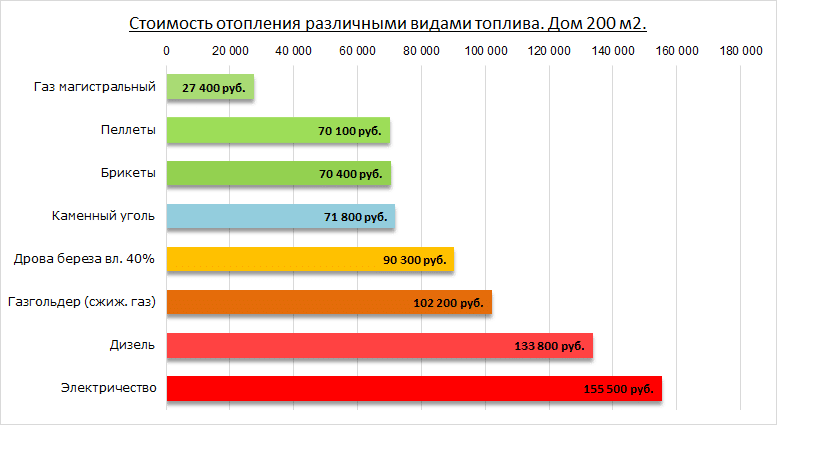

Calculating the consumption of pellets for heating in advance is the primary task of the owner of a private house who wants to install a pellet boiler. After all, granular fuel is more expensive than firewood, and the price of equipment is higher in comparison with solid fuel or electrical units. One pellet burner is comparable in cost to a whole wood-fired heat generator. To find out the costs of pellet heating, you need to make a simple theoretical calculation, which will be discussed below.

Pellet consumption calculation - initial data

To find out the theoretical fuel consumption for heating a country house, it is necessary to collect the following initial data:

- the amount of heat load on the heating system of a cottage or country house, expressed in kW;

- The efficiency of the pellet boiler model that you plan to install in your furnace;

- calculated heat of combustion of fuel pellets;

- to get the result in monetary terms, it is advisable to find out the price per ton of pellets in your region of residence.

The most difficult thing is to get a figure for the real heat load. It consists of heat losses through external walls, roofing, glazing and floors, plus the cost of heat energy for heating the ventilation air.

The ideal option is to contact a qualified heating engineer for such a calculation, then you will find out the exact figure. Otherwise, you will have to consider the heat load and fuel consumption in enlarged ways:

- Specific heat consumption per square meter of area. For dwellings in central Russia, it is assumed that a room with 1 window and one outer wall will consume 100 W of heat per 1 m², with two outer walls - 120 W / m², with 2 walls and two windows - 130 W / m².

- The same in relation to the volume of the premises. The method is used when the ceilings of the rooms exceed 2.8 m. The total heated volume is calculated, the resulting figure is multiplied by 40 W.

Comment. In the example of the calculation discussed below, the heat load for a private house of 100 m² is conventionally assumed equal to 10 kW, since the consumption of pellets is determined in an abstract building with a pellet boiler of an unknown manufacturer.

The heating unit together with the bunker takes up a lot of space, one of the placement options is in the basement or in the basement

The efficiency of a heat generator that burns wood pellets is indicated in its technical data sheet. If the model and manufacturer have not yet been selected, then the figure of 80% can be taken for calculations. Manufacturers leading the rating of heating equipment (for example, Viessmann or Buderus) declare the efficiency of their pellet boilers equal to 85%. But these are high-quality and reliable units that are not cheap. More affordable heaters are not as efficient.

The theoretical calorific value of pellets is a known value, it lies in the range of 4.9-5.2 kW / kg, depending on the quality of the fuel and the raw material from which they are made. If you do not take into account peat granules with high ash content and low heat transfer, then for calculations it is worth taking the average figure - 5 kW / kg.

Advantages and disadvantages of pellet fuel

As a kind of fuel for the home, many people doubt pellets - after all, firewood or coal is much more familiar. Let's try to understand the positive and negative qualities of fuel pellets. Pellet advantages:

- easy to transport;

- environmentally friendly;

- form colorless smoke and do not emit unpleasant odors during combustion;

- stored for a long time;

- when choosing heating with pellets, you can purchase special equipment with automatic fuel supply, that is, to almost completely minimize manual labor.

Note! When heating a house with pellets, no permits are needed to connect the boiler, in contrast to the use of liquid fuel.

Cons of pellet fuel:

- high price of heating equipment;

- purchase, delivery of fuel and maintenance of boilers can cause difficulties if the house is located in a village remote from a big city;

- presence on the market of low quality raw materials.

Important! Pellets can only be stored in a well-ventilated and dry place - if they come into contact with moisture, they can become damp and become covered with fungus.

How to calculate the consumption of pellets

The calculation is carried out in several stages, although in general it is quite simple. Its result should be the average monthly fuel consumption of a pellet boiler during the heating season and the average cost of such heating. For the sake of clarity, we will consider an example calculation for a 100 m² house.

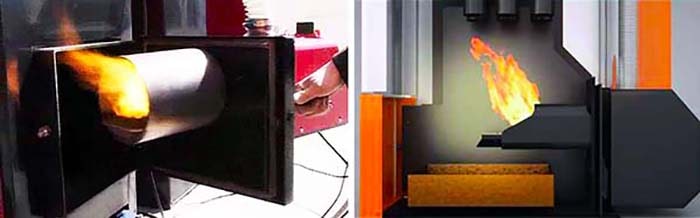

The torch-type burner is automatically ignited and extinguished at the command of the controller, this allows you to significantly save fuel

Stage one. First you need to understand how much heat actually gets into the heating system when burning 1 kg of fuel pellets. After all, the heating equipment is not so perfect as to direct all the energy received to heat the house, some of it will fly out into the chimney. For this, the heat of combustion of the pellets should be multiplied by the efficiency of the heat generator divided by 100:

5 kW / kg x 80% / 100 = 4 kW / kg.

Stage two. For the convenience of calculations, it is necessary to perform the opposite action in order to find out how much pellets need to be burned to obtain 1 kW of thermal energy in real conditions:

1 kW / 4 kW / kg = 0.25 kg.

Stage three. During the heating season, the weather outside changes and the temperature ranges from + 10 ° С to -30 ° С. Specific heat consumption on average for the entire season for a house of 100 m² will not be 10 kW, but half as much - 5 kW. Considering that the units of power are related to the time of 1 hour, the heat consumption per day will be:

5 kWh x 24 hours = 120 kW.

The same, only for a month:

120 kW x 30 days = 3600 kW.

Stage four. Now it is easy to calculate the average consumption of pellets per month for a building of 100 m² during the entire heating season:

3600 kW x 0.25 kg / kW = 900 kg.

If the cold season lasts 7 months, as in Moscow in the Russian Federation, then the total amount of fuel pellets for heating a private house with an area of 100 square meters will be 900 x 7 = 6.3 tons. In the same way, the average monthly consumption of pellets for a house with an area of 150 and 200 m² is determined, it is equal to 1.35 and 1.8 tons, respectively. Since pellets are sold by weight, not by volume, there is no need to convert this quantity into volumetric units.

Those who are interested in the approximate consumption of wood pellets on average per day can calculate it in this way (for our example):

120 kW x 0.25 kg / kW = 30 kg.

Attention! The calculated average should not be confused with actual fuel consumption on the coldest and warmest days. In a building of 100 m², it can vary between 15-60 kg of pellets per day.

To get approximate costs for pellet heating in monetary terms, you need to multiply the obtained figures by the price per ton, adopted in your region. At the prices of the capitals of the Russian Federation and Ukraine, the monthly costs for heating a private house of 100 square meters will be:

- for Moscow: 0.9 t х 8500 rubles / t = 7650 rubles;

- for Kiev: 0.9 t х 3000 UAH / t = 2700 UAH.

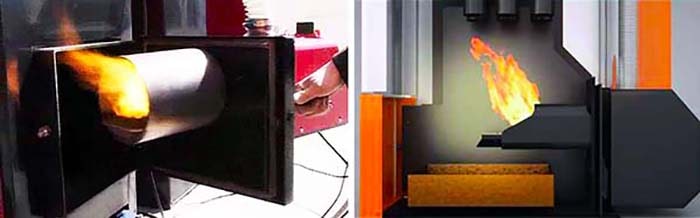

A retort burner is cheaper than a flare burner, it can be installed in a conventional TT boiler

It should be borne in mind that we carried out an abstract calculation, in the conditions of Ukraine the financial costs for pellet heating will be less due to the milder climate.

Features of pellet heating systems

In order to evaluate the efficiency of pellet heating, you need to know about the difference that exists between ordinary wood and pellets. During the manufacture of pellets, woodworking waste is used. Raw materials for the production of pellets or ordinary sawdust are first thoroughly dried, then treated with steam, as a result of which a viscous mass is formed, from which, under a pressure of 300 atmospheres, cylindrical granules with a length of about 70 mm and a diameter of 6 to 8 mm are formed. Boilers supplied to the market by manufacturers of pellet equipment differ from their counterparts using ordinary firewood as fuel, and have a higher degree of heat transfer. Quantitative indicators of the calorific value of various types of solid fuels are shown in the table.

| Fuel type | Calorific value (kW / kg) |

| Firewood | 2,84 |

| Fuel briquettes | 4,7 |

| Pellets | 4,99 |

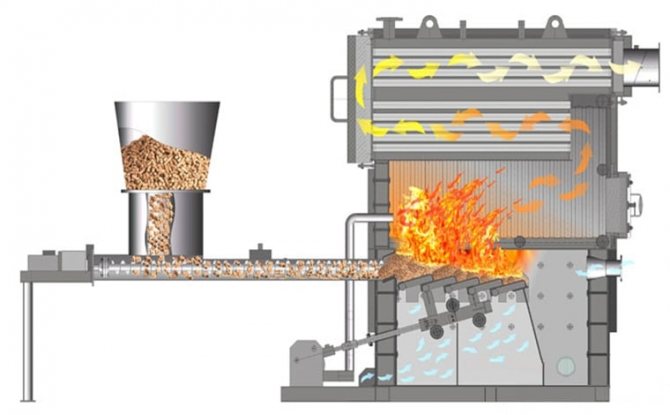

In addition to high heat transfer, pellet boilers have another advantage - their combustion chamber is loaded automatically. Automatic fuel supply is implemented as follows:

- In a special hopper made of stainless steel, a certain stock of pellets is stored. The presence of a bunker of significant volume allows it to be refueled with fuel once every few days.

- Fuel enters the boiler through a flexible cable and an auger located inside it. The granules by their own weight drive the auger into rotation, which ensures their supply to the boiler distribution chamber in the required amount.

- Further, from the distribution chamber, the pellets enter the zone of the air burner, where their incomplete combustion occurs, accompanied by the release of wood gas.

- The main source of high heat transfer is wood gas, which is completely burned in the afterburner.

Such a boiler design allows its owner, during continuous operation of the equipment, to fill the bunker with fuel only once every 3-4 days and remove solid combustion products, i.e. ash.

Real expense - user reviews on forums

The results of the theoretical calculation reflect only the general picture and give an understanding of the order of the figures of financial costs for wood pellets. The indicators published by users of the forums, for real heating with pellets, may differ depending on many factors:

- the efficiency of the heating unit;

- weather conditions in the region of residence;

- the degree of insulation of a residential building;

- the quality of the fuel used.

Therefore, homeowners who are inclined to heat with pellets of their country house, it will not hurt to study the reviews of real users and, on their basis, collect statistics and draw appropriate conclusions. Here are some of these reviews:

- Vladimir, Sochi, RF. I heat a part of the house with an area of 50 m² with pellets. At an outside temperature of 5-10 degrees of frost, I can withstand + 24 ° C in the rooms. About 20 kg of granules of the first grade, white, are consumed per day. The walls are aerated concrete, there is no insulation. The indicator suits me, I will finish the rest of the premises and I will heat the whole house with pellets (85 m²).

- Alexander, Moscow region, RF. Warehouse 400 squares with a ceiling height of 3.6 m, pellet boiler "Teplodar" with an APG-25 burner. When it is minus 30 ° С outside, it is possible to maintain + 10 ° С in the warehouse. On average, the boiler "eats" 120 kg of pellets per day, and the amount hardly changes when burning different pellets. We tried both white and brown, everything is the same.

- Valery, Kharkov, Ukraine. I put a pellet boiler in a one-story house of 140 m², I heat around the clock, stop once a week and clean for 30 minutes. I keep it inside +22 ° С, the consumption of pellets was recorded at a temperature overboard of -15 ° С - 50 kg per day. The walls are brick with foam insulation 5 cm, the roof was insulated with sawdust, I think to add Isover glass wool. In general, it is acceptable, and it is difficult to refuse comfort, you no longer want to indulge in an ordinary solid fuel boiler.

- Nikolay, g.Ochakov, Ukraine. Built a brick house with a heated area of 120 m² (total 140 square meters). The wall thickness is 1 brick (250 mm) plus external insulation with foam plastic 15 cm. My first boiler is just a pellet boiler, I am satisfied with the results. For the whole season I used up about 4 tons of pellets, I will not say for sure, because I bought in addition in the spring in packages.

Criteria for selecting the power of a pellet boiler

How to calculate the power of a pellet boiler? The criteria are as follows:

Collapse Contents:

- Heated area

- Wall material

- Wall thickness

- Indoor temperature

- Pellet quality

- Other factors

- Formula for calculation

- Calculation of power and approximate consumption of pellets for the house

- 35 sq.m

- 64 sq.m

- 100 sq.m

- 150 sq.m

- 200 sq.m

- 250 sq.m

- findings

- Room area. Power is taken at the rate of 1 kW per 10 m2. Household models start at 15kW. We recommend taking 20% as a reserve.

- Pellet boiler efficiency. It fluctuates from 85% to 95%. With the same power indicators, we choose the one whose efficiency is higher.

- The use of alternative fuels will reduce power by 20-40%.

- Using raw pellets will result in another 25-35% power loss.

Heated area

The area of the room is the main criterion for choosing a boiler. Winter temperatures can drop well below average. The cost of additional insulation can significantly exceed the cost of purchasing a more powerful modification of the boiler and cause a lot of household hassle.

Wall material

Different materials have different thermal conductivity. The lower the thermal conductivity of the wall, the less heat loss. For the calculation, you can take the thermal conductivity coefficients from SNiP 23-02-2003 and from SP 50.13330.2012.

The material changes its thermal conductivity under different operating conditions, in particular, with an increase in humidity. The thermal conductivity coefficient under different operating conditions can be found on the manufacturer's website.

Here is the average thermal conductivity of some materials under normal conditions:

- brick - 0.7 W / (m * ° C);

- reinforced concrete - 1.92 W / (m * ° C);

- pine - 0.14 W / (m * ° C);

- foam concrete - 0.28 W / (m * ° C);

- oak - 0.18 1.92 W / (m * ° C).

Wall thickness

The thickness of the wall is determined by a heat engineering calculation. Special complexes simplify the calculation process, where the user needs to enter initial data. The machine will carry out the calculations and give the finished result.

Window and door openings increase thermal conductivity. The larger the opening area, the higher the heat loss. The use of modern metal-plastic double-glazed windows can partially solve this problem.

Indoor temperature

Walls are only part of the sources of increased thermal conductivity. Heat transfer passes through the ceilings, the roof. The presence of a basement room will further increase heat loss. For maximum saving of resources, all structures must be carefully insulated.

A comfortable room temperature is +22 - +240 C. The optimum humidity is 60-80%. Supply and exhaust ventilation must be provided to create a full air exchange.

Pellet quality

Fuel quality plays a decisive role in heating your home. It is worth using raw pellets, and the boiler output will drop by 25-35%. Part of the energy obtained during combustion will be used for drying low-quality pellets. It is imperative to ensure optimal storage conditions for fuel. First of all, it must be a dry and warm place.

Raw materials also play an important role. In the west, this type of fuel has been used for over a century. The production system and criteria have been worked out and standardized at the state level. Our country cannot boast of this.

Uniform quality standards have not been developed for this type of product. Each manufacturer is forced to focus only on its own, alas, not rich experience. There is a high risk of buying substandard products.

Pellet boilers can operate on almost any type of solid waste.There are models that support different types of fuel. But the efficiency of such boilers is usually much lower.

Other factors

Other factors influencing the choice of a pellet boiler include:

- geographic area;

- average annual rainfall;

- average wind strength and direction;

- conditions and frequency of operation of the dwelling;

- type of fuel used;

- the quality of the materials from which the boiler is made;

- ceiling height;

- cost.

It is simply impossible to take into account all the factors in the calculation. Their performance can change quite significantly over time. For example, winter may be colder than usual. Or the wind speed, instead of the usual 4-6 points, will be 8 - 9.

findings

If you analyze the reviews and collect more statistics, it turns out that the estimated consumption of pellets for heating is not too different from the real one. If initially the calculation was done according to an enlarged scheme, the results are comparable to fuel consumption in a poorly insulated private house. When you have real indicators of heat load, then you will calculate the financial costs for pellet heating quite accurately.

When calculating costs, do not forget about the consumption of electricity by the boiler, for which you also pay money according to the meter. It must be taken into account, because the power consumption of the auger motor, electric ignition device and controller can reach 400-500 W / h, which is very significant. The power of an additional auger conveyor can be added to it, if you have one installed to move the pellets from the storage to the hopper.

Fuel quality criteria

As you might guess, in order to release a significant amount of heat energy, the pellets must be of the appropriate quality. Unfortunately, given the ever-increasing popularity of this heating method, low-quality fuel samples from unscrupulous manufacturers or outright crooks began to appear on the market. Undoubtedly, the use of handicraft technologies does not allow achieving effective heat transfer. There is a widespread misconception among many owners of pellet boilers that fuel consumption depends on the color of the pellets. This is not at all the case. High-quality dark-colored pellets are made on the basis of wood fractions in which tree bark is present, light yellow pellets are made from furniture industry waste, and dark brown pellets are made from logging waste. High quality pellets have a fairly high density, the numerical value of which exceeds 1, so they must sink in water. Also, an important parameter that determines the quality of this type of solid fuel is the amount of ash remaining after complete combustion of the pellets (ash content). According to the norms adopted in a number of European countries, this figure should not be more than 1.5%. In other words, after burning 10 kg of fuel, no more than 150 g of ash should remain. If this figure is higher, a significant amount of slag will form during combustion. And this significantly reduces the boiler performance.

In addition to the characteristics described above, high quality pellets should have the following characteristics:

- The moisture content of the pellets should not be more than 10%, otherwise the consumption of pellets will be significantly increased in view of the need to compensate for the loss of heat capacity.

- The dust content must not exceed 11%. Exceeding this indicator is accompanied by an increase in ash content.

The packaging must be airtight. The most optimal option is when the granules are sold in special bags with a waterproofing film on the inside. Such packaging allows the granules to retain their original quality characteristics for many years. Currently, 1 kg of fuel costs from 6 to 10 rubles.If a bunker of considerable volume is used with the boiler, it is best to purchase fuel in large bags (big bags). The weight of one such bag is 900 kg.

Combined solid fuel pellet boiler

Pellets are pressed wood that has been pre-shredded. It has high efficiency and automatic operation: all that remains is to fill up the fuel. The boiler does the rest.

The only thing that needs to be done is to remove the ash once a week.

When choosing such a technique, maintenance will have to be done minimal.

The consumption of pellets per day in winter at 25 kW is approximately 4-5 kg / hour - the maximum. When the boiler is on modulation, it is 1-2 kg / h. Such a boiler turns itself on and off: everything happens automatically. Hopper volume: at 240 l it can load 150-180 kg of pellets - depending on the size of the pellets. Works on different pellet diameters. If they run out, you can also load firewood.

The boiler is not picky about the type of fuel, since there is no GOST for pellets in Russia and manufacturers produce such combined boilers. If the pellets are of poor quality, then the boiler will work with reduced efficiency; when burning, low-quality material remains inside the boiler.

How to check pellets for quality? Take a glass of water and a handful of pellets. Let's mix all this: if in a few seconds the pellet has collected water and drowned, then this is a good pellet; if it continues to swim for a minute, it is most likely of poor quality.