How to close the gap between the laminate and the pipe

If the gap is small, then you can fill it with a sealant. They come in a variety of colors, so you can easily find the one that matches your gender. But the best option to decorate the gap would be special pipe linings.

They can be different in shape, for example, round or square. Also, there are bypasses with two holes, for cases where the pipes are located close to each other.

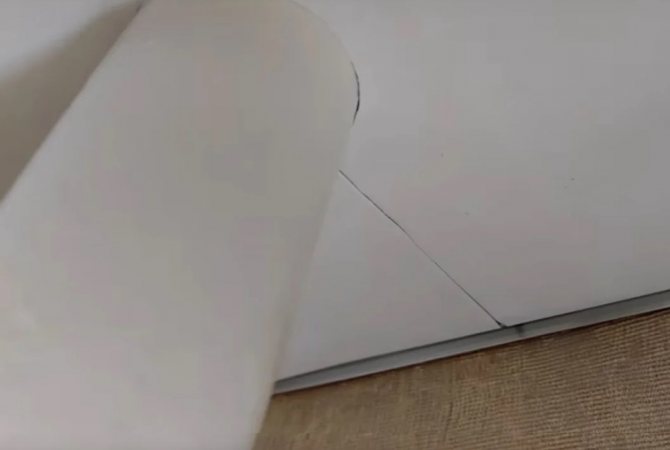

Stretch ceiling cut under the pipe

The most popular method of bypassing the pipe is by cutting the web. Such an incision can only be made when the canvas is completely tucked into the baguette.

The sequence of actions required to bypass the pipe is as follows:

- First, you need to choose the place where the incision will be made. The most suitable point is at the place where the pipe passes through the ceiling - in this place it will be possible to press the material well against the pipe so that there are no wrinkles.

- The incision is made with scissors or an oil-coated knife.

- An incision should be made towards the area where the pipe is located at a minimum distance from the wall. When cutting the fabric around the pipe, make sure that the edges of the fabric can converge behind it.

- When the cuts are made, the free-hanging fabric is tucked under the stretch ceiling in such a way that its direction coincides with the direction of the pipe.

- The last step is the installation of decorative panels, which allow you to beautifully mask the place of the pipe bypass.

Sometimes it turns out that after the pipe is bypassed, a little extra tissue remains. It needs to be cut off, leaving only a couple of centimeters, which are tucked into the baguette.

What are these linings called

When looking for suitable overlays, you may encounter the following difficulty: on different sites and in catalogs, these decor elements are called differently. The most common names are:

- pipe lines;

- decorative overlays;

- rings for pipes.

Do not be alarmed - all this is the name of the same subject, and its essence does not change from the wording. Therefore, if you cannot find the part you need in the catalog, it is worth trying a search by other words.

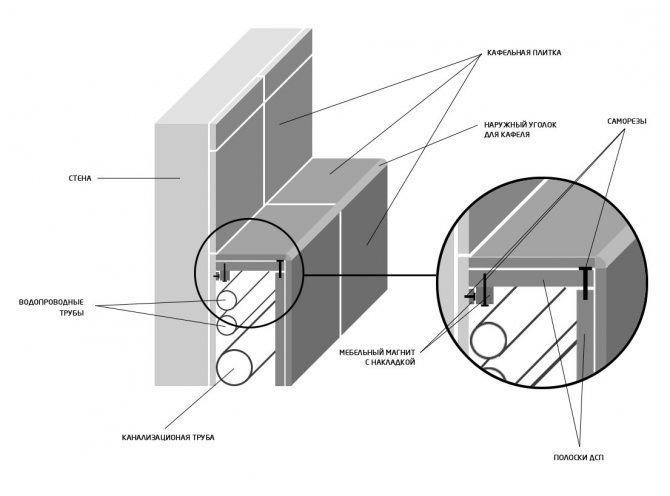

Water baseboard heating

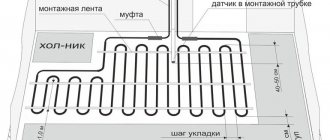

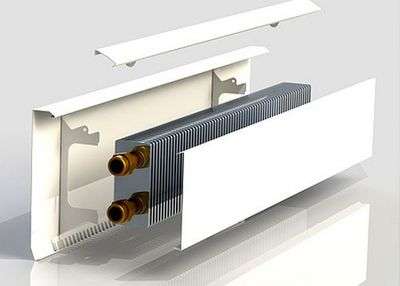

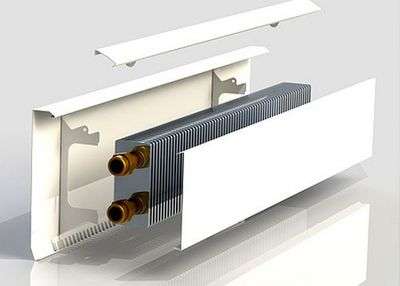

The basis is the radiators, into which the heated coolant is supplied. The system, in fact, is a version of water heating and consists of a boiler, collectors - a supply pipe and a return pipe with connection fittings, the actual baseboard - radiators, and a plastic double pipe through which water circulates.

The radiator consists of a heat exchanger and a box. The heat exchanger is usually a copper tube on which numerous aluminum or brass plates are attached to distribute heat and form a vertical airflow. The supply pipe is installed in the floor or wall and is hidden from view - this method not only ensures the compactness of the system, but also reduces heat loss.

It is recommended to install hot water heating during repairs, especially when it comes to the option with the placement of the pipeline in the floor.

- The return flow collectors are mounted on the wall using anchors. The place must be accessible for service.

- The collectors are connected to the supply and return pipes to the boiler. In most cases, a threaded connection is assumed, which facilitates do-it-yourself installation.

- From the collector to each radiator, two tubes are stretched - supply and return. They can be mounted on the wall or on the floor.

- At the planned places, fasteners for radiators are mounted - its type depends on the design of the device.

- A radiator with a connected pipeline is fixed to the fasteners.

- Decorative boxes are fixed on top. The photo shows a variant of using a warm water baseboard.

Water or antifreeze is used as a heat carrier. The system is completely filled with liquid, air is released using special fittings.

Electric baseboard heating

Installation of this option will require preliminary laying of a power cable with outputs for connecting radiators. The advantage is the absence of a heating boiler, the disadvantage is the increased consumption of electricity. As in the previous case, do-it-yourself installation is the last and easiest stage, judging by the reviews. The photo shows an electric baseboard radiator.

When organizing electric heating, you should accurately calculate the power of the devices used and their number. You cannot connect more than 17 radiators, while their total power should not exceed 200 watts.

- On the wall, at one level, the fastening is marked. According to the configuration of the rear wall of the radiator, holes are drilled in the wall and dowels are fixed.

- The fasteners must be carried out in such a way that there is a gap of at least 1-2 mm between the plinth and the floor in order to avoid overheating.

- A radiator is attached to the installed rear wall. Power jumpers are mounted and must be grounded.

- The modules are connected to the mains in parallel.

- Radiators are covered with decorative boxes.

- The thermostat is fixed to the wall in such a way that the distance required by the instructions is observed between it and the radiator. The thermostat measures the air temperature in the room, and therefore should not be obstructed by any interior details or furnishings. It is desirable that the power outlet is near.

- A trial run of the system is in progress.

The video shows in more detail the installation of baseboard heating.

Heating for Russia is not a luxury, but a necessity. The centralized system provides a comfortable temperature of +20 ° C, but the distribution of heat throughout the room is uneven. Physics comes into play: heated air goes up, cold air goes down. Is there an option in which the house is thoroughly warmed up without additional costs for underfloor heating? Yes, this is the so-called baseboard heating.

What materials are they made of, how much do they cost

Pipe lines come in three materials:

- plastic;

- tree;

- metal.

Most often they are selected depending on the floor covering. Wooden rings are better suited to parquet, plastic rings to linoleum.

But there are no strict rules in this matter, choose for yourself what you like best. In addition, plastic elements are produced with a wood-like texture, and from the height of a human being, you can hardly see the difference between wood and imitation.

Metal bypass for pipes Wooden bypass for pipes Plastic bypass for pipes

Plastic pads cost about 50 rubles for a package of 2 pieces. Wooden rings will cost more - about 120 rubles.

How you can carefully glue a hole in a laminate, see the article How to glue a hole in linoleum - the best ways.

Installation

Installation of such a device is simple and does not require special skills and tools. However, the installation of different types of rings has its own nuances:

- wooden ones are in two parts and simply snap around the pipe. Connecting joints are usually not visible;

- on plastic and metal there is a special gap with which you can expand and put on the pad. The connector is directed towards the wall so that it is not visible.

No additional commit is needed.This is very convenient, because if necessary, you can easily remove the outline, and then return it to its original place.

Corrugated pipe application

The main purpose of this material is to provide insulation. Unlike rigid metal thick-walled pipes, for which expensive auxiliary equipment must be used, corrugation for heating pipes does not require such tools and materials. At the same time, its functionality remains at a high level.

Its characteristic properties are:

- low weight per running meter;

- maximum flexibility due to texture and thin walls;

- sufficient strength, since the material is metal.

It is easy to work with the material even without assistance. It does not need welding equipment, which greatly simplifies the installation process. It takes a little time and effort during the isolation procedure.

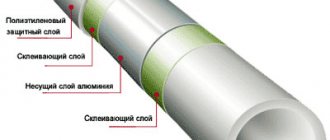

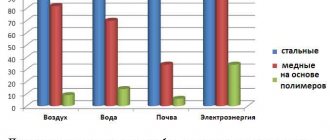

Manufacturers offer several types of pipes, the most popular of which are:

- Polymeric. They are based on polyethylene or polyvinyl chloride. These products are in demand for laying communication and electrical cables. They reliably protect from external negative mechanical influences and moisture penetration.

- Steel. They are in demand for works related to heating. Thanks to them, a reliable shelter is formed, which is difficult to overestimate. They are used in air conditioning, ventilation, in the installation of fireplaces and stoves. The disadvantage for them is their weak resistance to mechanical stress.

If there are no large power loads, then steel pipes will effectively cope with the task.

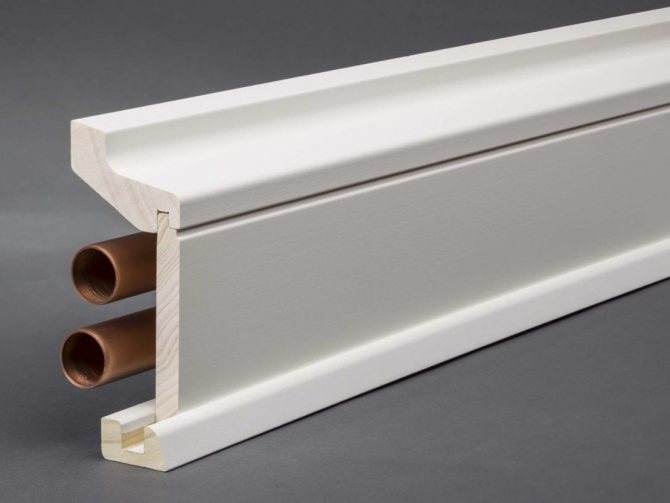

The use of skirting boards

The plinth for heating pipes is widely used. It provides the following results:

- the safety of operation is increased, since the distribution lines of the coolant are hidden;

- there is a reliable fixation of pipes;

- provides an aesthetic appearance in the interior.

Those who want to buy a plinth for heating pipes should know that it is possible to use main pipes with a diameter of not more than 22 mm.

Skirting board

What to do if the pipe is too close to the wall

This situation complicates the installation of a decorative rosette. But nothing is impossible. There are several options for solving the problem:

- try to find the right size for the part. Perhaps the smallest pad will fit into this gap;

- saw through the ring and make the connector wider, thus placing it flush against the wall.

- if you are using wood, you can only take one half of the outline

In the latter two cases, for additional fixation, you will have to use a sealant or liquid nails.

The use of such devices is gaining great popularity. It's beautiful, simple and not expensive. And most importantly, you do not need to rack your brains and come up with various homemade products - everything you need is already in any hardware store.

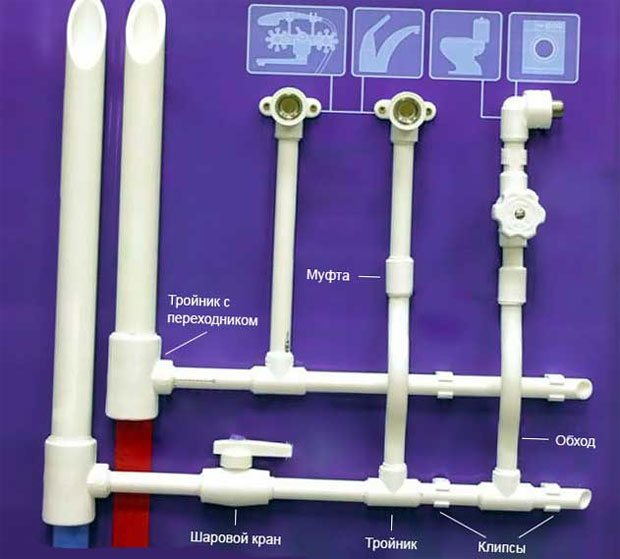

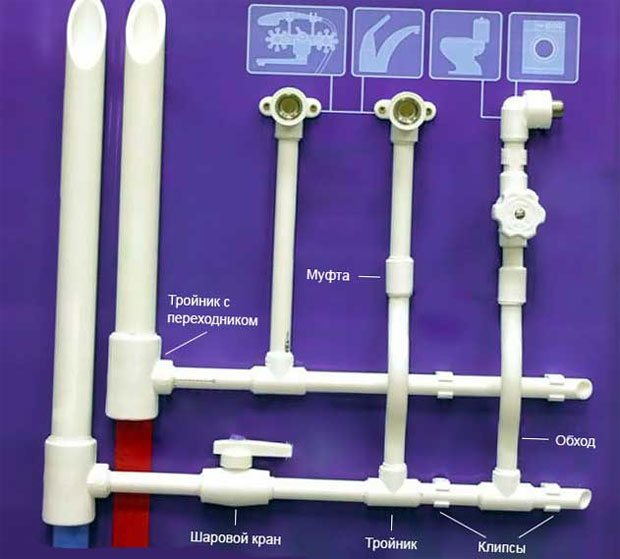

Types and types of water sockets

Water sockets are usually classified according to several criteria.

According to the scope of application of the pipeline element, there are:

- water sockets for cold water supply systems,

- hot water supply,

- heating.

The difference between the latter two and the first lies in the use of materials adapted to high-temperature thermal effects.

Also, water sockets are distinguished by the material of manufacture:

- Bronze and brass. Relatively inexpensive and practical products.

- Stainless steel products. They are able to withstand pressure up to 20 atmospheres, but at a cost higher than other types.

- Galvanized cast iron water sockets. They are cheaper than stainless steel, but less practical, and any damage to the outer protective layer will corrode.

- Polypropylene products, which, due to their reliability and low cost, are becoming more and more in demand among consumers. Perfect for both cold and hot water systems.

- PVC water sockets. They can be used in water supply networks where the temperature of the carrier does not exceed 40 degrees.

We recommend that you familiarize yourself with: How to make the right brick chimney with your own hands?

Note! For all the seeming similarity of polypropylene and PVC water sockets, their use in the same water supply scheme is prohibited. The fact is that these materials are completely incompatible during the soldering process.