Methods for determining the load

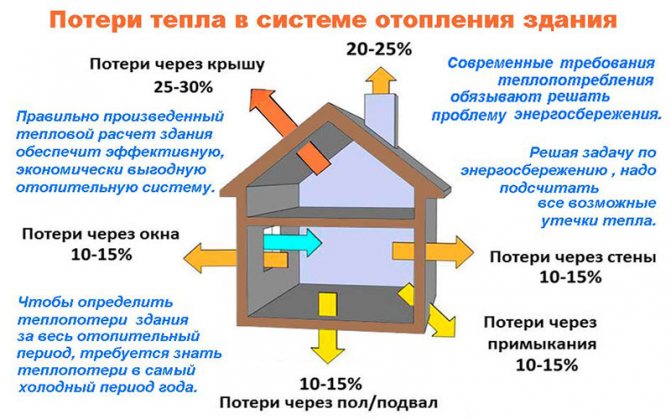

First, let's explain the meaning of the term. Heat load is the total amount of heat consumed by the heating system to heat the premises to the standard temperature during the coldest period. The value is calculated in units of energy - kilowatts, kilocalories (less often - kilojoules) and is denoted in the formulas by the Latin letter Q.

Knowing the heating load of a private house in general and the need of each room in particular, it is not difficult to choose a boiler, heaters and batteries of a water system in terms of power. How can this parameter be calculated:

- If the ceiling height does not reach 3 m, an enlarged calculation is made for the area of the heated rooms.

- With a ceiling height of 3 m or more, the heat consumption is calculated by the volume of the premises.

- Determination of heat loss through external fences and the cost of heating ventilation air in accordance with SNiP.

Note. In recent years, online calculators posted on the pages of various Internet resources have gained wide popularity. With their help, the determination of the amount of thermal energy is performed quickly and does not require additional instructions. The downside is that the reliability of the results must be checked, because the programs are written by people who are not heat engineers.

Photo of the building taken with a thermal imager

The first two calculation methods are based on the application of the specific thermal characteristic in relation to the heated area or the volume of the building. The algorithm is simple, it is used everywhere, but it gives very approximate results and does not take into account the degree of insulation of the cottage.

It is much more difficult to calculate the consumption of thermal energy according to SNiP, as design engineers do. You will have to collect a lot of reference data and work hard on the calculations, but the final numbers will reflect the real picture with an accuracy of 95%. We will try to simplify the methodology and make the calculation of the heating load as easy to understand as possible.

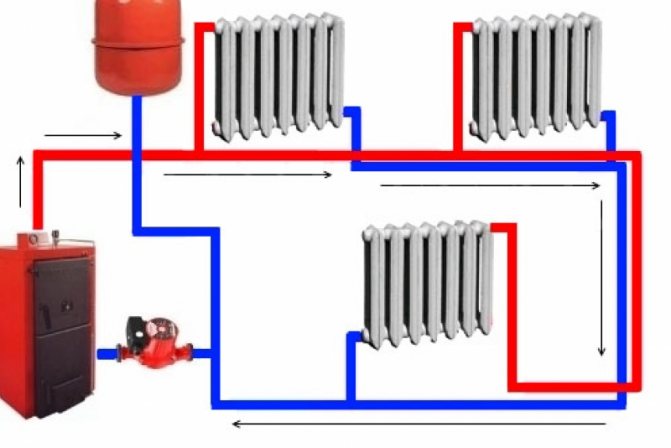

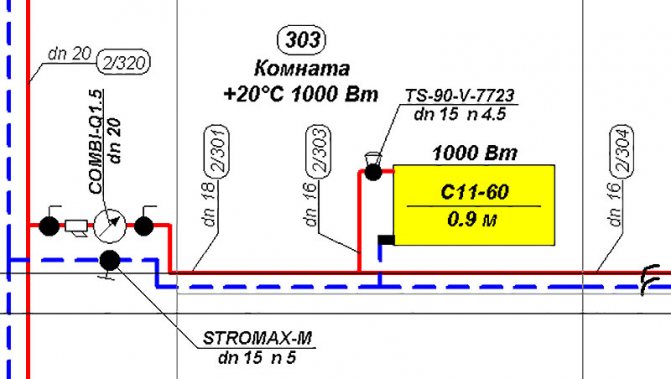

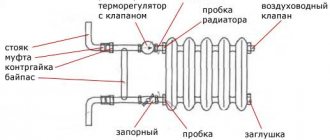

Connection method

Not everyone understands that the piping of the heating system and the correct connection affect the quality and efficiency of heat transfer. Let us examine this fact in more detail.

There are 4 ways to connect a radiator:

- Lateral. This option is most often used in urban apartments of multi-storey buildings. There are more apartments in the world than private houses, so manufacturers use this type of connection as a nominal way to determine the heat transfer of radiators. A factor of 1.0 is used to calculate it.

- Diagonal. Ideal connection, because the heating medium passes through the entire device, evenly distributing heat throughout its volume. Usually this type is used if there are more than 12 sections in the radiator. A multiplying factor of 1.1–1.2 is used in the calculation.

- Lower. In this case, the supply and return pipes are connected from the bottom of the radiator. Typically, this option is used for hidden pipe wiring. This type of connection has one drawback - heat loss of 10%.

- One-pipe. This is essentially a bottom connection. It is usually used in the Leningrad pipe distribution system. And here it was not without heat loss, however, they are several times more - 30-40%.

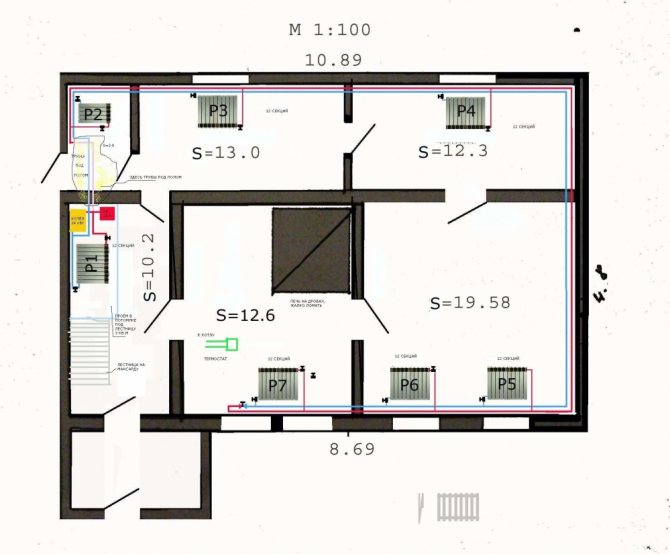

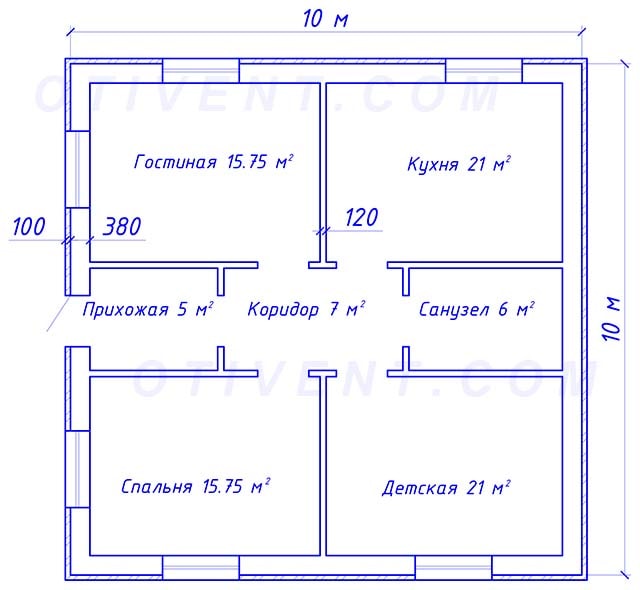

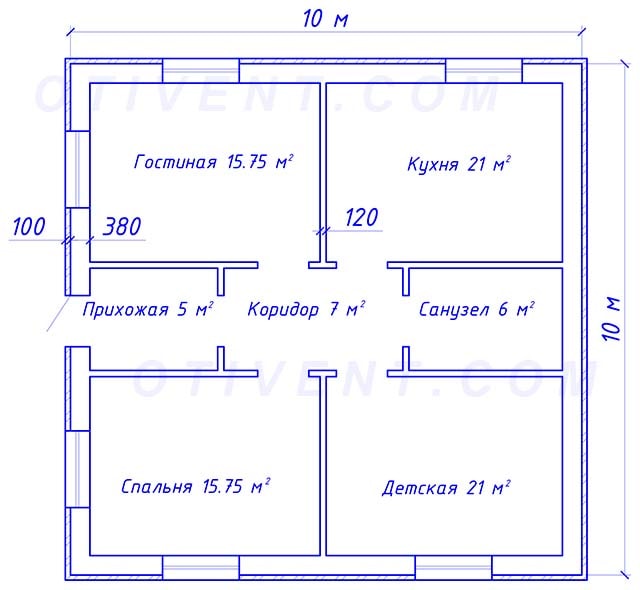

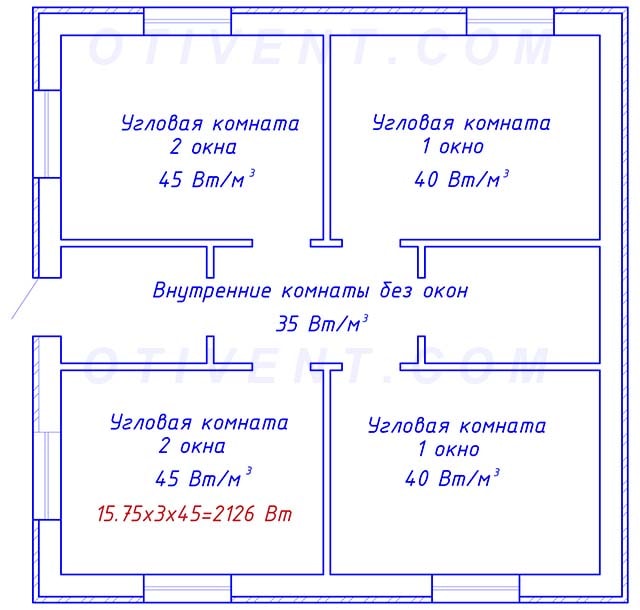

For example, a project of a one-story house of 100 m²

In order to clearly explain all the methods for determining the amount of heat energy, we suggest taking as an example a one-story house with a total area of 100 squares (by external measurement), shown in the drawing. Let's list the technical characteristics of the building:

- the region of construction is a zone of temperate climate (Minsk, Moscow);

- thickness of external fences - 38 cm, material - silicate brick;

- external wall insulation - polystyrene 100 mm thick, density - 25 kg / m³;

- floors - concrete on the ground, no basement;

- overlap - reinforced concrete slabs, insulated from the side of the cold attic with 10 cm foam;

- windows - standard metal-plastic for 2 glasses, size - 1500 x 1570 mm (h);

- entrance door - metal 100 x 200 cm, insulated from the inside with 20 mm extruded polystyrene foam.

The cottage has half-brick interior partitions (12 cm), the boiler room is located in a separate building. The areas of the rooms are indicated in the drawing, the height of the ceilings will be taken depending on the explained calculation method - 2.8 or 3 m.

Classification of heaters

Depending on the material used for the manufacture, heating radiators can be:

- steel;

- aluminum;

- bimetallic;

- cast iron.

Each of these types of radiators has its own advantages and disadvantages, so it is necessary to study their technical characteristics in more detail.

Cast iron batteries - time-tested heating devices

The main advantages of these devices are high inertia and fairly good heat transfer. Cast iron batteries take a long time to heat up and are also capable of giving off accumulated heat for a long time. Heat transfer of cast iron radiators is 80-160 W per section.

There are many disadvantages of these devices, among which the most serious are:

- a large difference between the flow area of risers and batteries, as a result of which the coolant moves slowly through the radiators, which leads to their rapid contamination;

- low resistance to water hammer, working pressure 9 kg / cm2;

- heavy weight;

- exactingness to regular care.

Aluminum radiators

Aluminum alloy batteries have many advantages. They are attractive, undemanding to regular maintenance, devoid of fragility, as a result of which they better resist water hammer than their cast-iron counterparts. Working pressure varies depending on the model and can be from 12 to 16 kg / cm2. Another indisputable advantage of aluminum batteries is the flow area, which is less than or equal to the inner diameter of the risers. Due to this, the coolant moves inside the sections at a high speed, which makes it almost impossible for dirt to accumulate inside the device.

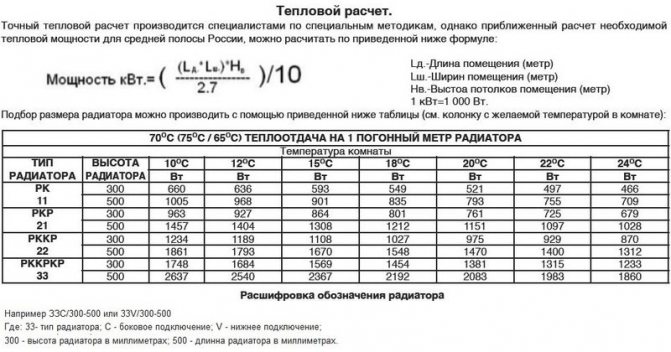

Many people believe that a small cross-section of radiators leads to low heat dissipation. This statement is incorrect, since the heat transfer of aluminum is higher than, for example, of cast iron, and the small cross-section in batteries is more than compensated by the area of the radiator fins. According to the table below, the heat dissipation of aluminum radiators depends on the model and can be from 138 to 210 W.

But, despite all the advantages, most experts do not recommend them for installation in apartments, since aluminum batteries may not withstand sudden pressure surges when testing central heating. Another disadvantage of aluminum batteries is the rapid destruction of the material when used in tandem with other metals. For example, connecting to radiator risers through brass or copper squeegees can lead to oxidation of their inner surface.

Bimetallic heating devices

These batteries do not have the disadvantages of their cast iron and aluminum rivals. The design feature of such radiators is the presence of a steel core in the aluminum fins of the radiator. As a result of this "fusion", the device can withstand a colossal pressure of 16-100 kg / cm2.

Engineering calculations have shown that the heat transfer of a bimetallic radiator practically does not differ from an aluminum one, and can vary from 130 to 200 W.

The flow area of the device, as a rule, is less than that of risers, therefore bimetallic radiators are practically not contaminated.

Despite its solid advantages, this product has a significant drawback - its high cost.

Steel radiators

Steel batteries are perfect for heating rooms powered by an autonomous heating system. However, such radiators are not the best choice for central heating, as they may not withstand pressure. They are quite lightweight and resistant to corrosion, with high inertia and good heat transfer rates. Their flow area is often less than that of standard risers, so they rarely clog.

Among the disadvantages, one can single out a rather low working pressure of 6-8 kg / cm2 and resistance to water hammer, up to 13 kg / cm2. The heat transfer index for steel batteries is 150 W per section.

The table shows the average heat transfer and operating pressure for heating radiators.

We calculate the heat consumption by quadrature

For an approximate estimate of the heating load, the simplest heat calculation is usually used: the area of the building is taken by the outer dimensions and multiplied by 100 W. Accordingly, the heat consumption for a country house of 100 m² will be 10,000 W or 10 kW. The result allows you to select a boiler with a safety factor of 1.2-1.3, in this case, the unit's power is assumed to be 12.5 kW.

We propose to perform more accurate calculations, taking into account the location of the rooms, the number of windows and the building region. So, with a ceiling height of up to 3 m, it is recommended to use the following formula:

The calculation is carried out for each room separately, then the results are summed up and multiplied by the regional coefficient. Explanation of the formula designations:

- Q is the required load value, W;

- Spom - square of the room, m²;

- q is the indicator of the specific thermal characteristics related to the area of the room, W / m2;

- k - coefficient taking into account the climate in the area of residence.

For reference. If a private house is located in a zone of temperate climate, the coefficient k is taken equal to one. In the southern regions, k = 0.7, in the northern regions, values of 1.5-2 are used.

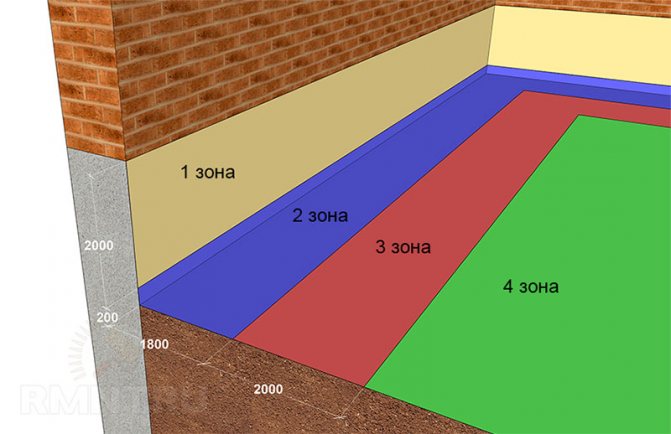

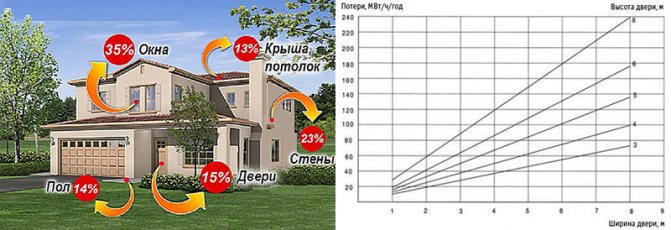

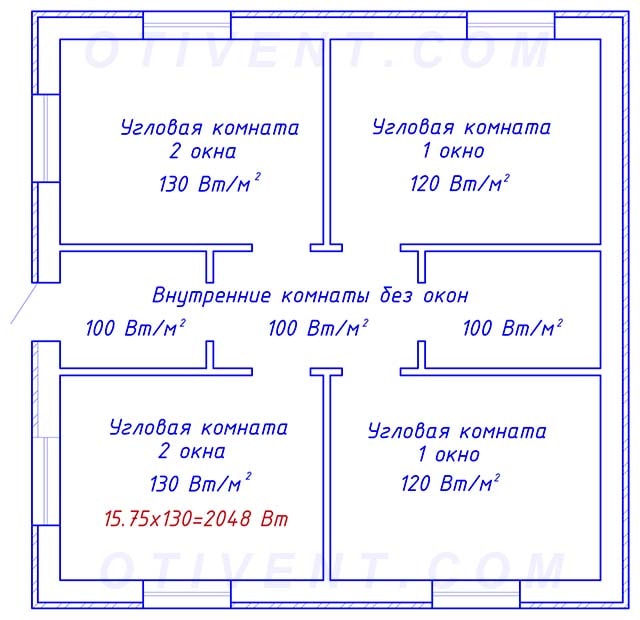

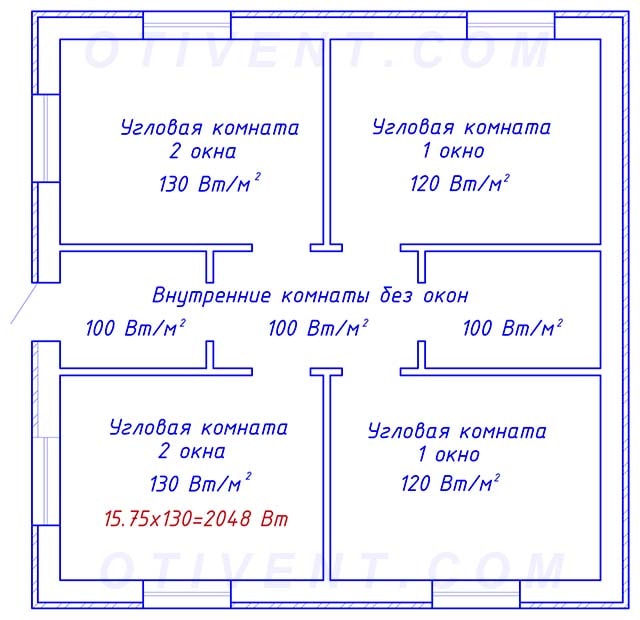

In an approximate calculation according to the general quadrature, the indicator q = 100 W / m². This approach does not take into account the location of the rooms and the different number of light openings. The corridor inside the cottage will lose much less heat than a corner bedroom with windows of the same area. We propose to take the value of the specific thermal characteristic q as follows:

- for rooms with one outer wall and a window (or door) q = 100 W / m²;

- corner rooms with one light opening - 120 W / m²;

- the same, with two windows - 130 W / m².

How to choose the correct q value is clearly shown on the building plan. For our example, the calculation looks like this:

Q = (15.75 x 130 + 21 x 120 + 5 x 100 + 7 x 100 + 6 x 100 + 15.75 x 130 + 21 x 120) x 1 = 10935 W ≈ 11 kW.

As you can see, the refined calculations gave a different result - in fact, 1 kW of heat energy more will be spent on heating a specific house of 100 m². The figure takes into account the heat consumption for heating the outside air that penetrates into the dwelling through openings and walls (infiltration).

Self-calculation of thermal power

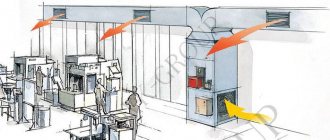

The beginning of the preparation of a heating project, both for residential country houses and industrial complexes, follows from a heat engineering calculation. A heat gun is assumed as a heat source.

What is a heat engineering calculation?

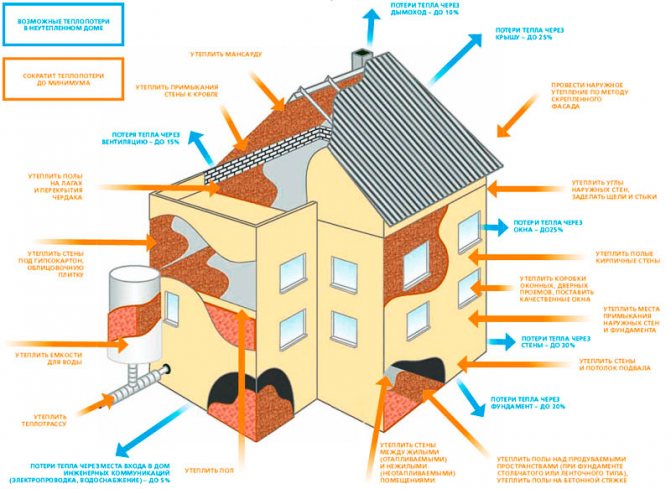

Calculation of heat losses is a fundamental document designed to solve such a problem as the organization of heat supply to a structure. It determines the daily and annual heat consumption, the minimum heat demand of a residential or industrial facility and heat losses for each room. When solving such a problem as a heat engineering calculation, one should take into account the complex of characteristics of the object:

- Object type (private house, one-story or multi-story building, administrative, industrial or warehouse).

- The number of people living in the building or working in one shift, the number of hot water supply points.

- The architectural part (dimensions of the roof, walls, floors, dimensions of door and window openings).

- Special data, for example, the number of working days per year (for industries), the duration of the heating season (for objects of any type).

- Temperature conditions in each of the premises of the facility (they are determined by CHiP 2.04.05-91).

- Functional purpose (warehouse production, residential, administrative or household).

- Roof structures, external walls, floors (type of insulation layers and materials used, floor thickness).

Why do you need a heat engineering calculation?

- To determine the boiler output. Suppose you have made a decision to equip a country house or company with an autonomous heating system. To determine the choice of equipment, first of all, you will need to calculate the power of the heating installation, which will be needed for the smooth operation of hot water supply, air conditioning, ventilation systems, as well as effective heating of the building. The capacity of the autonomous heating system is determined as the total amount of heat costs for heating all rooms, as well as heat costs for other technological needs. The heating system must have a certain power reserve so that operation at peak loads does not reduce its service life.

- To complete the agreement on gasification of the facility and obtain the technical specifications. It is necessary to obtain a permit for gasification of the facility if natural gas is used as fuel for the boiler. To obtain the TU, you will need to provide the values of the annual fuel consumption (natural gas), as well as the total values of the power of heat sources (Gcal / hour). These indicators are determined as a result of thermal calculation. Approval of the project for the implementation of gasification of the facility is a more expensive and time-consuming method of organizing autonomous heating, in relation to the installation of heating systems operating on waste oils, the installation of which does not require approvals and permits.

- To select the right equipment. Thermal calculation data are a determining factor when choosing devices for heating objects. Many parameters should be taken into account - orientation to the cardinal points, dimensions of door and window openings, dimensions of rooms and their location in the building.

How is the heat engineering calculation

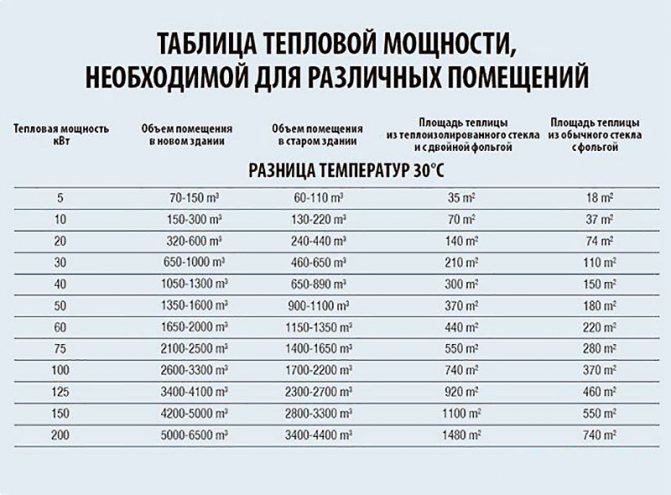

You can use simplified formulato determine the minimum allowable power of heating systems:

Qt (kW / h) = V * ΔT * K / 860, where

Qt is the heat load on a certain room; K is the heat loss coefficient of the building; V is the volume (in m3) of the heated room (the width of the room for the length and height); ΔT - the difference (designated C) between the required air temperature inside and outside temperature.

An indicator such as the coefficient of heat loss (K) depends on the insulation and type of construction of the room. You can use simplified values calculated for objects of different types:

- K = from 0.6 to 0.9 (increased degree of thermal insulation). A small number of double-glazed windows, double-insulated brick walls, high-quality roof material, solid subfloor;

- K = from 1 to 1.9 (medium thermal insulation). Double brickwork, roof with regular roofing, few windows;

- K = 2 to 2.9 (low thermal insulation). The structure of the building is simplified, the brickwork is single.

- K = 3 - 4 (no thermal insulation). A structure made of metal or corrugated sheet or a simplified wooden structure.

Determining the difference between the required temperature inside the heated space and the outside temperature (ΔT), you should proceed from the degree of comfort that you want to get from the heating installation, as well as from the climatic characteristics of the region in which the object is located.The default parameters are the values defined by CHiP 2.04.05-91:

- +18 - public buildings and production workshops;

- +12 - high-rise storage complexes, warehouses;

- + 5 - garages and warehouses without constant maintenance.

| City | Design outside temperature, ° C | City | Design outside temperature, ° C |

| Dnipropetrovsk | — 25 | Kaunas | — 22 |

| Yekaterinburg | — 35 | Lviv | — 19 |

| Zaporizhzhia | — 22 | Moscow | — 28 |

| Kaliningrad | — 18 | Minsk | — 25 |

| Krasnodar | — 19 | Novorossiysk | — 13 |

| Kazan | — 32 | Nizhny Novgorod | — 30 |

| Kiev | — 22 | Odessa | — 18 |

| Rostov | — 22 | St. Petersburg | — 26 |

| Samara | — 30 | Sevastopol | — 11 |

| Kharkiv | — 23 | Yalta | — 6 |

The calculation using a simplified formula does not allow taking into account the differences in heat losses of the building. depending on the type of enclosing structures, insulation and placement of premises. For example, rooms with large windows, high ceilings and corner rooms will require more heat. At the same time, rooms that do not have external fences are distinguished by minimal heat losses. It is advisable to use the following formula when calculating a parameter such as the minimum thermal power:

Qt (kW / h) = (100 W / m2 * S (m2) * K1 * K2 * K3 * K4 * K5 * K6 * K7) / 1000, where

S is the area of the room, m2; W / m2 - specific heat loss (65-80 watts / m2). This figure includes heat leakage through ventilation, absorption by walls, windows and other types of leakage; K1 - coefficient of heat leakage through the windows:

- in the presence of a triple glass unit K1 = 0.85;

- if the glass unit is double, then K1 = 1.0;

- with standard glazing K1 = 1.27;

K2 - coefficient of heat loss of walls:

- high thermal insulation (indicator K2 = 0.854);

- insulation with a thickness of 150 mm or walls in two bricks (indicator K2 = 1.0);

- low thermal insulation (indicator K2 = 1.27);

K3 is an indicator that determines the ratio of the areas (S) of windows and floor:

- 50% KZ = 1.2;

- 40% KZ = 1.1;

- 30% KZ = 1.0;

- 20% KZ = 0.9;

- 10% KZ = 0.8;

K4 - outdoor temperature coefficient:

- -35 ° C K4 = 1.5;

- -25 ° C K4 = 1.3;

- -20 ° C K4 = 1.1;

- -15 ° C K4 = 0.9;

- -10 ° C K4 = 0.7;

K5 - the number of outward walls:

- four walls K5 = 1.4;

- three walls K5 = 1.3;

- two walls K5 = 1.2;

- one wall K5 = 1.1;

K6 - type of thermal insulation of the room, which is located above the heated one:

- heated K6-0.8;

- warm attic K6 = 0.9;

- unheated attic K6 = 1.0;

K7 - ceiling height:

- 4.5 meters K7 = 1.2;

- 4.0 meters K7 = 1.15;

- 3.5 meters K7 = 1.1;

- 3.0 meters K7 = 1.05;

- 2.5 meters K7 = 1.0.

Let us give as an example the calculation of the minimum power of an autonomous heating installation (using two formulas) for a detached service room of the service station (ceiling height 4m, area 250 m2, volume 1000 m3, large windows with ordinary glazing, no thermal insulation of the ceiling and walls, the design is simplified).

By simplified calculation:

Qt (kW / h) = V * ΔT * K / 860 = 1000 * 30 * 4/860 = 139.53 kW, where

V is the air volume in the heated room (250 * 4), m3; ΔT is the difference in indicators between the air temperature outside the room and the required air temperature inside the room (30 ° C); K is the coefficient of heat loss of the structure (for buildings without thermal insulation K = 4.0); 860 - conversion to kW / hour.

More accurate calculation:

Qt (kW / h) = (100 W / m2 * S (m2) * K1 * K2 * K3 * K4 * K5 * K6 * K7) / 1000 = 100 * 250 * 1.27 * 1.27 * 1.1 * 1.5 * 1.4 * 1 * 1.15 / 1000 = 107.12 kW / h, where

S is the area of the room for which the calculation is performed (250 m2); K1 is the parameter of heat leakage through the windows (standard glazing, the K1 index is 1.27); K2 - the value of heat leakage through the walls (poor thermal insulation, the K2 indicator corresponds to 1.27); K3 is the parameter of the ratio of the dimensions of the windows to the floor area (40%, the indicator K3 is 1.1); K4 - outdoor temperature value (-35 ° C, K4 indicator corresponds to 1.5); K5 - the number of walls that go out (in this case, four K5 is 1.4); K6 - an indicator that determines the type of room located directly above the heated one (attic without insulation K6 = 1.0); K7 is an indicator that determines the height of the ceilings (4.0 m, parameter K7 corresponds to 1.15).

As you can see from the calculations performed, the second formula is preferable for calculating the power of heating installations, since it takes into account a much larger number of parameters (especially if it is necessary to determine the parameters of low-power equipment intended for operation in small rooms).To the obtained result it is necessary to add a small power reserve to increase the service life of the heating equipment. Having performed simple calculations, you can, without the help of specialists, determine the required capacity of an autonomous heating system for equipping residential or industrial facilities.

You can buy a heat gun and other heaters on the company's website or by visiting our retail store.

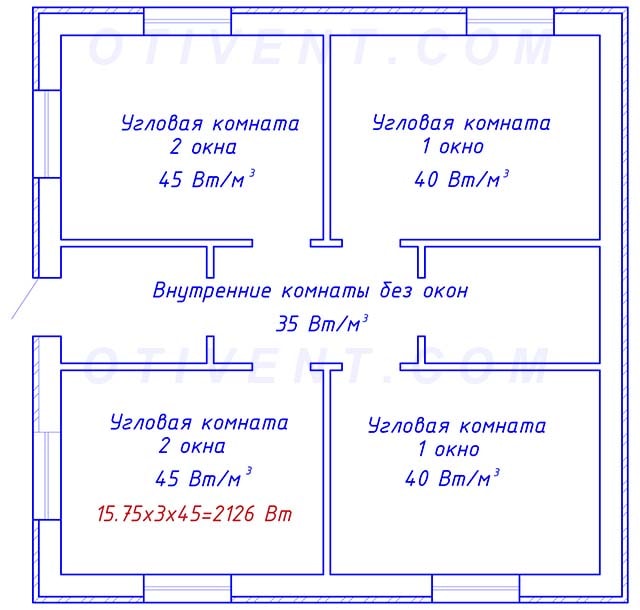

Calculation of heat load by volume of rooms

When the distance between the floors and the ceiling reaches 3 m or more, the previous calculation cannot be used - the result will be incorrect. In such cases, the heating load is considered to be based on specific aggregated indicators of heat consumption per 1 m³ of the room volume.

The formula and calculation algorithm remain the same, only the area parameter S changes to volume - V:

Accordingly, another indicator of the specific consumption q is taken, referred to the cubic capacity of each room:

- a room inside a building or with one external wall and a window - 35 W / m³;

- corner room with one window - 40 W / m³;

- the same, with two light openings - 45 W / m³.

Note. Increasing and decreasing regional coefficients k are applied in the formula without changes.

Now, for example, let's determine the heating load of our cottage, taking the ceiling height equal to 3 m:

Q = (47.25 x 45 + 63 x 40 + 15 x 35 + 21 x 35 + 18 x 35 + 47.25 x 45 + 63 x 40) x 1 = 11182 W ≈ 11.2 kW.

It is noticeable that the required heat output of the heating system has increased by 200 W compared to the previous calculation. If we take the height of the rooms 2.7-2.8 m and calculate the energy consumption through cubic capacity, then the figures will be approximately the same. That is, the method is quite applicable for the enlarged calculation of heat loss in rooms of any height.

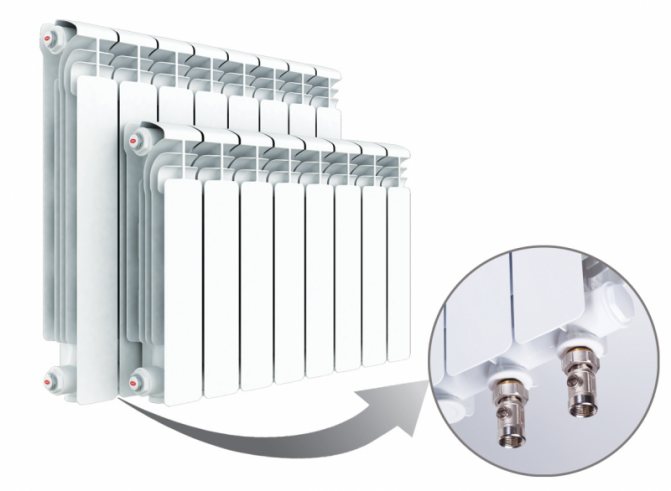

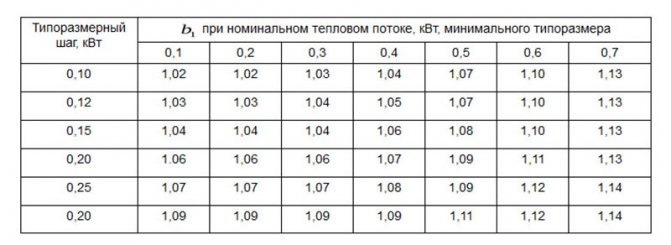

Calculation of the number of radiator sections

Collapsible radiators made of any material are good in that individual sections can be added or subtracted to achieve their design thermal power.

To determine the required number of "N" sections of batteries from the selected material, follow the formula:

N = Q / q,

Where:

- Q = the previously calculated required heat output of the devices for heating the room,

- q = heat specific power of a separate section of the batteries intended for installation.

Having calculated the total required number of radiator sections in the room, you need to understand how many batteries you need to install. This calculation is based on a comparison of the dimensions of the proposed installation sites for heating devices and the dimensions of the batteries, taking into account the supply.

battery elements are connected by nipples with multidirectional external threads using a radiator wrench, at the same time gaskets are installed in the joints

For preliminary calculations, you can arm yourself with data on the width of the sections of different radiators:

- cast iron = 93 mm,

- aluminum = 80 mm,

- bimetallic = 82 mm.

In the manufacture of collapsible radiators from steel pipes, manufacturers do not adhere to certain standards. If you want to put such batteries, you should approach the issue individually.

You can also use our free online calculator to calculate the number of sections:

How to take advantage of the results of calculations

Knowing the building's heat demand, a homeowner can:

- clearly select the power of heating equipment for heating a cottage;

- dial the required number of radiator sections;

- determine the required thickness of the insulation and insulate the building;

- find out the flow rate of the coolant at any part of the system and, if necessary, perform a hydraulic calculation of the pipelines;

- find out the average daily and monthly heat consumption.

The last point is of particular interest. We found the value of the heat load for 1 hour, but it can be recalculated for a longer period and the estimated fuel consumption - gas, firewood or pellets - can be calculated.

The choice of a radiator based on the calculation

Steel radiators

Let's leave the comparison of heating radiators outside the brackets and note only the nuances that you need to be aware of when choosing a radiator for your heating system.

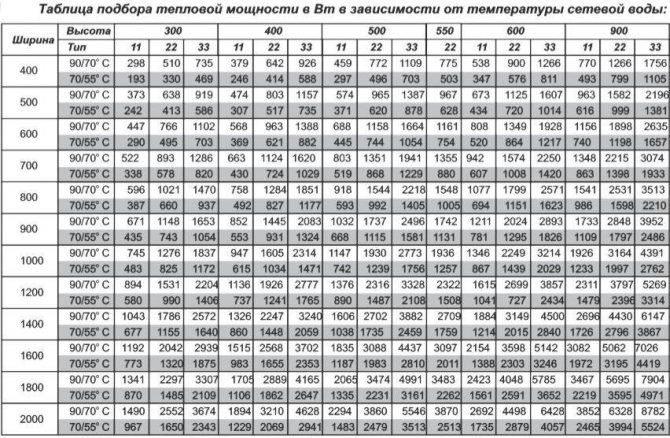

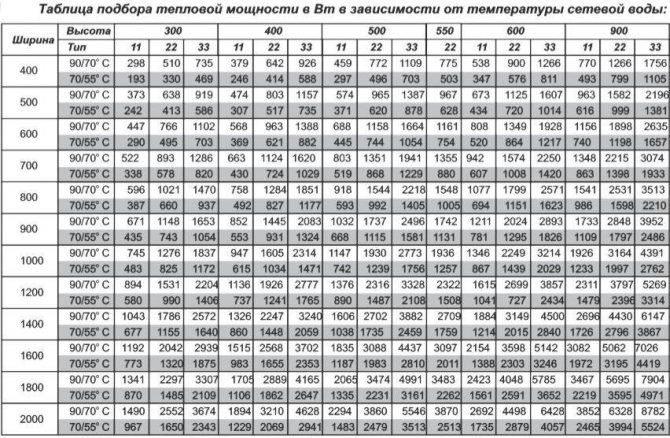

In the case of calculating the power of steel heating radiators, everything is simple. There is the required power for an already known room - 2025 watts. We look at the table and look for steel batteries that produce the required number of watts. Such tables are easy to find on the websites of manufacturers and sellers of similar goods. Pay attention to the temperature regimes under which the heating system will be operated. It is optimal to use the battery at 70/50 C.

The table indicates the type of radiator. Let's take type 22, as one of the most popular and quite decent in terms of consumer qualities. A 600 × 1400 radiator is a great fit. The power of the heating radiator will be 2020 W. Better to take a little with a margin.

Aluminum and bimetallic radiators

Aluminum and bimetallic radiators are often sold in sections. Power in tables and catalogs is indicated for one section. It is necessary to divide the power required to heat a given room by the power of one section of such a radiator, for example:

2025/150 = 14 (rounded up)

We got the required number of sections for a room with a volume of 45 cubic meters.