Repair and decoration

06/03/2018 Anastasia Prozheva

An automated control unit is a set of equipment and devices designed to provide automatic regulation of the temperature and flow rate of the coolant, which is carried out at the input of each building in accordance with the temperature schedule required for a particular building. Adjustment can also be made in accordance with the needs of the residents.

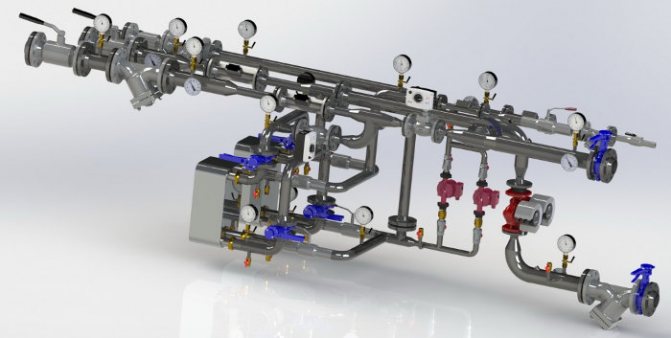

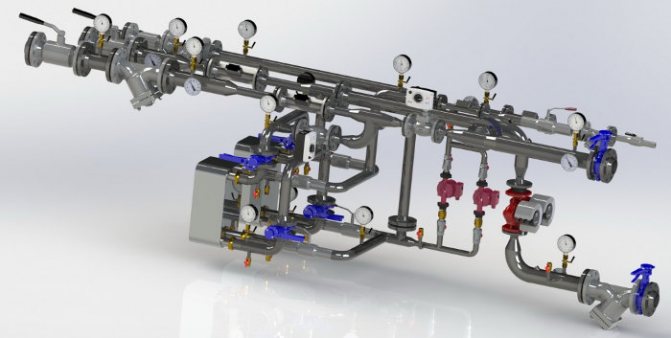

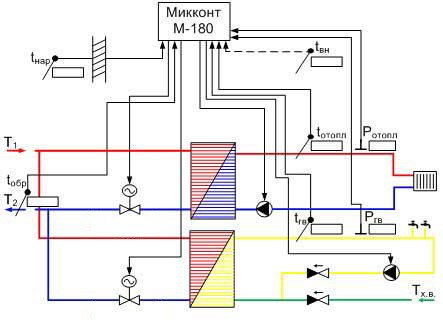

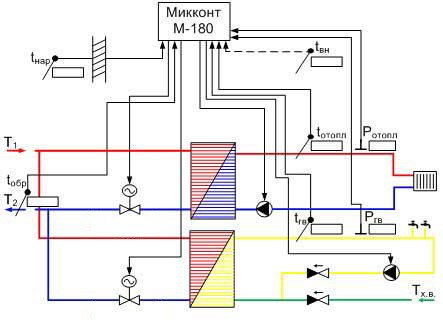

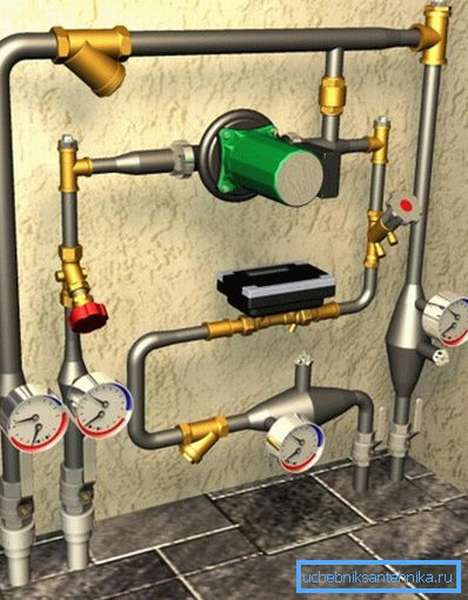

Water heater piping assembly.

Among the advantages of AUU, if we compare it with elevator and heating units, which have a fixed cross-section of the passage opening, is the possibility of varying the amount of the coolant, which depends on the temperature of the water in the return and supply pipelines.

An automated control unit is usually installed one for the entire building, which distinguishes it from an elevator unit, which is mounted on each section of the house.

In this case, the installation is carried out after the unit that takes into account the thermal energy of the system.

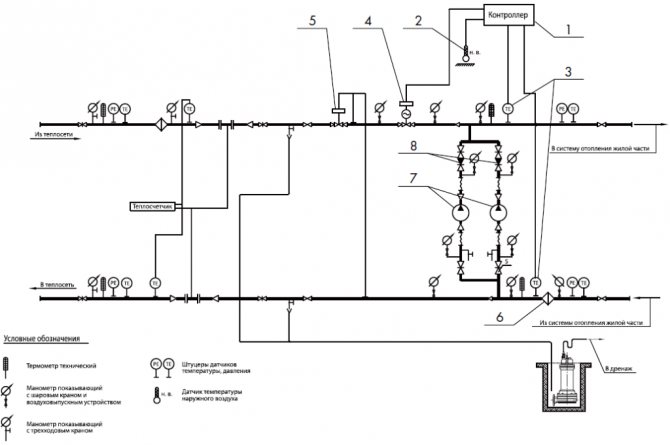

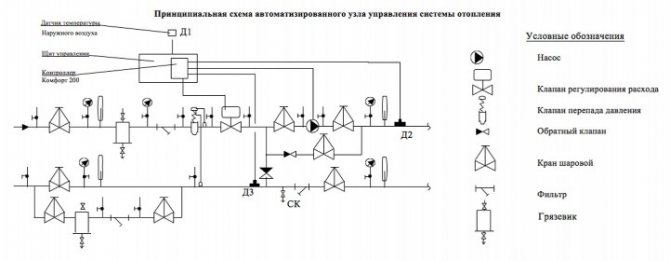

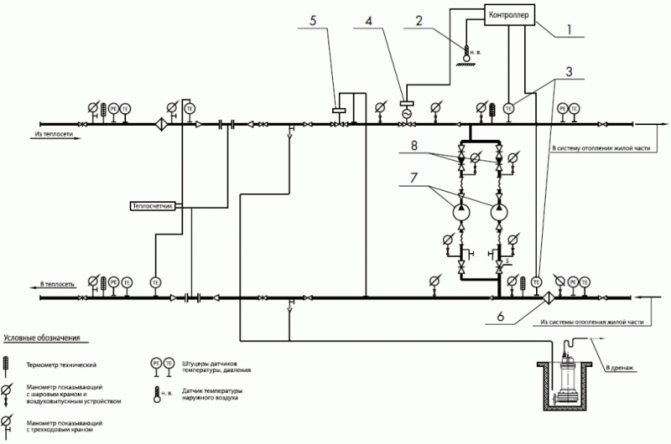

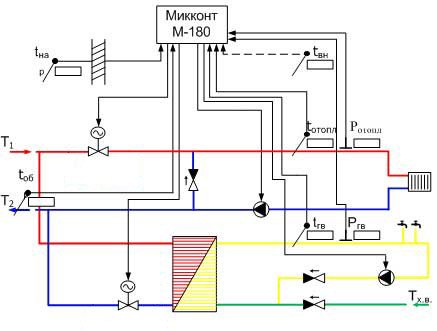

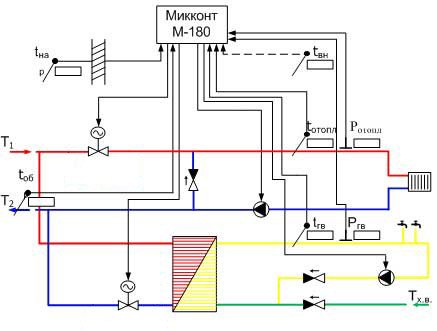

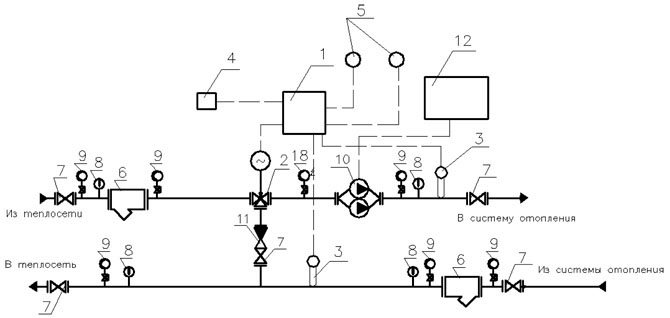

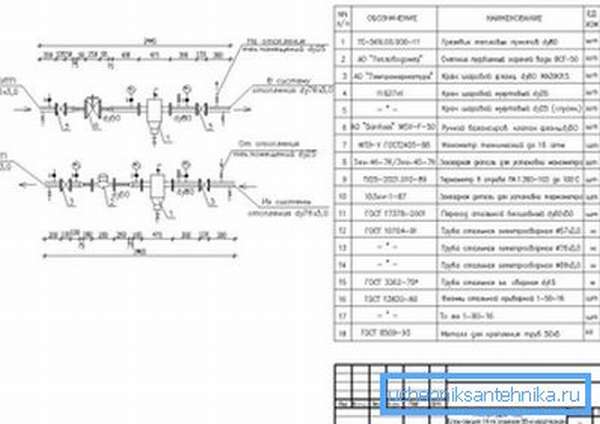

Image 1. A schematic diagram of the AUU with mixing pumps on the lintel for temperatures up to AUU t = 150-70 ˚C with one- and two-pipe heating systems with thermostats (P1 - P2 ≥ 12 mWC).

The automated control unit is represented by the diagram illustrated by IMAGE 1. The diagram provides: an electronic unit (1), which is represented by a control panel; outdoor temperature level sensor (2); temperature sensors in the coolant in the return and supply pipelines (3); flow control valve equipped with a gear drive (4); differential pressure control valve (5); filter (6); circulation pump (7); check valve (8).

As the diagram shows, the control unit basically consists of 3 parts: network, circulation and electronic.

The network part of the AUU includes a valve for a heat carrier flow regulator with a gear drive, a differential pressure regulator valve with a spring-loaded regulating element and a filter.

The circulation part of the control unit includes a mixing pump with a check valve. A pair of pumps serves for mixing. In this case, pumps must be used that meet the requirements of the automatic unit: they must work alternately with a cycle of 6 hours. Their operation should be monitored by a signal from the sensor, which is responsible for the differential pressure (the sensor is installed on the pumps).

Related article: What can be made from an old washing machine?

How it works

The operating principle of the heating system control unit is very simple:

When the outside temperature drops, for example to -20 ° C, the heating control unit supplies more heat to the rooms, thereby maintaining the indoor temperature at the required level, for example +20 ° C.

And vice versa.

When the outside temperature rises, for example to + 5 ° C, the weather control unit, as it is also called, delivers less heat to the premises.

Thus, heat consumption is reduced, and the temperature in the premises remains at the level we need, for example, +20 ° С and does not increase to +28 ° С, as is often the case during a sharp warming.

The temperature does not rise to +28 ° С

And if scientifically, the weather control unit is designed to ensure and maintain the required temperature of the coolant in the supply pipeline, depending on the outside air temperature.

Benefits

It is easy to control the system with your own hands from any distance.

What are the advantages of using an automatic heating control unit?

A modern controller with a communication module allows you to get the following advantages and benefits:

- Fine adjustment of the system in real time allows you to achieve maximum savings with an appropriate level of comfort;

- You can achieve exactly such temperature and climatic parameters of the room as you want, and for this it is enough just to set the values of the desired temperatures;

- The system of instant notification of emergency modes and abnormal events significantly increases the reliability and safety of work;

- You have the opportunity to leave the house with the heating system running and remotely monitor its condition, as well as control the operating modes, turn on or off the equipment remotely;

- A winter visit to a country house with the heating turned off requires entering a cold room, melting the unit and waiting for several hours until the room warms up. Now you can give the command to turn on in advance and not waste time.

You just need to get your phone out.

You can assemble and connect the control system yourself - no permissions or approvals are required for this. The job is easy to carry out following the manufacturer's instructions. The price of the kit can vary from 4 to 40 thousand rubles, depending on the configuration and the manufacturer.

Important! Most of the modules have connectors for connecting additional sensors, with which you can organize control over the opening of windows and doors, listening or monitoring and other useful functions.

The main advantages of installing an automated heating control unit

As we have already said, the purpose of this energy-saving measure is to optimize the consumption of thermal energy in the building, namely:

- a significant reduction in the cost of heating buildings and structures,

- improving the quality and reliability of heat supply,

- automatic regulation of heat supply to buildings and structures,

- the ability to remotely monitor the parameters of the coolant and the operating modes of the heat supply equipment,

- the ability, at no additional cost, to reconfigure the operation of the heating system, for example, after insulating facades, replacing windows, renovating a building,

- automation of the heat energy consumption metering system.

As practice shows, an automated control unit (AUU) saves about 25% - 37% of thermal energy and provides comfortable living conditions in each room.

Saving heat energy

Now more and more people are thinking about energy saving issues. And this is not surprising - why overpay for heating when you can save on it? The easiest way to save heat energy is to install meters (heat metering units). This method has been used for 10 years and allows to reduce the payment for heat energy by 20-30%. Practice has shown that, on average, the installation of a heat metering unit for an apartment building pays off within one heating season. If you have already installed a heat metering unit and have felt what effect it gives - do not stop. You can go further in this matter. There are several ways to reduce energy consumption and, as a result, reduce your costs.

The main ways to save energy: automatic regulation of the temperature of the coolant in the heating system and reduction of heat loss of the enclosing structure.

The first way to save energy by installing an automatic control system is due to two factors. Firstly, automatic control allows you to maintain the optimal room temperature based on the outside temperature, reducing the flow rate of the heat carrier from the heating network during periods of sharp temperature fluctuations.This is due to the reuse of part of the coolant in the heating system of the building, since a much smaller amount of coolant from the heating networks is required to ensure the required temperature. This option is suitable for residential, public and office buildings. Secondly, for industrial enterprises, thanks to automatic regulation, we can set the required coolant temperature at a time when the room is not used (at night, holidays and weekends). Thus, there is a reduction in the consumption of thermal energy, and, consequently, the saving of thermal energy. The approved standards for the consumption of thermal energy currently do not reflect the real picture of the consumption of the heat carrier by buildings and are overestimated.

Installation of a heat metering unit allows you to go to calculations for the actual consumed amount of energy, as well as to reduce its consumption.

The power supply organization does not regulate the supply of the coolant in full, which leads to an obvious overspending of the energy resource, and as a result of heating costs.

The presence of a well-functioning automation system for the supply of thermal energy directly in the building, as well as the correct organization and adjustment of the heating system, can significantly reduce the consumption of thermal energy for heating needs. When connecting the heating system of a building according to a dependent scheme (without a central heating station), heating costs can be reduced by up to 50% during the transition period, and when connecting a heating system according to an independent scheme (regulation at a central heating station), costs can be reduced by 10-15%, depending on the quality of regulation at the central heating station. Also, the device for automating the supply of thermal energy will allow to achieve optimal comfortable conditions inside residential premises, improving the living conditions of residents.

When is it advisable to install AUU - examples and calculation of the payback period

Let's look at 3 examples of installing a metering unit and calculate the payback period for this event.

All examples are from real life and are based on energy surveys that we have conducted.

And so, we have three administrative buildings (offices):

- Building 1 with an area of 1300 m2

- Building 2 with an area of 4800 m2

- Building 3 with an area of 18,500 m2

All three buildings are located in Moscow.

Here are the main results of installing a heating system control unit:

| Area, m2 | Total heat consumption for the heating period before the installation of AUU | Total heat consumption for the heating period after the installation of the AUU | Reduction of heat consumption Gcal | Cost of Gcal thousand rubles. (2018 y.) | Savings for the heating period thousand rubles. | |

| Building No. 1 | 1 300 | 340 | 266 | 74 | 2,0 | 148 |

| Building No. 2 | 4 800 | 550 | 418 | 132 | 2,0 | 264 |

| Building No. 3 | 18 500 | 4 400 | 3 720 | 680 | 2,0 | 1 360 |

As can be seen from the table, the installation of a heating control unit helped to reduce heat consumption during the heating period by:

- Building No. 1 - 74 Gcal,

- Building No. 2 - 132 Gcal,

- Building No. 3 - 680 Gcal.

Such a significant difference in the reduction in consumption is mainly due to:

- the size of buildings (area and number of storeys)

- the number of hours of operation,

- appointment.

The following table shows:

- saving heat for the heating period (based on the cost of 2 thousand rubles per Gcal)

- the cost of installing and installing the heating control unit and

- payback period.

| Savings for the heating period thousand rubles. | AUU cost (equipment and installation) | Simple payback period in years | |

| Building No. 1 | 148 | 1 556 | 10,5 |

| Building No. 2 | 264 | 1 856 | 7,0 |

| Building No. 3 | 1 360 | 2 000 | 1,5 |

The main conclusion that we can draw from the calculation of the payback period of the AUU

It is advisable to install an automated heating control unit in buildings with significant heat energy consumption and in buildings with overheating.

In small buildings and buildings with low thermal energy consumption, an automated heating control unit will pay off for a very long time or never.

In small buildings, it is more advisable to revise the elevator units or install them, as well as install a system of balancing valves on the main risers of the heating system.

Heating system control unit

Errors in the process of introducing an automatic node

Heating and hot water control unit according to an independent heating and hot water supply circuit according to a closed circuit.

Errors can occur even at the time of planning and subsequent organization of work on the implementation of the heating system. Certain mistakes are often made at the time of choosing a technical solution. One should not overlook the rules for the construction of an individual heating point. Ultimately, at the time of installation of the heating control unit, duplication of the functionality of the equipment that is installed in the central heating station may occur, this, in turn, contradicts the rules for the operation of thermal installations. So, the installation of heating control units with a balancing valve can lead to high hydraulic resistance in the system, which will entail the need to replace or reconstruct thermal and mechanical equipment.

An incomplete installation of heating control units can also be called a mistake, which will certainly violate the established thermal and hydraulic balance in the intra-quarter networks. This will cause a deterioration in the performance of the heating system in almost every connected building. It is necessary to make a thermal adjustment at the time of operation of the heating equipment.

Errors often occur in the process of entering a heating control unit at the design stage. This is due to the lack of working projects, the use of a standard project, devoid of calculations, binding and selection of equipment to certain conditions. The result is a violation of heat supply regimes.

Why is it more profitable to install AUU in buildings with high heat consumption?

The heating control unit costs about the same for large and small buildings (the difference in the cost of equipment and installation is 20% -30%).

At the same time, a large building can save 5-10 times more heat energy than a small building.

In our example, we see:

- The heating control unit pays for itself in 10.5 years in building No. 1, with an area of 1,300 m2 and a heat consumption of 340 Gcal before the installation of the AUU.

- The same unit pays for itself in 1.5 years in building No. 3, with an area of 18,500 m2 and heat consumption before the installation of AUU 4,400 Gcal.

Our analysis and calculation are not universal.

They only give you a basic understanding in which buildings it is more expedient to install automated heating control units.

We recommend making a calculation of the feasibility and payback period of the heating control unit individually for each building, based on the specific circumstances and conditions.

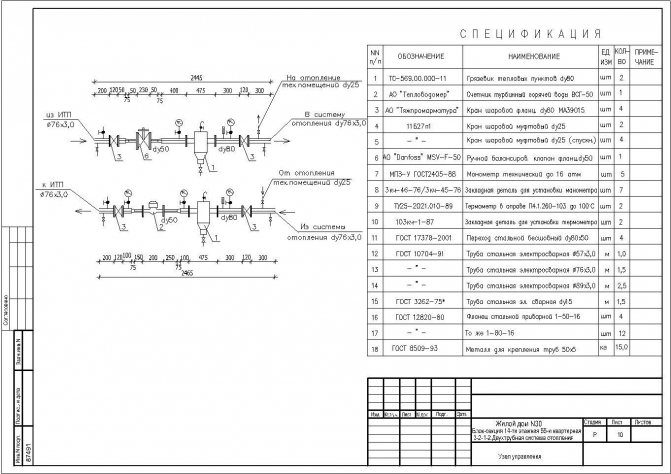

How is the installation of an automated heating system control unit

There is no fundamental change in the heat supply scheme of a building when installing an automated heating system control unit (AUU).

Unlike elevator units installed on each section of a house, AUU is mounted, as a rule, one per building.

Connection of the control unit is performed after the heat energy metering unit.

The weather control unit includes the following elements:

- control element,

- control valve with an actuator,

- circulation pump,

- outdoor temperature sensors,

- room temperature sensors.

The control element of the weather control unit allows you to manually change the settings that determine the operating mode of the heating system and allow you to maintain different temperatures in the building at different times.

For example, in office buildings on weekends and holidays, you can reduce the air temperature inside to +12 ° C.

On weekdays, the temperature can be raised to +18 ° C.

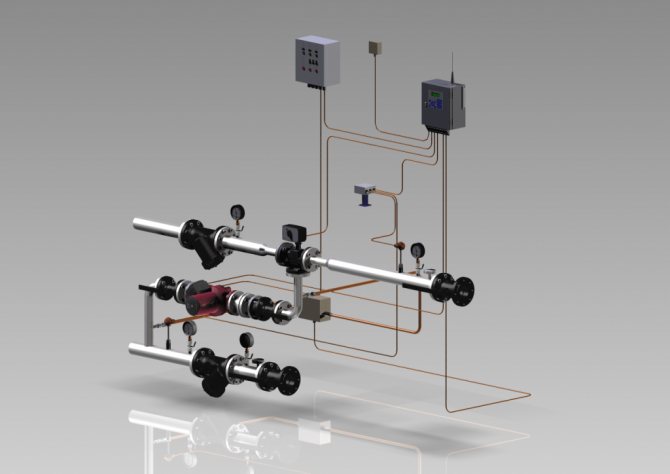

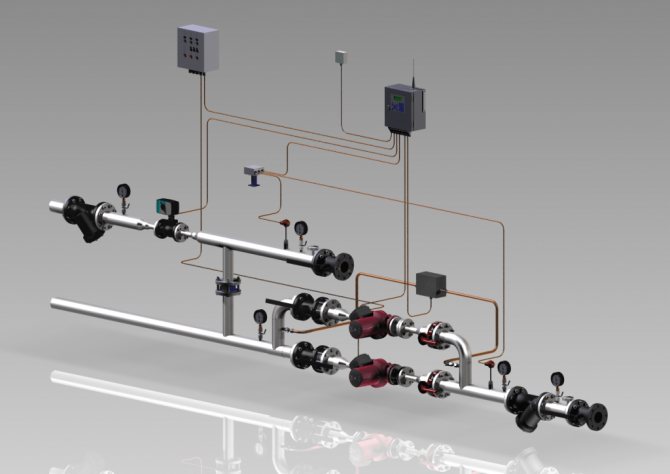

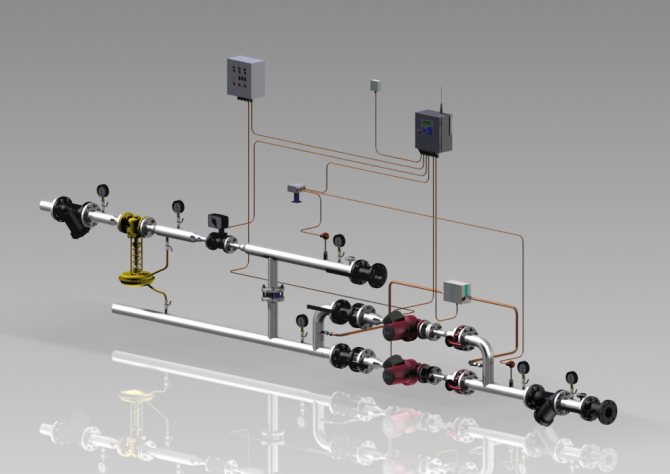

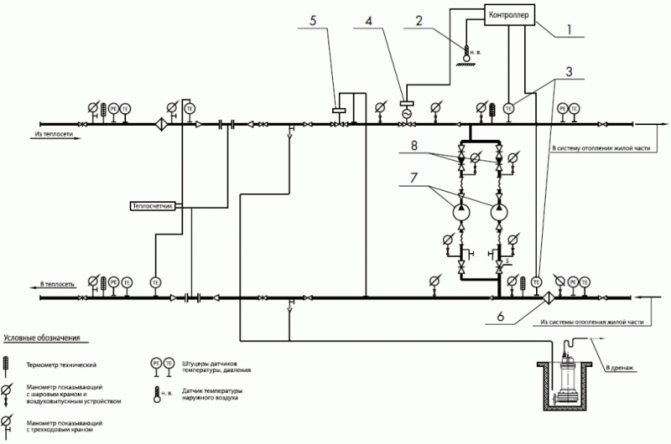

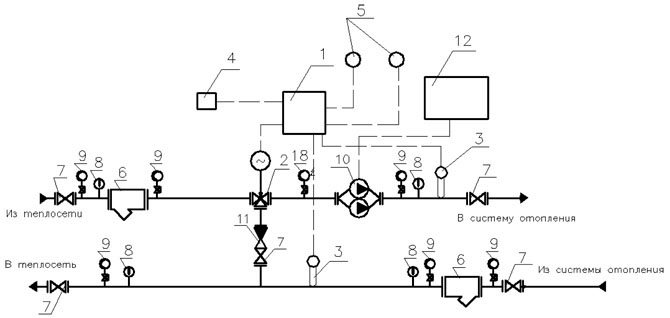

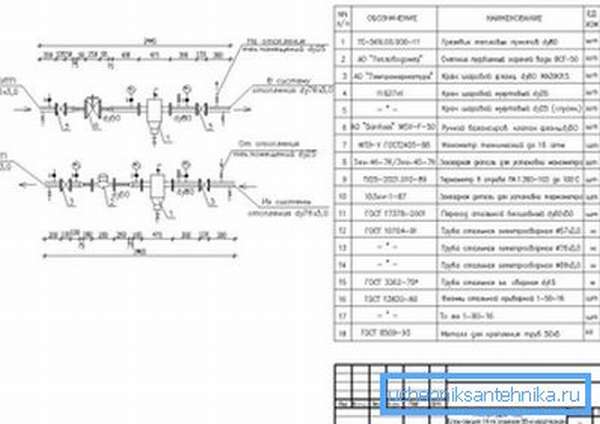

The diagram and general view of the automated weather control unit are shown in the figures below.

The scheme provides for:

- automatic switching between the main and standby pump in case of failure of one of the pumps,

- the possibility of introducing a flexible schedule for regulating the air temperature in the premises, taking into account the night time, weekends and holidays for the entire heating season,

- mandatory control of the return heat carrier temperature,

- maintaining the temperature schedule.

The temperature of the heating system is controlled by changing the throughput of the valve and adding heating water using a circulation pump.

During operation, the controller:

- periodically polls the coolant temperature sensors, the indoor air sensor (if any) and the outdoor air sensor,

- processes the information received and

- generates control signals giving a command to the actuator to open or close.

The control action from the controller changes the opening of the flow area of the control valve.

In the absence of an indoor air sensor, the main control priority is to maintain the temperature schedule.

Additional requirements when putting the heating control unit into operation

Heating and hot water control unit according to an independent scheme.

The selected schemes for installing heating control units may not correspond to the required ones, which negatively affects the heat supply. It also happens that at the time the system is put into operation, the technical conditions used do not correspond to the real parameters. This can lead to incorrect selection of the node layout.

At the time of commissioning of the automation unit, it should be borne in mind that the heating system could have previously undergone major repairs and reconstruction, during which the circuit could be changed from one-pipe to two-pipe. Problems can arise when a node is calculated for a system that existed before the reconstruction.

The process of putting the system into operation should not be carried out in winter, so that the system is launched in a timely manner.

Diagram of an automated control unit for the heating system (AUU) at home.

It should be remembered that air temperature sensors must be mounted on the north side, which is necessary for the correct setting of the temperature regime, in which case solar radiation cannot affect the heating of the sensor.

During the commissioning process, a backup power supply of the node should be provided, which will help to avoid stopping the central heating system in the event of a power outage. It is necessary to carry out adjustment and commissioning work, as well as measures for noise reduction, the unit must be serviced. It should be noted that non-observance of one or more of the rules can lead to non-heating of the system, and the absence of damping equipment will lead to uncomfortable noise.

The introduction of the control unit must be accompanied by a check of the issued technical specifications, they must correspond to the actual data. And technical supervision must be carried out at each stage of work. After all work on the system has been completed, the maintenance of the unit should begin, which is carried out by a specialized organization. Otherwise, the downtime of expensive equipment of an automated unit or its unskilled maintenance can lead to failure and other negative consequences, including the loss of technical documentation.

Effective use of automated metering stations

The use of AUU is most effective:

- in large buildings with significant heat consumption,

- in houses connected to city heating networks,

- in buildings with insufficient pressure drop in the central heating system and with the obligatory installation of central heating pumps,

- in buildings with decentralized hot water supply and central heating.

Automatic control unit

Appointment

The automatic control unit is a personal heating point designed to control the parameters of the coolant circulating in the heating system, depending on the temperature indicators in the room, outside, in the supply and return pipelines of the circuit.

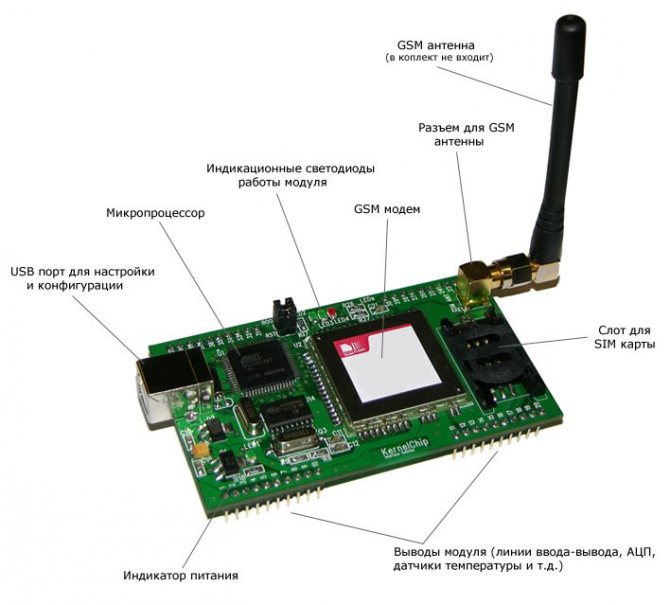

In addition, the system allows you to implement protection against emergency situations, switching equipment operating modes, GSM heating control. In the event of a breakdown or an abnormal situation, the module is able to notify all subscribers included in the mailing list via SMS.

But this is not a complete list of functions.

The control unit can supply:

- parameters and operating modes of the circulation pump of the heating system, the set rate of circulation of the coolant,

- fulfillment and control of maintaining the set temperature schedule of the supply and return pipelines... This allows the system to be protected from hypothermia and overheating,

- Maintaining a predetermined constant differential pressure at the supply and return inlet to the building, which allows the normal operation of all automation in normal mode,

- Narrow and rough cleaning of the heating medium,

- Visual control of all system performance indicators: temperatures in key areas, pressure difference at the outlet and inlet from the unit, set operating mode, alarms,

- Remote control of heating by telephone and via the Internet,

- Remote control of the premises, alarms, gates and entrance doors by means of additional sensors.

Note! To install such a system, other equipment and the boiler must be adapted to be electronically controlled. Dilapidated frames with mechanical valves with such a scheme will not work.

principle and device of action

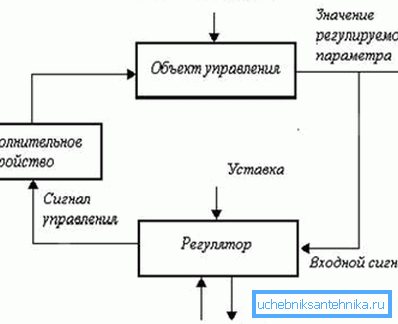

The structure of any automatic control system includes sensors nodes:

- and such Sensors, which collect the necessary data in different places in the system,

- processors and controllers, which compare the data received from the sensors with the values dictated by the instruction (program) written on the memory card, make a decision and, on its basis, give commands to the executing mechanisms,

- Executing mechanisms, which acquire commands from controllers and do simple actions - shut off valves and taps, increase the power of the units, switch the operating modes of heating equipment, make emergency shutdowns of broken units.

Temperature and pressure sensors act as sensors, and each additional sensors, which allow to control various processes. The most serious are the temperature sensors for the supply and return flow of the coolant, indoor and outdoor temperature sensors, and pressure sensors at the inlet to the system.

The role of the controller is played by a low-power computer that reads data from all sensors. The computer memory card contains a program that determines the temperature conditions.

The controller compares the obtained values with the set ones, and, if necessary, makes a decision on making transformations: increasing the supply of the coolant to one or another circuit, turning off the boiler or transferring it to another operating mode, etc.

Upon making a decision, the controller sends a control signal to one or another neat device: a switching relay, a valve or damper servo drive, a switch or boiler electronics.Depending on the set program, the GSM module for heating control can send messages to the owner about this or that event, and after waiting for a response, it can take certain measures.

Heating control in a country house via GSM is carried out by means of a special module built into the computer.

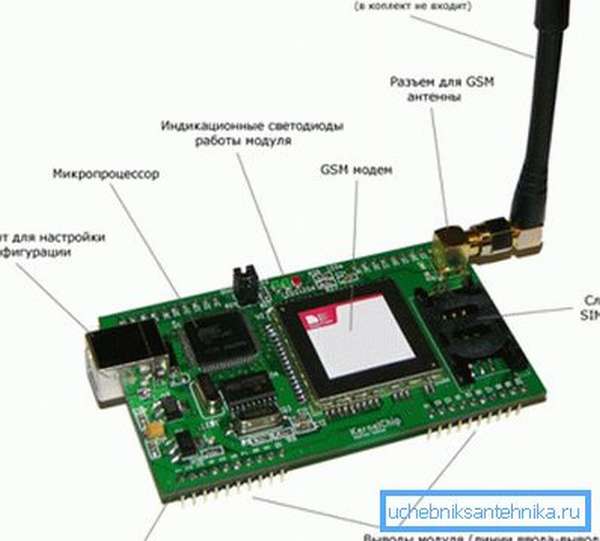

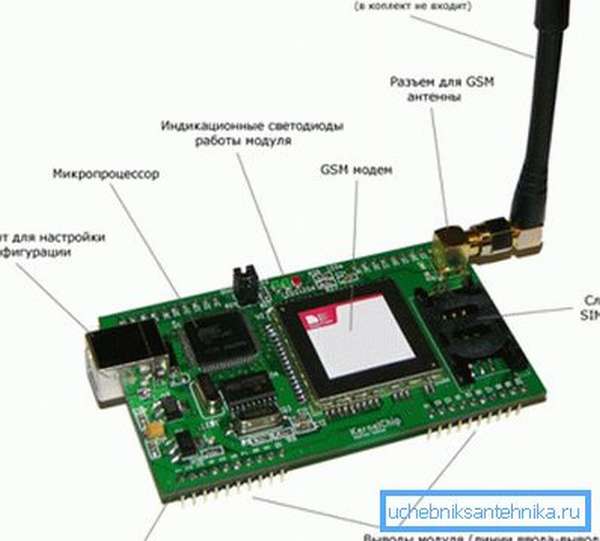

This module includes the following elements:

- SIM card slot,

- Power supply and battery,

- GSM modem,

- Antenna connector,

- LAN port for connecting to an Internet provider,

- CPU,

- Memory card,

- USB port for configuration and setup,

- LED indicators or liquid crystal display,

- Contact group with outputs and inputs for data collection and sending control signals.

Note! Along with the module for GSM-control, software must be supplied for installation on the OS of the cell phone. The program will help organize the operator and the controller's remote communication.