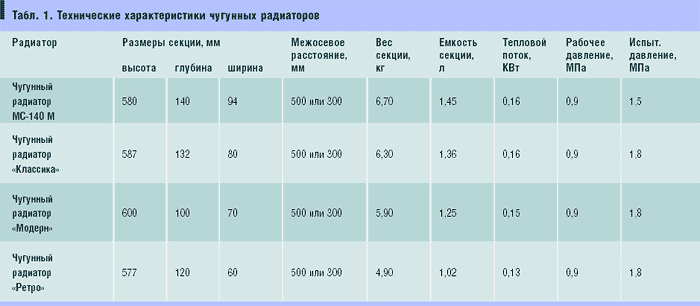

SNiP requirements

Any construction work, including the installation of heating radiators, is carried out in accordance with certain rules and regulations. The technical data sheet for each heater contains detailed information on the type of battery holder. Nevertheless, it will not be superfluous to familiarize yourself with the requirements specified in SNiP 3.05.01-85.

Here are the main standards:

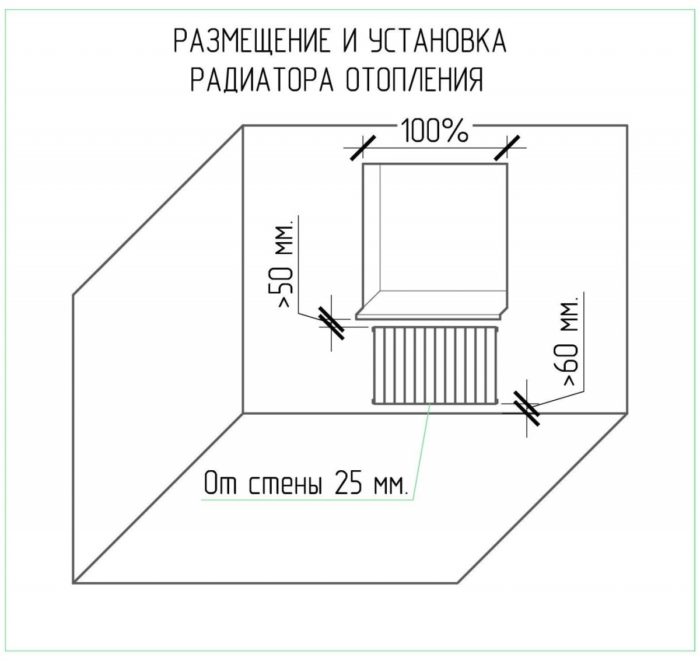

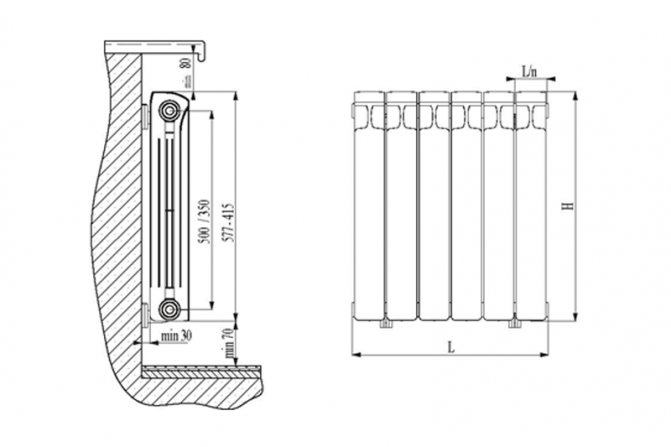

- The location of the heater is considered optimal if its center point is as close as possible or completely coincides with the central vertical axis of the window. A deviation in one direction or another is allowed no more than 20 mm.

- The width of the heater should be about 50-75% of the window size. This rule is not strictly binding and is rather advisory in nature. The fact is that the reliability of fastening for heating radiator batteries does not depend on their size - it will only affect the amount of heat transfer.

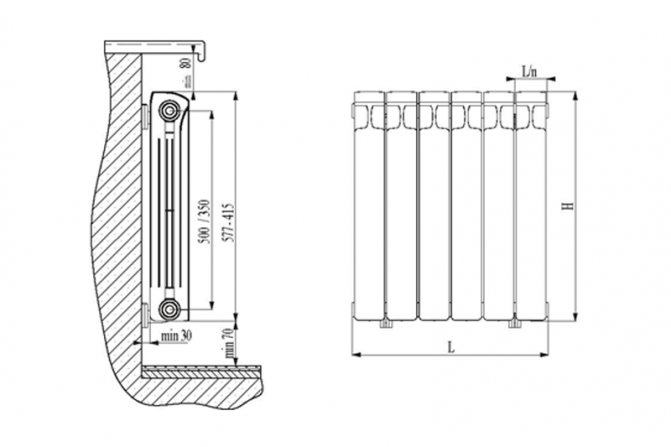

- The distance from the radiator to the floor covering must be at least 60 mm - this is a fire safety requirement.

- There must be a gap of at least 25 mm between the heating radiator and the wall, and even better - 30-50 mm.

- There must also be a gap of at least 50 mm between the window sill and the battery.

- It is important to choose the right number of support points, that is, wall mounts for heating radiators. For a radiator with 6-8 sections, you will need two upper and one lower holder. For each subsequent 5-7 sections, it will be necessary to add one more holder at the top and bottom.

- In the same way, the number of floor stands for radiators is selected. A battery for 6-8 teeth is installed on two points of support, and when each subsequent 5-7 sections are added, one more mount is installed.

- The number of cells on the heating radiator should not be too large. If the system operates in conditions with natural water circulation, for example, in a private house, no more than 12 teeth in a row can be installed there. If we are talking about multi-storey buildings in which the coolant circulates under constant pressure, it is allowed to install a radiator with a total of up to 24 sections.

Please note that to reduce heat loss as a result of senseless heating of the outer wall, it is recommended to place heat-insulating foil material behind the radiator. It will redirect heat waves inside the room.

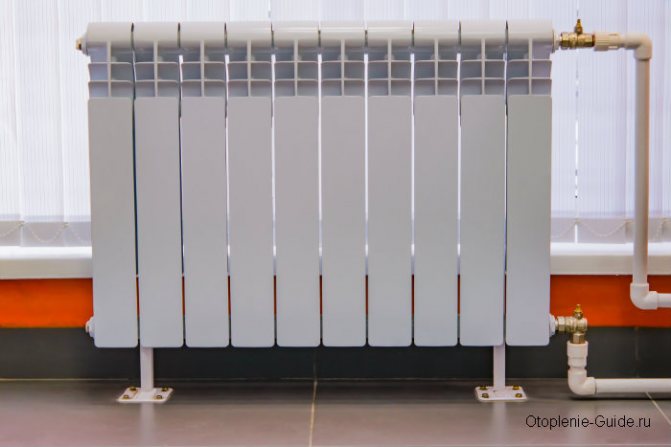

Benefits of Floor Fasteners

The radiator floor bracket will come to the rescue if the structural material of the wall is not able to withstand the weight of the battery, and therefore the wall bracket cannot be used. The above device is used when installing a heating element opposite a panoramic window. The floor holder can be an excellent decor element in the design of a room.

It is used to support particularly massive cast iron radiators or to install very large radiators. Installing brackets for floor-standing radiators will ensure reliable fixation of the equipment. During the work, no specialist assistance is required, since the device is easy to use.

A distinction is made between the following types of battery holders:

- fixed and adjustable, possibly with a plastic cover;

- combined product;

- specialized, the width of which lies in the range of 80 mm - 100 mm.

Everything that may interest you about hydrogen heating can be found on our website.

Although solar convectors for home heating are still very expensive, many are already introducing them as additional sources of heat. Details here.

Fasteners for cast iron batteries

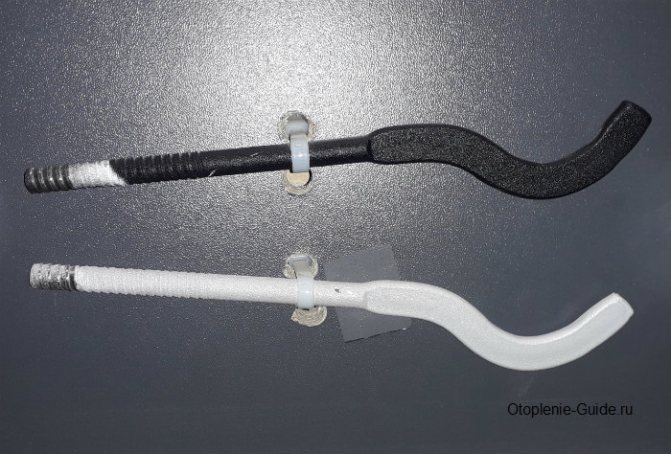

Cast-iron radiators, which are quite popular at the present time, are distinguished by a large weight, therefore, the stand for a cast-iron battery must be reliable enough to withstand such a load. As a rule, for cast iron radiators, metal pins are used that are bent in the shape of a section.

The installation technology in this case is quite simple. First, a hole of the required diameter is drilled in the brick, then a dowel is inserted into it and the fastening pin is screwed in. If it is necessary to fix the bracket in a reinforced concrete wall, the technology will be slightly different.

Since it is rather difficult to make a deep hole in a reinforced concrete slab, the fastening pin is fixed to a small metal plate. It is attached to the slab at four points, but at a shallower depth. The reliability of such an attachment in both versions is approximately the same.

The base for a cast iron radiator is sometimes a mounting plate with two support points. Such a fastener is fixed to the wall in such a way that the upper and lower brackets bear approximately the same weight of the radiator. On sale you can find strips with brackets fixed at a certain distance, as well as with adjustable elements.

Quite often, floor mounting racks are used for cast-iron batteries. Just like vertical strips, racks are monolithic and adjustable.

Note that there are two ways to secure the battery to the stand. The standard option is to mount with a metal bracket. Some models use a flexible multi-link chain for fastening.

It is worth noting that the markings on the cast iron radiator mounts indicate that they are reinforced. This information should be considered when selecting the mounting brackets.

Types of holders

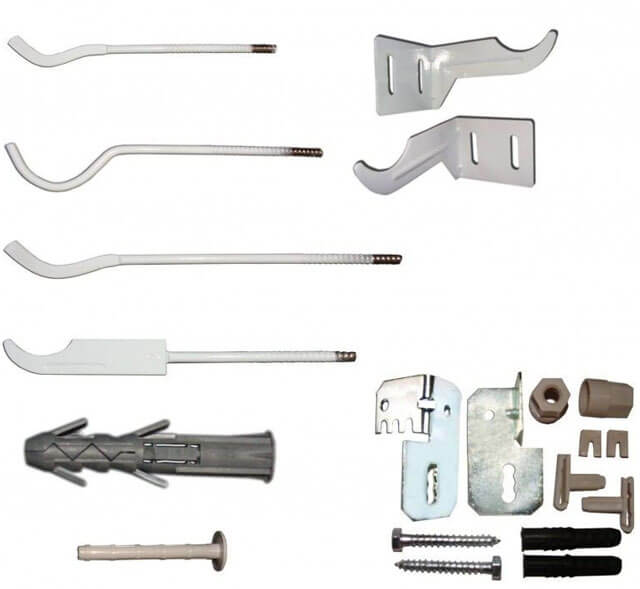

Hooks on a steel bar.

The procedure and rules for installing batteries do not depend on their type, only the type of holders changes.

Cast iron radiator supports

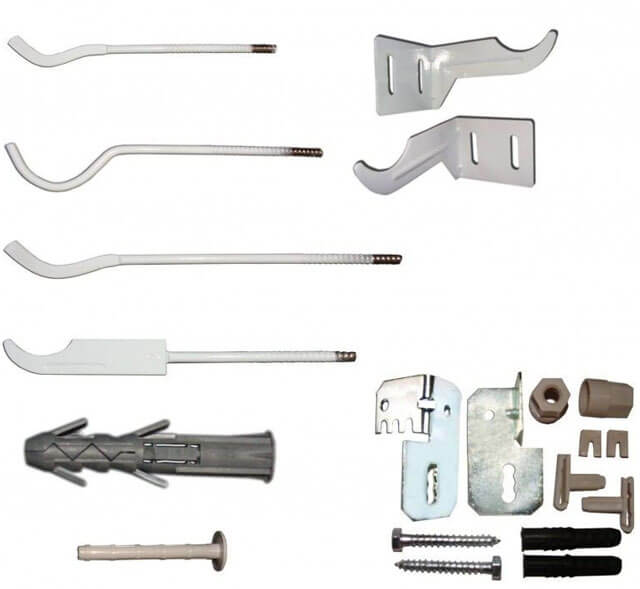

The mountings for cast iron heating radiators are the thickest and heaviest, because must hold a lot of weight for years. These curved pins or flat hooks are manufactured separately or attached to a steel bar in 2-3 pieces.

Products are not painted or white (standard) coating is applied to them. Other colors can be selected to order.

The most common such mount is for cast iron radiators.

The photo shows a steel pin holder.

- Cast iron pin holders.

- Adjustable steel legs. They make it possible to change the gap between the wall and the radiator, at the same time trimming the battery horizontally and in height.

- Steel pin brackets.

- Holders grouped on a metal strip.

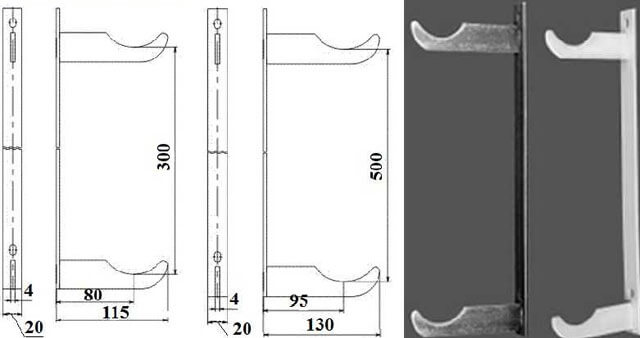

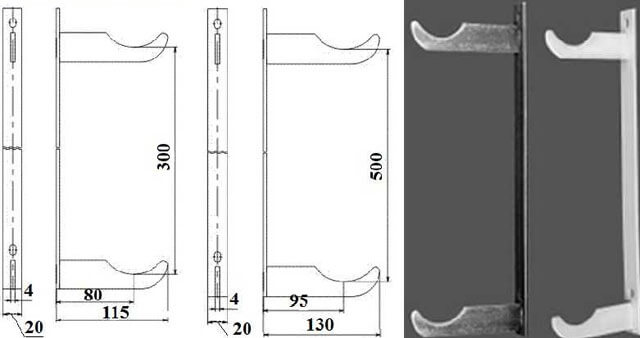

Note! Consider the dimensions of the supports before purchasing. They are made for fastening sections with different depths. In any case, the holder must provide a gap to the walls of at least 30-50 mm.

In addition to pin brackets for batteries, hooks are made of cast iron. They are completed with dowels. The product is mounted as follows: a hole is drilled into which a plastic dowel is driven. A holder is screwed into it, which has a thread on one side.

Brief instructions for installing brackets.

In addition to wall fixing, there is also a cast iron floor installation using legs. Their price depends on whether their height can be adjusted or not.

The upper arcs, which fasten the sections to the support, also differ. They are made of steel wire or have the form of a chain of movable conjugate links. In any case, the radiators are fixed to the stop with bolts and arcs.

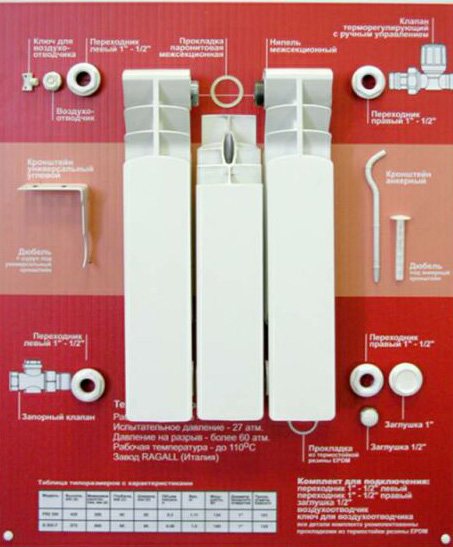

Fasteners for bimetallic and aluminum batteries

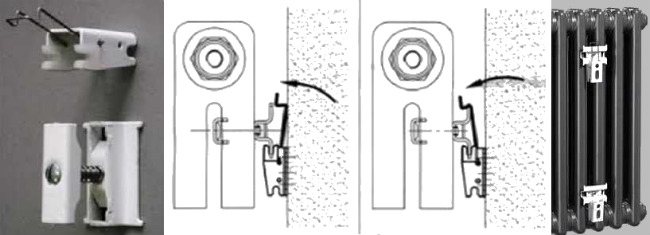

Universal holder for bimetal and aluminum.

The mount for aluminum radiators and bimetal is similar to the counterparts for cast iron, but is made of thin metal.

- The most popular corner universal holders for both types of devices. They are equipped with collector recesses at the top and bottom. Thanks to this, they can be attached to both the left and right.

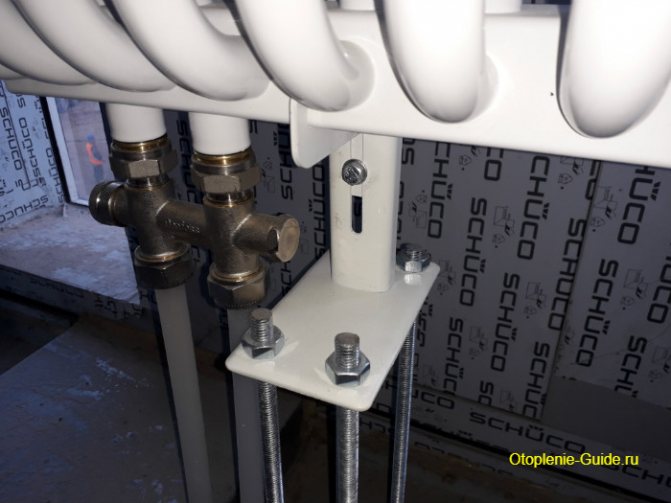

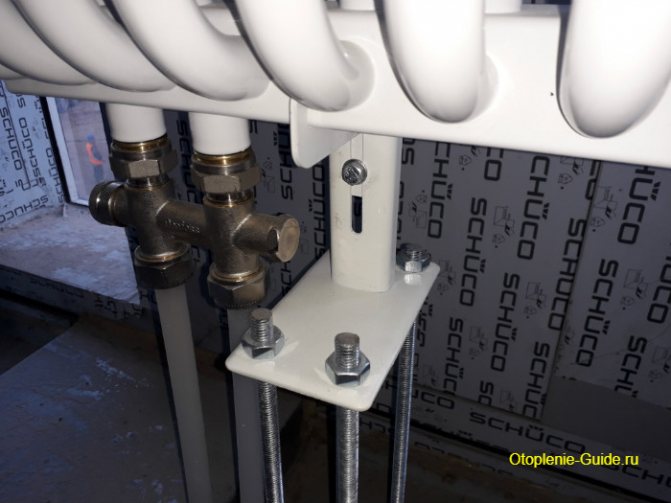

Floor stands.

- Legs for bimetal and aluminum are not produced. But they produce racks that allow for floor-standing installation of batteries. First, such a support is attached to the floor, then a radiator is placed and attached to it.

The use of floor stands is optimal when the walls cannot support the additional weight. For example, it is difficult to attach radiators to sandwich panels, glass, gypsum board.

Steel instrument supports

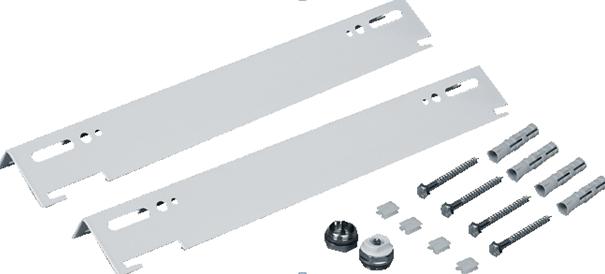

Standard mounting for panel radiator.

There are two types of such devices: panel and tubular counterparts.

They need different types of fasteners.

- Special brackets are welded to the back walls of panel batteries. With their help, devices are hung on brackets. Such a fastener for steel radiators has a special shape designed for brackets.

Note! When installing panel devices, you should carefully monitor the vertical placement of the brackets, because 4-6 shackles should hit the hooks exactly. It is necessary that the wall is absolutely smooth and even.

- Since the weight of the radiator is small, it will be enough to fix it on the brackets from above. You can put supports from below, they will give it a horizontal direction. They cling to the staples with hooks and only abut against the wall.

- For greater reliability, the part of the fastening for steel radiators facing the wall expands.

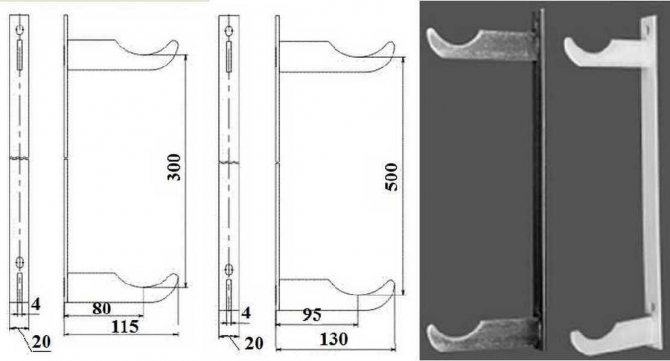

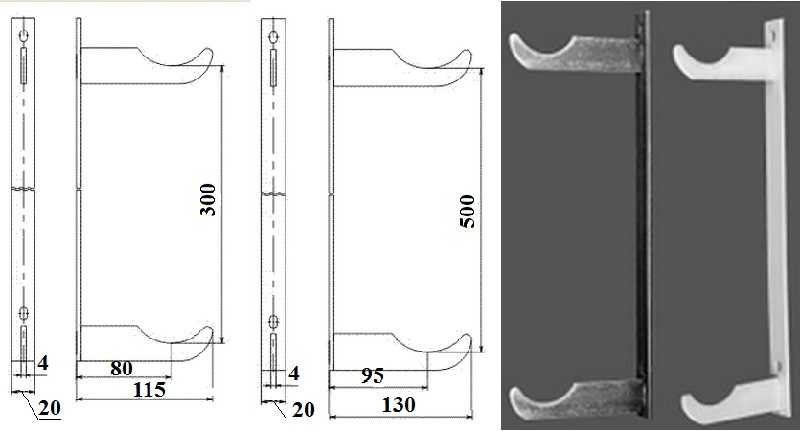

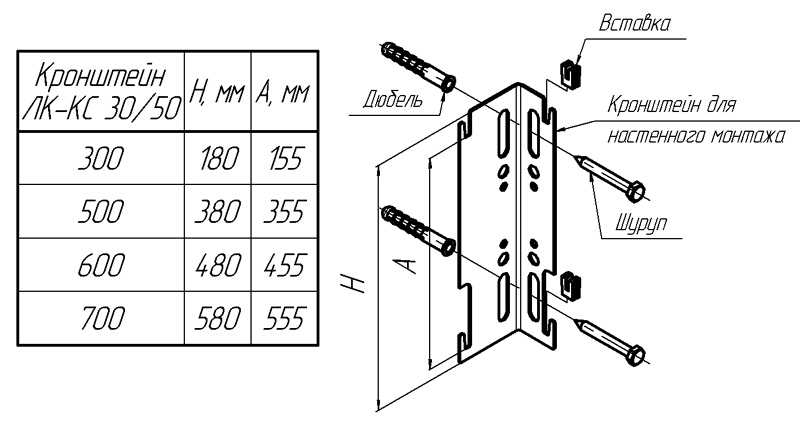

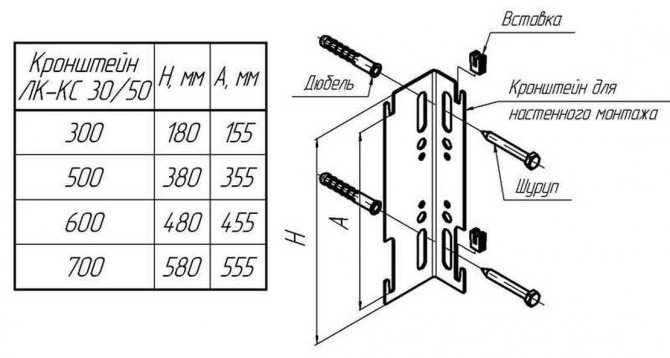

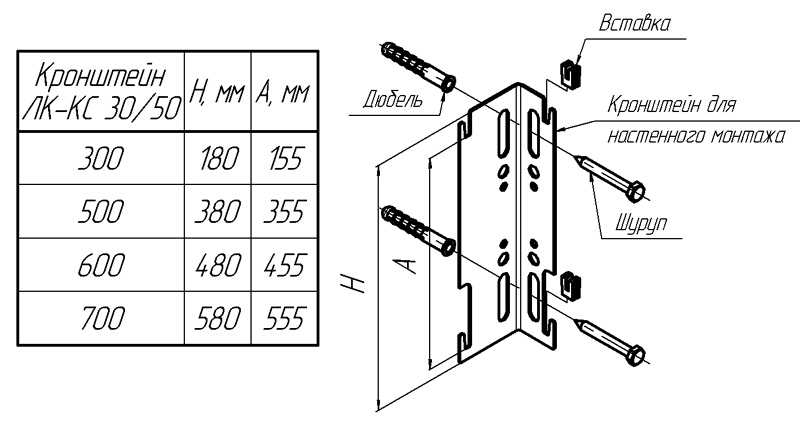

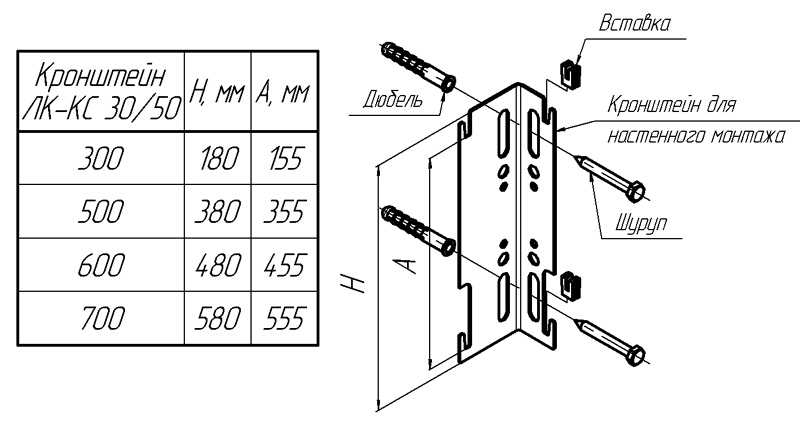

The table below shows the dimensions of the fasteners described.

| Bracket model | Length in centimeters | Overall height in centimeters (H) | Distance between bottom and top hook in centimeters (A) |

| LK-KS / 30 | 30 | 18 | 15.5 |

| LK-KS / 50 | 50 | 38 | 35.5 |

| LC-KS / 60 | 60 | 48 | 45.5 |

| LK-KS / 70 | 70 | 58 | 55.5 |

There are also special strips for simplified installation. These are metal strips with plastic clips on the bottom and top. With this method of fixing the brackets on the radiator are not needed. The strips are screwed to the wall, a battery is inserted into them, held by plastic hooks.

The bracket for fastening a tubular heating radiator is similar to a product for a sectional analogue.

It also consists of hooks, only of a different size, which are equipped with plastic pads.

SMB mount.

- Manufacturers also produce a special SMB holder with tube grippers.

- This is a steel bar with plastic clips and a support-shelf for the battery at the bottom.

- Such fasteners can be used when the weight of the radiator filled with coolant is no more than 100 kg.

- Battery installation is extremely simple here. Install the device on a support, bring it up to the clamps. Those, clasping the nearest tube, snap into place.

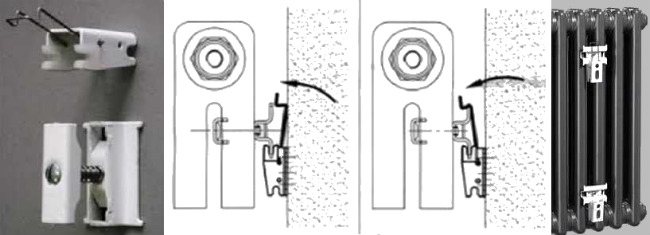

There is also a second model for simplified installation - the SVD holder. It consists of two nodes. The first is fixed on the wall, the second on the battery. When installing the device, they are mated and connected with a steel loop.

Floor fixing of such batteries can be carried out using tubular stops welded already at the factory or stands with hooks. The device is hung on them, the stand itself for attaching the radiator is fixed to the floor.

Brackets for steel radiators

Steel batteries are available in several configurations - they can be tubular or panel. In this regard, the holder for the heating radiator must be selected individually, based on the type of fixation.

To mount panel heating batteries on the wall, special brackets are produced that look like metal corners.One wing of the wall bracket for the heating radiator is fixed to the wall with anchors, and the other is equipped with special hooks for hanging the battery. On the panel-type radiator itself, there are brackets with which it is attached to the hooks.

Some models of steel panel radiators do not contain mounting brackets, so they are mounted on vertical strips with clips. Since these batteries are lightweight, this type of mount is quite acceptable.

Tubular steel radiators are attached in a slightly different way. Due to the low weight of the structure, only 2 upper supports are enough to fix it. At the bottom of the radiator, plastic clips are installed, which abut against the wall to hold the battery in an upright position.

Selecting and installing mounts

When choosing fixing elements, you should focus on the following points:

- the material from which the radiators are made;

- battery sizes;

- wall material;

- dimensions of windows, their number and location features;

- room design project.

Important! The instruction notes that the heavier the heater, the thicker the holder must be. The materials of the radiator and fasteners must match each other.

After evaluating the above aspects, you will be able to choose the right type of holders and determine the required number.

Fastener calculation

Distances to be maintained when installing batteries.

When installed under windows, the following distances are maintained:

- from the floors should be at least 8-12 cm;

- to the walls about 3-5 cm;

- to window sills at least 6-10 cm.

About how many fasteners are needed for a heating radiator.

Their number depends on the length of the heater.

- When there are few sections - up to 10 pieces, 2 holders are placed at the top, another one is mounted at the bottom.

- If the battery consists of 10-14 cells, 3 fasteners are installed at the top, 2 at the bottom.

- Under each subsequent 4-7 sections of cast-iron batteries and 10 analogs of aluminum and tubular with their own hands, one support is added at the top and bottom.

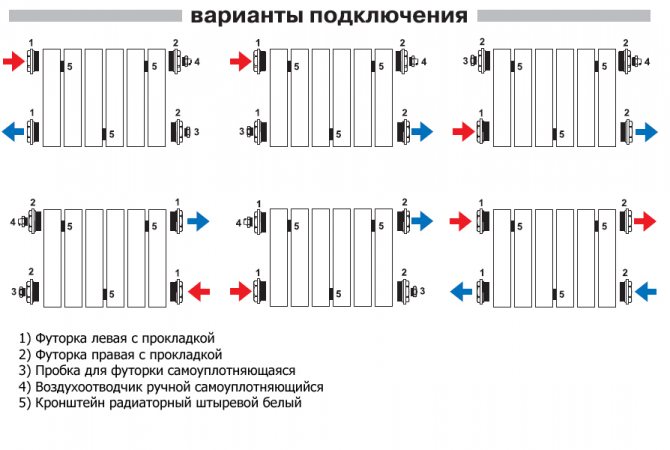

Each detail has its own place

Layout for mounting holders

The question of how to mark the mountings for the radiators is very important.

- The best option is when the heater is located exactly in the middle of the window. Based on this, find the center of the opening on the wall and draw a vertical line.

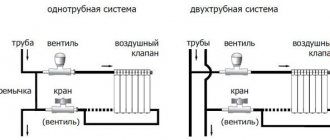

- Then there are 2 options. If the wiring is bottom, draw a horizontal line to mark the top edge of the battery. When installing radiators with side connections, it is important to place the heating pipes. In this case, set aside the horizontal line coming from the supply (upper) pipe.

- Measure the spaces between the holders on the battery. Set them aside in relation to the drawn lines.

Fixation of bimetallic and aluminum batteries

If we talk about the mass of bimetallic and aluminum radiators, then in this parameter they are almost identical. Therefore, the bracket for a bimetallic radiator can be successfully used to mount an aluminum battery.

A fastener of this type practically does not differ from a stand for a cast iron radiator. The only difference is the lower bearing capacity. As a rule, such clamps are universal corners, one side of which is fixed to the wall, and the other contains recesses on both sides. This configuration allows such fasteners to be mounted in any direction.

It is noteworthy that bimetallic and aluminum batteries do not initially provide for the possibility of floor mounting. However, it is not possible to attach radiators to surfaces such as glass, drywall or sandwich panels. In this case, a floor bracket for aluminum radiators is used, similar to the stands for cast iron batteries.

Features of the wall mount system

Any bracket for a wall-mounted radiator is a crescent-shaped hook. The loop itself can be made in the form of a semicircle or have a rectangular shape. At the end of the locking device, either a mounting plate can be located (it sits on self-tapping screws), or in the case of a pin lock, this is a regular thread. With its help, the pin is screwed into the wall, where the dowel is previously inserted.

The bracket for attaching the radiator to the wall can be of the following types:

- cast iron (used only for fixing batteries from a similar construction material);

- steel, pin fixed (used to fix cast iron, aluminum and steel heating elements);

- steel adjustable element (cast iron, steel, bimetallic heating devices);

- plate retainer made of steel (cast iron, steel batteries);

- corner conventional or reinforced structures (for aluminum and bimetallic products).

The panel radiator bracket is often in the shape of a hook. It fixes the heating device through a special bracket that is welded to its back panel. From a design point of view, this is the most successful installation method, as it is absolutely invisible.

Work technology

The owners of private houses can replace radiators at any time convenient for them. To do this, you just need to turn off the boiler and drain the water from the heating circuit. But in the apartment of a multi-storey building, the replacement of the radiator will have to be previously agreed with the service utility organization.

If all installation work is carried out in the summer, when the heating is turned off, there will be less difficulties. However, you still have to clarify whether the water was drained from the system or not.

Please note that many experienced locksmiths advise replacing radiators just in the conditions of a working central heating. This is done because when the coolant is supplied to the circuit under pressure, you can immediately check the operability of the radiator - if the installation was performed incorrectly, leaks will occur.

The efficiency of their work will depend on how well the radiators are fastened to the floor or to the wall. The fasteners must be installed absolutely evenly, as in case of skewing, problems can arise when connecting the system.

Using the tools at hand - a pencil, a level, a plumb line and a tape measure - perform the initial marking. Mark the central axis of the window, which should coincide with the middle of the radiator. A horizontal line is drawn through this point along which the upper supports will be attached.

In cases where there is only one lower support element, it is mounted on the central axis. If there are several of them, another horizontal line is drawn parallel to the upper line. After marking, start drilling holes and mounting brackets.

Output

There are many types of fasteners for heating radiators. They can be both wall-mounted and floor-mounted. Standard models are reliable, however, they are more difficult to install. Fixtures and strips for simplified installation save labor and time, but they are more expensive.

The video in this article contains visual information.

Did you like the article? Subscribe to our channel Yandex.Zen

Holders for cast iron radiators

The heaviest batteries are cast iron, therefore, the most durable and massive fasteners are used for them. Such a fastener must withstand not only the weight of the heater, but also the coolant circulating in it. Since the pipe gaps in cast-iron batteries are significant, a lot of heat carrier circulates in them, which increases the already rather large weight of the radiator.

Fastening cast iron heating radiators and how much does the installation cost

For mounting cast-iron batteries on the wall, free-standing pins or the same elements fixed to the bar are used. Typically, such fasteners are of considerable thickness and are labeled as “reinforced”. The bracket itself can be painted or not. The standard color scheme of such holders is white, but when installing a designer battery, the bracket can be repainted in the desired shade.

Attention! The dimensions of the bracket are selected depending on the depth of the section in order to ensure the installation of the radiator in compliance with the standard distance from the wall of 3-5 cm.

In addition to special brackets, cast iron batteries can be hung on conventional hooks. These items are sold together with dowels. There is a thread on one side of this hook.

Installation is carried out as follows:

- a hole is drilled in the wall in the right place;

- a dowel is driven into it;

- a hook is screwed into this dowel by means of a thread on one side.

There is also a special bracket for an underfloor heating radiator. These stands can be adjusted in height or come with predefined standard dimensions. Floor fasteners may differ in upper arcs, which are responsible for fixing the section to the rack. So, there are arcs in the form of a chain consisting of moving links, as well as elements of steel wire. Such stands for heating radiators come complete with clamping bolts.

Bracket types

At the place of attachment, there are 2 types of brackets: wall and floor. Most often they are sold as a set.

If the battery is mounted near aerated concrete, plasterboard partitions or near a floor-to-ceiling window (the wall does not allow the installation of brackets), only floor stands are used.

Depending on the type of battery, the fasteners are also divided into holders:

- for cast iron;

- steel;

- aluminum or bimetallic batteries.

Brackets for cast iron heating radiators

Brackets for heavy cast-iron batteries are often marked with a "reinforced" marker, they are made of extra strong material, and the mounts themselves are massive.

Pin... Standard, used for small structures.

Appearance - pins, hooks, separate or mounted on one bar. They are distinguished by ease of installation. For this, a recess is drilled in the wall (more than 12 cm deep). A dowel is driven in, into which the battery fastener is screwed. The recess itself is cemented.

Anchor brackets.

Fastenings for "self-tapping"... It is used on large structures, where the usual fastening to the radiator pin holders is impossible.

Floor standing... They are produced in two types: with height adjustment and non-adjustable.

The arcs that secure the battery can be made from solid steel wire or from dynamic links fastened together.

Supplied with chain-arc.

This type of fastener is used both in combination with wall brackets and as independent structures that are installed in places where fastening to the wall is impossible.

Brackets for steel radiators

Steel radiators differ in shape (tubular and panel). Fasteners for these types of radiators, respectively, have their own characteristics.

There are brackets on the rear panel batteries:

Steel panel radiator, rear view, brackets.

When installing a standard bracket, precise marking is required, the brackets must be accurately put on the hooks:

Mounting the panel battery on the corner holder.

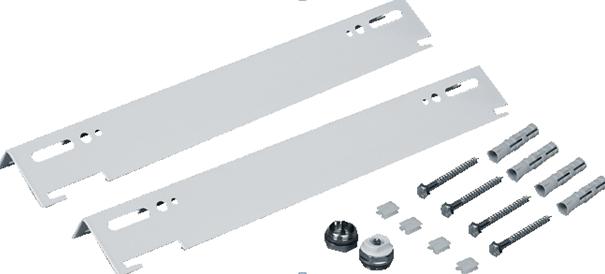

Standard set of brackets for steel panel radiators.

Therefore, a different set of fasteners is more often used, including an upper hook and a lower stop.The lower stop is hooked to the battery bracket, but not attached to the wall, but only abuts, which allows you to accurately set the vertical position of the radiator.

Fastening tubular radiators

For tubular heat exchangers, a similar kit is used, only the shape of the upper hook is adapted for hanging the upper collector tube.

Bracket support for tubular radiator KZTO RS2.

Also, a popular mount for light tubular radiators (whose weight together with the coolant is not more than 100 kg) are strips that are fixed on the wall, and the battery is installed on the bottom shelf and fixed with plastic grips. This fastener is referred to as an SMB holder.

Radiator holder for Leroy Merlin.

Another way to install steel batteries is with SVD fasteners. The holder is in two parts. One is fixed on the wall, the second on the radiator. During installation, they are hinged to each other:

SVD fasteners.

Brackets for aluminum and bimetallic batteries

If fasteners are selected for sectional heating batteries, its device does not differ much from fasteners for cast-iron radiators. Only the thickness of the metal can be less.

Aluminum and bimetallic radiators are not available in a floor-standing version, but if necessary, the usual structure can be mounted on racks (this is often used in buildings with glass walls):

Radiator mounted on floor brackets.

Corner holders are also used for lightweight structures. The corner bracket can be attached to the left or right thanks to the recesses on both sides.

Bracket 3.2 reinforced universal (100 mm).

As our quick overview shows, there is a wide variety of fasteners for radiators. At the same time, many manufacturers produce batteries that come with a set of brackets. On the one hand, this facilitates installation, but in situations with non-standard walls, the user has to independently select the desired mounting option for the batteries.