 mm thick is attached to the lower cut of the log. The height of the fixture should be comfortable for work.

Sand cushion under the foundation - when you need it

Before starting construction, it is necessary to assess not only the condition of the soil in the area of \ u200b \ u200bthe construction of the house (bearing capacity, proximity of underwater waters), but also the climate conditions, as well as the total weight of the structure. Heaving soil is compulsorily rammed, which is significantly deformed during freezing and thawing. If you make a mistake with the choice of material for installing a slab under the foundation, most likely the building will shrink heavily, which will entail the formation of cracks in the walls and the foundation itself. In addition, if the soil in the construction area has a high bearing capacity, and the water table is extremely low, you can do without creating a sand cushion.

Of all the materials that are used to create a pillow, it is sand that is most acceptable. It not only allows you to save a decent amount, compared to a slab of crushed stone or concrete, in addition, it is quite acceptable to tamp sand with your own hands - for example, it is much more difficult to work with crushed stone. There is only one limitation on the construction of a sand cushion - heavy buildings (apartment buildings, shopping centers) cannot be built on it, but for private low-rise construction, it is almost an ideal material.

Sand pillow

A properly designed sand cushion has many benefits:

- The base created with sand fully complies with all standards used in low-rise construction.

- Complete protection of the entire building from the negative effects of groundwater.

- Creation of a perfectly flat construction site without the use of complex and expensive technologies.

- The ability to carry out all work on your own.

- Quite affordable cost of this important stage of work.

General information

What is it for

Ramming, i.e. vibrating plate, consists of five main elements. it engine, which is gasoline, electric and diesel, and drives all the parts of the tool. Belting helps to transfer torque from the engine to eccentric... That, in turn, helps to create vibrational vibrations in order to perform ramming.

The impact on the treated surface is created using base plates, and you can manage everything with the help operator handles. The vibrating plate has a heavy and powerful base, which, together with vibration at high frequencies, allows the surface to be compacted. The efficiency of the work done will depend on the power of the device and the volume of its electric or gasoline engine.In most models, the devices are quite maneuverable, and this makes it possible to perform tasks even on inconvenient and sometimes curved surface areas.

Application area

The pneumatic soil compaction rammer has been designed to compact bulk materials using oscillating movements. After the materials are poured onto the surface, their particles will not be located close enough to each other. In order for them to fit as tightly as possible to each other, a tamper should be used. This will help change the load-bearing properties of some of the materials so that future construction work can be carried out on this surface. Tamping with a vibrating plate is used for a large number of areas of construction.

It is especially often used for such cases:

- Road construction.

- Laying lawns.

- Creation of a loose cushion for foundations in a large number of buildings, and also on floors in tall buildings.

- Construction of parking lots and sports grounds.

- Asphalt laying.

- Seals for trenches and pits, laying of utilities.

In special cases, tamping is used to lay paving slabs and paving stones. This makes it possible to perform work several times faster.

Site preparation

Before ordering grass in rolls and arranging the lawn, you need to prepare the site. First, they remove garbage and all unnecessary objects, uproot the stumps. Be sure to get rid of weeds, by weeding or using herbicides - they work for two to three weeks, they are applied to the greens. It is necessary to remove the roots of all weeds, pest larvae. Sometimes there is a need for drainage - in cases where puddles remain on the site after precipitation. To do this, you need to cut off a layer of earth - about 40 cm - and fold it to the side. Then gravel - 10 cm is poured into the formed recess and compacted, and sand is placed on it. Now you need to cover everything with earth that was cut off at the beginning. The humus on the site should be about 15 cm thick and fertile.

Leveling and compacting the surface

Now on the territory you need to create a flat horizontal surface. This is done by pulling the string over the pegs. By the distance to the ground, you can determine how much soil you need to add or remove, and in what places. If there is no drainage system, then the site should have a slope of 6 degrees. Then the soil is rolled with a garden roller or a log to avoid subsidence in the future. A soil that does not sag underfoot is considered to be well prepared for a lawn. It should be noted that after laying the lawn will become about 2.5 cm higher. It is now the turn of watering and fertilizing the land. For warm weather, choose nitrogenous, for autumn - phosphorus-potassium supplements. After the fertilizers have been applied, we recommend leveling the soil with a rake. Next, we start laying the finished lawn.

Lawn device: sequence of actions in the prepared area

- The device of the lawn begins with the fact that a thin rope is pulled over the pegs, outlining the perimeter of the future lawn.

- You need to start laying from the side of the site where the unloaded rolls lie. Unfold the first canvas and straighten it so that it lies correctly.

- Next - with the long side to each other, lay the second canvas. Make sure that the edges of the rolls do not overlap one another, but only slightly touch.

- To avoid overlapping seams from the second blade, cut off half. Thus, laying the lawn should be similar to that of brickwork. This manipulation must be repeated in every second row, and the cut parts must be laid at the end of these rows.

- To the first two rolls, to their narrow sides, the next are applied, and so on.

The canvases should only be rolled straight without bending, even if there are rounded objects on the site.Otherwise, a ruptured bale may leave folds and bald spots on the lawn. Short cut pieces can be stacked in the middle, because from the edge they take root worse. If the site has a slope, grass canvases are laid across it and strengthened with pegs. After tamping the lawn, the laying does not end; the grass and soil must be moistened. At this stage, check for pits or bumps. If they are found, lift the blade up and level the surface underneath. Then tamp the lawn again. The cut edges of the canvases should be mulched and covered with earth. The same is done with the seams between the rolls. It is necessary to water the laid lawn not with a jet from a hose, but with a sprinkler. Moisture must penetrate to a depth of 3 centimeters. This work is done only in the early morning or evening hours. For the first week or two, the lawn is watered every day. Moisture must penetrate to a depth of 5 centimeters. This completes the lawn device.

How to work with it correctly?

In order to start using the vibratory plate, no special skills are required.

Any person can cope with such a task if he remembers the safety rules and acts extremely carefully:

- Before starting work, a very thorough inspection of the vibrating plate should be carried out to find out if there is any malfunction in it. Particular attention should be paid to the transmission belt guard, as it is this that protects the engine from dust. If the vibrating plate is powered by diesel or gasoline, then it is required to check the presence of oil and fuel in the engine.

- The area you plan to work with the vibrating plate should be well leveled and cleaned of debris. Do not work on a dry or very wet surface, immediately after heavy rain.

- The mechanism should be started. In 80% of models, this requires only pressing the "START" button. On separate vibration plates there is also a manual starter, so to use such models, you should smoothly start pulling on the cord and wait until the equipment warms up well. Start the engine only on a level surface.

- The operator of the device must always be behind the vibrating plate during work. He should not lean over the device too much or try to speed up the work with artificial methods. the tool will operate in a precise mode that will be selected according to the surface.

- Use the special handle to operate the vibrating plate for ramming and compaction. It enables the device to turn in all directions. After turning, you should quickly go over the plate so as not to accidentally injure yourself.

Do not forget that the consumables of the device should be changed in a timely manner. The oil should be changed at least once a month, or every 100 hours of operation. Use gasoline and oil only of the brand that is allowed, as otherwise it will lead to the fact that the plate compactor will quickly fail. The brands of gasoline and oil must necessarily correspond to what is indicated by the manufacturer to the technical manual for the device. Before tamping any loose materials, the surface to be treated should be cleaned. To do this, you should remove various debris from it - fragments of bricks, pieces of boards, cobblestones.

Sand

Compaction of the sand mixture is carried out using a different technology.

Operating principle for ramming with a vibrating plate:

- An even layer of sand should be poured onto the prepared surface. Its thickness must be at least 60 cm. Specific indicators will depend on how much your device weighs.

- Moisten the entire surface evenly with water.

- After that, the vibrating plate should be passed over the entire area at least 4 times.

- If the sand has acquired the required density, then you can fill in the second layer, and if it is loose enough, then go through the device a couple of additional times.

- On the second filled layer, repeat everything one more time.

When tamping is complete, the surface compaction factor should be at least 0.95. If you plan to install columns in the selected area, then additional equipment may be required for compaction.

Just as when compacting the soil with a manual rammer, the sand should also be moistened, this is an obligatory item in the plan. If this is not done, then during operation the vibrating plates will begin to create a lot of dust, and this, in turn, will cause the air-cleaning filters to quickly clog (this is especially important for vibrating plates on a gasoline engine). But keep in mind that you cannot use too much water, as otherwise it will start to clog between the material and will interfere with its effective bonding. To achieve the desired cementing effect, water should be poured, but in moderation.

Safety precautions for work

When compacting the soil with a pneumatic primer and using it for other materials, you should first go through the safety rules.

From the recommendations that already exist, remember the following:

- For safe work, the operator must always cover the body and face with personal protective equipment, namely headphones, glasses, hard hats, durable clothing and shoes.

- If the work will be carried out on a small hill, then the operator and other workers must be above the device. In this case, the work should be done from top to bottom.

If the vibrating plate for some reason stumbles upon an obstacle, then you should urgently turn it off. After that, remove the obstacle, and the tool should be inspected so that it does not have any malfunctions.

Note that the higher the unit's center of gravity, the easier it is to tip over. In addition, the technician should be careful when working with equipment that has a small footprint.

Work especially carefully with a vibrating plate that has a soft start button, since if the work is done in a closed room, then it will be much safer for a person to use models with a remote control. Naturally, such devices are more expensive, but they fully justify their cost. Tamping with a vibrating plate helps to cope with any task that is associated with the compaction of bulk materials. To obtain a high-quality result, you should take into account the characteristics of specific surfaces, and also calculate the appropriate thickness for the layer. The main attention should be paid to safety. Failure to follow these basic rules can result in serious injury and damage to the instrument.