Outside and inside diameters are the main parameters of pipes. The length of the pipeline, its working pressure, the parameters of the transported medium and the general functionality depend on these indicators. Since products made of iron and non-ferrous metals are products standardized by GOST, the diameters of copper pipes are expressed in inches and millimeters. It is important to be able to translate these values in order to exclude an error in matching. Especially when it comes to joining line sections made of a different material, since each type of pipe is produced according to its own standards.

Copper pipes are available in different sizes, the diameter of the products is indicated in inches or millimeters

Features of copper pipes

These products are made on the basis of seamless production technology. The material for copper products does not enter into chemical reactions, it is impermeable to various types of liquids, such as fats, oils, and does not promote the growth of viruses and bacteria.

It is known that tap water contains chlorine, but it does not contribute to the destruction of copper pipes, but promotes the formation of a protective layer on their inner surface against oxidative processes, which gives the pipelines increased stability and strength.

By analogy with plastic products, there are almost no build-ups from all kinds of deposits, such as limescale, on copper pipe products. According to the provisions of GOST, a copper pipe can be in working condition at a temperature range between -200 and +250 degrees. These products are very resistant to sudden changes in temperature, since they are characterized by a small value of the coefficient of thermal expansion.

Copper pipes, when water freezes in them, remain intact and in a sealed state. Unlike plastic pipe products intended for water and heat supply, ultraviolet light is not dangerous for copper products. They are painted not so much to protect the pipeline as to give it an appropriate appearance. Today, in order to increase the attractiveness of copper products, chrome-plated products are produced from this material.

Since such pipes are characterized by a low roughness index in comparison with products made of metals and polymers, under equal conditions it is possible to lay a pipeline of a smaller cross-section.

Rules for the selection of pipes for various systems

Each pipeline has its own characteristics, so all parameters should be taken into account when choosing pipes.

Selection of pipes for water supply and drainage systems

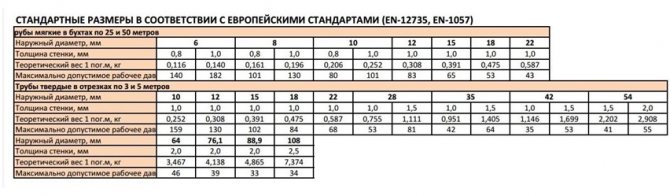

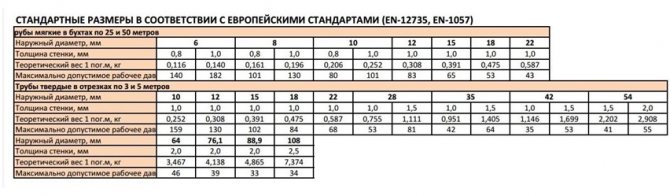

For the water supply system, pipes of circular section with a diameter of 8 mm - 22 mm are mainly used. The wall thickness of such pipes does not exceed 1 mm.

To determine the optimal outer diameter of copper pipes for an indoor water supply system, experts use a complex mathematical formula. An easier way to determine the diameter is as follows:

- if the pressure in the water supply system exceeds 3 atmospheres, then the minimum diameter is 8 mm;

- if more than one tap is connected to the collector, then the minimum pipe diameter is 15 mm;

- if the water supply system is connected from a central collector, then the first connecting copper pipe with a diameter of 20 mm is installed;

- if water is supplied in the system at a pressure of less than 2 atmospheres, then the diameter of the pipes to be installed is accordingly increased by one typical size, that is, instead of 8 mm, 10 mm should be used and so on (table of typical sizes below);

- if the length of the private water supply from the point of entry to the points of consumption is more than 20 m, then in order to obtain the normal water pressure in all devices, it is necessary to increase the nominal dimensions of the pipes by one typical size.

Standard Typical Parameters of Copper Pipes

For drainage systems, pipes with a diameter of 32 mm to 42 mm are used.

Selection of pipes for the heating system

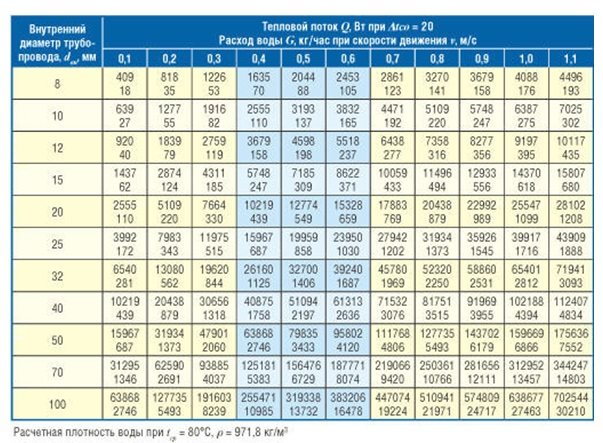

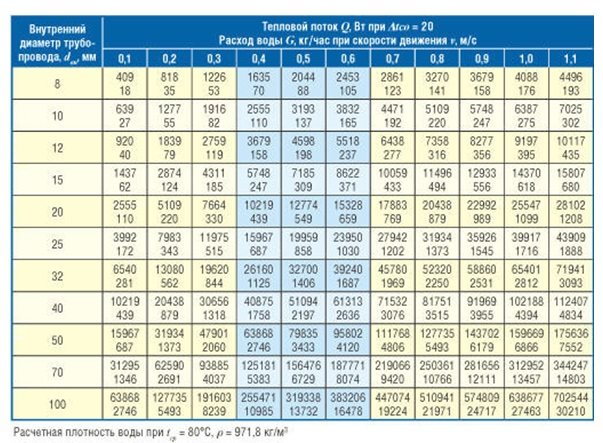

To calculate the diameter of a pipe in heating systems, parameters such as are used:

- pipeline layout;

- pipe resistance coefficient;

- the speed of movement of the coolant in the system;

- inlet and outlet diameters.

It is almost impossible to determine the diameter of the pipes on your own due to the complexity of the calculations, therefore, to determine the parameter, you can use the table below or the calculation method.

Calculation of the optimal pipe diameter for the heating system

The pipe diameter in the heating system cannot be larger than the outlet diameter of the heating equipment.

Copper pipes in the heating system are described in detail in the video.

Selection of pipes for gas supply

Depending on the pressure in the system, gas pipelines are divided into the following types:

- with low pressure (less than 0.005MPa);

- with medium pressure (0.005 MPa - 0.3 MPa);

- with high pressure (more than 0.3 MPa).

Copper pipes are allowed to be used only when installing gas pipelines with low and medium pressure, that is, for domestic gas pipelines.

According to regulatory documents, copper pipes are used for laying the pipeline:

- with a diameter of no more than 15.9 cm;

- wall thickness up to 5 mm.

A more accurate calculation of the diameter is carried out exclusively by specialists.

Scope of copper pipelines

The area of use of copper pipe products is extensive, but most often they are used for laying:

- heating systems;

- pipelines for water supply;

- highways through which compressed air or gas is transported;

- fuel pipelines;

- condensate drainage systems;

- structures for connecting technological equipment;

- pipelines supplying freon to refrigeration units;

- air conditioning systems, etc.

Methods for the production of copper pipe products

Copper pipe sizes vary. When arranging household systems, copper products of two types are usually used:

- unannealed (in more detail: "Types of copper unannealed pipes, characteristics, areas of use");

- annealed.

The first type of pipes are sold in straight lengths ranging from 1 to 5 meters.

In the second case, the products undergo heat treatment - they are fired, after which they become soft, and the strength characteristics decrease slightly, but the installation of copper fittings becomes easier. Annealed pipes are sold to consumers in lengths from 2 to 50 meters, packed in bays.

In addition to products with round sections, manufacturers produce rectangular products. Due to their non-standard shape, such pipes are difficult to manufacture and therefore their cost is higher compared to conventional products.

Cross-sections and sizes of copper pipes

The high malleability of copper makes it possible to make a product of almost any shape from this metal. And even an outdated regulatory document for copper pipes - GOST 617-19 - amazes the imagination with an abundance of standard sizes. In the new GOST 617 of 2006, about 130 units of assortment with original cross-sectional dimensions are included in the range of copper pipes.

Moreover, unlike the first GOST of the 20s of the twentieth century, in the new regulatory document, all dimensions are indicated not in inches, but in millimeters. For example, instead of such a unit of assortment as a copper pipe 3/8 inch, a pipe of 10 millimeters appeared. In addition, previously unprecedented dimensions appeared in the new GOST, for example, a 1/4 inch copper pipe was replaced by two products at once - pipes with a diameter of 6 and 7 millimeters.

The specific dimensions of copper pipes depend on the manufacturing method of the product. So round copper pipes, obtained as a result of cold deformation of the workpiece, have a diameter of 3 to 350 millimeters. The number of standard sizes of rolled tubes exceeds seven dozen.And this is only if the outer diameter is taken into account. The wall thickness of such products ranges between 0.8 and 10 millimeters.

Dimensions of welded products, which include rectangular copper pipes, are smaller. The diameter of such products starts from 30 millimeters and ends with 280 millimeters. The number of products with the original outer diameter in the welded assortment approaches 50. The wall thickness in this case can be more significant: from 5 to 30 millimeters.

The length of rolled pipes depends on the diameter. And pipes with a diameter of up to 18 millimeters are produced in the form of measured segments of 1-6 meters (with a step of 0.5 meters) or coils with a total length of pipes of 10 meters. Larger pipes are produced in the form of measured or unmeasured sections, the length of which ranges from 1.5 to 6 meters.

Of course, the indicated dimensions are characteristic only for domestic products, but the copper pipe KME (a well-known trademark from Germany) may have slightly different dimensions. Indeed, the European Union has its own quality standards.

However, when joining pipes, it does not matter at all what size the jointed product will have. Installation technology depends on other reasons. And what are these reasons you will become clear after studying the next paragraph.

Feature of the installation of copper pipelines

Before starting to create a copper pipeline, you should make the necessary measurements and cut the pipes into pieces. The cut of the product should turn out to be smooth and therefore use a special cutter. By the way, no thread is made on copper pipes.

The connection of individual sections of a copper pipeline can be performed in the following ways:

- by soldering;

- pressing.

The most effective of them is docking using capillary brazing technology, so it has become more widespread. This method ensures the reliability and absolute tightness of the pipe joints. Square copper products are connected using capillary soldering, which is performed using fittings and sockets.

This method of laying pipelines from copper components is used when the pipeline is planned to be operated in conditions of extremely high temperatures.

Compression joining involves the use of different types of fittings, including compression and self-locking. Also, special flanges and clamps are used to provide a tie. Pressing is used in cases where an open flame cannot affect the pipeline.

Installation

Installation of solid and semi-solid pipes is carried out by soldering methods or pressing. For the installation of soft pipes, only compression fittings are required.

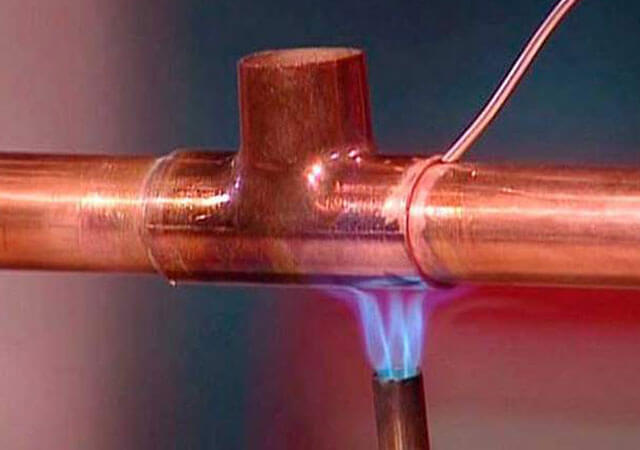

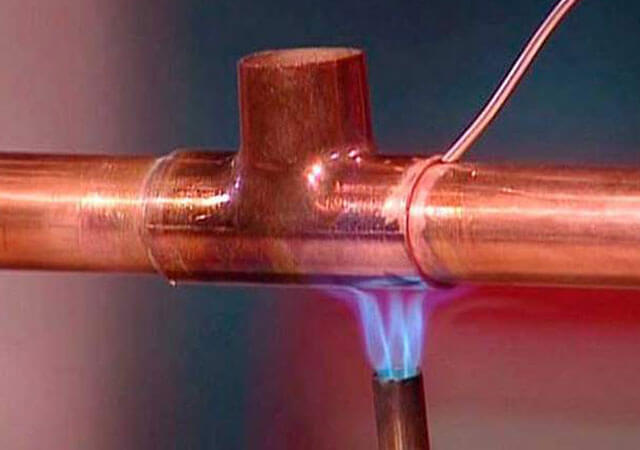

Soldering is done with hard or soft solder. Brazing is carried out using solder (wire) and a gas torch.

The material is heated to a high temperature with a gas burner, solder is used, which, under the action of high temperatures, spreads independently and fills the joints, the joints are fastened with a fitting (coupling, tee, etc.). This method provides high strength of the seam and is suitable for gas supply systems.

Soft soldering consists of creating a sealed joint using flux paste, solder (tin, lead, zinc) and a soldering iron. Before installation, the surface is cleaned of external contamination, covered with flux, the connections are fixed with a fitting and solder is applied using a soldering iron.

In the pressing method, the pipes are inserted all the way into the fitting (crimp) and the connection is fixed using a press., in which the metal is literally pressed into the metal, which ensures the durability and tightness of the joint.

Copper Pipe Fittings

For laying copper pipelines, crimp or solder fittings are used.The first type of connecting elements is usually made of brass. The tightness of such a joint is ensured by the presence of a compression ring inside the fitting, which is tightened with a wrench. A compression fitting is used to connect pipes of different diameters at the location of the pipeline, provided that there is access in order to check the tightness (in more detail: "Which compression fittings for copper pipes are better to use, the rules for choosing compression fittings and installation").

Such parts are usually involved when it is necessary to lay a line designed for operation, when the working medium moves along it under low pressure. In this case, during the operation of the pipeline, it is necessary to periodically monitor the condition of the fittings.

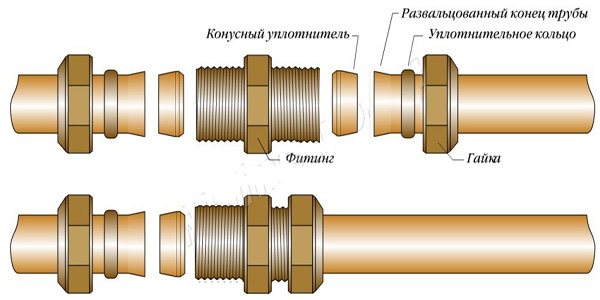

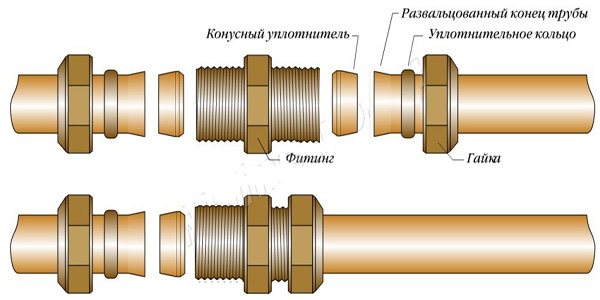

The connection process is carried out in the following sequence:

- The fitting is disassembled into its constituent parts.

- The clamping nut and the clamping ring are placed on the pipe.

- The end of the pipe, which has a ring and a nut, is inserted into the fitting.

- The nut is fixed until it stops, and the tapered ring must be inserted into the tapered part without skewing.

- The nut is tightened with a wrench 0.5-1.25 turns - which depends on the diameter of the pipe used.

When doing the work, the main thing is not to overdo it, because if too much force is applied, the wall of the pipe products can be damaged.

The type of connection described above cannot be called perfect - compression fittings often leak, so their condition should be constantly monitored.

Fitting

The origin of the word fitting is borrowed from English ("Fit"), which translates as connection. Fittings are used for the installation of the pipeline: connections, branching, change of direction, extension and transition to another diameter.

Fittings are classified by appointment:

- Connecting. Coupling - used for fastening pipes of the same diameter, adapter coupling - for connecting different diameters, combined coupling - for fastening different materials, for example, copper and steel.

- Branching... Tees (150, 300, 450, 900), crosses: one-plane, two-plane, left, right, front, horizontal (150, 300, 450,900), solder and threaded manifolds (the number of outlets is not limited).

- Squares, bends and bypass elbows (single-socket, double-socket). They are used for bends, turns, and obstacle lines in the pipeline.

- Plugs - for soldering and threaded (internal and external).

Distinguish fittings by fastening method:

- Threaded... Equipped with a thread on the inside, with which fixation occurs.

- For soldering or for welding - the most common fittings used in brazing installations.

- Compression and press fittings... They are used for installation by pressing. The clamping ring ensures tightness.

- Crimp... They are used in the assembly of metal-plastic, copper, aluminum pipelines by twisting. The tightness is ensured by the clamping relief ring.

- Self-locking... Fixation takes place using a crimping gear ring. This connection is very convenient, since it remains collapsible after assembly.

For copper pipes, copper and brass fittings are used for soldering (soldering method), crimping and compression (press method) and threaded (the fitting is sealed to the pipe, then fixed by the twisting method).

How to correctly and rationally choose pipes for water supply in a private house. PVC pipes and fittings for plumbing have many advantages, read here.

How to properly make water supply to a private house from a well with your own hands, find out more in our article.

Docking copper pipes with other materials

When laying communications from copper pipes, they can be docked with pipe products made of plastic, steel and brass.With regard to the connection with galvanized products, experts recommend avoiding such combinations, since there is a high probability of chemical processes between two elements - copper and zinc.

When joining pipes of this type, brass fittings are used - they are mounted so that the movement of the water flow occurs in the direction from zinc to copper.

Modern copper pipe products are durable and therefore such a water supply system will be an excellent choice.

Output

Using the information above, you can quite easily determine the diameter in mm of a copper pipe 1 2 inches, calculate the specific gravity of such a product, and understand whether it is suitable for the task before us. However, over time, a skill will appear, and you simply won't have to do calculations.

And in order to develop this skill faster, we recommend that you often apply the knowledge gained in practice, and carefully study all the available additional information, first of all, the video in this article.

Did you like the article? Subscribe to our channel Yandex.Zen