The main / Plumbing / Equipment / What is the service life of metal-plastic pipes for water supply and heating

Metal-plastic pipes are used in those areas of human activity where strength and durability are required.

Reinforced-plastic pipes (MPT) are designed for the installation of a water supply system, heating system, warm floor.

MPT have found application in many areas, the main advantage of such pipe products is the operating time, subject to the installation rules and operating conditions. pipes serve from 35 to 50 years.

Composition and production

For household use, products are manufactured in accordance with GOST R 53630-2009.

The standard is intended for the manufacture of pressure multilayer pipes with a circular cross-section, which are intended for the transportation of water, including drinking water, and for the installation of water supply and heat supply.

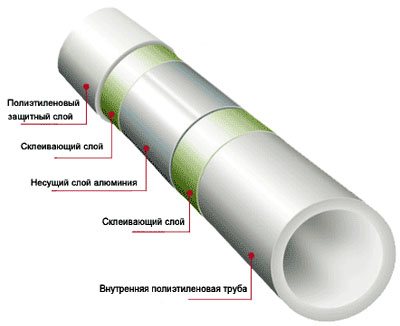

MPT consists of several layers of plastic, metal and special glue:

- layer - inner, is in constant contact with liquid, plastic;

- adhesive layer;

- barrier layer, thin rolled aluminum or fiberglass;

- adhesive layer;

- layer - outer, exposed to environmental influences, plastic.

The adhesive composition consists of composites based on thermoplastic polymers with adhesion to layers and a melting point of 120 degrees. Plastic components for the inner layer produced on the basis of the following polymers:

- cross-linked polyethylene, with a strength of 8 MPa (what kind of tool you need to buy for installing pipes);

- polyethylene with increased heat resistance and strength from 8 MPa;

- polypropylene with a strength of 8 MPa;

- polybutene with a strength of 12.5 MPa.

Do you know the installation height of the heated towel rail? Instructions on how to equip a bathroom with a year-round coolant are posted in a useful article.

About polypropylene or cross-linked polyethylene for heating is written on this page.

The metal layer is made of thin aluminum or fiberglass tape. The outer layer is made of polymers with low oxygen permeability.

The production of MPT is a complex high-tech process.

The molten polymers are uniformly fed into the molding mechanisms, where the layers are glued together. At the same time, pipes are molded along the outer and inner diameters.

At the exit, the product enters the cooling tanks, after which it is cut or wound into coils.

Application of polymers and metal made it possible to use the advantages of each material, achieving the combination of useful characteristics from the pipes.

Polymer layers protect the reinforcing aluminum layer from corrosive processes. Metal makes products flexible, increasing fracture toughness.

Thanks to this combination, the pipes can withstand the temperature of hot water without changing their technical characteristics (read about the use of cold welding for pipes under pressure in this article.).

Combination of metal and plastic

The metal-plastic wall is made of an aluminum base covered with high-density polyethylene. A special adhesive layer is applied to it using the extrusion method from the inside and outside. The outer layer of polyethylene protects the product from atmospheric corrosion and mechanical damage.

Aluminum

The middle aluminum layer gives the pipe mechanical and hydraulic strength and makes it oxygen-tight. The thermal deformability of polyethylene is reduced by more than 7 times due to the presence of aluminum.

The edges of the aluminum base can be joined by laser butt welding or ultrasonic overlap welding. Laser welding gives a more durable option.

Polyethylene

The inner layer is made of heat-resistant polyethylene. It forms a smooth surface and corrosion protection of the metal. Polyethylene, which is used in production, does not contain harmful chemicals. This suggests that the metal-plastic pipelines are suitable for drinking water supply. Polyethylene prevents the multiplication and spread of microorganisms in the water.

To provide thermal insulation and reduce heat loss, pipelines with closed pores and concentric insulation are used.

Characteristics and technical description

Tubular products have not only technical characteristics, but also operational characteristics.

By purchasing metal-plastic products, are determined with a choice for all characteristics.

Some technical details can tell a lot about plumbing pipes, but are incomprehensible to the average person.

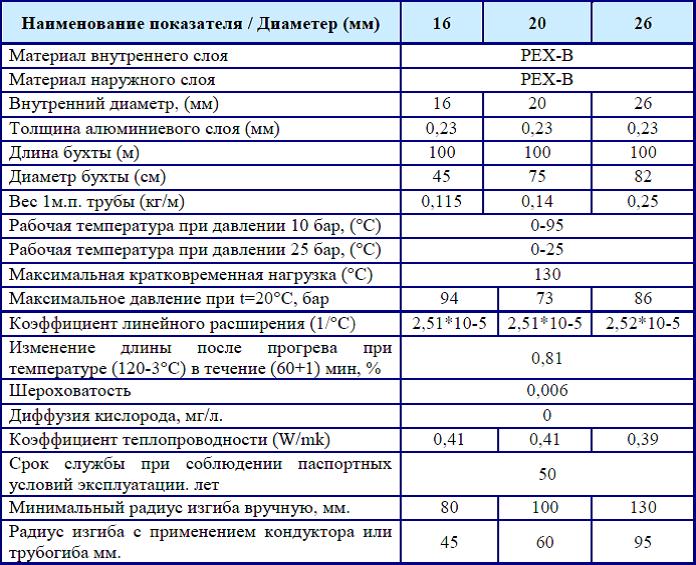

When choosing MPT, they are guided by the following technical parameters:

- external diameter, products with an indicator from 16 to 63 millimeters are produced;

- Wall thickness, produce pipes with a thickness of 2 and 3 millimeters;

- reinforcing layer thickness, depending on the purpose, is 0.19-0.3 millimeters;

- weight depends on length and diameter (find out about the weight of a steel, galvanized pipe on this page);

- operating pressure - up to 10 bar for hot water, up to 25 bar for cold water;

- short-term temperature impact up to 110 degrees.

You can choose MPT for a water supply system based on operational data.

They do not give numerical characteristics, but reflect the reaction of the material and product to certain influences.

The main performance characteristics are:

- no harmful effects on the environment;

- rust, scale, mineral deposits do not form on pipes;

- products restore their shape after bending;

- plasticity will allow you to bypass the elements of the premises and save on stainless steel fittings (described here);

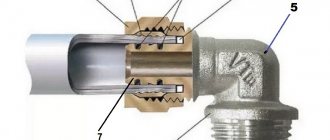

- installation is in progress without the use of special tools (compression fittings);

- no waste after assembly;

- smooth inner surface facilitates water flow;

- MPT compatible with pipes from other materials;

- resistant to condensation and freezing;

- the composition of the water remains unchanged;

- used for re-assembly;

- do not require external paint coating.

What do you know about XLPE pipe fittings? Read on for a helpful article on how to mount innovative products.

What the diameters of ceramic pipes can be is written here.

On the page: it is written what is the name of the cable for cleaning the sewer.

The positive qualities of MPT are due to the design features and materials used.

The combination of the strength of metal and the flexibility of plastic makes the pipe plastic, with the ability to restore its original shape.

Dimensions (edit)

The most demanded standard sizes of metal-plastic pipes are presented in the table:

Diameters of pipes made of metal-plastic

Reinforced-plastic pipes with a diameter of 16 mm to 25 mm are used, as a rule, for intra-apartment wiring. Reinforced-plastic pipes with a diameter of 32 mm and 40 mm are used for the installation of general water supply systems.

Reinforced-plastic pipes are produced in other diameters (50 mm, 63 mm), but they are less in demand.

It is not difficult to select fittings for metal-plastic pipes, since the size range of manufactured fittings for metal-plastic pipes corresponds to the dimensions of the pipes produced.

Disadvantages of MPT

Right choice takes into account both the negative aspects of operation and installation of pipe metal-plastic products.

There are few of them:

- concealed installation does not allow use collapsible connections;

- the polymers included in the pipes are destroyed by prolonged exposure to ultraviolet radiation;

- with prolonged exposure to low temperatures on a cold water supply system, pipes burst. Insulating materials must be used.

Pipes are delivered in coils... The length of the bay is 50-200 meters. When sold, products are cut by meter.

How long will cast iron pipes last?

Despite the wide popularity of plastic and composite structures, cast iron products are still preferred when arranging sewer communications. Such systems are able to work without major repairs from 70 to 100 years, and with careful care and regular cleaning - and more than this period.

The service life of the cast-iron structure is reduced only due to the joints, which become unusable after 5-7 years. Regular flushing of the pipeline from internal deposits will help to increase the service life, and if there is access to the external surface, then cleaning it.

If you do not monitor the state of communications, the service life of cast iron products will be halved.

Areas of use

The spread of metal-plastic pipe products is explained by a range of technical features:

- internal cold and hot water supply;

- space heating (how to remove air from the system in a private house);

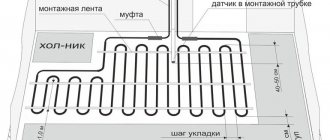

- floor heating structures, playgrounds, swimming pools;

- movement of liquids and gases, including chemically active ones, in enterprises and in agriculture;

- compressed air supply;

- air conditioning pipelines;

- protective frame for electricians;

- production of ships and wagons;

- water supply for irrigation, irrigation measures, drainage of water from water pumps.

Such a pipe replaces plastic and alloy products.... The reason is the long service life.

Spheres of application of metal-plastic pipes

Products made from a material such as metal-plastic are used in various fields of activity:

- they can be found in the internal systems of buildings that have recently been built or renovated;

- they are used in the arrangement of the transportation of gaseous and liquid substances in industrial, agricultural and transport areas;

- for compressed air supply;

- when replacing a pipeline that has become unusable at any time of the year without resettling people living in the building;

- in indoor systems installed for air conditioning;

- as a shield to protect power cables.

Operating rules

During installation and operation, the technical and operational characteristics of metal-plastic pipes are taken into account.

This made it possible to reduce the harmful effects for products and use the pipeline for the prescribed period.

- In places where the pipeline is laid there should be no mechanical and high-temperature effects on the pipes.

Direct exposure to ultraviolet rays is excluded.The pipes are mounted on holders that are 50 centimeters apart.

The holes in the walls are equipped with sleeves through which the pipes are mounted.

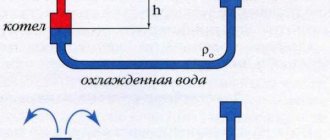

- Heating installation determines the service life of MPT... In a private house, a two-pipe system with a collector is used.

The use of "Leningrad" is undesirable.With a small number of branches, a tee is used.

- Operating pressureexceeding 10 bar destroys the pipeline structure.

In your home, where the pressure does not exceed 7-8 bar, the pipes are operated normally.In apartment buildings, at the time of pressure testing, the pressure rises to 25 bar.

In such systems, a pressure reducer is installed.

- Polymers and metal have different coefficients of expansion when exposed to heat.

Pipes that are used to supply cold water cannot transport hot water.In this case, stratification of the product begins, leaks appear.

During installation, use connecting elements made of appropriate materials.

Hot and cold pipelines passing nearby are not closer than 30 centimeters.

- Installation of structures made of MPT is carried out at an ambient temperature of at least plus ten degrees.

IMPORTANT! Do not use metal-plastic pipes for installing underfloor heating in a cold room.

Outdoor use of MPT and outbuildings are recommended only in warm weather. For the winter period, water from such pipelines is drained.

The service life of half a century and the ratio of price and quality allow metal-plastic pipes to successfully replace products from other materials.

In what condition are the metal-plastic pipes after 7 years of operation, see the proposed video.

Subscribe to updates by E-Mail:

What is the service life of polypropylene pipes, what temperature can they withstand

Polypropylene pipes have proven themselves well in heating systems. They have become a worthy replacement for metal heating pipes.

The service life of polypropylene pipes is not less than the service life of metal pipes.

PP pipes are not afraid of corrosion, resistant to chemicals that are used in everyday life, in addition, when water freezes, they are not destroyed.

Therefore, in heating systems, polypropylene pipes can be used for 25 years, and in cold water supply pipelines - about 50 years.

The strength and reliability of the polypropylene water supply system is also ensured by the way they are connected. It is carried out by welding. This ensures solidity and strength. During operation, there is no need to constantly tighten the connections, as is the case with metal pipelines.

What temperature can polypropylene pipes withstand?

Many people still mistrust polypropylene pipes in heating systems. Let's figure out what temperature they can withstand, what is the service life of polypropylene pipes and whether it is possible to use them to heat a house.

The material that is taken for the manufacture of pipes is obtained by polymerizing polypropylene with the participation of metal catalysts. Polypropylene softens at + 140C, this material melts at a temperature of + 175C.

It becomes obvious that prolonged exposure to high temperatures and excess pressure will lead to deformation of the pipeline.

Manufacturers give guarantees of normal operation of polypropylene pipes in the heating system at temperatures up to + 95C. But there is still a margin of safety, which allows a short-term increase in the temperature of the coolant to a temperature of + 140C. But frequent jumps in temperature to this value will lead to a reduction in the life of the pipeline, although it will not melt itself.

When buying polypropylene pipes, you need to pay attention to their marking. For the cold water supply system, polypropylene pipes PN10 to PN25 are used

Pipes PN20 can be used up to + 60C, and PN25 can be used if the temperature of the heat carrier is up to + 95C.

What pressure can polypropylene pipes of different types withstand?

Many buyers who decide to install a polypropylene pipeline for cold water supply or for heating are interested in how much pressure they withstand. The service life of polypropylene pipes will depend on this. This question is very important. Since the pressure in the water supply system or in the heating system, which polypropylene experiences throughout its entire period of use, affects the service life of the product.If the temperature in the pipeline is constantly high, but there is little pressure (or vice versa), then the pipe will serve for a long time. But if there is both high pressure and high temperature in the system, then the service life will be sharply reduced.

In order for the pipeline to serve the 50 years promised by the manufacturer, it is necessary that the pressure in the system be 4-6 atmospheres, and the temperature of the coolant does not exceed 75 degrees.

Polypropylene pipes in the heating system

Polypropylene pipes are now quite popular material for installing a heating system. They are resistant to deformation, abrasion, and are characterized by low oxygen permeability. In addition, they perfectly withstand temperatures with minus, are not afraid of water freezing.

But, when choosing them, you need to take into account the following points:

Polypropylene pipes are rigid, do not bend. To create contours or turns, you need to use corners, which is not always convenient. For polypropylene pipes, fittings are produced with a large cross-section when compared with fittings of other system elements, for example, radiators. This circumstance negatively affects the appearance of the system. Polypropylene stretches strongly when heated

If the system is made in an open way, then it looks ugly due to sagging pipes. It is important not to overheat the pipes during installation, as the passage may decrease when inserting pipes into fittings. Such an installation error will lead to poor performance of the heating system.

It is not recommended to use polypropylene pipes when piping boilers. In boiler rooms, the temperature of the pipes often changes, but polypropylene is an unsuitable material for such conditions.

If we take into account all the negative points described above, then polypropylene pipes for heating systems are a good option.

Varieties of chimneys

The modern range of smoke evacuation pipes is pleasing to the eye. This includes expensive ceramic smoke structures (usually used for baths), and steel and thermoplastic products. However, stainless steel pipes are considered the most reliable today - they can withstand heating up to + 600 ° C. Due to the perfect fit, the entire structure made of this material is airtight, so there is almost no soot and condensation.

But ceramic products, on the contrary, are used quite rarely, since they have a solid weight that only a massive stationary stove used to heat a residential building can withstand.

When building a summer house, a country house or carrying out repairs in an apartment, special attention should be paid to the arrangement of communication facilities: water supply, gas pipeline, sewage. For each type of communications, a certain type of pipes is suitable, differing in characteristics and service life.

What is the best way to make sewer pipes?

For the device of the sewage system, two types of pipes are used:

- cast iron,

- plastic.

Cast iron structures will last more than 80 years, but they have their drawbacks, including high cost, heavy weight, and uneven interior surfaces that lead to waste retention and clogging.

Plastic pipes have maximum flow capacity due to the fact that they have smooth walls. In such systems, blockages are almost never created.