Today, apartments are equipped with mixers of various designs, including ball valves. They are more reliable than simple sealed valves, but they do break from time to time. It is quite possible to repair a ball valve with your own hands, although the design of such a mixer differs markedly from the usual design of a crane with rubber gaskets. Consider the order in which the repair should be carried out.

Almost every home craftsman with minimal plumbing experience knows how to change the gaskets in the tap. There is nothing difficult in performing this work, just unscrew a couple of nuts, remove the old gasket and install a new one in its place.

If a ball valve is installed on the kitchen sink or in the bathroom, then when doing repairs with your own hands this device will have to sweat. But if the master is well prepared and understands the design of the mechanism in advance, then the work will not require significant effort.

Possible malfunctions of ball valves and their causes

If the tap is leaking, then, first of all, it is necessary to find out the cause of the malfunction.

- Damage to the case. Such a malfunction is typical for inexpensive models, the body of which is not made of brass, but of silumin. This material is quite brittle, therefore, it can crack upon impact or other mechanical stress. Such cracks may not be noticeable at first glance, but over time, the body will burst at the site of damage and the tap will begin to let water through.

Advice! If the body of the mixer is damaged, then as an emergency repair measure, we can recommend the "cold welding" putty of the gap. But this will not help for long, so the mixer will need to be replaced in the near future.

Advice! With inexpensive mixers, clogging is often caused by wear and tear on the O-rings. Therefore, when performing repairs, it is necessary not only to clean the hole, but also to change the seal.

- If the water from the tap comes with a poor pressure, provided that the water supply is working normally, then the reason for this is most likely a clogged shutter.

Advice! To avoid blockages, it is recommended to install filters - in the water inlet to the house or on the pipe supplying water to the sink (washbasin).

How is the shutter?

The easiest way to fix the problem is if the valve is clogged. It can be an obstacle to the normal flow of water with a powerful pressure. First you need to dismantle the aerator. Then they let water in without this element. By how the pressure changes, it will be seen whether the aerator is the cause of the breakdown. To restore the operation of the tap, it is enough to clean and rinse the device in water, and then reinstall it. But more often the aerator is replaced.

This stem level grease injection system is optional and is included in the valve when required by the customer. To completely eliminate seat leakage, it is necessary to replace the removal and removal of the inline valve to replace the damaged component. Use clean rags and a water-based degreaser to clean all components. After cleaning, carefully check each component to avoid damaging moving metal parts and sealing surfaces. Also check the condition of the O-rings and anti-expansion rings.

Carrying out repairs

To carry out repairs, you need to have a certain set of tools.

Instrument preparation

A home craftsman should have on hand:

- Hollow screwdriver;

- Pliers;

- Adjustable wrench;

- Hexagonal socket wrench;

- Hammer.

- Means for instant rust remover (like "Liquid Key");

- Special silicone grease for sanitary ware (odorless and toxic).

Dismantling work

Any repair begins with the disassembly of the crane. The work goes like this:

Carrying out repairs

After the valve is disassembled, you will need to carefully inspect it, clean all cavities and replace worn parts. As a rule, these are the already mentioned seals with springs. In addition, sometimes the tie bolts are damaged, in which case they must also be replaced. When buying new bolts, you need to carefully monitor that they are exactly the same size as the old ones, otherwise the repair work will not give a positive result.

If in the process of work blockages are revealed, then it will be necessary to thoroughly clean all cavities. The mixer has its own filter (a small mesh installed in front of the ball), but if the quality of the water coming through the pipes is not high enough, it will not save the day.

Therefore, it is recommended to install additional filters on the pipes. These preventive measures will significantly increase the life of the ball mixers. If, during inspection, severe wear and corrosion of the ball is noticed, then it is better to replace this part entirely. After the repair, the crane is assembled and the final check of its operability is carried out.

Ball mixers can be repaired by yourself. Beginners should not only read, but also see how the ball valve is being repaired - a video with a detailed description of the process can be found on relevant sites.

Our habit of solving small everyday problems on our own is ineradicable. And it's not even a matter of saving finances, although they are never superfluous. There is something very attractive and understandable in living in an interior that is not only lovingly conceived, but also independently embodied. But the repair of modern plumbing fixtures, done by hand, can be complicated by the variety of designs of the same mixers. Today we will show you how to disassemble and repair a ball mixer. This will help you not to resort to the help of specialists if you can fix the problem yourself.

Until recently, there was no alternative to the valve mixer. And so, with the advent of the single-lever mixer with a ball switch, users were faced with a choice: which tap to prefer? It turned out that it is the spherical structure that is in high demand. This is explained by the remarkable performance characteristics of this type of mixers.

Another undoubted advantage of the ball mixer is its modern and attractive appearance: it can easily fit into any interior

It is very convenient to use a new tap. You do not have to twist anything to set the required temperature and water pressure. Simply put the lever in the desired position. This elementary procedure is performed automatically over time.

Those who have long preferred this particular design know roughly what position the rotary handle should be in so that both the pressure and the water temperature are as comfortable as possible for a variety of purposes. For beginners, it is useful to know that the water pressure is regulated by moving the handle up and down, and the temperature - left and right.

The ball mixer is very functional: it is easy to adjust it to the pressure and temperature you need with one movement of your hand

In addition, it is believed that there is no more reliable ball mixer.

Repair features

So let's take a look at what needs to be done if repairs are imminent.Repairing the device is quite simple - any home craftsman can handle it. For work, you will need a standard set of tools:

- Adjustable wrench.

- Hexagons.

- Screwdriver or thin needle.

- Lantern.

The first step is to shut off the water. Next, dismantling is performed. There is a plug on the body of the device. They're filming her too. There is a hole under this plug through which the screw holding the lever can be accessed. This screw should be unscrewed. The lever can now be removed. If the appliance has been in use for a long time and the ball mixer has not been disassembled, it may be necessary to make some effort.

Disassemble the valve from the pipeline. The valve must be positioned horizontally so that the top is accessible. Remove the stud bolts from the terminal. Lift the terminal carefully to avoid damaging the ring, and then remove the spirometallic packaging from the terminal. Unscrew the stud bolts from the body. Remove the ball from the body. Suspend the ball with a nylon strap to avoid damaging it. Place it on the wooden spatula Remove the metal seats from the body and terminal and then remove the rings from the rings. Remove blowout protection rings, if you have them.

Now there is access to the dome part of the product and plastic eccentrics. These details are also removed. A cartridge will be installed under them. All dirt must be carefully removed. Next, the mixer switch is removed from the housing. It should be carefully examined from all sides. If damaged, the cartridge must be replaced.

Next, check the rubber sealing elements. If their elasticity is reduced or lost, then the parts are replaced with new ones. The seals on which the switch is installed are also subject to replacement (for maintenance).

Next, it remains to install all the parts in place and assemble the structure in the reverse order. The product should then work normally again. But the leak can also be under the tap. In this case, remove it and replace the seals under the drain.

Remove the saddle springs from their cords at the body and end. Clean each of the components for inspection and testing to determine the cause of the failure and decide which parts to replace. Determine if the valve can be repaired. Install the end housing gasket studs. Insert the springs into the corresponding holes. Prepare the seat ring with matching rings or blowout protection rings, if you have one. Insert the ring into the corresponding ring on the body and leave this body on the side flange.

Prepare the ball by placing the anti-friction horns Insert the ball into the body cavity and leave on the ring center and orient the ball according to the cultivation holes. Place the spirometry pack, place the ring in the slot. Insert another seat with matching rings or blowout rings, if you have one. Press the ring into the corresponding slot on the terminal. Remove the terminal with the ring down and carefully insert it into the housing. Correct position to.

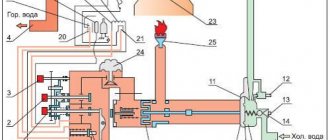

Single lever mixer design with ball switch

Alas, modern mixers, like their valve assemblies, fail from time to time. Indeed, in their production, the same materials are used: metal, rubber and plastic, which can wear out during operation or under the influence of external factors.

To repair a ball valve, you need to understand its device and be able to dismantle it if necessary. The ball device includes:

- rotary handle; At its core, it is a lever that is sometimes called a "butterfly."

- stock; The stem seal is adjusted with a nut and washer, which are also included.

- body with nut; Inside this body, the ball cartridge and stem are located.

- ball cartridge; It is secured with rubber saddles.

A ball cartridge is a non-separable element with three holes: for incoming cold and hot water and for outputting mixed water of the required temperature and pressure from the device.

The operation algorithm of a crane of this design is quite simple:

- when the lever is lifted, the ball starts to rotate;

- the holes in the ball cartridge begin to line up with those in the seats;

- depending on the area of coincidence of these holes, the jet pressure changes.

If you handle the mixer with care, without exerting excessive forces where they are not needed, products of this design can serve without failure for a long time. Nevertheless, the following breakdowns can be called typical for them:

- When the lever is in the blocking position, the flow of water from the tap does not stop.

- A defective ball mixer provides too little water pressure, despite the fact that the pressure in your home's water system has not dropped, which can be checked by opening other taps.

- The regulation of the water temperature in the mixers was violated: it is impossible to achieve the desired parameters, since the mixing of hot and cold streams occurs in a chaotic mode.

A fairly common malfunction of the ball mixer is manifested by water leakage when the device itself is in the blocking position

Before proceeding with the repair, you should understand what is the cause of the malfunction, which manifested itself in one of the above ways.

Ball mixer: the main invention for plumbing

Despite the fact that the ball mixer has been in operation in our country for some two decades, this design has been developed a very long time ago. It was created by engineer Alex Manukyan. In 1929 Manukyan created a small company that produced various parts for cars and Ford. In 1940, from a small company, this company turned into a large production with a turnover of millions of dollars. In 1940, an inventor from California approached Manukyan and offered to acquire the right to manufacture a revolutionary crane. The innovation consisted in the fact that instead of the traditional two taps for hot and cold water, one was used. With the help of it, it was possible to simultaneously adjust both the pressure and temperature. The innovation was poorly received and even laughed at the inventor. But Manukyan considered one small perspective that everyone else just missed. The design of the ball mixer is such that it has only one movable element. There are no gaskets here, as well as parts subject to rapid wear.

Valve repair is considered economical if it can be rebuilt at a cost not exceeding 65% of the replacement price. On average, repair costs are 50% of the replacement cost; However, many valves are not repaired because the cost is higher than indicated. Typically, a valve cannot be repaired if it cannot take advantage of the body, as the cost of repair will exceed the recoverable cost.

Control Valve Maintenance Ease of maintenance starts with the design phase. As long as you specify the correct valve, made of the correct materials and well-positioned with access, problems should be minimal. In cases where severe corrosion exists, make sure the specified alloy is used. Must have spare parts. A well-equipped workshop will be equipped with a work table with everything needed and some devices for lifting and stowing heavy valves.

After a while, it became clear that, despite the lack of gaskets, the mixer was fully operational. And now Alex Manukyan, together with experienced engineers, begins work on finalizing the design.In 1954, the work was completed and a revolutionary new product was released, which is now installed in most bathrooms. By the way, Manukyan made himself a huge fortune on this.

You also need fasteners for large equipment and don't dump things. Air hoses, regulators, and a range of tubing and fittings are also required, including hose quick connectors. The easiest way to tell if you have closed the valve is to test for leaks using air at a moderate inlet pressure and hear the outlet if there is a leak. To this end, a set of special flanges drilled for the hose connector and groove can be used for valve flanges of different sizes.

The good performance of each valve must be maintained. In addition, cost and maintenance records help justify changes to reduce maintenance and improve reliability. For any diagnosis, the first thing to do is to apply common sense, and the most important method is to take a logical step-by-step analysis of all symptoms and information. All too often, it is tempting to assume that if something fixes the problem, it will work this time too.

Types of malfunctions

There is a space between the ball cartridge and the rubber seats that hold the element in place. Clogging is the most common cause of ball valve failure. Even a seemingly insignificant speck can lead to a leakage of the connection. As a result, the rubber seat may deform, causing the ball mount to become unusable.

Another common breakdown is clogging of the shutter. As such, repairs are not needed in this case. This problem is solved by simply cleaning the plumbing fixture. True, for this the crane will have to be disassembled. But then, when you collect it, everything will be in order again.

Water may seep out from under the knob cap. In this case, tighten the connection. If the flow of water stopped, then the reason for it was hidden precisely in the loose connection.

A clogged aerator leads to insufficient water pressure flowing from the mixer spout, this malfunction is corrected by simply cleaning the aerator itself or replacing it

The easiest way to solve the problem is the clogging of the aerator. It is he who can become an obstacle to creating a normal water pressure. If you remove the aerator and try to run water without it, then by changing the pressure it will become clear whether the aerator was the cause of the malfunction. The aerator can be rinsed and replaced. Or you can simply change it to a new one, as they do in the event of a complete failure of this part.

O-rings can also wear out. In this case, water may seep out from under the base of the tap. Such a malfunction is eliminated by replacing the failed seals. Before starting work, we shut off the water supply, after which we remove the mixer, disconnecting it from the inlets and unscrewing the nut fixing it. The worn out gasket is replaced with a product of the same diameter. If the gasket is selected correctly, it will be forced into place. It remains only to assemble the crane.

The only breakdown in which you have to completely change the mixer is a crack in its body: even if the ball switch is mechanically damaged, only this element can be replaced

The situation is worse if the ball cartridge itself is broken. It can crack and, alas, then it cannot be repaired. We'll have to simply replace it with a new one. You will have to act in the same way in case of mechanical damage to the mixer body. Repair it to no purpose. It's easier to buy and install a new tap.If you are unable to replace the valve immediately, you can use a sealant to temporarily stop the leak, but remember that the device needs to be replaced. And the faster the better.

Most often, problems arise due to the increased hardness of the water circulating in your water supply system. And the type of mixer you use doesn't really matter. In order not to change the mixers indefinitely, you should install a filter that purifies the water. Even a coarse cleaning device is capable of blocking those particles that cause major breakdowns in plumbing fixtures.

Typical malfunctions

With careful operation, without applying special efforts to the device, the product can serve without breakdowns for a long time. However, more often these cranes are operated differently and fail.

Among the typical malfunctions, one can single out a leak when the lever is in a blocking position, a weak pressure at a normal level of pressure in the water supply system. Also, adjustments are often violated. It is impossible to adjust the water to the desired temperature, as mixing is done chaotically. Before repairing ball faucets for a bathroom, you need to determine the cause of the malfunction.

The purpose of this is to remove any small metal particles adhering to surfaces. Once lapping is complete, any trace of imperfections such as gray areas or scratches will be checked as this will require repeating the full lapping until the desired finish is achieved. Along with this, a log should be kept that will collect all data, which includes aspects such as: Marking, inlet and outlet size, Hole, Adjustment pressure, Back pressure, Service, Line or equipment in which it is installed, ID number From the installation, valve serial number, discharge capacity and temperature.

We start repair work

Let's say that all the precautions have been taken, but still repairing the ball valve on your mixer is inevitable. You can, of course, invite a plumber to fix the ball mixer. But it's better to try to do this work yourself. There is nothing super complicated in it. Just heed our advice.

To carry out repair work, you will need tools, which must be prepared in advance so that they are at hand.

No special tools are required to carry out repair work with a faulty ball mixer: all these items are sure to be present in the arsenal of any home craftsman.

- adjustable wrench;

- a hex key of a suitable size;

- a screwdriver that can be used as needed and like a thin needle;

- pliers;

- Lantern.

To begin with, you should turn off the hot and cold water supply, otherwise your manipulations with plumbing fixtures can lead to a flood. Do not forget that there may be residual water in the tap, which should also be drained. Before starting work, you need to close the sink with a rag. This measure will protect her from possible damage.

Now you can start dismantling the mixer.

At the initial stage of repair work, the decorative plug with the image of hot and cold water should be removed, it closes access to the screw that secures the lever

The sequence of work in this case is as follows:

- There should be a decorative plug on the mixer body, which will have to be removed.

- There is a hole under the plug through which you can reach the screw holding the mixer arm. This screw should be unscrewed.

- The lever is now free and can be removed. If the crane has been installed for a long time, and no one has unscrewed it, considerable effort may be required at this stage. It is important to proceed with caution and not damage anything.

- So, the dome of the crane and the eccentric located under it, made of plastic, became available to us. Both parts need to be removed. Below them is a ball cartridge. All contamination that can be found during the dismantling process must be carefully removed.

- The ball switch is removed from the mixer. It must be examined from all sides. As mentioned earlier, if damage was found on this one, it must be replaced with a new one. Sealing the cracks on the ball is useless.

- We examine the rubber seals. They can lose elasticity or simply wear out. In place of the expired seals, you need to put new ones. The elements holding the ball switch are also better replaced. If they have worked for a long time, then this should be done even simply for preventive purposes.

Plumbing gaskets are consumables: they often fail and have to be changed; If you have to buy a new pad, take the old one with you so you don't get the wrong size

It remains only to assemble the mixer. This should be done in reverse order.

You can get more information about the repair from this video:

If you did everything correctly, the mixer should now work properly again. However, the leak can be under the spout, which is also called a spout or gander. Then you will have to remove the spout and replace the old O-rings with new ones.

Particular attention should be paid to the mixer in the event that you have an old plumbing in your house. In this case, rust particles and other contaminants can clog the holes in the switch, through which hot and cold water flows. These blockages can be cleaned with a cloth or hands. Such a procedure should be performed periodically, even just for preventive purposes.

Another problem that may be of concern to ball valve owners is the annoying noise generated when opening the water. It occurs due to vibration generated by air and water currents. Due to its effect on rubber seals, they can also begin to vibrate. To avoid this effect, you can reduce the water pressure, install a filter, or achieve a tighter fit of the rubber gaskets.

Outwardly, a silumin mixer looks no worse than any other model, but such products rarely last more than a year; You can distinguish them by weight: silumin is very light

The service life of a ball mixer is influenced not only by external factors, but also by the material from which the valve itself is made. There are often cheap models on sale that are made from silumin - an alloy of silicon and aluminum. They are short-lived, but great for training lovers to do everything with their own hands. And for a long and trouble-free service, it is better to choose a more expensive, but also reliable model.

If a cartridge breaks down

The situation is worse here. These elements can crack. But the problem is that these products cannot be repaired. They are replaced with new ones. The same is done if there is damage to the device case. If it is not possible to quickly replace the mixer ball switch, a sealant can be used. But this is only a temporary solution to the issue.

Water flow along the stock

Unscrew the upper bolts. Remove the stem and top pin group from the body. Remove the spirometric wrap from the stump. Remove the stem from the top stem. Remove anti-extrusion rings, pin rings, top ring bolts and anti-friction bar. Unscrew the bottom bolts. If the valve works, the first thing to do is to depressurize the valve and remove the breather cap and drain plug. Open the drain valve to reduce the internal body pressure and then place the valve in the open position.

How to repair a ball faucet in a bathroom

This type of malfunction of the bathroom faucet, which we want to tell you about, is quite common. Therefore, we decided to consider this type of repair of a ball mixer in the bathroom with our own hands in this article. So, we are trying to switch the water from the faucet spout to the shower, but the switch lever spontaneously switches over. It turns out that the water flows from the spout normally, but it is impossible to put it into the shower.

Ball mixers are often used in the bathroom, they can also be repaired on their own; Typically, this repair is limited to replacing the top or bottom gasket.

We will try to find the cause of the malfunction ourselves. In this case, you will have to act at random, since there may be several reasons for such a malfunction.

The initial sequence of actions is as follows:

- unscrew the union nut, and then remove the hose;

- remove the upper gasket, after prying it with a thin knitting needle;

- we replace the newly removed gasket with a new one, moistening it with water before installing;

- we assemble the mixer, bringing it to its original working position.

If the upper gasket was the cause of the breakdown, then, with its replacement, the malfunction will be eliminated. If we are mistaken, then it's okay: gaskets are consumables, sooner or later they should be replaced anyway.

Shower still not working? Then we will deal with the bottom gasket.

For this:

- we shut off hot and cold water;

- remove the flexible hose;

- after that comes the turn of the adapter, spout and switch lever: we must also remove them;

- now you have access to the eccentric, which must also be removed;

- the spool should be next: we will also dismantle it;

- and here is the lower gasket ring, remove it and replace it with a new one;

- the mixer is assembled in the reverse order of dismantling.

Before heading to the store for new pads, be sure to check if you yourself have a stock of these consumables. Usually several spare parts of this type are included in the mixer package. If there are no gaskets or they are lost, then they can be made independently, using hard rubber 3-4 mm thick for this purpose.

To properly repair the mixer and not forget anything, this video will help you:

A coupling ball valve is often assembled by the manufacturer in such a way that its body is difficult to disassemble. Those. it is assembled in two parts on a threaded connection with the use of a strong hold sealant in the thread. As a result, it is very difficult to untwist such a connection in a domestic environment. In fact, the crane is considered not collapsible, but in the event of a breakdown, it must be changed entirely.

But nothing is impossible. To untwist the ball valve (threaded connection), you can do the following. Clamp the body in a vise, heat the body in the area of connection with the coupling with a gas burner until it darkens slightly, and unscrew the coupling with a suitable powerful wrench.

Thus, access to the ball valve and the seals between which it is located is obtained. This is the main point related to the repair of a coupling ball valve.

Another question is whether there are seals suitable for this particular crane model that need to be inserted instead of the damaged ones? If so, then you can start repairing the coupling ball valve.

Design

The ball valve has a fairly simple design and a minimum of details. To understand how to disassemble and how to repair the ball valve, just look at the picture presented here.

The following details:

- Housing.

- Seals in the body (two seals in the form of Teflon rings between which there is a ball-valve).

- Ball valve with a through hole located between the seals (seats).

- Ball valve control rod.

- Seals, bearing and stoppers on the control rod.

- Handle with fastening elements.

Disassembly sequence

- Unscrew the handle attachment (bolt or nut), remove the handle;

- We unscrew the valve body with a large key;

- We take out the seal-saddle, ball valve, and one more seal-saddle;

- We take out the stem retaining ring (unscrew the stem nut), take out the seals, the bearing (if any), and then the stem itself;

The actual disassembly of the ball valve is complete. Now we inspect all the details. True, without proper experience, it can be difficult to determine the nature of the damage. But mainly the seals and possibly the ball valve are changing. If there are spare parts, we assemble the ball valve in the reverse order, inserting the necessary parts into their places.

How to repair

You can find out what parts it consists of, how the ball valve is disassembled and repaired from the video presented

Types of malfunctions

- Incomplete water shut-off.

- Leakage of liquid along the handle stem.

- Tight rotation of the handle.

Causes of breakdowns

- The ball valve or its parts are not made of standard materials. Simply, - we have a fake in front of us. In this case, there is definitely no point in repairing the crane, it is much more profitable to replace it.

- The supply of a chemically aggressive liquid to the valve, which has damaged the seals.

- Supply to the tap of a liquid contaminated with a high concentration of abrasive substances. The seals and the ball-valve are damaged.

The most important engineering system in every home is the plumbing.

With its help, hot and cold water is supplied to our homes.

To mix both streams of liquid to a comfortable temperature for consumers, a special technical device called a mixer is installed in the kitchen or bathroom.

Just like any other mechanism or device, mixers tend to break down. They sometimes become clogged and stop functioning normally.

Each owner in the house, if he considers himself as such, should be able to cope with the simple work of repairing plumbing equipment.

DIY mixer repair # 8212 examples of some frequent breakdowns and their repair

It just so happened that our men, and sometimes women, are used to dealing with minor home repairs on their own. We glue the wallpaper ourselves, repair the floors, install the plumbing and even lay the tiles. And such a trifle as do-it-yourself mixer repair is within the power of almost everyone. If 10 years ago, in all the houses and apartments of our vast homeland, there were mixers of the same design, then their today's variety can confuse even an experienced home craftsman. Let's figure out what kind of mixers are presented on the shelves of our stores today and what to do if it suddenly leaks where it shouldn't.

Content

Ball valve is the most popular option

The most common design of the mixer today can be safely called a ball valve. It is a mechanism with one rotary handle. When the handle moves up and down, the water pressure is regulated, to the right and left - its temperature. The popularity of such a device is explained not only by its simplicity and ease of use, but also by its increased reliability.

Single lever mixer device

In order to answer the question "how to repair a ball mixer", you need to understand how the system works. This is how the ball valve looks in section.

Sectional diagram of a single-lever mixer, where: 1.Decorative plug with the designation of hot and cold water 2.Screw 3.Adjustment shaft 4.Hollow ball for mixing water 5.Rubber saddle 6.Adjustment ring 7.Steam cuff 8.Adjusting cuff 9. Hot and cold water outlet 10.Mixed outlet 11.Ball sleeve 12.Aerator

The main difficulty in repairing such a mixer is that most of its parts are part of a non-separable cartridge. This means that you will not be able to replace them individually - you will have to change the cartridge completely.

Causes of malfunctions and remedies

There can be several reasons for trouble:

Crack on the case

Before you repair the mixer, you need to carefully examine the body of the product, if you find a crack or chip, you can try to eliminate it with a sealant. However, this measure is temporary and the cracked mixer will still have to be changed.

Wear of gaskets

If the body is intact, you will have to remove the mixer. To do this, you need to take a number of preliminary measures:

- We close the valves on the pipes of hot and cold water

- We open the tap and drain the water

- We unscrew the inlets from the mixer and carefully drain the water into a previously prepared container

Now you can start dismantling. Here, simply unscrew the locking nut. In most kitchen faucets, it is located under the sink. Inspect the gasket carefully. If it is out of shape or cracked, it needs to be replaced. A new gasket costs mere pennies, and you can buy it at any hardware store.

Note! It is important to select the correct gasket diameter. It should fit into the groove with some effort.

Clogged cartridge

If the replacement of the gasket did not help, then the matter is in the cartridge. Quite often, a mixer of this design “leaks” due to small debris getting into its mechanism. In this case, do-it-yourself repair of a single-lever mixer consists in a complete replacement of the cartridge.

To replace the cartridge, you need to remove the regulator knob

This is done according to the following algorithm:

- We overlap and drain the water

- We dismantle the mixer

- Pry off the decorative plug with a knife or screwdriver and remove it

- Unscrew the screw

- Removing the lever

- We take out the cartridge and install a new one in its place

- We make the assembly.

That's all. Your faucet will now work like new for sure.

Blockage in the aerator

When the water in the bathroom flows in a thin stream, and in the kitchen it beats with a powerful stream, there is no need to talk about the fault of the water utility. So how do you fix a bathroom faucet if the water pressure drops? The most common and easily corrected cause of this problem is a clogged aerator.

If the aerator is corroded or heavily overgrown, it is best to replace it.

It is very easy to check if this is your case. Unscrew the aerator and open the tap. If the water pressure has returned to normal, the culprit is found. It is better to replace a very rusty aerator, but just rinse the clogged one, direct a stream of water to its outer surface. Now we put the part in place and you're done.

Blockage in the water pipe or hose

If simple manipulations with the aerator did not work, most likely the pipe or hose is clogged. Quite often, in houses with old metal pipes, rust that has fallen off from their inner surface blocks the cross section, which leads to a drop in pressure in the mixer. Cleaning the pipes will help to cope with the problem, but it is better to replace them with plastic ones. The inner surface of modern polymer pipes is very smooth and does not corrode, which means it does not "overgrow".

If there is no opportunity to replace the pipeline yet, arm yourself with a thin "snake" cable, disconnect the pipe from both sides and start cleaning.

Problems with the shower-bath switch

Now we turn to the answer to the question of how to repair the mixer in the bathroom if the water supply to the shower stops by itself. The switch lever lowers spontaneously, and water flows only through the tap.

The cause of such a malfunction may be the wear of the spool gaskets. If only the top gasket is damaged, the mixer does not need to be removed. Since it is impossible to determine this "by eye", first it is worth replacing it, and only then draw conclusions:

- Unscrew the union nut of the hose and remove it

- Use a thin hook or awl to pry the gasket

- Wet the new gasket with water and install it in place.

- Putting the mixer together.

If the breakdown cannot be eliminated in this way, you will have to change the lower gasket:

- We shut off the water

- Remove the flexible hose by unscrewing the union nut

- Removing the spout and adapter

- Remove the switch and remove the eccentric

- We take out the spool

With a thin screwdriver or hook, remove the lower gasket (the upper one has already been replaced)

If the upper spool gasket has already been replaced, it does not need to be done again.

- We put on a new gasket, moisten it with water and install the spool back

- Putting the mixer together.

Note! Spool gaskets are generally not sold separately from the mixer. If the spare rings supplied with the mixer are not preserved, you can make them yourself from hard rubber with a thickness of 3-4mm.

Two-valve mixer version

Despite the emergence of many new technologies, traditional two-valve models have not finally given way to their positions.

The design of a two-valve mixer is quite simple, everyone can figure it out

If this equipment is installed in your home, it will not be superfluous to know how to repair a mixer of this design.

Two-valve mixer design

Modern two-valve mixers can be fundamentally different in design. As a rule, the cheapest models are equipped with a worm gear, and the more expensive ones are equipped with a crane-axle box with ceramic discs. The latter are more reliable, which means that we will pay more attention to the former in this article.

Worm gear crane repair

So what to do if a worm gear mixer drips. The most common cause of this trouble is a failed gasket that blocks the inlet. We need to replace it. You can buy a new rubber ring at the store or make your own from thick rubber. Now we disassemble the mixer and make a replacement.

You need to act according to the following algorithm:

- Turning counterclockwise, unscrew the valve body

- Remove the gasket and install a new one

- We reel under the stubborn edge of the fum

This is what ceramic (left) and rubber (right) spacers look like.

The mixer should now work properly. However, it happens that repairing a kitchen faucet with your own hands turns out to be effective for only a few days. And then the leak appears again. The reason for this rapid wear can be the roughness of the seat - the place where the gasket stops. You need to polish it. Sometimes this process is also called "roller cutter", after the name of a special cutter, which must be inserted in place of the worm gear and rotated with a drill. When the surface of the “seat” is smooth, you can install a new gasket and no longer worry about its life.

Elimination of leaks in the crane box

The crane box can also be installed in a conventional mixer in place of a worm gear; technologically, there are no obstacles for this. For the first few years after installation, you do not even need to look in the direction of the tap - it will not leak.

The design of the ceramic valve is as follows: two discs pressed against each other have through holes. When the tap is open, the holes are aligned; when closed, they are not. Simple, as everything is ingenious.

If, after a while, such a valve still leaks, it is enough to tighten the counter-nut on the body and the problem will be solved.

Video instructions for replacing the gasket

Types of mixers

There are three types of mixers:

- single-lever,

- valve,

- ball.

In this article we will talk about the most common type - the ball type of construction. The mechanism itself is quite simple - just a single swing arm.

When it is up or down, the water pressure is adjusted, and by turning the knob to the left or right, the water temperature is coordinated.

Due to the simplicity of the device, such mixers are considered the most reliable and economical.

If you have to hear the annoying, monotonous sound of water dripping from the tap every day, this means that the tap has become unusable and needs to be repaired or replaced.

The faucet is considered to be such an important element of plumbing equipment that its damage requires your immediate attention.

The following reasons may be the basis for the appearance of breakdowns:

- the occurrence of tap leaks,

- reducing the volume of water flow,

- leakage of liquid from under the valve.

If you find at least one of the above signs, the product must be disassembled.

Do you want not only to dismantle the crane yourself, but also to try to fix the problem, and then also to assemble it correctly?

To do this, you need to thoroughly know the mixer device.

.

If you have information as to what components this device consists of, then you can insure yourself against errors and significantly reduce the time for its repair.

Types of breakdowns

The ball cartridge is seated in the body with rubber seats. There is free space between these elements. If it becomes clogged, it will cause a malfunction. Even an insignificant speck is enough to break the tightness. As a result, the rubber seat is deformed. The ball mount fails.

Also, one of the most common troubles is a blockage in the shutter. In this case, you can even do without repairs, and the problem can be solved with a simple cleaning. But for this you have to disassemble the crane. But after assembly, everything will fall into place again and the device will work like new.

The manufacturer must provide the user or purchaser with a maintenance manual that includes the following items: Visual inspection, disassembly, maintenance of internal parts, seat lapping, parts repair, assembly, testing, adjustment, troubleshooting. It is imperative for the user to follow the instructions of the manuals issued by the manufacturers, work performed on these safety devices should only be performed by personnel demonstrating that they have received a rigorous product training program, as the responsibility for refurbishment will depend on the user.

Often, all breakdowns occur due to the water that flows in the pipes. She's very tough. At the same time, it does not depend at all what type of mixer is installed. In order not to change plumbing fixtures often, experts recommend installing filter elements. Another nuisance is water that flows from under the knob. Tighten the connection here.

A remanufactured or repaired safety valve must have the same degree of reliability as a new valve. In gaps at seat level. The following guidelines will help you until your experience with the equipment dictates otherwise: Lubricate at least once a year. Every three months if the valve does not operate frequently. Every 500 cycles if the valve is operated under severe or aggressive conditions and more than ten times a day.

The grease can be used to reduce friction or as a sealant at both lubrication points. Wherever possible, a lubricating grease is recommended to facilitate movement and to limit the use of sealant only in emergencies where valve seats are leaking.

Product structure

Ball mixers are characterized as reliable and durable devices due to the non-separable cartridge included in their mechanism.

All its constituent elements are carefully lapped in relation to each other.

The basic basis of these designs is a hollow ball, located in the valve body, polished to a high gloss with holes and a pin for attaching it to the handle, which ensures the rotation of the ball.

Cold and hot water through two brass pipes and flexible pipes enters this ball.

After that, it mixes there and flows out through a tap of a certain temperature.

Tightness is achieved due to the presence of gaskets.

As a preventive measure

from the user's getting burns, the tap cartridges are equipped with a special ring that limits the angle of rotation of the handle in the direction of hot water.

The cartridge inside can be made of stainless steel or ceramic.

Ceramic consists of two plates

, high-quality polished using ultrasound and perfectly ground to each other.

This surface polishing prevents liquid droplets from seeping between the plates.

If you disassemble the cartridge, remove the washers from it and lay them on top of each other, then the elements should be attracted to each other, as if magnetized.

Using this elementary method, the quality of the cartridge is determined. In a single-lever device, no additional seals are provided in the mixer mechanism.

Due to the lack of seals and the strict compatibility of all parts, there is nothing to wear off in ball mixers.

Moreover, this work is not very difficult, and almost any man who has the following tools on the farm can handle it:

- hex key,

- flat screwdriver,

- small hammer,

- pliers.

Before you start disassembling the tap, you need to turn off the water supply in the house or apartment (read where the insert in the water supply network is located).

Shower Switch Repair

This malfunction occurs quite often. When you try to turn on the water from the spout into the shower hose, the lever switches itself. Fluid flows from the spout and cannot be supplied to the shower. To find the reasons, the hose is unscrewed and dismantled. Then remove the top gasket. You may need to pry it off with a thin knitting needle. The gasket is changed to a new one. The mixer is assembled and tested.

If the device still does not work, then they turn off the water again, remove the shower hose. Then remove the adapter, spout and lever. Now remove the eccentric and spool. Next, access to the ring of the lower gasket opens. It should be replaced. Next, the device is assembled and tested. Before heading to the store for supplies, it is worth seeing if these gaskets are at home. Often, several seals are included with the device. If there are still no materials, then you can do them yourself. Hard rubber 3-4 millimeters thick will do.

How to properly disassemble a 2-valve mixer

Cope with this job is also quite simple.

To accomplish this goal, you will need a screwdriver and an adjustable wrench.

- First of all, we shut off the water supply to the apartment (it is written about a storage tank for water supply of 500 liters).

- Remove the blue and red plugs from the taps. Dismantling them, you will find screws that must be removed with a screwdriver.

- After that, you will be able to see the condition of the rubber pads. By their appearance, you will understand whether they need to be replaced or the poor operation of the mixer is due to the fact that deposits have appeared (read about equipment for deferrizing water in the article) or loose connections.

- Another reason for the disgusting operation of the crane is limescale accumulated inside it. To remove it, take a long, flat screwdriver and use it to try to remove all the dirt.

There are springs in front of the rubber seal that need to be checked for functionality. If they do not fulfill their purpose, then they need to be replaced with new ones.

Please note that the new products are much longer and stronger than the old ones. This fact must be taken into account when installing the springs.

When changing the sealing gum, do not forget to use silicone grease, it will greatly extend their service life.

The rubbing parts of the mixer will be easier to "walk" if a small amount of lubricant is applied to them.

To assemble the crane, all actions are performed in a strictly reverse order.

Occasionally, leaks form at the top of the mixer or at the bottom of the mixer. You can fix this problem as follows:

- after removing the ball, lift the nose at the base and pull up a little.

The rotating outlet of the ball mixer is sealed with two rings. Namely, they tend to leak over time.

The gaskets must be removed very carefully. After replacing them and before reinstalling the ball mixer, the O-rings must be lubricated with silicone so that wear is minimized.

Buy parts that require replacement only of high quality, they will significantly increase the life of the product.

If you replaced the gaskets, assembled the tap, and the leak did not disappear, it means that the new parts do not fit in size or you did not press them well.

You may need to disassemble the tap again

, look for and eliminate the cause of the leak.

It should be borne in mind that in the modern plumbing market, ball valves are presented in various modifications. Therefore, the methods of disassembling them may differ slightly among themselves.

When installing the ball mixer and at each subsequent repair, all threaded connections must be sealed with a special thread or tape made of fluoroplastic.

Please note that dismantling work will be carried out much faster

if you think through all your actions in advance or sketch out a small plan that you will follow.

Keep the above guidelines in mind and you can disassemble and reassemble the product quickly and without unnecessary fuss.

How to repair a mixer yourself at home, see the video.

Bookmark this site

- Choice

- Installation

- Finishing

- Repairs

- Installation

- Device

- Cleaning

- The device of ball valves

- Repair and maintenance of ball valves

Situations when it is necessary to troubleshoot ball valves on your own at home are quite common. By its design, the ball valve differs from other similar devices. However, almost every man with the minimum knowledge and skills necessary for this can carry out its repair. And for this you need to know the device of the tap and the principle of water supply.

Ball valve device diagram.

Many are accustomed to the fact that in an ordinary tap, you just need to replace the silicone or rubber gasket, after which you can continue to use it. In the ball valve, both similar malfunctions and many other breakdowns can occur, leading to its poor performance.

If water seeps out from under the base of the mixer

This malfunction can be eliminated.Before you start repairing ball mixers with your own hands, you first need to turn off the water. Then the mixer is dismantled and disconnected. Also unscrew the fixing nut.

A worn-out gasket must be replaced with the same one, only a new one. If it is selected correctly, then it will need to make a little effort to install it.

Replace damaged components. Lubricate the o-rings. Anti-friction washers and horns do not need to be lubricated with oil as they self-lubricate. Packing and ring material will depend on the operating conditions of the valve. Be careful not to damage the shaft, wrench, or drive or gearbox by any impact resulting from the disassembly operation. Then remove the key from the stem. Lift the valve up and leave it on the side body flange so that the pipe is vertical. Unscrew the adapter mounting bolts and remove the adapter flange.

The device of ball valves

The ball valve consists of the following parts: a shut-off device is mounted inside the tap or mixer, which looks like a metal ball with special holes for water outlet. When this ball turns, the water pressure decreases or increases, or the tap is completely closed. The faucet has two openings for hot and cold water. At the outlet, there is a single hole for water outlet of the required temperature.

Therefore, if difficulties arise, the repair of such devices should be entrusted to a plumber, who will do it efficiently and quickly.

However, you can save a little and fix all the faults yourself.

Back to the table of contents

Operating principle

The mixer ball valve works according to a certain algorithm. When the lever is lifted, the ball rotates. Meanwhile, the holes in the cartridge line up with the holes in the seats. Depending on what the area of the holes will be as a result, the temperature of the water and its pressure change.

Thus, the lapping operation is performed with a swinging motion in several directions, keeping the free shoulder ring on the fingers and allowing it to rest on the seat surface. The movement of the ring must be controlled to prevent crossing the inner and outer edges of the ring. If the edges touch the surface of the seat, they can scratch or twist. Tilting the ring should be avoided as this can lead to unevenness on the surface of the seat. Before rubbing the discs and nozzle spots, the shoulder or edges of the seats should be thoroughly cleaned with fine-grained emery paper.