Features of Rehau pipes

The production of pipes using a new technology determines the fundamental features of the products, which consist in the following aspects:

- increased noise insulation. XLPE is capable of absorbing sounds produced by the flow of water;

- installation of Rehau pipes is carried out using a unique method that allows you to create the most durable connection;

- the material from which the pipes are made is versatile. From pipes, you can create systems for hot and cold water supply, heating, and use for arranging a warm floor. The maximum temperature of the liquid in the pipe is 95 ° C;

- pipes are practically not susceptible to cracking and deformation during mechanical damage, so they can be laid under plaster or covered with other structures;

- high degree of thermal insulation, which helps to save natural resources;

- any pipe is able to withstand the temperature differences of the liquid and internal pressure;

- complete safety for humans. The company's products are certified;

- a special coating of the inner walls of the pipes prevents the formation of plaque and a reduction in throughput.

Materials that give Rehau pipes unique qualities

Rehau pipes and various fittings can be used to design pipelines of any complexity and purpose.

The only drawback of Rehau pipes is the high cost of products and fittings.

A little about Rehau pipes

Rehau started the production of pipes and fittings back in 1948.

Despite the colossal experience, cross-linked polyethylene began to be used by the company relatively recently, and the technology immediately gained popularity among consumers.

The main advantages of Rehau XLPE are the following factors:

- High noise insulation has a beneficial effect on the comfort of use. This is possible thanks to the multi-layer construction, which reduces the noise level of the flowing liquid.

- The special design of the mounting assemblies guarantees the creation of strong connections, thereby increasing the reliability of the structure.

- Excellent resistance to temperature extremes. This property allows the use of Rehau cross-linked polyethylene pipes for heating, cold and hot water supply, and underfloor heating.

- Durability of materials, resistance to cracking, geometry change or corrosion. Such properties made it possible to mount wires under plaster or in the body of walls.

- Lack of emitted harmful substances when heated.

- Some models can withstand a lot of pressure.

- High-quality layers of thermal insulation allow you to save energy on space heating due to the absence of losses during transportation.

- The smooth surface of the inner shell provides sufficient resistance to the formation of deposits, which reduce the flow area of the pipe.

The widest selection of fittings makes it possible to create wiring of different types and designs. The only drawback of the product is its high cost, which is fully compensated by its quality.

Installation of pipes

To install Rehau pipes with your own hands, you need:

- purchase the necessary tool;

- pre-familiarize yourself with the instructions for assembling the pipeline.

Tools required for installation

Before proceeding with the installation of pipes, you must:

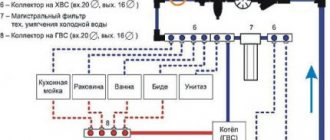

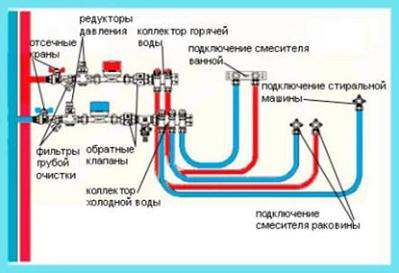

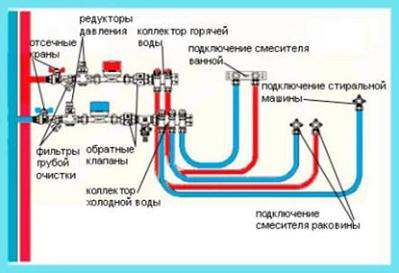

- purchase the required number of pipes, connecting fittings and adapters. To calculate the necessary materials, a water supply diagram is drawn up;

An approximate wiring diagram for hot and cold water pipes in a city apartment

- prepare a tool for installing Rehau pipes:

Expander for pipe mounting

press clamp with additional attachments of different diameters. Since the installation of the type of pipes in question is somewhat different from conventional welding, then such a specific tool for installing Rehau pipes is also required for the procedure;

Hand press used for connecting pipes, REHAU RAUTOOL

pipe cutting tool. Standard pipe cutter, used for all types of plastic pipes;

Tool for cutting polymer pipes

tape measure, pipe marker.

Standard measuring tool used in construction

All tools can be purchased individually or as a set. The average cost of a set is 2,500 rubles.

Pipeline assembly process

The installation of Rehau XLPE pipes begins with the preparation of the pipes. Preparation consists of two steps:

- according to the previously prepared drawing, pipes of various sizes are cut;

The process of cutting a pipe to the desired size

- the fittings required for the assembly of a specific section of the pipeline are prepared.

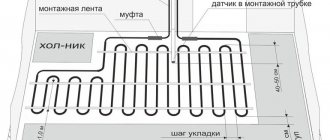

If heating with Rehau pipes is being installed, then it is more expedient to immediately prepare all sections of the system, and then first check the correctness of the sections according to the scheme.

For inspection, all pipes and fittings are placed on the floor in a specific order. This is especially true for heating in city apartments, since it is required to turn off the heating throughout the house.

When cutting pipes, one should be guided by an old Russian proverb - “measure seven times, cut once”. Mistakes in pipe cutting can make it impossible to install the piping system indoors.

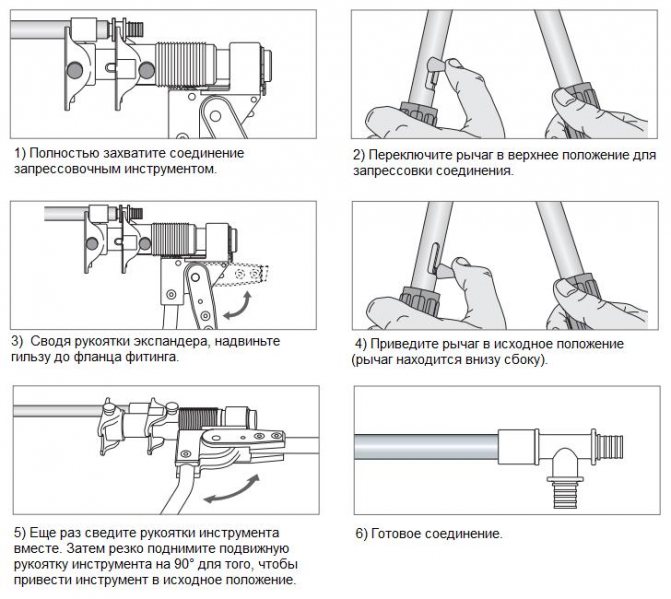

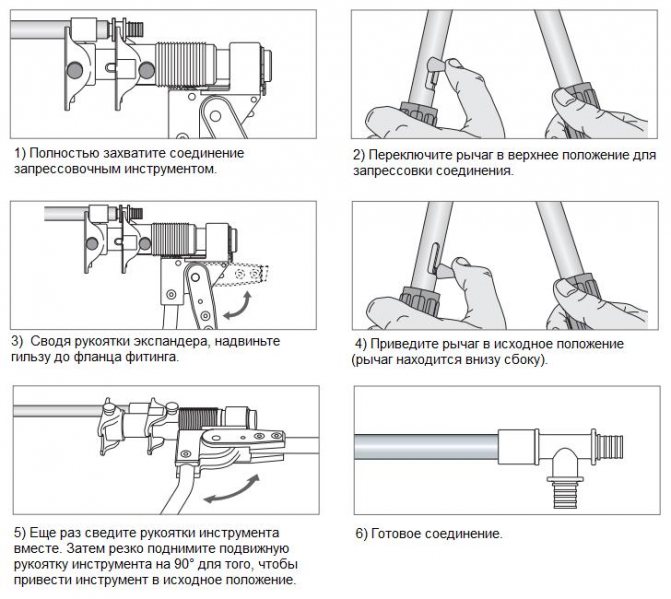

Docking of pipes and fittings to each other is carried out using sleeves, which are fixed as follows:

- a nozzle is selected on the expander, the diameter of which fully corresponds to the diameter of the pipe used. In this case, the tool handle must be completely divorced (the ends of the handle are at right angles to each other);

- the nozzle on the expander should hold firmly and sit on the pin until it stops;

- a sleeve is put on the piece of pipe that needs to be connected to the fitting. The diameter of the sleeve used must also match the diameter of the pipe;

Each sleeve is chamfered. During installation, it should be directed towards the future joint.

- a pipe is put on the other end of the nozzle installed on the expander. When the handle of the expander is brought together, the pipe expands;

Pipe expansion process for further installation

- the expanded end of the pipe is connected to the fitting that must be installed in this place;

Inserting a fitting into a prepared pipe end

- a previously installed sleeve is supplied to the fitting;

- using a press clamp, the sleeve is pushed all the way into the fitting. A strong and reliable connection is ready.

Fixing the fitting with a press clamp

When arranging the connection of pipes and fittings, even the slightest distortions must not be allowed. All connecting parts should be located strictly horizontally to each other. Otherwise, the connection will be unreliable.

Step-by-step diagram of work with a press clamp

Installation of Rehau pipes for heating, gas or water supply must be carried out in compliance with all safety standards. First of all, care must be taken to protect the eyes (use of a mask) and hands, which are not recommended to be inserted into moving parts.

The video below for the installation of Rehau pipes will allow you to observe the process from the outside in order to more accurately find out all the most important aspects.

Everyone can install pipes of the German manufacturer Rehau. The main thing is to have the necessary tool and strictly follow the instructions above.

Mounting Rehau Fittings - Helpful Hints

The most important part of the work is the installation of XLPE pipe fittings. The durability of the structure and the possibility of its operation in principle depend on the quality of the connection.

Installation of Rehau pipes must be carried out in strict compliance with safety regulations. It is necessary to protect your eyes, do not bring your fingers to the working parts of the tools during their operation.

- A construction drawing is being prepared, further work will be carried out on it.

- All sizes are carefully measured. The first stage is extremely important, since after cutting the pipe, it will be impossible to change its length. There are times when a too short segment goes to waste, due to the impossibility of adjusting the dimensions.

- Lay out all the elements according to the scheme and complete the joints with fittings, couplings. This is especially important when installing heating pipes, when you need to do everything very quickly.

- After everything is checked, everything is enough, the system is pressed. Pre-prepared fittings are installed in the network. Then the performance of the pipeline is checked, all joints are carefully checked for leaks.

Preparation for installation work

The collector outlets should be the first items requiring increased attention. Only their correct processing will ensure complete tightness in the system.

Before installation, the workplace must be completely free of dust and debris, as well as the equipment. Welding, threading and gluing are the most widespread methods during installation. You only need to purchase the appropriate type of fitting, depending on the method of installation you have chosen.

Watch video: Bir Pex systems

Absolutely all parts that are used during installation must be whole and clean. A visual inspection is required prior to purchase. This will ensure the quality of the finished product. Their transportation deserves special attention.

Methods for joining metal-plastic pipes

The connection of the elements of the metal-plastic pipeline can be carried out using two types of fittings:

In the latter case, ferrules or push-in press fittings can be used.

When using press fittings, a tool for installing metal-plastic pipes is required - press tongs, which can be mechanical or hydraulically driven. Mechanical pliers are usually used for domestic purposes, while hydraulic power tools are used for professional purposes.

Regardless of the type of fittings, you will need the following tools:

- tape measure,

- pipe cutter,

- calibrator,

- for push-on press fitting - expander,

- wrench.

Why is unprofessional installation dangerous?

Installation of Rehau pipes in an apartment, which is carried out by non-specialists and without the use of professional equipment, can entail the most disastrous consequences. In the event of a burst of pipes, the flooding of the dwelling and all adjacent areas is ensured.

If a gust has passed on the heating system, then in winter you are threatened with a complete defrosting of the system and the difficulty of restoring it. If you order the installation of the Rehau pipeline in, then you will not face any of the unpleasant consequences.

The work done by professionals has several distinctive characteristics:

- the pipeline layout is the most optimal, does not interfere with other systems and the conduct of normal life processes for the owners of the living quarters;

- each pipe connection is of high quality and has even seams;

- the correct type of pipes was selected for installation, which is compatible in parameters with the system being installed;

Required installation tool

Before connecting REHAU pipes, you need to buy a sufficient number of tubing products, fittings and adapters. The scope of all materials will become clear after drawing up a complete water supply scheme.

Of the tools for installing REHAU pipes, you will need:

- Expander (expander) with replaceable nozzles for pipes with different sections.

- Press clamp with replaceable attachments for different sections. Since the laying of the described pipes differs slightly from the usual welding, then a specific tool for REHAU pipes will also be needed.

- A common pipe cutter that is suitable for cutting all kinds of plastic pipes.

- Roulette and marker for marking.

The entire list of tools can be purchased as one set or separately.

What are the main advantages and features

- Reverse shrinkage. Products are able to resist high levels of pressure, and after prolonged exposure, they return to their original form. Other materials with similar parameters simply stretch after a while and become unusable completely.

- Increased heat resistance. Such pipes work normally at temperatures up to 120 degrees.

- Availability of prices.

- The ability to resist freezing.

- They tolerate high temperatures and pressures.

- Convenient installation.

- Low weight.

- Bir Peks, Rehau and other firms have a high rate of sound insulation. Thanks to this, the room itself is protected from extraneous sounds. The pressure surges are completely absorbed by the system itself.

- Long service life combined with high strength. You can forget about rotting and corrosion when working with this material.

- Environmental friendliness. Polyethylene does not emit harmful substances, even when it is very hot.

- Elasticity.

Tools required for working with a reinforced plastic pipe

First you need to figure out that a metal-plastic pipe, depending on the type of fittings used, can be assembled using a special press or by means of crimping nuts.

If we talk about the reliability of certain fittings, then they are approximately at the same level. The difference between them is that, unlike crimp, pressed limit switches that have leaked, there is no way to fix it. The leaked fitting should only be thrown away and replaced with a new one.

Connection of metal-plastic pipes - fittings

In addition, for the installation of such a pipe, an expensive press is required, which makes no sense to purchase it for a one-time job. Therefore, in the master class we will focus on the most common crimp fittings, which even a schoolboy can assemble with his own hands.

Installation process

Installation technology includes several steps.

- We screw the nozzle with the required diameter onto the expander.

- After that, we put on the crimp rings on the pipes themselves. And we do this so that the place of the pipe expansion is not occupied.

- An expander must be inserted into the pipe. It expands when the installer pushes the special handle. The next step is to turn the pipe itself or the expander by 30 degrees. And then they press the handle again. You can repeat the operation to consolidate the result. After that, proceed to using the fitting.

- The shutter is retracted from the press with your own hands. Next, pull out the pins used for fastening. The next step is threading the nozzles that are fixed with pins. The shutter clicks.

- The connection takes on a finished form. The product must be pulled out of the press.

Do-it-yourself installation of metal-plastic pipes using press fittings

The device for connecting pipes using press fittings has a number of advantages:

- unlike screw press fittings, they form permanent connections that do not need control and tightening;

- the connections are strong and durable, the service life can reach 50 years,

- permissible operating pressure at the docking points - 10 atm;

- their indoor installation, pouring with concrete is permissible.

If it was decided to use metal-plastic pipes, do-it-yourself installation can be done simply and quickly if you use press fittings, since in this case welding, soldering and threading are not required.

The first step in installing a pipe with press fittings is to cut the pipe at right angles. The edge is processed by chamfering, the pipe diameter is adjusted to the desired size. A stainless steel sleeve is put on the end of the pipe.

Fitting fittings are installed in the pipe up to the stop. A hand or hydraulic press clamp is applied to the sleeve. Tool handles are brought together to the stop.

Installation of a cross-linked polyethylene pipe

Materials (edit)

Before starting work, prepare the necessary tools and consumables. You will need:

- Vise.

- Fittings: couplings, adapters, elbows, tees, sliding sleeves (when installing a sliding sleeve, you do not need to use rubber gaskets, which increases the reliability of the structure).

- Expansion device.

- Roulette.

- Pipe cutting tool.

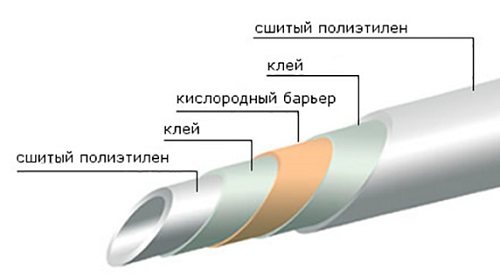

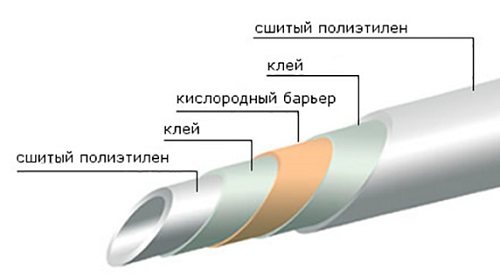

Rehau pipe - construction

Installation of metal-plastic pipes. Fastening the fitting

It is necessary to cut a piece of pipe to the required length. We do this with special scissors.

IMPORTANT! If you use any other tools, then there is a high probability of damage to the protective layer of the pipe, moreover, the cut will most likely turn out to be uneven. In the future, this will entail problems associated with the reliability of the connections - leaks may occur in these places!

To make a high-quality and reliable seal, O-rings are used on the fitting of the fitting.

In order not to damage these rings during installation, the pipe should be expanded with a calibrator! To connect a metal-plastic pipe with a fitting, nuts and a clamping clamp are used.

To begin with, we put a nut and a clamping clamp on the pipe.

It should be borne in mind that before performing the installation of a metal-plastic pipe, it is necessary to remove sharp edges inside the pipe along the edges. This can be done with the help of a special device or with the help of improvised tools.

Sharp edges are removed so that during the installation of the pipe on the fitting, the inner edges of the pipes do not damage the sealing elastic bands, because otherwise, insufficient tightness of the connection may occur and, as a result, leakage.

The inner sharp edge of the pipes can be removed with a small diameter sharpened drill (designed for metal work). This operation can also be performed with a round file.

Sometimes cutting pipes leads to their partial deformation. To give the pipe a perfectly round shape, you can use a special tool - a calibrator.

Using a calibrator, flare the end of the pipe, put it on the fitting union.

Aligning tightly with the fitting squeegee, return the clamping collar.

We return the fitting nut and begin to tighten.

It is important!

When tightening the nut, be careful not to use too much force. It is necessary to tighten until a certain crackling appears. If a crack appears, then the nut has already tightly squeezed the clamp around the metal-plastic pipe.

In the case when you need to bend a metal-plastic pipe with your own hands at a right angle, it is advisable to use a special spring - it will not allow the pipe to be squeezed at the bend! You can find more details on the page of our website - bending of metal-plastic pipes.

To install metal-plastic pipes to the surface, as an option, you can use special devices - clips.

There are clips in various sizes and designed for different types of pipe sizes. In order to lay the pipe along the clips neatly and evenly, it is necessary to mark them for fixing them.

The clips are fixed with screws, dowels, self-tapping screws and even nails.Since the pipe snaps into place quite easily with the clips, you don't have to work hard.

Source: gvozdem.ru

XLPE and its benefits

In production, the company uses high quality polyethylene, in which a linear bond is crosslinked with peroxide inside its structure. This material is marked with PE-Xa, thanks to which the products have high strength and heat resistance. Polyethylene is able to repair damaged areas due to the fact that the bond between molecules is not broken. The video shows the technology for the production of polyethylene products.

Important! The high cost of products is due to the company's use of high-quality and environmentally friendly raw materials.

The main advantages of the material:

- all products are certified and tested;

- has a high resistance to corrosion processes, the pipe walls do not crack, break or chise;

- the material does not allow dirt to accumulate inside the pipes, which excludes the formation of build-ups;

- the pipeline works without noise;

- has great resistance to high temperatures inside the system, the structure is able to withstand 100 degrees, and with a slight heating of water and 200 degrees;

- retains its shape at low temperature conditions, is shock-resistant;

- high resistance to chemicals;

- environmentally friendly material that is not capable of harming human life and health;

- the service life is more than 50 years;

- installation does not cause any problems, you can do it yourself.

How to connect metal-plastic pipes

Now about the direct connection of the pipe and fitting. To begin with, you need to put on a nut on the end of the pipe to be connected and then pull the brass compression ring after it.

In different models of metal-plastic pipes, the crimp ring can be made in different ways - some manufacturers make it a cone, while others make it straight with large chamfers. Those with chamfers can be installed on either side, and those made with a cone are put on the pipe with the thin side of the fitting.

Have you put it on? Now, the trimmed edge needs to be calibrated. As a rule, the inner diameter of reinforced-plastic pipes is slightly smaller than the nipple of the fitting - this is done in order to achieve a high crimp density.

In the normal state, it is rather difficult to pull the pipe over the fitting. We insert the gauge into the inner hole of the pipe and, turning it in different directions, immerse it a couple of centimeters deep.

Some craftsmen, instead of a calibrator, use the handle of an adjustable wrench - this is wrong and can lead to unpleasant consequences in the form of deformation of the pipe end and, as a result, leakage of the connection.

Working with reinforced plastic pipes - calibration

After slightly moistening the fitting with water, we put a pipe on it. It is necessary to pull it up to the very end, until the pipe rests against a small white ring. If you do not insert the pipe completely, the chances that it will be ripped off during operation increase several times. At this stage, you should check the evenness of the cut - if the pipe rested against the white ring evenly from all sides, then everything is in order.

If there is a gap of more than a millimeter on either side, then it is better to remove the pipe and cut its end again, since such a joint can lead to a leakage.

Connection of reinforced-plastic pipe and fitting

If everything is connected properly, then you can move the nut as close as possible to the fitting and, using adjustable wrenches, clamp it with all force until a characteristic squeak or squeak appears.

Do not be afraid to pull - if the fitting is of high quality, then the nut will withstand any load. If it bursts, it’s even better. You will get rid of low-quality spare parts, the operation of which could lead to a flood.

Do-it-yourself installation of metal-plastic pipes: where to start

We will begin to study working with metal-plastic pipes by learning how to cut them correctly. The fact is that this type of pipe itself is a relatively soft material - incorrect or inaccurate pressure with scissors can simply flatten the end of the pipe. A deformed pipe, even if it is leveled, crimps much worse, therefore, the likelihood of leakage increases.

Do-it-yourself installation of metal-plastic pipes - trimming

The process of cutting metal-plastic pipes looks like this: first, with a slight pressure, you need to make a small cut in half the diameter of the pipe, after which, turning the scissors in a circle, we cut the pipe to the end. In this way, a smooth and uncrumpled pipe edge is obtained.

Crosslinked polyethylene Rehau characteristics

At the moment, Rehau is the world leader in the production of cross-linked polyethylene for centralized and underfloor heating systems, as well as hot water supply. The production of Rehau products is carried out by the peroxide method with the application of an oxygen-protective layer EVAL on top.

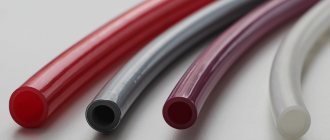

Currently, the release of several Rehau systems has been imposed, which differ in the color of the pipe and the area of use of the product.

- The main types of the Rehau pipeline are the following systems:

- Rehau Rautitan Heath (white);

- Rehau Rautitan Flex, Rehau Rautitan Stabil (silver);

- Rehau Rautitan Pink (pink);

- Rehau Rauterm S (red).

Rehau pipes are supplied with the necessary tools and fittings for installation.

The Rehau pipe has a service life of about 50 years, is suitable for installation in the most inaccessible places, for example, under a concrete screed or baseboard wiring, requires minimal effort to repair and replace damaged areas.

- All this made it possible to widely use Rehau products, in particular for the following purposes:

- hot and cold water supply;

- heating and heating mains;

- gas supply;

- sewerage;

- laying pipelines under plaster.