Factors affecting the level of solid fuel consumption

It will not be difficult to calculate how much a solid fuel heating boiler consumes. It is more difficult to correctly select the initial data for performing calculations.

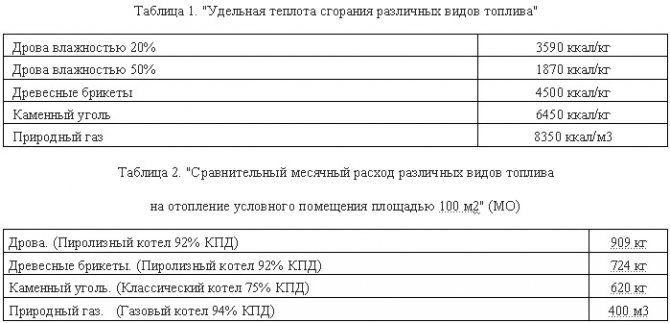

The following is the calculation methodology and at the same time the calculation of the consumption of the amount of firewood for heating a dwelling of 100 m² is given. However, let's look at the initial data first:

- the type of wood that is selected for kindling;

- the degree of moisture in the wood;

- efficiency of a solid fuel furnace or boiler;

- thermal power required to heat the room.

If you have ever used a stove, then, for sure, you are aware that when firewood is burned, different amounts of heat emanate from different trees. Let's say birch logs emit more heat than poplar or pine. This is due to the difference in density and heat output of the tree species. In addition, the volume of firewood per 1 kW of heat energy depends on the moisture content in them. Accordingly, the higher the humidity, the more heat is spent on the evaporation of liquid from the wood, and less is left for heating the dwelling. As a result, more fuel will be consumed to heat the house.

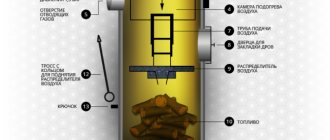

How rationally the energy in the fuel will be used depends on the efficiency of a particular heat source. For example, a fireplace or stove emit most of the energy into the atmosphere along with the combustion products, therefore, their heat transfer reaches only 60%. At the same time, a solid fuel or pyrolysis (long burning) boiler operates with a heat output of 80%. These nuances should be taken into account when calculating the cost of heating a home.

The value of the thermal power required to heat the house is best taken according to the calculation made by the craftsmen during the design period of the dwelling. However, this data is often not kept by the property owners. Therefore, the amount of firewood and their cost can be found by the average value of the power consumption. It is determined in the standard way: 1 kW of heat is consumed for heating 10 m² under the worst conditions, and the average rate for the season is 0.5 kW. The average figure for a 100 m² dwelling will be 5 kWh.

The best ways to stack firewood for storage

You cut down trees, sawed and chopped wood. The hard work is over, but one of the biggest challenges remains - transforming the messy pile of wood into a neat, attractive stack of wood that will keep your fireplace cool throughout the cold period.

When it comes to harvesting firewood, stacking can be the most enjoyable part of the job. Well-stacked firewood looks attractive, but the real benefit is that it will be dry when you need it. Dried wood burns efficiently, does not require constant attention, and creates less smoke, not only in the form of smoke, but also steam that remains in wet wood.

There are several ways to stack woodpiles:

- Towers

how to fold the woodpile correctlyOne of the most common ways to stack firewood is the traditional tower arrangement. Two towers are assembled in which the firewood is stacked (each layer is perpendicular to the previous one), the rest of the firewood is stacked between them in a chaotic manner. The trick here is that such a pile of firewood will not crumble, thanks to the towers located on both sides - they make the messy pile of firewood stable.

- Round stack This method has enjoyed great success in Scandinavia for many centuries. Round wood stackers are easier to stack and more stable than traditional firewood towers.

Around the post (or stake), make a circle with a 1 meter rope, thereby you will mark the perfect circle and an even inner edge of the future heap. Arrange the wood so that there is space in the middle.When the stack is more than 1 meter high, lay the top rows so that there is a slope for rainwater drainage. Finally, make a canopy made of polyethylene or profiled sheet.

Regardless of which method you choose, keep in mind that there should be a base (concrete or wood) at the bottom of your pile. The moisture in the ground will not allow the wood to dry out, so make an elevation from below for ventilation.

Firewood on pallets

Calculation of firewood consumption by a long-burning boiler

To calculate the consumption of firewood in a solid fuel boiler for long burning for a day, use the following formula.

V = 24Q / (q x 0.01KPD) V - means the volume of firewood required for 1 hour, m³; Q is the required power for heating, kW; q - heat output of a certain type of wood with a specific degree of moisture, kW / m³; Efficiency is the boiler efficiency, in%.

Let's say you purchase a solid fuel pyrolysis boiler with a heat transfer rate of 75%. Load dry pine logs. The calculation will look like this.

V = 24 x 5 / (2166 x 0.01 x 75) = 0.074 m³.

Samples to carry out the correct calculation of fuel consumption in a pyrolysis boiler, you need to remember about the nuances of its work. The efficiency of 75-80% is displayed in the formula if the wood has a maximum moisture content of 25%. If the indicator is higher, then the boiler efficiency drops to 70%.

The consumption of firewood in a solid fuel boiler of long burning for a month is done as follows:

0.074 x 30 = 2.22 m³

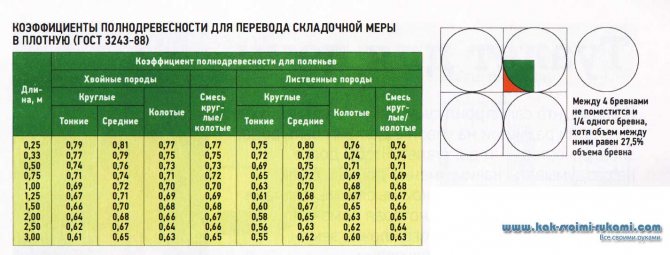

However, this is not the final result, since the formula uses the calorific value for "clean" m³, and in reality, firewood in the woodpile takes up more space due to the density of the stacking. To correctly calculate the firewood in cubes, you need to know the number of storage meters.

GOST 3242-88, where the standard is indicated, will help to carry out these calculations. In connection with this, the folded firewood must be measured, the storage meters must be calculated, and then converted into dense meters, m³. the translation is made by multiplying the volume of the woodpile by the value of full wood.

Wood content coefficients for converting a fold measure close to

| Length, m | Conifers | Hardwood | ||||||

| Round | Split | A mix of chopped and round | Round | Split | A mix of chopped and round | |||

| Thin | Average | Thin | Average | |||||

| 0,25 0,33 0,50 0,75 1,00 1,25 1,50 2,00 2,50 3,00 | 0,79 0,77 0,74 0,71 0,69 0,67 0,66 0,64 0,62 0,61 | 0,81 0,79 0,76 0,74 0,72 0,71 0,703 0,68 0,67 0,65 | 0,77 0,75 0,73 0,71 0,70 0,69 0,68 0,66 0,64 0,63 | 0,77 0,75 0,73 0,72 0,70 0,69 0,68 0,67 0,66 0,65 | 0,75 0,72 0,69 0,65 0,63 0,61 0,60 0,58 0,56 0,55 | 0,80 0,78 0,75 0,72 0,70 0,68 0,67 0,65 0,63 0,62 | 0,76 0,74 0,71 0,69 0,68 0,67 0,65 0,63 0,62 0,60 | 0,76 0,74 0,71 0,69 0,68 0,67 0,66 0,65 0,64 0,63 |

Since in our case there is an inverse problem, then the fuel volume calculated above must be divided by one of the coefficients that corresponds to the present conditions.

Let's say you take chopped wood 0.5 m long. For conifers, you need to take an indicator of 0.73. At the end, we calculate the real consumption of solid fuel from dry pine for a month for a dwelling with an area of 100 m²:

2.22 m³ / 0.73 = 3.04 m³

Four tips for drying wood

- Harvest firewood in the spring or early summer so that it dries for at least 6-9 months. The firewood will not have time to dry if you chopped it in the fall or winter, such firewood can only be used next year. Certain types of wood, such as oak or larger woods, can dry for a year or more.

- The best place to dry freshly cut firewood is outside. If you throw wood into a wood shed, it will take twice as long to dry (18-24 months) because the wood will not get any help from the sun or air movement.

- A lot of smoke and little heat emanate from wet wood, in fact, such wood may not burn at all. Typically, wood has a moisture content of 30-50%, and you need to bring these indicators to 15-20%, for this, the firewood must be stacked so that the ends where the sawing took place remain open. In this way, the air will draw moisture out of the incision.

- You can leave the wood outside to dry - open, this will speed up the drying process, but a protruding canopy is needed. For example, a long corrugated sheet can be used as a roof, which should not lie directly on the wood.The bottom row of firewood should not be laid on the ground, but it is better to put a kind of foundation under it - bricks, stones, pallets.

Algorithm for calculating coal consumption

A modern type boiler can efficiently operate both on hard coal and on drill. But if there is a choice, then it is better to choose high quality coal - anthracite. It is he who is characterized by the highest thermal capacity and burns out almost without residue. However, the cost of anthracite is higher than other varieties. It is necessary to consider the price of fuel, delivery and its heat capacity, and choose the best option.

Which coal to choose for heating in a private house?

There are two ways to calculate the consumption of coal in a solid fuel boiler. The very first one is elementary, using a bucket. Usually coal is measured in tons, however, it is unlikely that your boiler room will have a scale to accurately weigh the required dose for loading.

One bucket holds about 18 kg of hard coal.

Approximately, to heat a dwelling of 200 m², the following amount of corner will go:

- In September-October, one bucket per day.

- From November to February - 10 buckets.

- In March-April there are about two buckets.

If you take that there are 30 days in a month and add up all the values, you can find out the total number of buckets (780 buckets). In kilograms it turns out:

780 x 18 = 14040 kg

Thus, during the heating season for heating a dwelling of 200 m², a coal-fired boiler will consume a little more than 14 tons of coal.

The second way to calculate the consumption of coal in a solid fuel boiler is more scientific. Combustion of 200 g of coal will consume about 1 kW of heat. For a comfortable stay during the heating period, approximately 50,000 kW of heat is needed:

50,000 x 0.2 = 10,000 kg (10 tons)

What is the most economical solid fuel boiler?

Naturally, if the word "economy" sounds, then you should start counting money. An economical solid fuel boiler capable of heating a house in automatic or semi-automatic mode will not be cheap. The cost of automatic boilers for coal, pellets and wood can be compared - these are numbers of the same order.

The cost of an automatic low-power pellet boiler starts from 120-140 thousand rubles, the coal "Karborobot" starts from 170 thousand rubles, and the wood-fired pyrolysis "semi-automatic" starts from 90 thousand rubles.

You can calculate the cost of fuel in your area yourself, based on the power required to heat the house.

Let the boiler service life declared by the manufacturer be 25 years. You need to add to the cost of the boiler the cost of the fuel that you burn over these 25 years and then divide it all by the number of years. So you will get the cost of heating your home for 1 season, taking into account the depreciation of the boiler equipment.

Those comrades who begin to calculate only the cost of fuel are doing the wrong thing. Do not forget about the cost of the heating unit itself, as well as about the cost of its maintenance and the planned replacement of boiler parts (grates, feeding elements, etc.)

More on this topic on our website:

- Solid fuel boiler ZOTA Mix - review and feedback from owners ZOTA boilers are manufactured at the Krasnoyarsk plant of heating equipment and automation. The plant specializes in the production of solid fuel and electric heating boilers….

- Solid fuel boilers Aton - description and characteristics Aton is a proven Ukrainian manufacturer of high quality heating equipment. The history of the company dates back to the 30s of the last century….

- Diesel heating boiler - what is the normal fuel consumption? If apartment buildings have a centralized heating system, then when building a private house, its owner is responsible for choosing the type of this system ....

- Calorific value of wood - a table of the calorific value of firewood For those owners who have decided to heat their house with solid fuel, this material is intended. It is not immediately possible to figure out what kind of fuel to heat ...

Algorithm for calculating the consumption of pellets

A wood pellet boiler is especially relevant for residents of those regions who do not have the ability to heat their house with gas. Pellets are made from waste of the wood processing industry, therefore they are an environmentally friendly type of fuel and, moreover, with a sufficiently high efficiency.

About what pellet boilers are good for and about their disadvantages, it is written here.

Roughly, to calculate the consumption of pellets for heating a house of 100 m², you can use the following formula. The number of granules is equal to:

70 W / m² x 100 m² x 24 hours x 180 days x 0.7 / 5000 W / hour = 4234 kg 70 W / m² - an indicator of heat loss for 1 m² of the house; 100 m² - the area of the house; 24 hours - hours in a day; 180 days are the days of the heating season; 0.7 - boiler load value; 5000 W / h is the amount of heat generated by the combustion of 1 kg of high quality pellets.

Again, these calculations are approximate. There are many nuances due to which the values can vary.

It is safe to say that it is not difficult to calculate the need for a solid fuel boiler in the amount of fuel. The main thing is not to confuse all the data, and at the end, multiply the obtained cubic meters by the cost of fuel in your area. Remember that when ordering firewood, it is better to clarify the measures used by the supplier: these are storage meters or "pure cubic meters". Otherwise, you risk making a mistake and thereby overpaying or receiving less firewood.

What are energy saving solid fuel boilers?

Let's try to understand what energy-saving solid fuel boilers are, and what meaning manufacturers put into this phrase when they indicate it in their advertising brochures and on websites.

Any economical solid fuel boiler will already be "energy-saving" - you will burn firewood in it with better efficiency than in a conventional "boiler". That is, it will save energy - this is an axiom. This means that we write in this category all solid fuel boilers with high efficiency.

No top-secret technologies are used in the production of TT boilers. Good engineering design, well-calculated heating technology, and advanced knowledge of resilience are all that is required to design the right solid fuel heat generator.

Further, technologies, modern machine tools and welding, and workers interested in their work in production, come into play.

I tend to attribute the tale about "energy-saving boilers" to marketing gimmicks. When a product does not have good real-world characteristics, "products of the defense industry" and "side effects of space technologies" are born.

The amount of firewood for the winter, the mathematical calculation of how much firewood is needed to heat the house

One of the paradoxes of the universe: the more common and familiar an object of natural origin, the more complex its mathematical description. In order to calculate the volume of a Galaxy or a star, it is enough to remember the school geometry course. If someone really needs to know the exact volume of a log, it is impossible to do without methods of differential calculus. From the astronomer's mistake, the layman is neither hot nor cold; but with an incorrect calculation of fuel reserves for the winter, the cold in the house is ensured.

Everything seems simple: the duration of the heating season in days is multiplied by the area of the house and by the average daily consumption of firewood. Do not believe this simplicity, it is deceiving and requires a lot of clarifications. In fact, it is also necessary to take into account the height of the ceiling, i.e. not area, but volume. The fun begins when it comes to the average daily consumption of firewood. This value depends on the calorific value of the fuel, the efficiency of the stove, climatic conditions, heat loss and many other factors, including the radius of curvature of the hands of the master.The last parameter is an irrational value that can reduce heating efficiency to zero. If you set yourself the goal of deriving a universal formula for an accurate calculation, the material will be quite enough for more than a dozen theses. It is much faster to make inquiries with neighbors or former owners of the house.

If you plan to install a solid fuel boiler, it is easier to calculate its "appetite" - the main technical characteristics are known. The easiest way to get an approximate figure is using formulas or online calculators posted on specialized sites.

Let's try to calculate.

As a reference, let's take a house with a total area of 150 sq. m and insulated, respectively, SNiP. In the coldest time, about 100 W / m² will be needed to heat the room. Let's take an average energy consumption of 50 W / m². The heating season lasts 7 months (214 days). With continuous heating we get:

150 m² • 50 W / m² • 24 hours • 214 days = 38.52 MW • h, which approximately corresponds to 33 Gcal.

The specific net calorific value of absolutely dry wood is 4440 kcal / kg. With natural drying for about two years, the residual moisture content of the wood is 20%, the specific heat of combustion is 3400 kcal / kg. We will take the efficiency of a solid fuel boiler as 70%.

We calculate the required amount of firewood: 33000 kcal • 1000/3400 kcal / kg / 0.7 / 0.730 kg / m³≈19 m³, where 0.730 kg / m³ is the density of oak wood. In terms of maple or birch, the required value is 21.3 m³, for pine - 26.4 m³. In practice, less or more firewood may be needed, depending on the state of the house's insulation and the weather.

All-knowing statistics claim that 4-6 cubic meters of firewood per season is quite enough for heating a small insulated log house in central Russia. The most economically justified stock of firewood for two or three seasons: current + 1-2 next. In this case, you will probably have enough fuel even for the most prolonged cold period. Another reason: firewood, like good alcohol, only gets better over time.

“God have mercy, what kind of wood? We are civilized people, we have gas! " - this position is fundamentally wrong. Firstly, because we were lucky enough to live in the most amazing country in the world. here from time immemorial, two scenarios have been observed: the unlikely and the worst. Secondly, the civilized world is returning to proven and, most importantly, renewable energy sources. Firewood, straw and peat are the same as hundreds of years ago, adjusted for modern technology.

Having a solid fuel boiler and at least a year's supply of firewood in a gasified house is not a whim, but a completely reasonable decision. Optimism is good, but twice as good - optimism backed by strategic reserves.

You can also use our online calculator for calculating the amount of chopped wood for heating a country house, cottage or bathhouse.

drova-mo.ru

Five ways to find out if your wood is dry

- Dried wood becomes lighter in weight, lighter in color, and the bark usually flakes off easily.

- Cracks may appear in the fiber from the end of the wood, but this also depends on the type of wood.

- From the end, the wood will feel warm and dry, and vice versa, freshly cut wood will be cold and damp.

- Hit two logs together, the sound of the impact will be hollow, and the sound of wet wood is dull.

- Throw a small piece of wood into a hot coal - wet wood will sizzle, dry wood will ignite within 1 minute.

What is the best firewood?

Wood, which serves as a raw material for firewood, is far from the same in its properties.

- Hard tree species such as birch, oak, hornbeam, beech, yew burn hotter, have a high fiber density, and burn more slowly.

- Soft varieties have their advantages, for example: aspen, gives less heat than birch by 25%, but it perfectly maintains the heat in a melted oven. Alder also shares a delicious aroma, as do the conifers. Alder and aspen added to the stove at the end of the heating process remove soot deposits and soot in the chimney. But the formation of plaque, which can lead to clogging of the chimney, occurs when essential oils and resin of pine, fir, spruce are burned. Conifers are also inferior in calorific value to birch and oak, but they dry out faster and are more suitable for kindling. Only fir sparks strongly, and larch at the end of combustion emits a lot of carbon monoxide and you need to be more careful with the damper.

- Some types of fruit trees are medium-hard and have an average calorific value. They burn, emitting an aroma, they are easy to harvest, since firewood can be chopped without much effort.

Based on the above, it is difficult to advise any one type of wood for stove or fireplace firewood. As fuel - the most rational are hard deciduous tree varieties. Smooth flame, high heat output, less soot, ash. But the scent of conifers has a therapeutic effect, and is well suited to ignite. By combining several varieties, it is possible to maintain both the working condition of the chimney, the stove, and a comfortable microclimate during the entire cold period, subject to the initial investment in a good one. Otherwise, any heat, along with your funds, will fly into the pipe, evaporate through the cracks.