Here you will find out:

- Thermal power of heating radiators

- Bimetallic radiators

- Area calculation

- Simple calculation

- Very accurate calculation

Designing a heating system includes such an important stage as calculating heating radiators by area using a calculator or manually. It helps to calculate the number of sections required to heat a particular room. A variety of parameters are taken, ranging from the area of \ u200b \ u200bthe premises and ending with the characteristics of insulation. The correctness of the calculations will depend on:

- uniformity of heating rooms;

- comfortable temperature in the bedrooms;

- lack of cold places in home ownership.

Let's see how heating radiators are calculated and what is taken into account in the calculations.

Thermal power of heating radiators

The calculation of heating radiators for a private house begins with the selection of the devices themselves. The assortment for consumers includes cast iron, steel, aluminum and bimetallic models that differ in their thermal power (heat transfer). Some of them heat better, and some are worse - here you should focus on the number of sections and the size of the batteries. Let's see what thermal power these or those structures have.

Bimetallic radiators

Sectional bimetallic radiators are made of two components - steel and aluminum. Their inner core is made of high pressure resistant steel, resistant to water hammer and aggressive heat transfer fluid.... An aluminum "jacket" is applied over the steel core by injection molding. It is she who is responsible for high heat transfer. As a result, we get a kind of sandwich that is resistant to any negative influences and is characterized by a decent heat output.

The heat transfer of bimetallic radiators depends on the center distance and on the specifically selected model. For example, devices from the Rifar company boast a thermal power of up to 204 W with a center-to-center distance of 500 mm. Similar models, but with a center distance of 350 mm, have a thermal power of 136 W. For small radiators with a center-to-center distance of 200 mm, the heat transfer is 104 W.

The heat transfer of bimetallic radiators from other manufacturers may differ downward (on average 180-190 W with a distance between the axes of 500 mm). For example, the maximum thermal power of the Global batteries is 185 W per section with a center-to-center distance of 500 mm.

Aluminum radiators

The thermal power of aluminum devices is practically no different from the heat transfer of bimetallic models. On average, it is about 180-190 W per section with a distance between the axes of 500 mm. The maximum indicator reaches 210 W, but one must take into account the high cost of such models. Let's give more accurate data using the Rifar as an example:

- center distance 350 mm - heat transfer 139 W;

- center distance 500 mm - heat transfer 183 W;

- center distance 350 mm (with lower connection) - heat transfer 153 W.

For products from other manufacturers, this parameter may differ in one direction or another.

Aluminum appliances are designed for use as part of individual heating systems... They are made in a simple but attractive design, are distinguished by high heat transfer and operate at pressures up to 12-16 atm. They are not suitable for installation in centralized heating systems due to the lack of resistance to aggressive coolant and water hammer.

Are you designing a heating system for your own household? We advise you to purchase aluminum batteries for this - they will provide high-quality heating with their minimum size.

Steel plate radiators

Aluminum and bimetallic radiators have a sectional design. Therefore, when using them, it is customary to take into account the heat transfer of one section. In the case of non-separable steel radiators, the heat transfer of the entire device is taken into account at certain dimensions. For example, the heat transfer of a Kermi FTV-22 double-row radiator with a 200 mm high and 1100 mm wide bottom connection is 1010 W. If we take a Buderus Logatrend VK-Profil 22-500-900 panel steel radiator, then its heat transfer will be 1644 W.

When calculating the heating radiators of a private house, it is necessary to record the calculated thermal power for each room. Based on the data obtained, the necessary equipment is purchased. When choosing steel radiators, pay attention to their row - with the same dimensions, three-row models have higher heat transfer than their single-row counterparts.

Steel radiators, both panel and tubular, can be used in private houses and apartments - they can withstand pressures up to 10-15 atm and are resistant to aggressive coolants.

Cast iron radiators

The heat transfer of cast iron radiators is 120-150 W, depending on the distance between the axles. For some models, this figure reaches 180 W and even more. Cast iron batteries can operate at a coolant pressure of up to 10 bar, well withstanding destructive corrosion. They are used both in private houses and in apartments (not counting new buildings, where steel and bimetallic models prevail).

When choosing cast-iron batteries for heating your own home, it is necessary to take into account the heat transfer of one section - based on this, batteries are purchased with one or another number of sections. For example, for MC-140-500 cast-iron batteries with a center-to-center distance of 500 mm, the heat transfer is 175 W. The power of models with a center distance of 300 mm is 120 W.

Cast iron are well suited for installation in private houses, pleasing with a long service life, high heat capacity and good heat transfer. But you need to take into account their disadvantages:

- heavy weight - 10 sections with a center distance of 500 mm weigh more than 70 kg;

- inconvenience in installation - this drawback smoothly follows from the previous one;

- high inertia - contributes to too long warm-up and unnecessary heat generation costs.

Despite some drawbacks, they are still in demand.

Why accurate calculation is necessary

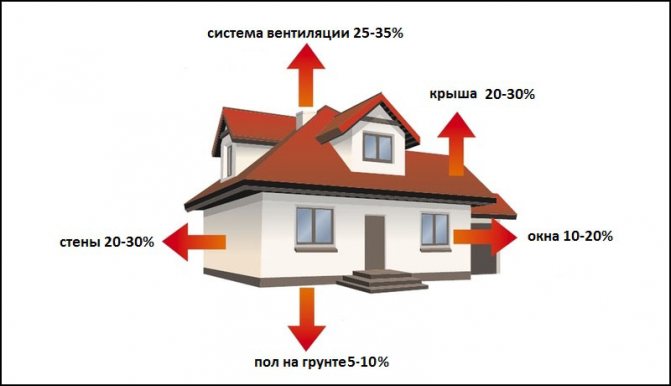

The heat transfer of heat supply devices depends on the material of manufacture and the area of individual sections. Not only the heat in the house depends on correct calculations, but also the balance and efficiency of the system as a whole: an insufficient number of installed radiator sections will not provide adequate heat in the room, and an excessive number of sections will hit your pocket.

For calculations, it is necessary to determine the type of batteries and heat supply system. For example, the calculation of aluminum heat supply radiators for a private house differs from other elements of the system. Radiators are cast iron, steel, aluminum, anodized aluminum and bimetallic:

- The most famous are cast-iron batteries, the so-called "accordions". They are durable, resistant to corrosion, have a power of 160 W sections at a height of 50 cm and a water temperature of 70 degrees. A significant drawback of these devices is an unsightly appearance, but modern manufacturers produce smooth and fairly aesthetic cast iron batteries, preserving all the advantages of the material and making them competitive.

- Aluminum radiators surpass cast iron products in terms of thermal power, they are durable, have a light dead weight, which gives an advantage during installation. The only drawback is susceptibility to oxygen corrosion.To eliminate it, the production of anodized aluminum radiators has been adopted.

- Steel appliances do not have sufficient thermal power, cannot be disassembled and sections increased if necessary, are subject to corrosion, and therefore are not popular.

- Bimetallic heating radiators are a combination of steel and aluminum parts. Heat transfer media and fasteners in them are steel pipes and threaded joints, covered with an aluminum casing. The disadvantage is the rather high cost.

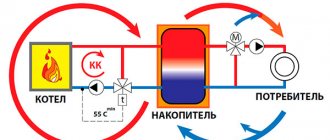

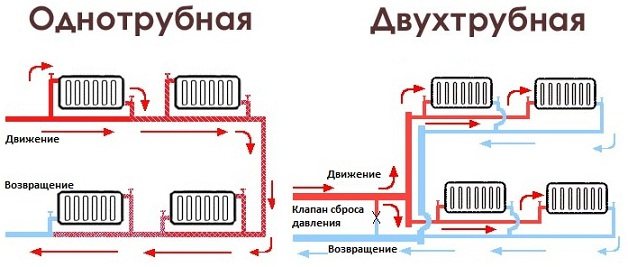

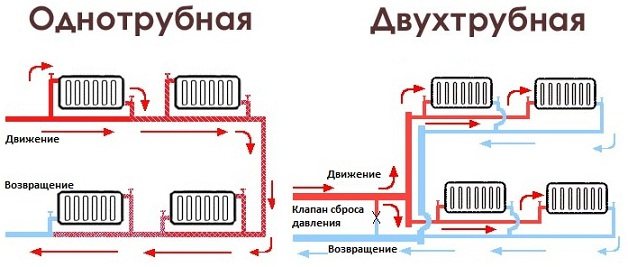

According to the type of heat supply system, one-pipe and two-pipe connection of heating elements are distinguished. In multi-storey residential buildings, a single-pipe heat supply system is mainly used. The disadvantage here is a rather significant difference in the temperature of the incoming and outgoing water at different ends of the system, which indicates the uneven distribution of thermal energy among the battery devices.

For even distribution of thermal energy in private houses, a two-pipe heat supply system can be used, when hot water is supplied through one pipe, and cooled water is removed through another.

In addition, the exact calculation of the number of heating batteries in a private house depends on the connection diagram of the devices, the height of the ceiling, the area of the window openings, the number of external walls, the type of room, the enclosure of the devices with decorative panels and other factors.

Remember!

It is necessary to correctly calculate the required number of heating radiators in a private house in order to guarantee a sufficient amount of heat in the room and ensure financial savings.

Area calculation

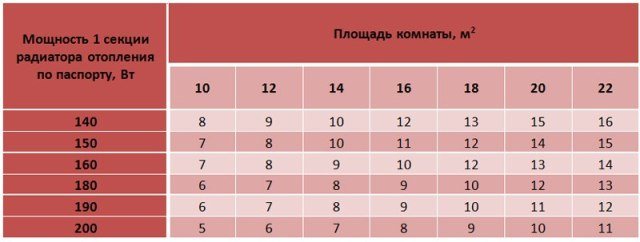

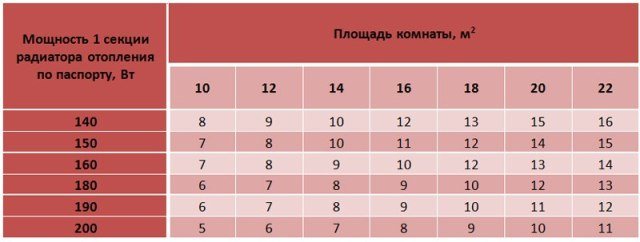

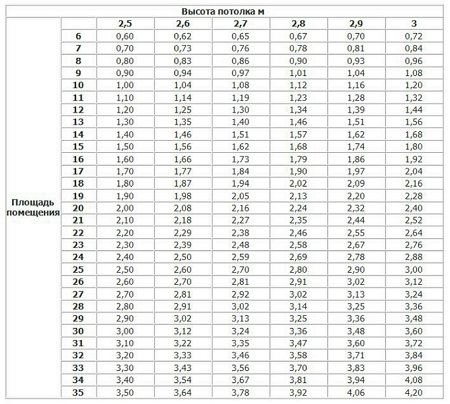

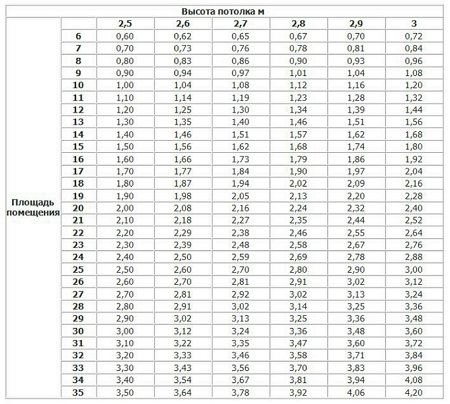

A simple table for calculating the power of a radiator for heating a room of a certain area.

How is the heating battery calculated per square meter of the heated area? First you need to familiarize yourself with the basic parameters taken into account in the calculations, which include:

- thermal power for heating 1 sq. m - 100 W;

- standard ceiling height - 2.7 m;

- one outer wall.

Based on such data, the thermal power required to heat a room with an area of 10 sq. m is 1000 W. The received power is divided by the heat transfer of one section - as a result, we get the required number of sections (or we select a suitable steel panel or tubular radiator).

For the southernmost and coldest northern regions, additional coefficients are used, both increasing and decreasing, - we will talk about them further.

Simple calculation

Table for calculating the required number of sections depending on the area of the heated room and the capacity of one section.

Calculating the number of radiator sections using a calculator gives good results. Let us give the simplest example for heating a room with an area of 10 sq. m - if the room is not angular and double-glazed windows are installed in it, the required thermal power will be 1000 W... If we want to install aluminum batteries with a heat transfer of 180 W, we need 6 sections - we just divide the received power by the heat transfer of one section.

Accordingly, if you buy radiators with a heat transfer of one section of 200 W, then the number of sections will be 5 pcs. Will the room have high ceilings up to 3.5 m? Then the number of sections will increase to 6 pieces. Does the room have two outer walls (corner room)? In this case, you need to add one more section.

You also need to take into account the thermal power reserve in case of a too cold winter - it is 10-20% of the calculated one.

You can find out information about the heat transfer of batteries from their passport data. For example, the calculation of the number of sections of aluminum heating radiators is based on the calculation of the heat transfer of one section. The same applies to bimetallic radiators (and cast iron, although they are non-separable).When using steel radiators, the passport power of the entire device is taken (we gave examples above).

Accurate calculation of heating devices

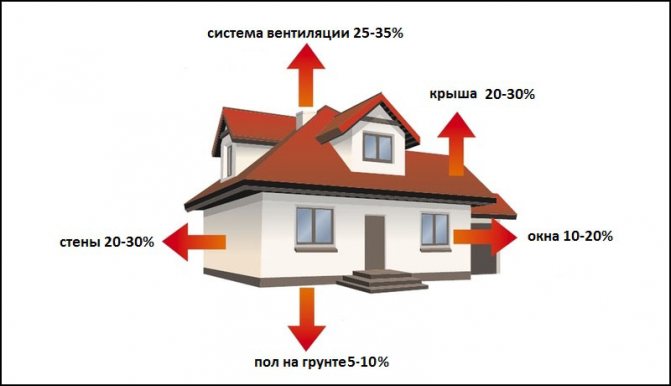

Heat loss of the building

The most accurate formula for the required heat output is as follows:

Q = S * 100 * (K1 * K2 * ... * Kn-1 * Kn), where

K1, K2… Kn - coefficients depending on various conditions.

What conditions affect the indoor climate? For an accurate calculation, up to 10 indicators are taken into account.

K1 is an indicator that depends on the number of external walls, the more the surface is in contact with the external environment, the greater the loss of thermal energy:

- with one outer wall, the indicator is equal to one;

- if there are two outer walls - 1.2;

- if there are three external walls - 1.3;

- if all four walls are external (i.e. one-room building) - 1.4.

K2 - takes into account the orientation of the building: it is believed that rooms warm up well if they are located in the south and west directions, here K2 = 1.0, and vice versa, it is not enough - when the windows face north or east - K2 = 1.1. One can argue with this: in the eastern direction, the room still warms up in the morning, so it is more expedient to apply a coefficient of 1.05.

We calculate how much the battery should warm up

K3 is an indicator of external wall insulation, depending on the material and the degree of thermal insulation:

- for external walls in two bricks, as well as when using insulation for non-insulated walls, the indicator is equal to one;

- for non-insulated walls - K3 = 1.27;

- when insulating a dwelling on the basis of heat engineering calculations according to SNiP - K3 = 0.85.

K4 is a coefficient that takes into account the lowest temperatures of the cold season for a specific region:

- up to 35 ° C K4 = 1.5;

- from 25 ° C to 35 ° C K4 = 1.3;

- up to 20 ° C K4 = 1.1;

- up to 15 ° C K4 = 0.9;

- up to 10 ° C K4 = 0.7.

Calculation of heating radiators by area

K5 - depends on the height of the room from floor to ceiling. The standard height is h = 2.7 m with an indicator equal to one. If the height of the room differs from the standard one, a correction factor is introduced:

- 2.8-3.0 m - K5 = 1.05;

- 3.1-3.5 m - K5 = 1.1;

- 3.6-4.0 m - K5 = 1.15;

- more than 4 m - K5 = 1.2.

K6 is an indicator that takes into account the nature of the room located above. The floors of residential buildings are always insulated, the rooms above can be heated or cold, and this will inevitably affect the microclimate of the calculated space:

- for a cold attic, and also if the room is not heated from above, the indicator will be equal to one;

- with a warmed attic or roof - K6 = 0.9;

- if a heated room is located on top - K6 = 0.8.

K7 is an indicator that takes into account the type of window blocks. The design of the window has a significant effect on heat loss. In this case, the value of the coefficient K7 is determined as follows:

- since wooden windows with double glazing do not sufficiently protect the room, the highest indicator is K7 = 1.27;

- double-glazed windows have excellent properties of protection against heat loss, with a single-chamber double-glazed window of two glasses K7 is equal to one;

- improved single-chamber glass unit with argon filling or double glass unit, consisting of three glasses K7 = 0.85.

One-pipe and two-pipe heating system

K8 is a coefficient depending on the area of glazing of window openings. Heat loss depends on the number and area of the installed windows. The ratio of the area of the windows to the area of the room should be adjusted in such a way that the coefficient has the lowest values. Depending on the ratio of the area of the windows to the area of the room, the desired indicator is determined:

- less than 0.1 - K8 = 0.8;

- from 0.11 to 0.2 - K8 = 0.9;

- from 0.21 to 0.3 - K8 = 1.0;

- from 0.31 to 0.4 - K8 = 1.1;

- from 0.41 to 0.5 - K8 = 1.2.

Heating devices connection diagrams

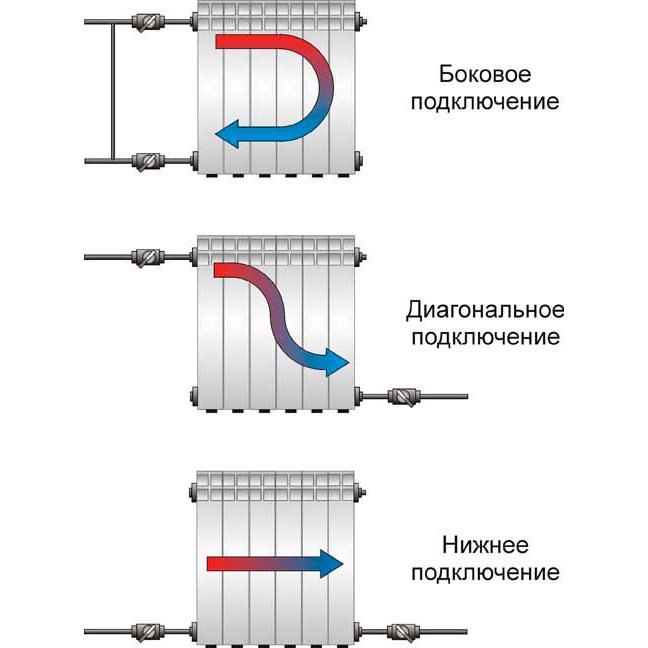

K9 - takes into account the device connection diagram. Heat dissipation depends on the method of connecting hot and cold water. This factor must be taken into account when installing and determining the required area of heating devices. Taking into account the connection diagram:

- with a diagonal arrangement of pipes, hot water is supplied from above, return flow - from below on the other side of the battery, and the indicator is equal to one;

- when connecting the supply and return from one side and from above and below one section K9 = 1.03;

- the abutment of pipes on both sides implies both supply and return from below, while the coefficient K9 = 1.13;

- variant of diagonal connection, when the supply is from the bottom, return from the top K9 = 1.25;

- option of one-sided connection with bottom feed, top return and one-sided bottom connection K9 = 1.28.

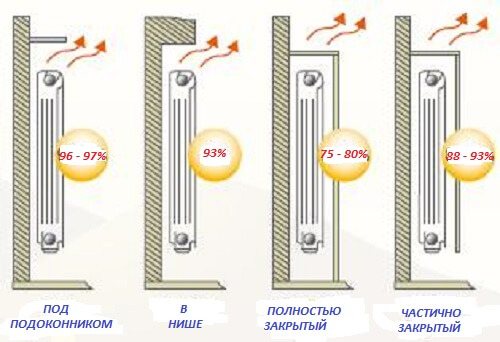

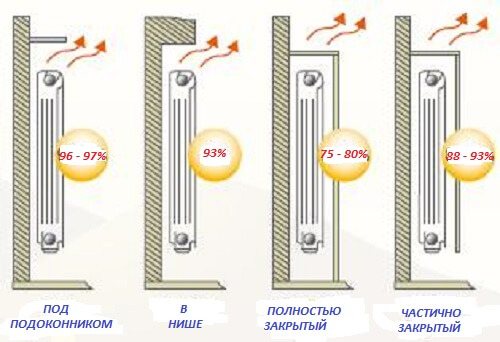

Loss of heat dissipation due to installation of the radiator shield

K10 is a coefficient that depends on the degree of coverage of the devices with decorative panels. The openness of devices for the free exchange of heat with the space of the room is of no small importance, since the creation of artificial barriers reduces the heat transfer of the batteries.

Existing or artificially created barriers can significantly reduce the efficiency of the battery due to the deterioration in the exchange of heat with the room. Depending on these conditions, the coefficient is:

- when the radiator is open on the wall from all sides 0.9;

- if the device is covered from above by the unit;

- when the radiators are covered on top of the wall niche 1.07;

- if the device is covered with a window sill and a decorative element 1.12;

- when the radiators are completely covered with a decorative casing 1.2.

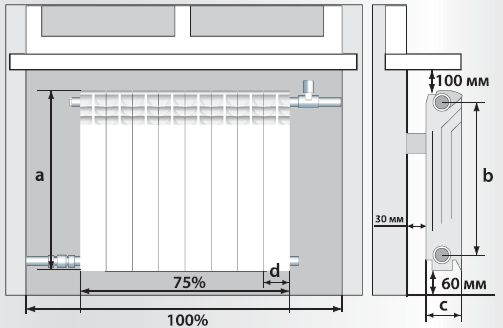

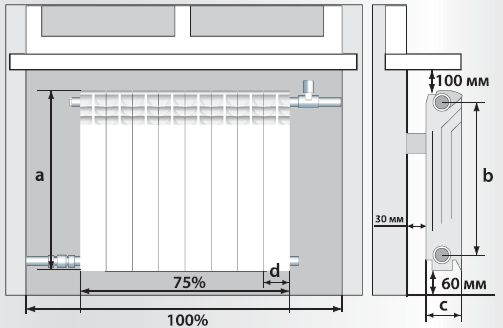

Installation rules for heating radiators.

In addition, there are special norms for the location of heating devices that must be observed. That is, the battery should be placed at least on:

- 10 cm from the bottom of the windowsill;

- 12 cm from the floor;

- 2 cm from the surface of the outer wall.

Substituting all the necessary indicators, you can get a fairly accurate value of the required heat output of the room. By dividing the results obtained into the passport data of the heat transfer of one section of the selected device and rounding up to an integer, we obtain the number of required sections. Now you can, without fear of the consequences, select and install the necessary equipment with the required heat output.

Installing a heating battery in the house