What is a water heat-insulated floor

Water underfloor heating is a low-temperature heating system, where the coolant is supplied with a temperature of 35-45 ° C, according to the norms not higher than 55 ° C. In addition, underfloor heating is a separate circulation circuit, which requires a separate circulation pump.

Underfloor heating has limitations on the temperature of the floor surface - 26-31oC. The maximum temperature difference between the distribution of the supply and return of a warm water floor is allowed no more than 10 ° C. The maximum flow rate of the coolant is 0.6 m / s.

Mixing unit installation

Installation of the underfloor heating mixing unit is not very difficult. To do this, you can use one of several connection schemes. For all assembly details, see this video:

Location

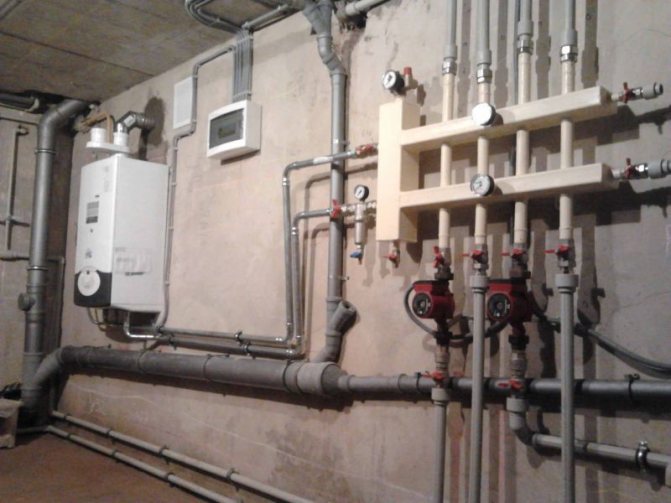

Optimally install the collector between the heating boiler and the underfloor heating

You can install the system in your home anywhere, for example, between the boiler and the underfloor heating system. The connection points of the mixing unit can be located in the following places:

- Directly in a room equipped with a water floor system.

- In the boiler room, at any point convenient for this.

- In a special cabinet, if heating circuits are controlled in several rooms with the help of a manifold.

Related article: Stainless steel toilet

Features of installing the collector

Remember to ground all electrical appliances.

For the correct and safe operation of the system, a number of nuances should be observed during its installation:

- a water mixing valve with a thermostat is always installed at the inlet to the heating circuit;

- all electrical devices that make up the unit must be grounded;

- any possibility of moisture ingress on electrical appliances should be excluded during operation.

The assembled mix manifold should be connected to the supply and return pipes, according to the installation scheme you have chosen. If you are not good at plumbing or do not have the opportunity to personally assemble the mixing unit from individual parts, you can purchase a ready-made unit in various configurations. In this case, you just have to connect it to the heating system. For more information on setting up an automatic thermostat, see this video:

After you have equipped your house with a coolant adjustment unit, you should connect it to the power supply and configure the devices.

Setting up control devices

Components of the heating system

The mixing unit is set up in several stages.

- We remove the thermostat with servo drives so that it cannot influence the setting of the valves.

- We set the bypass valve to the maximum mark so that it does not work during system setup.

- We adjust the balancing valve. Taking as a basis the temperature indicators at the outlet of the boiler for 95 ºС, and the maximum temperature in the pipes of water floor heating at the inlet for 45, and at the outlet - for 35 ºС, after calculations according to the formula below, we obtain the coefficient 4. It and set it on our balancing valve ...

- The next step is to adjust the pressure of the circulation pump. We set the pump power to a minimum and gradually increase it until the pressure in the system reaches the desired value.

- The last step is to adjust the bypass valve. We set a reading on it 10% higher than the maximum working pressure in the bypass valve.

If the mixing unit ensures the operation of several heating circuits, the pressure in them should be balanced by adjusting the corresponding shut-off valves installed at the inlet of each circuit.

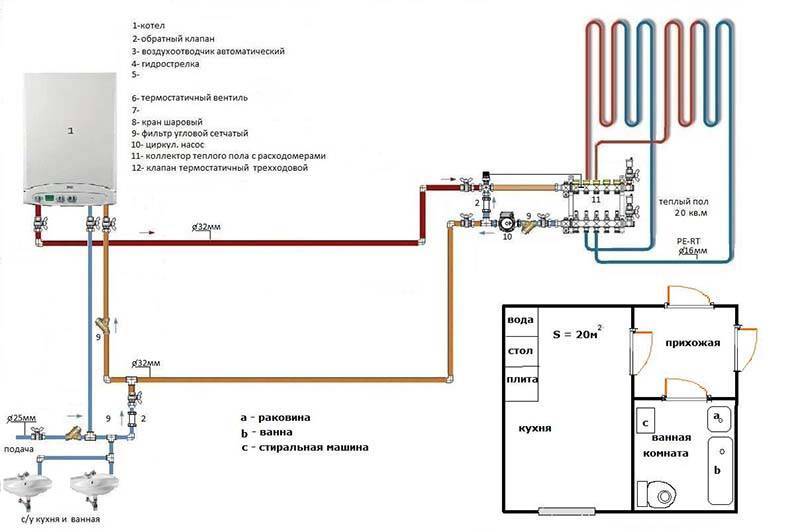

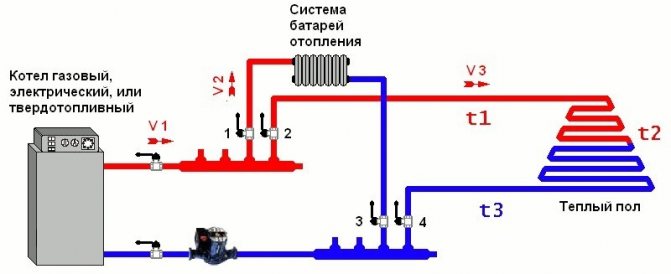

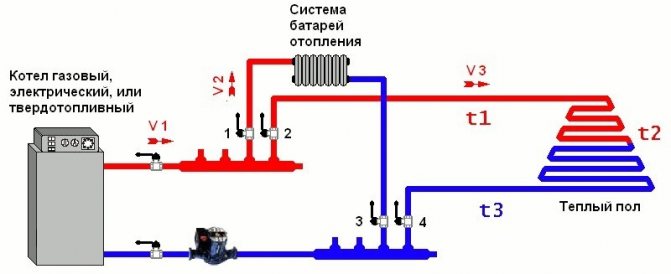

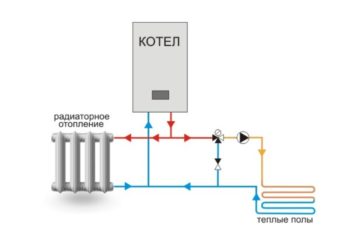

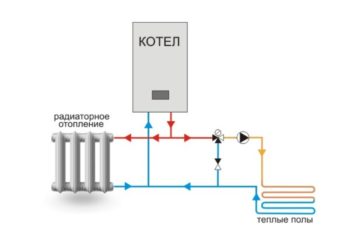

Scheme 1. Connection of underfloor heating directly from the boiler

This connection diagram for a water-heated floor has a heat generator, safety fittings with a pump. The heat carrier directly from the boiler enters the underfloor heating distribution manifold and then diverges in loops and reverses back to the boiler. The boiler must be set to the underfloor heating temperature.

In this case, two nuances arise:

- It is advisable to use a condensing boiler in the installation, because low temperature mode is optimal for him. In this mode, the condensing boiler has maximum efficiency. In a conventional boiler, when operating in low-temperature mode, the heat exchanger will fail very quickly. If the boiler is solid fuel, then a buffer tank is needed to correct the temperature, since this boiler is difficult to temperature control.

- A good option for underfloor heating is when it is connected to a heat pump.

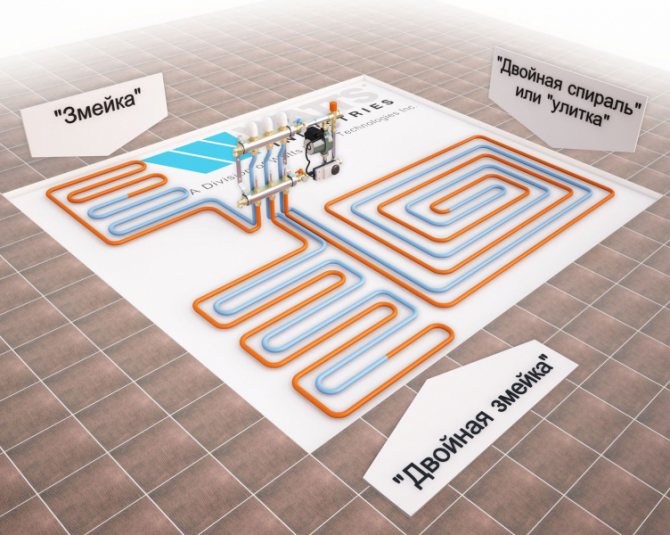

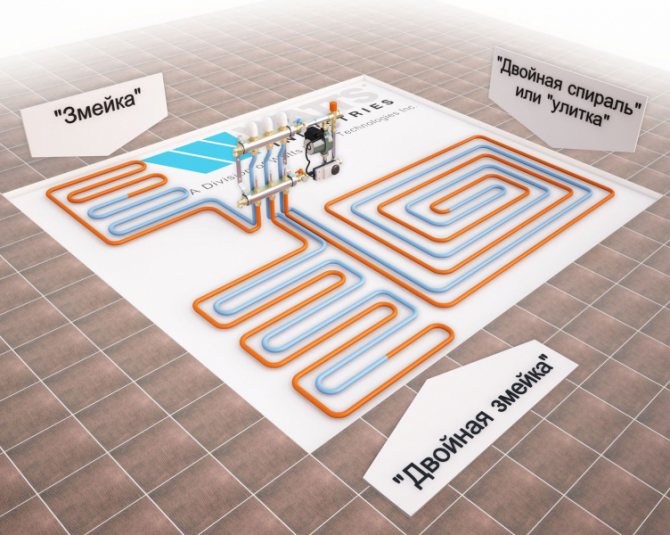

Features of laying a warm floor with a snail

If a warm floor is the only heating option, then the room is conventionally divided into 2 zones: edge and main.

The marginal zone is located along street walls, window openings, where the total heat loss is greater. In the presence of one cold wall, the edge zone has a rectangular shape with a side deep into the room - 1 m. In the corner room, where two street walls dock, the edge zone is made L-shaped.

In the edge zone, pipes are laid with a smaller step, it is about 10 cm.

Whereas in the main zone, the laying step is usually 20 cm. In a large room, the edge and main zones are formed with two pipe loops. With a small area, one loop is used.

It is laid in different areas in different ways. It takes a certain skill and experience to masterfully lay out one loop in two different zones. Moreover, the main principle must be observed: the smaller the laying step, the greater the heat flow.

Scheme 2. Installation of underfloor heating from a three-way valve

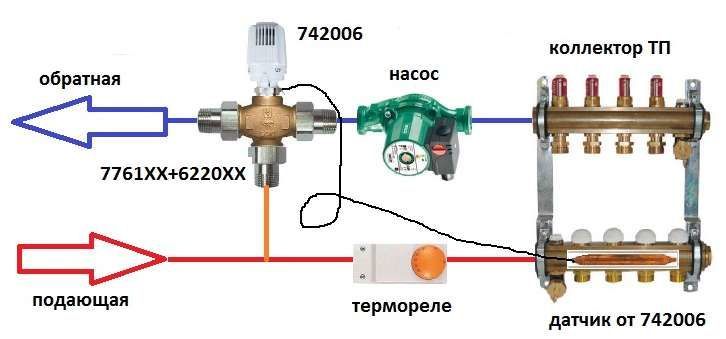

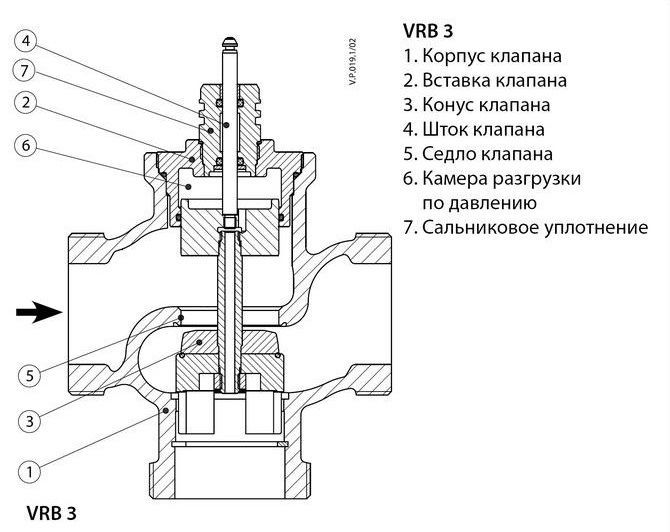

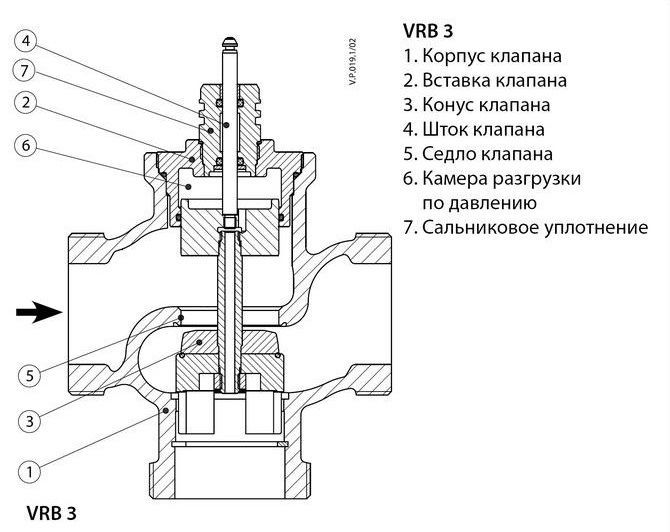

3-way thermostatic valve circuit

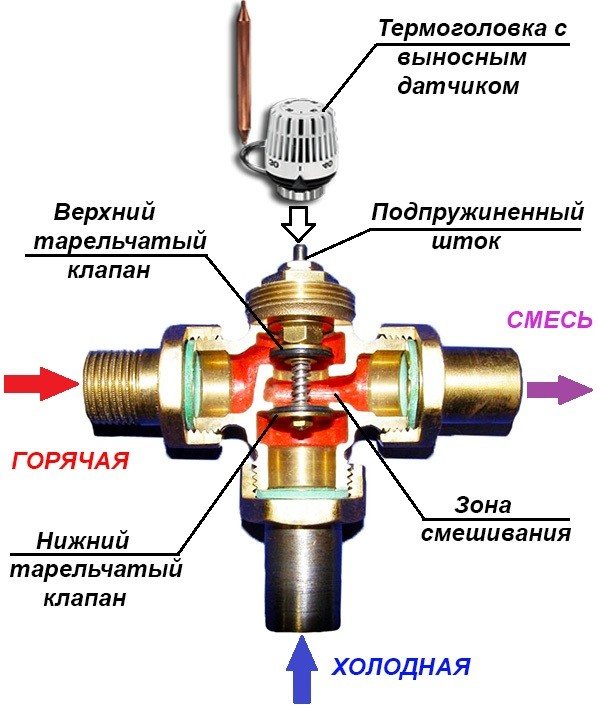

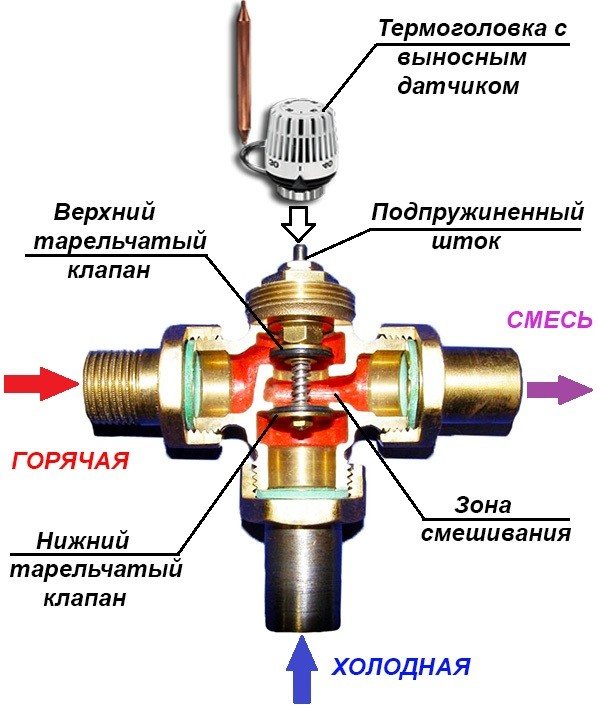

In most cases, with such a scheme of installation and connection of a water heated floor, we have a combined heating system, there are heating radiators with a temperature of 70-80 ° C and a floor heating circuit with a temperature of 40 ° C. The question is how to make forty out of these eighty.

For this, a three-way thermostatic valve is used. The valve is installed on the supply, after which a circulation pump must be installed. From the underfloor heating return, the cooled coolant is mixed with the coolant, which is obtained from the boiler circuit and which is subsequently lowered to the operating temperature with the help of a three-way valve.

The disadvantage of such a layout for a warm floor is the impossibility of dosing the proportionality of the mixture of the cooled coolant to the hot one, and subcooled or overheated coolant can enter the warm floor. This reduces the comfort and efficiency of the system.

The advantage of this scheme is ease of installation and low cost of equipment.

This scheme is more suitable for heating small areas and where there are no high customer requirements for comfort and efficiency, where there is a desire to save money.

In real life, the circuit is extremely rare due to the instability of the operation of radiators connected to a single pipe. When the three-way valve is opened slightly, the heating circuit is fed, and the pump pressure is transferred to the main line.

Implementation example:

Options for installing a heated floor system without using a unit and a manifold

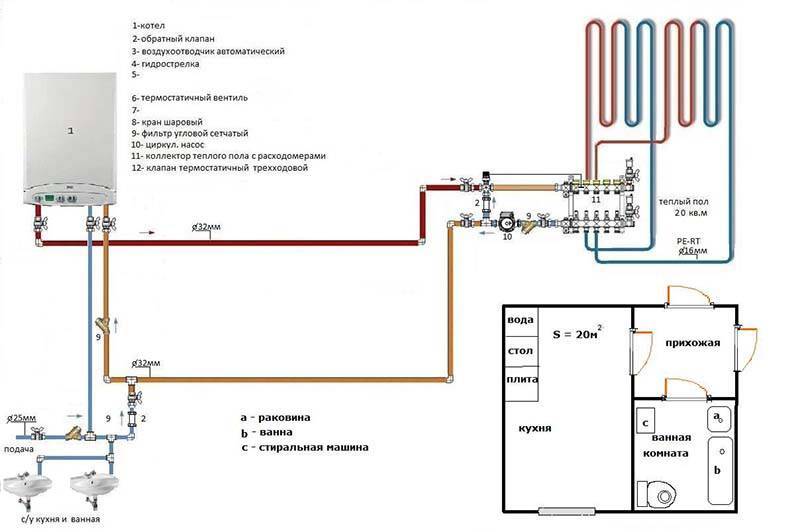

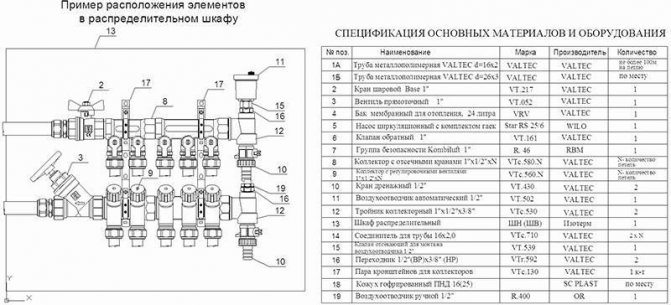

For the installation of a water heating system for heated floors without using a manifold, the following materials and devices are required:

- pipes for the circuit;

- boiler;

- accessories for the pipeline;

- three-way thermostatic valve.

Laying scheme for underfloor heating from a centralized heating system

Some craftsmen try to use the easiest installation method - to equip the heating system by connecting it to the central heating. This decision threatens subsequently with pipeline malfunctions, since the temperature of the coolant of the batteries is significantly higher than that required for the floor. And if supervisory organizations discover the presence of this "self-made device" without the permission of the relevant authorities, the owner will be issued a considerable fine and required to dismantle the water-heated floor system.

Laying the pipe contour

Several methods are used to lay the pipeline circuit, the most acceptable are a snail and a snake. These circuits consist of two parallel loops of the water floor (supply and return). The advantage of the "snake" is the distribution of heating zones, for example, you can bypass the plumbing. The advantage of the "snail" is the uniform heating of the area. After installation, the pipes are connected to the boiler according to the connection diagram.

To accelerate the movement of water through the pipes under the boiler, a pump is mounted on the supply, which is controlled automatically or manually. In a system where there is no mixing unit, a three-way thermostatic valve closes the circuit between the pipeline and the boiler.

Attention! In order for the warm floor to function without a pump, it is recommended to choose a powerful boiler, no matter whether it is gas or electric. The main thing is that its power is enough for a warm floor covering. It is worth choosing a boiler with a built-in pump.

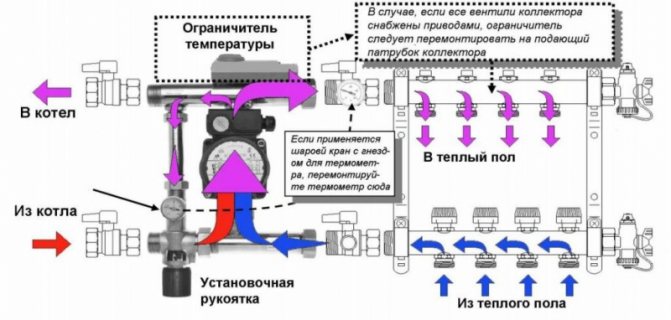

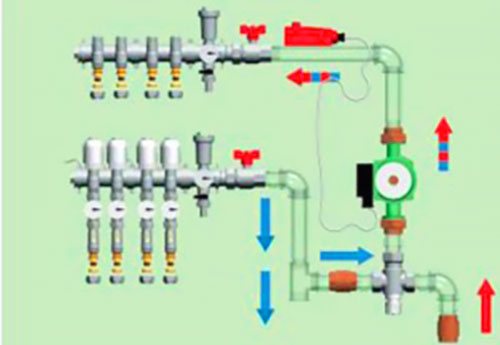

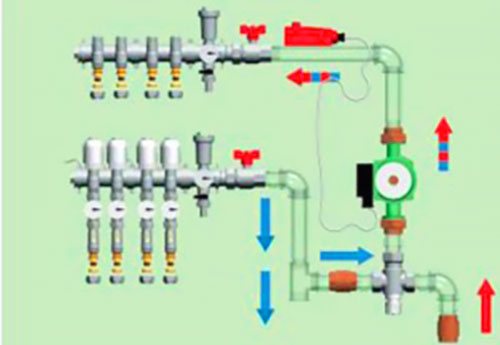

Scheme 3. Layout of underfloor heating from the pumping and mixing unit

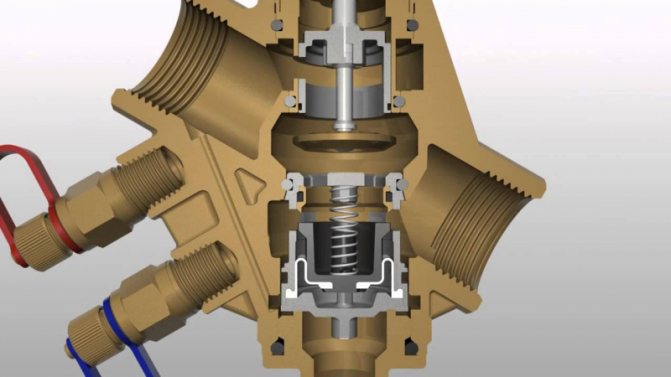

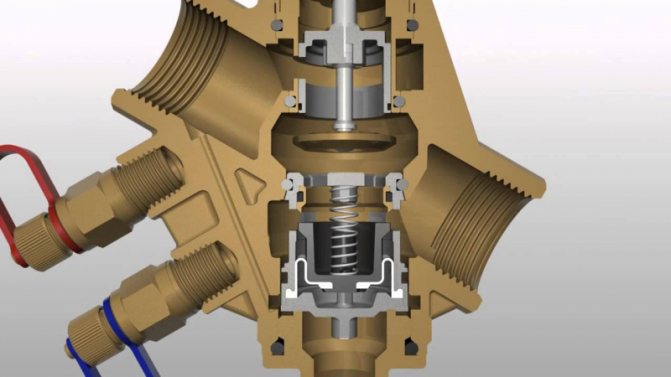

mixing module

This is a mixed connection scheme for a water heated floor, where there is a radiator heating zone, a warm floor and a pump and mixing unit is used. The cooled coolant is mixed from the return line of the heated floor to the boiler.

All mixing units have a balancing valve, with which you can meter the amount of cooled coolant when mixed with hot. This allows you to achieve a well-defined temperature of the coolant at the outlet from the unit, i.e. at the entrance to the underfloor heating loops. This significantly increases consumer comfort and the efficiency of the system as a whole.

Depending on the model of the unit, it may include other useful elements: a bypass with a bypass valve, a balancing valve in the primary boiler circuit, or ball valves on both sides of the circulation pump.

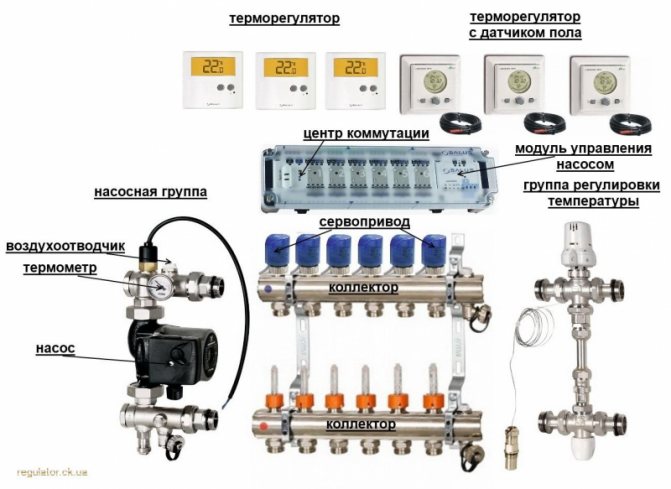

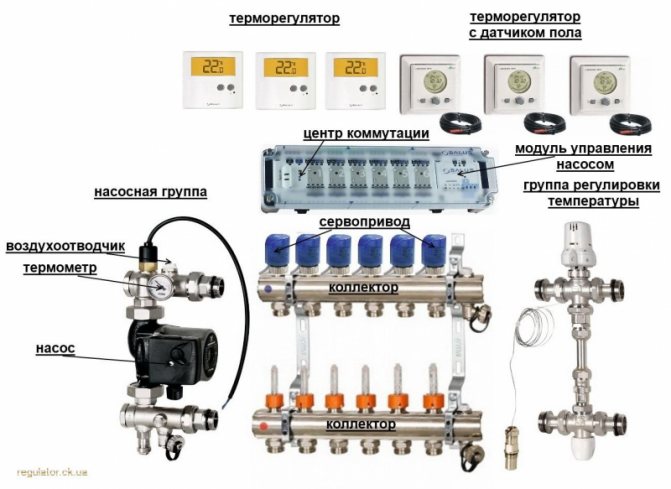

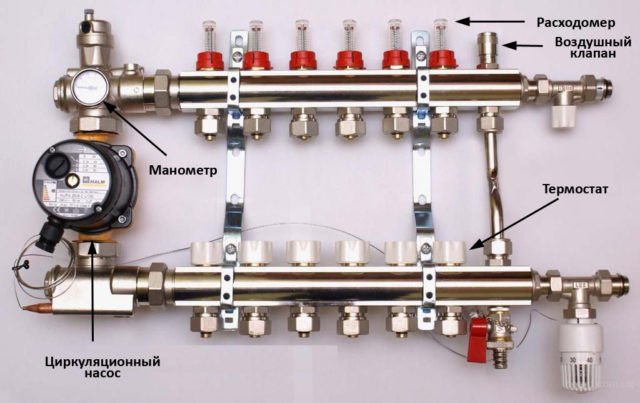

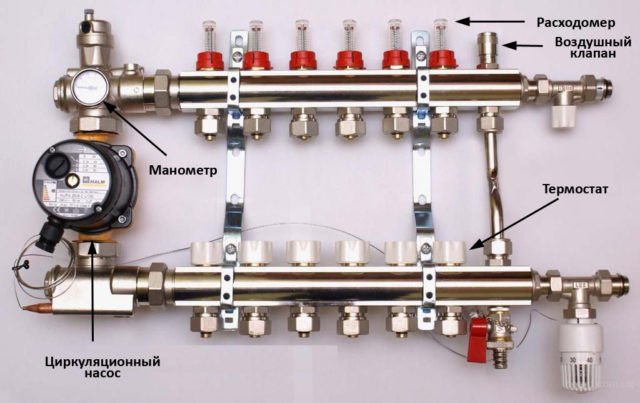

Component parts

The pump-mixing unit for a heat-insulated floor consists of several parts that allow, if necessary, to mix in cold liquid into the heating system.

Circulation pump

Circulation pump

It is designed to create pressure in the system and move the coolant in the pipes. Also, with the help of a pump, forced mixing of cold and hot heat carriers in the collector is carried out.

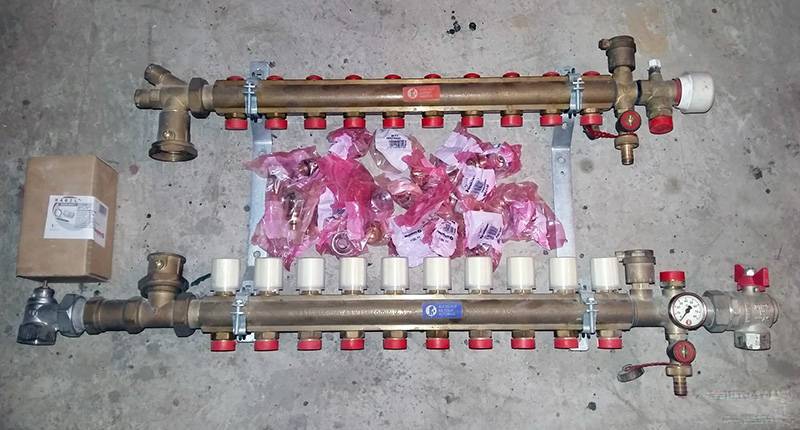

Collector block

The main part of the manifold system, including taps assembled in one block for all the necessary devices. Each block is designed for a certain number of heating circuits - from 2 or more.

In a plumbing store, you can purchase a ready-to-install device or make it yourself. For this, a piece of water pipe is taken, which is muffled on one side. Next, several bends are welded onto the pipe - two for each heating circuit.

The principle of operation of the circulation pump

But, as practice shows, it is much easier to purchase a collector block in a store than to try to make it yourself.

Thermostat

The thermostat has a two- or three-way valve

Related article: Options for placing a TV in the kitchen

The thermostat serves to supply hot water to the collector when the temperature in the heating elements drops below the set limit. The thermostat valve can be 2-way or 3-way.

The 2-way valve provides fluid from the return circuit to the floor heating circuit, and, if necessary, raises the operating temperature of the coolant and adds hot water from the supply circuit to it. Such a valve has a small throughput, therefore, the change in the temperature of the water in the pipes of the water floor occurs gradually.

The 3-way valve combines simultaneously with a mixer and bypass functions. Therefore, it is not necessary to use an additional pressure balancing valve when installing it. Often, such a valve has servo drives for controlling thermostats and controllers. Also, the 3-way valve can work in conjunction with weather-dependent sensors - in the event of a cold snap, the valve automatically increases the water supply to the supply circuit. For information on how you can adjust the heating temperature without a mixer, see this video:

In a private house, it is advisable to use a 2-way valve. It is able to ensure the normal operation of the mixer manifold circuit for a home with a total area of up to 200 sq. m. At the same time, its cost is significantly lower than that of a 3-way valve.

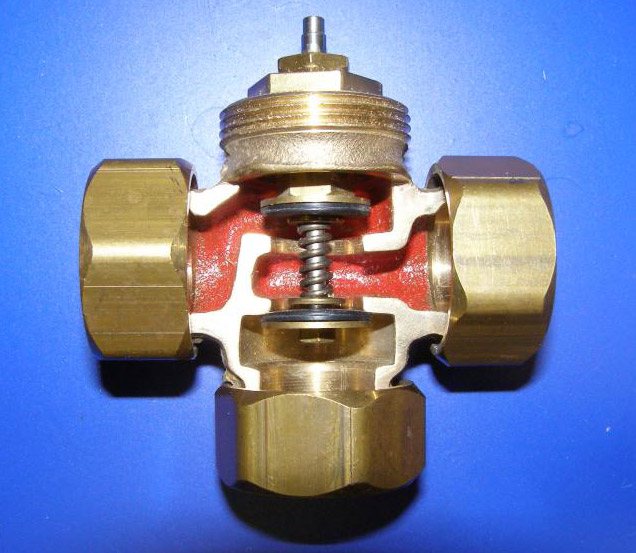

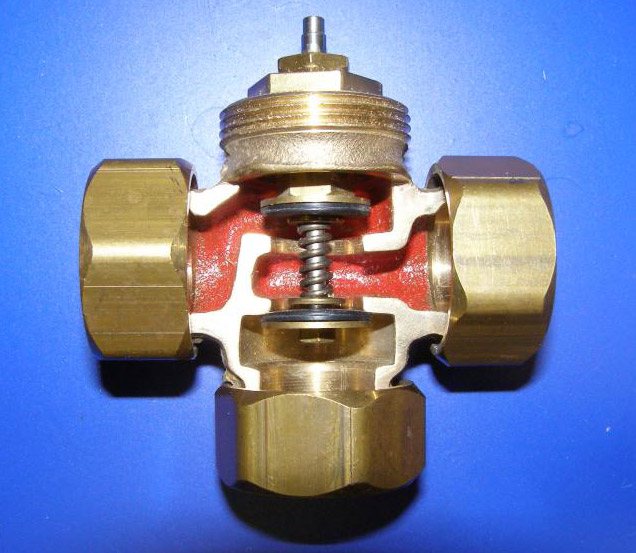

Balancing valve

Balancing valve device

The balancing valve is designed to dump excess coolant from the supply circuit to the reverse in case of excess pressure in the underfloor heating mix manifold.

In addition to the listed details, the floor heating mixing unit diagram may include filters, a thermometer, a pressure gauge, air relief valves and other additional monitoring and control devices.

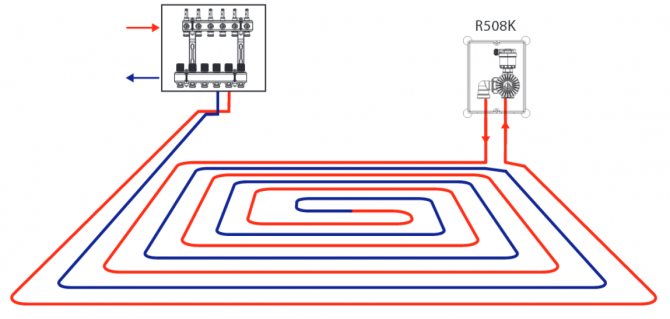

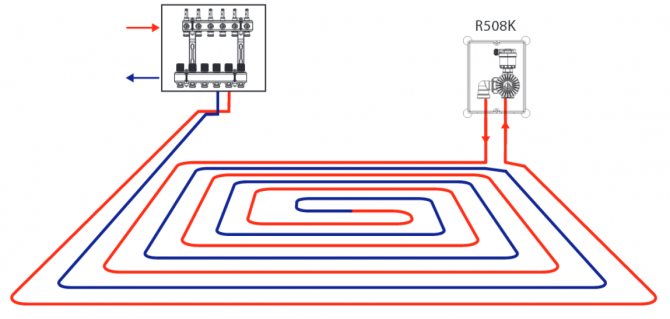

Scheme 4. Connecting a warm floor from a radiator

These are special kits designed to connect one underfloor heating loop for an area of 15-20 sq.m. They look like a plastic box, inside which, depending on the manufacturer and configuration, there may be temperature limiters for the coolant, room temperature limiters and an air vent.

The heat carrier enters the loop of the connected water underfloor heating directly from the high-temperature circuit, i.e. with a temperature of 70-80 ° C, it cools down in the loop to a predetermined value and a new batch of hot coolant enters. An additional pump is not required here, the boiler must handle it.

The disadvantage is low comfort. Overheating zones will be present.

The advantage of this connection diagram for a water-heated floor is easy installation. Similar kits are used when there is a small heated floor area, a small room with an infrequent stay of residents. Not recommended for use in bedrooms. Suitable for heating bathrooms, corridors, loggias, etc.

Let's summarize and summarize in a table:

| Connection type | Comfort | Efficiency | Installation and setup | Reliability | Price |

| Conventional gas, TT or diesel | ± | ± | + | ± | + |

| Condensing boiler or heat pump | + | + | + | ± | — |

| Three-way thermostatic valve | ± | ± | + | + | ± |

| Pump-mixing unit | + | + | ± | + | — |

| Thermal assembly kit | — | ± | + | + | + |

Plumbers and experts in heat and gas supply recommend avoiding schemes for connecting a water heated floor to working heating branches. It is better to supply the heating circuits of the underfloor heating directly to the boiler so that the underfloor heating can function independently of the batteries, especially in summer.

Temperature control of underfloor heating is carried out in different ways:

With a three-way mixer and an automation kit. The simplest is the circuit with a three-way valve equipped with a servo drive. The required temperature in the system is provided by adding the required volume of a colder heat carrier to a hotter one coming from the boiler.

Mixing the heating medium with a three-way valve

Regulation is carried out, as a rule, automatically. An increase in indoor temperature due to, for example, sunlight or an increase in the number of people means that the air will soon be as warm as the floor. As soon as this point of equality is reached, the electronic system gives a command to the three-way mixer to increase the admixture of cold water.

Regulation by means of pump-mixing groups It became widespread due to the emergence of pump-mixing groups of quick installation (for example, OVENTROP, MEIBES, Hydrologo, etc.), which allow you to quickly assemble a system with several heating circuits. However, such modules are mainly used to regulate the flow temperature of the heating medium without regard to the room temperature or the temperature of the floor surface. In this case, it is recommended to use room thermostats with servo drives in the underfloor heating manifold. Advantages: extremely easy to install and noticeably reduce the risk of human error. assembled and tested for operability at the factory.

Regulation by boiler automation Most of the leading manufacturers of boiler equipment offer modern microprocessor control panels that allow you to maintain different temperatures in several heating circuits at once. Systems with this principle of regulation are called meteorological or weather-dependent. To monitor the outside temperature, these systems use an outdoor sensor installed outside the building on the north side. In some systems, the principle of modular construction is laid, which allows you to complete the system for specific user requirements, as well as connect additional circuits and control their operation by installing the appropriate module without replacing the control panel as a whole, which gives significant cost savings

Basics of radiant heating design

The purpose of calculating a radiant heating system is to: • determine the heat input into the premises from the underfloor heating system; • selection of the step of laying pipelines for a given type of flooring and a certain temperature of the floor surface; • determination of the hydraulic characteristics of the system and the values of the presettings of the control valves on the manifolds (balancing); • selection of a circulation pump.

Laying schemes for a water-heated floor

Ways to lay out pipes for underfloor heating

There are three main ways of laying a water-heated floor: snake, spiral (snail) and a combination of these options. Most often, a warm floor is mounted with a snail, in some places a snake is used.

Installation scheme "Snail"

Laying the warm snail allows the heat to be more evenly distributed throughout the room. With such a wiring, the pipe is mounted in a circle to the center, then from in a circle in the opposite direction.

When laying out a warm floor with a snail, you need to lay an indent for laying the pipe in the opposite direction.

Laying underfloor heating with a snake

With this installation, the underfloor heating pipe is mounted in one direction and at the end of the circuit layout it simply returns to the collector return. With such a device, at the beginning of the circuit, the coolant temperature is hotter, at the end it is colder. Therefore, the snake layout is rarely used.

Application features

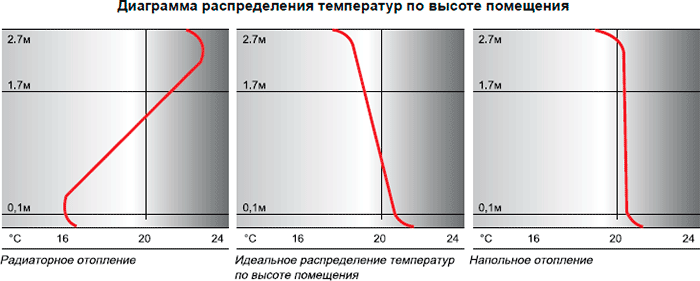

Underfloor heating first of all heats the lower surface and the person

Warm floors, unlike wall radiators, belong to low-temperature heating systems.If the recommended temperature regime of 30 - 35 ° C is exceeded, people in the room will experience obvious discomfort. It's all about the difference in room heating schemes when using these two heating methods.

Wall-mounted radiators primarily heat the upper half of the room. Therefore, in this case, the temperature at the floor may differ several times from the air temperature at the ceiling.

Ways of laying pipes for underfloor heating

The heating scheme of the room when using underfloor heating is completely opposite - the zone of greatest heating in this case is located in the lower part of the room, where people are usually located. Therefore, exceeding the recommended temperature of the coolant leads to tangible discomfort for the inhabitants of the house.

Related article: How to make a ceiling lamp with your own hands

In addition, the increased temperature of the heating circuit can deform or peel the finished floor covering. To avoid this, the underfloor heating mixing unit is intended. A warm floor without a mixing unit will be completely impossible to adjust.

When setting the maximum temperature on the thermostat, take into account the nature of the floor covering. If the floors in the room are covered with laminate, parquet or carpets, this can significantly reduce heat dissipation. In this case, the maximum temperature threshold will need to be raised to 40 - 55 ºС.

Underfloor heating calculation

Before connecting a warm floor according to the developed scheme, it is necessary to make a preliminary calculation. You can do a rough calculation yourself in the following steps:

- Determine the location of the manifold. Most often it is mounted in the center of the floor.

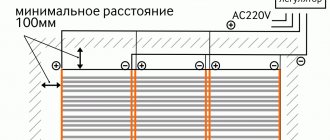

- Try to schematically depict the layout of the underfloor heating pipes, observing the following information: at a step of 15 cm, 6.5 meters of pipe are spent per square meter of pipe, the length of the pipe should not exceed 100 meters, the contours should all be approximately the same.

- We decide on the footage of all the contours and, in general, we can proceed with the installation.

Also, do not forget to make thermal calculations of the building. There are many ready-made calculators on the Internet. If the heat loss in the room does not exceed 100 W per square meter, then the warm floor will not require additional heating devices.

Two way valve

A two-way valve (aka travel valve) is a mechanical device that independently turns off the supply of hot water. The mechanism is recommended for installation in large living areas.

The principle of operation of the two-way valve for underfloor heating

The hot water cut-off function is performed by a thermal head with a liquid sensor. How does regulation take place? Water that has passed a full circle through the heating system enters the two-way valve - the sensor analyzes its temperature and, if necessary, adds hot liquid.

The mixing unit for underfloor heating on a two-way valve significantly increases the service life of the pipeline and saves energy costs for heating. Smooth adjustment and small flow capacity - this is the second group of parameters that distinguish the two-way valve. The main disadvantage: the heated area should not exceed 200 m².

In modern heating, a three-way unit for underfloor heating is used. You can buy them or assemble them yourself. Note that the second option costs little financial costs, but it takes time and a good understanding of the functioning of the entire structure.

All three-way valves are temperature rated. Types of three-way valves:

Diagram of a three-way thermostatic mixing valve

- Low capacity models (approx. 1–2 m³ / hour). They are designed for rooms with a small area: from 10 to 40-50 m².Experts do not recommend installing models with low performance for large apartments, say, 100 or more square meters;

- Valves for large apartments have a high performance (from 2 to 4 m³ / hour). In addition to manual adjustment, the devices can be controlled by a servo drive. Designed to service premises with an area of more than 100 m². They are installed in large apartments, catering places, supermarkets or restaurants.

Underfloor heating installation

As you decide on the layout and connection of the water floor, you need to proceed with the installation.

- Prepare the base of the warm floor. It should be flat with a minimum height difference.

- Install waterproofing as required by local regulations

- Lay 10 cm polystyrene on the first floor and 5 cm on the following.

- Lay polyethylene so that less screed comes into contact with the insulation

- If your fastening method is a reinforcing mesh, then lay it on polyethylene

- Lay out the underfloor heating pipe according to the approved scheme

- Pressurize the system

- Fill the screed

Comparison of underfloor heating with radiators

Heat distribution at the warm floor and radiators

If we compare the already familiar radiator heating system with a warm floor, then in the case of the first, hot air streams rush first upward when heated, and then only go down. Therefore, with radiators, we often feel a cold floor.

The installed underfloor heating works on a different principle. Floor heating pipes first heat the screed, then the screed radiates heat evenly from bottom to top. The higher, the less intense heating.

Therefore, in terms of heat distribution, warm floors look much more advantageous. In terms of economy, both systems are plus or minus the same.

Very often they like to mention that underfloor heating is more economical than other systems.

This is a big misconception. The task of any heating system is to compensate for the heat loss at home. And heat loss is always unchanged.

Therefore, resources must be spent equally. Underfloor heating can indeed be much more economical. If you use advanced solutions for low temperature systems.

How to choose the right 3-way valve

The key parameter of any three-way valve is throughput, i.e. the volume of water that the device is capable of passing through itself per unit of time. When choosing a device, this parameter should be correlated with the boiler performance.

One more nuance should be taken into account here. Even if the diameter of the valve inlets and outlets appears to be suitable in size, this in no way indicates the actual capacity of the device. This parameter is entirely determined by the internal section of the holes, which, depending on the design, are closed by a ball lock or a regulating head.

In some models, the dimensions of this hole can be 4 times less than the inlet diameter. In order not to be mistaken and not to be faced with the need to rework an expensive unit, you should carefully study the accompanying documentation before buying.

Another important parameter of the device is the cross section. Ideally, the valve should fit exactly the dimensions of the pipes of the heating system. If an exact match cannot be achieved, you will have to buy adapters.

In addition, you should pay attention to the following nuances:

- It is imperative to check the availability of accompanying documentation: warranty coupons, instructions for installation and operation, certificates and licenses.

- When choosing a material, you should give preference to brass or bronze. It is these metals that are best combined with hot liquids, and also have a low level of thermal expansion.You can distinguish products made of non-ferrous metals by weight - they are much heavier than cheap “stamping” from powder pressed materials that do not have the required level of strength.

As for specific models, on the market you can find products of several companies that have long established themselves as reliable manufacturers:

- Esbe... A Swedish company whose products are distinguished by reliability, good performance and attractive appearance. The warranty period is at least 5 years.

- Valtec... A joint Russian-Italian venture producing thermo-mixing valves that combine affordable cost and good technical characteristics. The whole range of devices is guaranteed for 7 years.

- Honeywell... An American manufacturer, who has placed at the forefront the ease of installation of manufactured products. Three-way valves of this brand have a striking design, high reliability, but no less high cost.

We recommend that you familiarize yourself with: Features and types of pipes for circular air ducts