Water

Water is used to fill heating pipes and radiators more often than any other liquid, since it is the cheapest.

Technical characteristics of water:

- high heat capacity - at 20 ℃ it is 4183 J / kg · deg;

- low viscosity, which minimizes the load on the circulation pump;

- non-toxic substance;

- oxidation processes occur only during contact of steel with water in the presence of oxygen;

- thermal expansion coefficient - 0.03% / deg.

When it is necessary to fill the circuit, why drain the coolant

Heat supply pipelines in a country house are filled in the following cases:

- After installation of heating systems and commissioning of communication. This usually happens in the fall at the beginning of the season.

- After renovation work.

The water is drained from the circuit at the end of spring due to contamination of the coolant and corrosion of the walls of pipes and heating radiators. If this is not done in time, solid particles will clog the filter or fall under the impeller of the circulation pump, which can cause it to break. Another reason for draining is the possibility of water freezing in the spring in the absence of the owner in a country house.

Note! A heating scheme made of polypropylene pipes avoids the harmful effects of corrosion. It is best to use antifreeze as a coolant. A quality substance does not freeze at a temperature of -30 degrees. This fluid can be used for 15 years. Poor-quality antifreeze is drained after 2 years.

Antifreeze

The main purpose of antifreeze during its development several decades ago was to use it as a filler for water cooling of a car engine in winter. Due to its properties, antifreeze began to be used for filling heating systems. The freezing point of a substance is put down in its marking as a numerical value - 30, 40 or 65.

Antifreeze characteristics:

- low price;

- the average level of heat capacity is 3520 J / kg · deg;

- due to the high viscosity of the substance, the pump for filling the heating system is subjected to significant loads;

- the presence of anti-corrosion additives protects the metal from oxidation;

- it is highly toxic, since it contains the poisonous substance ethylene glycol;

- thermal expansion coefficient - 0.05% / deg.

Please note that an expansion tank is provided in a closed heating system to compensate for thermal expansion when heating the coolant. It should be the greater, the higher the value of this coefficient for the coolant.

Since antifreeze is characterized by zero corrosiveness, the system with such a carrier must be absolutely tight. Otherwise, any crack will result in a coolant leak. In the case of other liquids, such as water, small defects become clogged with rust or precipitated salts.

Filling methods

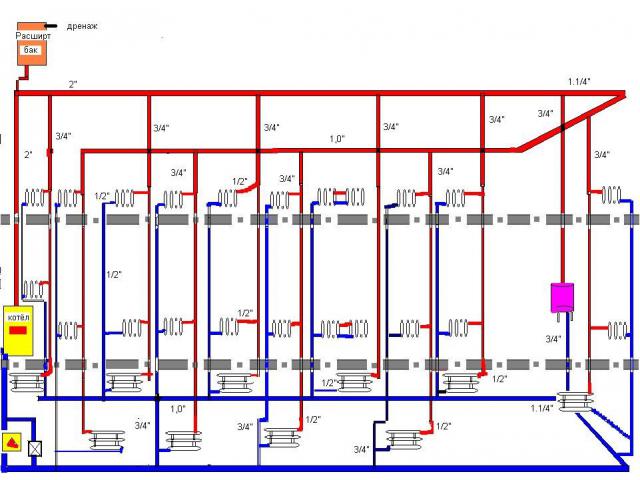

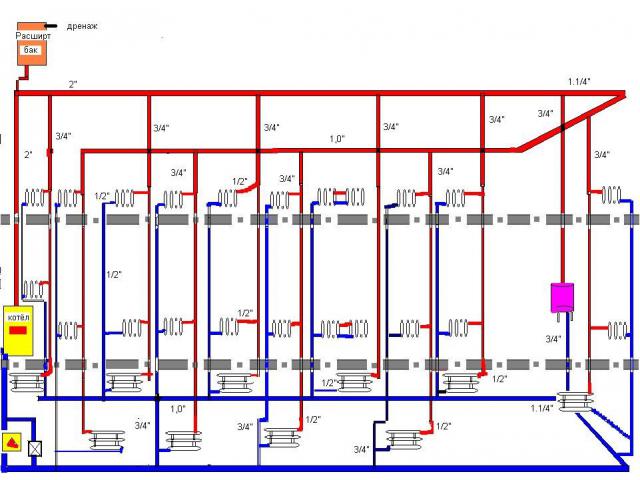

Launching an apartment building system

The procedure for the bottom filling house will be as follows:

- With the house valve on the supply closed, open the discharge on the supply pipeline. The return line discharge is closed.

- SLOWLY open the valve on the return pipe. If you do this quickly, there is a possibility of a water hammer with the most unpleasant consequences, up to and including the radiators breaking off.

- We are waiting until water without air comes out of the discharge.

- We close the discharge and open the gate valve on the feed.

- We bleed air from the access heating circuits, office premises, and so on - in a word, wherever there is access.

Please note: in the case of top filling, the procedure is much simpler. It is enough to slowly open both valves with closed discharges, go up to the attic and bleed air from the air vent on the expansion tank.

The top filling greatly simplifies the heating start-up.

Gravity open heating system start-up

Are you expecting difficulties? They are not expected: it is enough just to pour a few buckets of water into an open expansion tank. Water should show up at the bottom. Do not try to fill it with a margin, so as to add the coolant less often: when heated, the water will increase in volume and pour onto the floor of the attic.

Of course, if the heating circuit is self-assembled and filled for the first time, it is worth going through and looking at all threaded and welded joints for leaks.

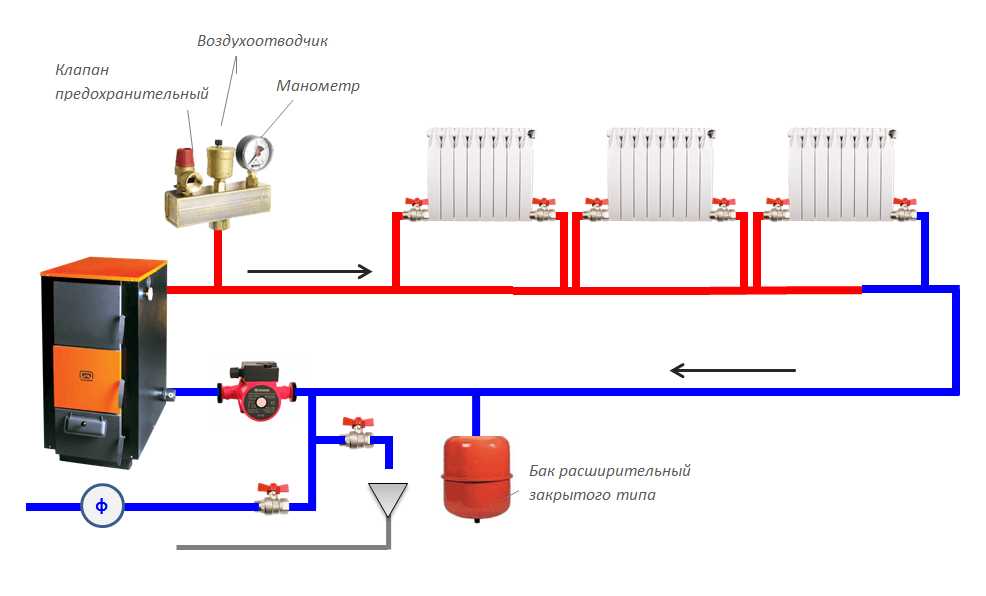

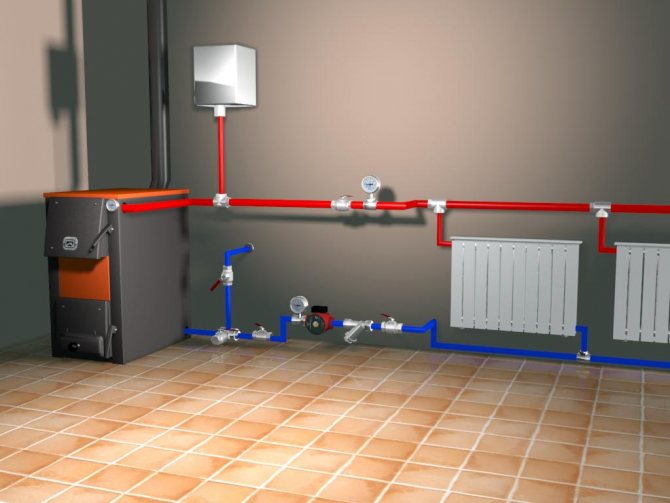

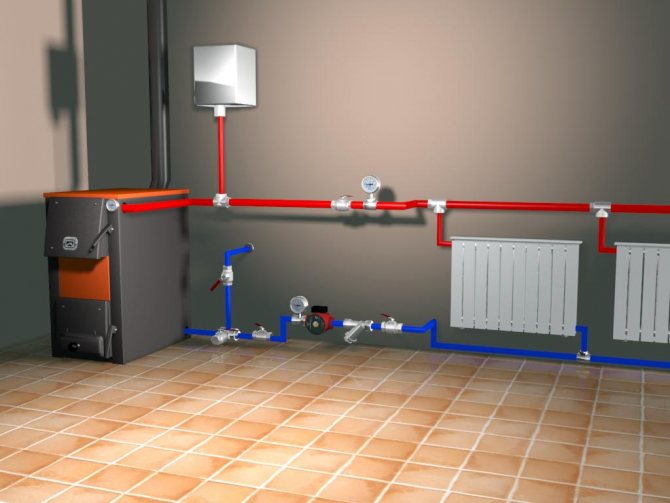

Starting a closed heating system

What is the difference between a closed system with forced circulation in terms of filling it with a coolant?

- Overpressure is required for the operation of the boiler and the circulation pump. Usually its recommended value is 1.5 kgf / cm2.

- Before starting in normal mode, it is recommended to pressurize the heating system with one and a half times higher pressure. This operation is especially important for systems with a water heat-insulated floor: it will be buried in the screed, where repair work is ... let's say, difficult.

How to create the required pressure in the circuit?

If there is a central water supply in the house, the problem is solved extremely simply: for pressure testing, the system is filled through a jumper with a water supply with continuous pressure monitoring by a manometer. After pressure testing and checking for leaks, excess water is discharged through any valve or air vent.

In the water supply system, the pressure is usually at least 3 kgf / cm. This is clearly more than the crimping pressure of the heating system, not to mention the operating pressure.

How to fill the heating system with water if the water source is a well or a river? Or when the system is filled with ethylene glycol or other antifreeze medium?

Normally, in such cases, a special pump is used to fill the heating system and pressurize - manual or electric. It connects to the circuit through a valve; after the required overpressure has been created, the valve is closed.

The photo shows a manual pressure test pump.

Is it possible to do without a pump?

Let's remember: 1.5 atmospheres of overpressure corresponds to 15 meters of water column. The obvious and simplest solution is to connect an ordinary reinforced garden hose to the relief valve, raise its other end by a half dozen meters and fill it with water through a funnel. This option is easy to implement if the house is on a slope or there are tall trees nearby.

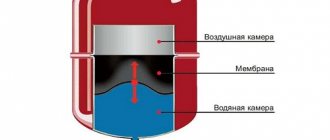

Finally, the expansion tank can solve the problem. Its main function is to contain the excess coolant when it expands. Water is practically incompressible, and reinforced plastic or metal pipes are not very elastic.

The diaphragm expansion tank is a container that is divided into two parts by a rubber elastic partition. One of them is intended for the coolant, the second contains air. All tanks are equipped with a nipple that allows you to adjust the pressure in it by bleeding off excess air or pumping it with an ordinary bicycle pump.

The solution will be simple:

- We bleed air from the tank by unscrewing the nipple. Expansion tanks are supplied with an overpressure of just 1.5 atmospheres.

- We fill the system with water. The tank is mounted with a thread for connecting upwards, therefore, its own weight will help the coolant overcome the elasticity of the membrane.

Please note that you do not need to fill the tank completely with water.The final amount of air in it should be equal to about one tenth of the total volume of the coolant, otherwise the expansion tank will simply not perform its main function - to contain the excess of heated water.

- We pump air with a bicycle pump through the nipple, controlling the pressure on the manometer.

To create the right pressure in the expansion tank, you need a regular bicycle pump.

The price of a large-volume expansion tank is relatively high, but we do not lose anything: it is in any case necessary for the normal operation of a closed heating system.

Find out also about the field of application of the solid fuel boiler with a water circuit.

Propylene glycol

Propylene glycol is used for the production of special anti-freezing fluids, which are used as a heat carrier in heating systems. In its pure form, propylene glycol has a rather low heat capacity (2400 J / kg · deg). Therefore, before pumping the coolant into a closed heating system, it is diluted with water. It significantly increases the heat capacity of a substance. As a result, the solution has a heat capacity index close to antifreeze (depending on concentration - 3500-4000 J / kg · deg).

Other characteristics of propylene glycol:

- high viscosity;

- low corrosiveness due to the presence of additives;

- non-toxic - the cans with the substance are labeled "Eco";

- thermal expansion coefficient - 0.05% / deg.

Key parameters of pressure testing pumps

Consider the main parameters of pumps for flushing and pressing the heating system:

- The maximum pressure generated by the heating system. It, in turn, can be divided into four categories depending on the performance of the pressure head pump:

- up to a pressure of 20 to 30 bar;

- Pressure from 50 to 60 bar;

- from about 100 to 120 bar;

- more than 150 bar.

- Performance. Determines the amount of liquid that should be pumped by the device per unit of time. It depends on the model and type of pump.

- Bath fluid used to pressurize the heating system. This can be water, hydraulic oil, antifreeze.

- The volume of the tank for storing the working fluid.

- Pump size and weight.

There are two types of system pressure relief mechanisms, depending on the type of actuator:

- mechanical (manual);

- electricity.

High pressure hand pump

Mechanical test benches. The required pressure in the system is achieved due to the piston movement integrated into the system. The piston, connected to the lever, begins to work after the operator's muscular force is applied to it. This introduces an additional parameter for mechanical pump types - lever force.

Mechanical pumps are suitable for system pressures from 30 to 60 bar. Dual valves in the device keep the pressure in the working part of the device at a stable level, minimizing the likelihood of failure of the fluid supply system.

Due to the technological properties of the test hose, an error in measuring the required parameters is practically excluded.

Benefits of mechanical pumps:

- The weight and dimensions of the device make it easy to carry it by hand and use it in confined spaces;

- Test accuracy remains high;

- Unlike electric pumps, they can be used far from the power source and in pipeline sections without water supply.

Important: It is strongly not recommended to use a mechanical pressure valve at low temperatures or with a clogged filter.

High pressure electric pump

Electrical pressure testers. Devices of this type differ from mechanical pumps in the principle of pressurizing the system. This is done using an electric motor powered by the 220th century mains.

With the help of such a solution, labor productivity could be increased several times. At the same time, electrical pressure testers are self-priming, eliminating the need to pre-pump fluid into the system.

All parts and components are made of high quality materials and withstand high loads. This type of device also provides the ability to adjust the required pressure by rotating the bypass valve around its axis.

They have the following advantages:

This eliminates the need for physical strength while working; The high performance of the device allows it to be used in urban heat supply systems; Control of a given number of atmospheres in automatic mode.

Expert Advice: Monitor the quality of your hydraulic fluid carefully to make sure it does not contain fine solid particles that could damage pump pores or damage the pump.

Saline solution

For open-type heating systems with natural circulation of the coolant, one of the possible options for the coolant is a concentrated solution of sodium chloride, calcium chloride or other mineral salts. It is used to prevent the heating circuit pipes from freezing in winter. Moreover, the stronger the salt concentration, the lower the freezing temperature of the solution.

Brine specifications:

- rather low heat capacity - a solution with a salt concentration of 30% gives off 2700 J / kg · deg;

- low viscosity;

- very high corrosive activity - steel pipes "burn out" very quickly from constant contact with salt;

- lack of toxins;

- thermal expansion coefficient - 0.03% / deg;

- low price of salt.

The disadvantage of the solution is that, under the condition of a low circulation rate of the coolant, salt will be deposited on the inner surface of the pipes, reducing their clearance. In addition, salt has a detrimental effect on the components of the circulation pump - the shaft and impeller, since the fouling of crystals leads to a decrease in its performance.

Interim findings

So, before filling a closed heating system, you need to assess the conditions for using the heating system.

The conclusions will be as follows:

- Provided that you will use heating all the time, and a positive temperature will be maintained in the system, water will be the best option for a heat carrier. Distilled water is best, but you can also just use it from the tap.

- In cases where the house will be heated only from time to time in winter, the best option is to fill the heating system with antifreeze, that is, an ethylene glycol-based coolant.

Features of filling a closed heating system

To complete the work, you need pump and expansion tank. It is recommended to do this together... Task the first - fill the circuit with water while the second controls the air release.

If you have to do everything in alone, it is enough to turn on a weak head. The gas relief valve should be located in the upper part of the pipeline, away from the boiler.

Before starting, a container is placed under the place where the liquid flows out to collect it.

The tap to remove water is set down below... Not far from it, near the boiler, a supply pipe is mounted. For filling, a hose is used, which is placed in a water supply system or connected to a pump. A successful process is facilitated high head. The system will fill when liquid emerges from the vent valve. Then the air is released and the pressure is checked. Repeat the procedure if necessary.

In a two-circuit system the process is easier. For the bay use make-up system, if there is. It will automatically balance, remove gas and select the preset pressure.If it is absent, you will need to connect the water supply to the boiler with a hose and fill it through the latter. In this case, you will have to manually clean the circuit from air.

If the boiler gas, you will have to remove face cover... There is a booster pump. The device is turned on by heating the coolant.

The liquid is mixed with the gas that needs to be removed: for this, the valve inside the device is slightly opened with a screwdriver. When water appears from it, the valve is plugged.

The procedure is repeated 3-5 times with an interval of 2-3 minutes. If the boiler has ceased to boil, the pressure is checked.

Having finished filling the closed system, they proceed to inspect the integrity of the pipes. After it, debugging and hydraulic tests are done.

Filling and discharging the coolant from the system

Filling the heating circuit in a house with a coolant is usually performed in the following cases:

- Initial start-up of heating in a private house.

- Bringing the heating system into working condition after planned or unforeseen repairs or replacement of the boiler, shut-off fittings, and other elements.

- Refilling before the heating period after draining the heating agent from the heating system in a house that has not been heated for a long time.

To discharge the coolant, it is necessary to open special valves in the lower part of the circuit, as well as at least one valve for air intake so that water flows freely from the system.

Selection principles

The choice between mechanical or electrical pumps depends solely on the task at hand.

In the event of a failure of the heating system of a residential building at the level of the heating season, the group of employees does not have time to manually pump the required pressure to determine where the air leak or leak is.

Therefore, a rational solution would be to use a high-performance electric press.

A hand tool with a capacity of 2-3 liters per minute is the ideal assistant for heating a private house or cabin.

Watch a video where a technician shows you how to flush a heat pump using a case study:

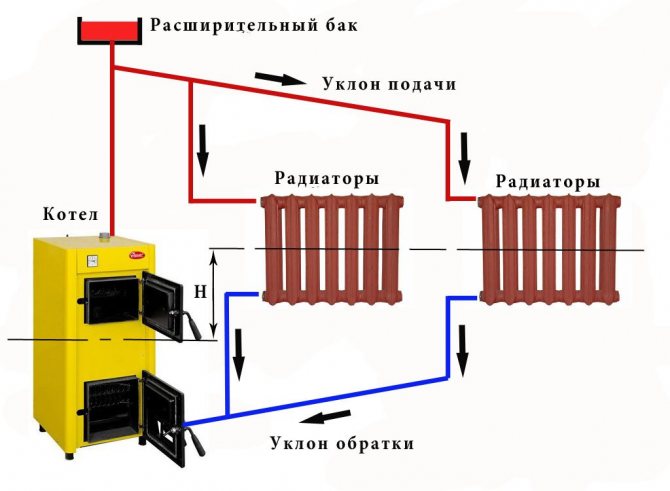

How to properly fill an open heating system

Before adding water to the heating system, it is worth deciding on what scheme it functions.

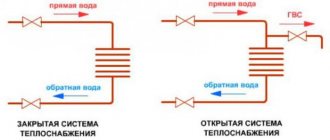

There are two types of heating circuit assembly in a private house:

- Open system - the pressure in it is equal to the height of the water column from the lower to the upper point of the circuit. By means of an open expansion tank, the system is in communication with the atmosphere.

- The closed type of heating operates at an overpressure of 1.5-2.5 atmospheres. It contains a membrane tank that compensates for the thermal expansion of the coolant when its temperature rises.

In an open heating system, all pipes of the circuit are laid so as to create a slight slope from the expansion vessel to the top of the circuit.

In this case, you do not have to rack your brains on how to properly pour water into the heating system. It is fed directly through an expansion tank installed under the ceiling or in the attic. You can fill it with any container, or connect the tap to the central water supply.

Please note that excess air from the system will also escape through the expansion vessel.

Thus, in the case of an open type of heating system - how to properly power it, problems should not arise. After firing up the furnace or boiler, the water will begin to circulate in a natural way, or forcibly after turning on the circulation pump, if it is provided for by the scheme.

Water drain technology, cleaning heating pipes

Drain valve in the heating system

Before filling the heating system of a double-circuit boiler, it is necessary to drain the old coolant.This procedure is mandatory and, despite its apparent simplicity, must be performed according to a certain technological scheme. First you need to turn off the heating and wait until the water temperature drops to room temperature. Only then can the closed heating system be properly filled with distilled water.

The drain valve is then opened, located at the lowest point in the system. After waiting for the water to drain, you need to open the Mayevsky tap, which is located at the top point of the circuit. This is necessary to stabilize the pressure in the pipes. After completing these works, you need to flush the system. This is done before the heating system in a private house is filled. This requires the use of special tools and equipment. A pump is connected to the heating circuit, which pumps flushing liquid into the heating system. It also has a destructive effect on deposits in pipes. After several cycles of passage, contaminants are removed along with the liquid.

The used liquid must not be discharged into the sewer system. It must be collected in sealed containers, which are then disposed of by special companies.