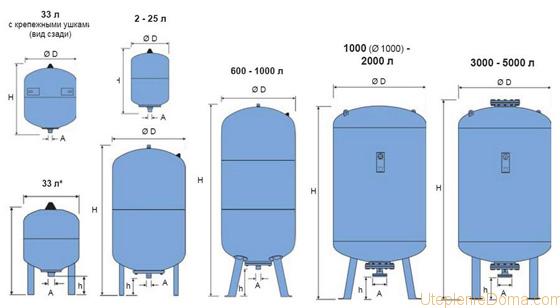

Tank sizes

After reading this material, you can once and for all leave behind the problem of calculating an expansion tank for closed and open heating systems. Below you can find the formulas. The topic of possible problems due to the wrong choice of this equipment is also touched upon.

One of the key tasks that must be performed is the calculation of the expansion tank for a closed heating system. In turn, in open circuits, this does not matter so much. In principle, the calculation is not difficult if you have the information. Despite the simplicity of the calculations, in practice mistakes are made that lead to negative consequences. The most common mistake is negligent choice. It so happens that people do not pay enough attention to calculating the volume of the expansion tank for heating and begin to understand the nuances only after the first problems appear and the system requires repair.

Possible problems

First, let's look at the consequences of incorrectly calculating the expansion tank for a closed heating system. Perhaps you also have an unusable reservoir for your system, and you do not even know about it. If the volume of the tank has been calculated correctly, there will always be a stable pressure in the circuit. It doesn't matter if your system is open or closed, the calculation of the volume of the expansion tank for heating both types is similar, since the principle of their operation is approximately the same. The bottom line is that the water in the pipes acts as a heat carrier.

That is, it carries heat around the entire circuit and gives it away through radiators and pipe walls. Thanks to this, the room becomes warm. In this case, the amount of water always changes. After it heats up, there is more of it, and after it cools down - less. It is impossible to squeeze water mechanically, which means that you need to temporarily remove its excess from the circuit. And it is necessary in such quantities that the pressure in the system is always kept at the required level, without drops. So we come to the main thing - these are pressure drops.

If pressure drops occur in the circuit, these are the first bells of malfunction. This may be due to the incorrectly calculated volume of the expansion tank for the heating system.

Calculation example

The example below shows how to choose an expansion tank for heating a cottage with the following parameters:

- total area - 180 sq. m .;

- number of floors - 3;

- ceiling height - 2.5 m;

- heat carrier - water with the addition of ethylene glycol 20%;

- working pressure - 2.5 atm;

- maximum temperature - no more than + 80C.

Calculation of the volume of the expansion tank:

- set the total height of the heated premises: 3 * 2.5 = 7.5 m;

- the compensating pressure will be: DB = 7.5 * 0.1 = 0.75 atm;

- determine the efficiency: E = (2.5-0.75) / (2.5 + 1) = 0.5;

- to heat such a building, you will need a boiler with a capacity of 18 kW (one kW for every 10 sq. m of area);

- without accurate measurement, you can set the approximate amount of heat carrier as follows: 18 * 15 = 270;

- substituting the values into the formula, calculate the volume of the expansion tank for heating: O = (270 * 0.0349) / 0.5 = 18.846 liters.

Next, we will select a suitable model in the list of current offers. It is necessary to purchase a tank with a margin of capacity in order to eliminate problems during operation.

The design parameters correspond, for example, to Reflex NG 25 with the following characteristics:

- tank volume - 25 l;

- mounting method - wall-mounted;

- maximum pressure - 6 atm;

- coolant temperature - no more than +120 С;

- connecting dimensions of the liner - 3⁄4 inch;

- diameter x height - 28 x 50 cm;

- empty product weight - 4 kg.

In a similar way, a water supply expansion tank is purchased: the choice, installation corresponds to the above recommendations. The main difference is that only clean water is used in the transport system so that the water supply tank is selected correctly.

The required expansion factors should be used in the calculations. The formulas take into account the capacity of the transport system and the boiler.

The expansion tank for water supply (hot) is designed for a lower operating temperature compared to the analogue discussed above (up to +70 C). To eliminate errors, manufacturers use blue and red color on the outer surface of the case (hot water supply and heating, respectively).

At the same time, they increase strength to prevent damage from water hammer. Serial products are able to withstand an increase in pressure up to 10-12 atm.

The selection of an expansion tank for hot water supply is performed simultaneously with shut-off devices, pressure gauges, and other related parts.

How do the drops occur?

Possible options:

- increase;

- lowering.

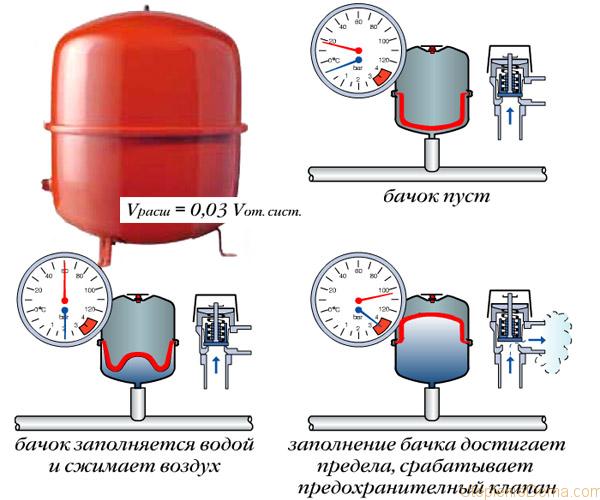

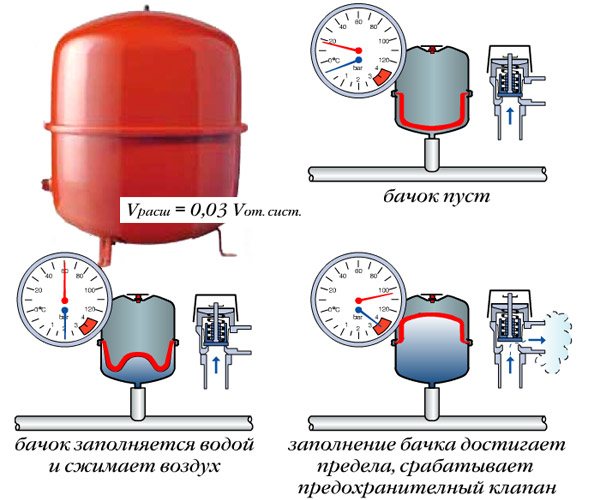

Both processes are interconnected. An increase in pressure in the circuit means that the coolant has nowhere to go after it has increased in volume. One of the reasons, not the only one, may be the incorrect calculation of the expansion tank for closed-type heating. How does this happen in practice? Take, for example, a circuit containing one hundred liters of coolant:

- there is one hundred liters of cold liquid in the system;

- the boiler turns on and heats the coolant;

- the water expands and it becomes no longer a hundred, but approximately one hundred and five liters;

- excess liquid must go somewhere. For this, an expansion tank is installed in the circuit;

- after the coolant cooled down, it was not enough in the circuit, as part of it squeezed out into the tank. Accordingly, the water must be returned to the pipes, which happens if everything is fine.

Pressure drops

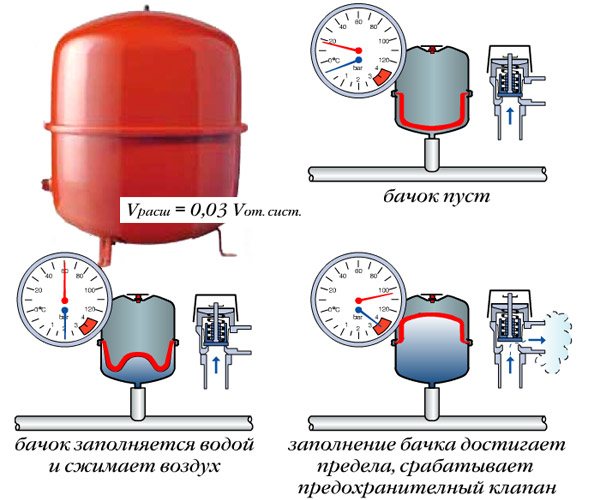

If the volume of the expansion tank for a closed heating system is less than necessary, then all the liquid that does not fit will be discharged outside. Special valves are provided in the circuit that release the coolant if the pressure rises to a critical level. Modern boilers are also equipped with such valves. This is a prerequisite for the safe operation of heating. An increase in pressure can even lead to an explosion. Imagine the consequences when the pipes simply burst and hot water flies in all directions. In addition to the fact that you can get injured from a shock, such an emergency could cause burns to people and animals in the vicinity.

Later, after cooling down, the water decreases in volume. The liquid from the tank is forced back into the pipes, but the coolant is still not enough. This is because the withdrawn water did not return to the outside, it left irrevocably. As a result, the pressure in the circuit drops sharply. This leads to the following results:

- stopping the boiler. Heaters have a certain minimum pressure threshold at which it can operate. If this value is not maintained, it simply cannot turn on, the automation does not allow it to be done;

- defrosting the system. If the stopping of the heating equipment occurred in the winter, and you are not at home, a serious accident may occur. The system will freeze in a few hours, depending on the level of thermal insulation of your home;

- the need for recharge. It is necessary to add the missing amount of water to the circuit.

These are the results of gross errors made when calculating the expansion tank for heating, or if you relied on a tank built into the boiler.

Modern boilers have built-in tanks, the volume of which is often insufficient.Be sure to take this fact into account and, if necessary, install additional tanks.

It also happens that the tank is completely filled, the pressure continues to rise, but does not reach the critical level. The pressure gauge needle balances on the verge of the operating maximum of the circuit, while everything is functioning. Such cases are countless. People very often ask questions about such differences. Of course, such processes worry them, since they are not the norm. With such increases, the circuit operates under extreme conditions, which leads to its early wear. Also, such processes adversely affect the boiler, and it costs money and is not small.

Varieties

Depending on the design, they are divided into open and closed.

Open

These are cylindrical or rectangular tanks that mounted at the top of the heating system (often in the attic)... The tank is connected to the water supply system to replenish the water supply and to the sewerage system to drain excess coolant.

Photo 1. Expansion tank of open type. The unit is rectangular, installed at the top of the heating system.

The disadvantage of this type of equipment is that there is no automatic adjustment of the water level. You will have to control the amount of liquid in it visually, and to add water, open the valve in front of the inlet pipe. Another inconvenience is the complicated installation, because the tank has a considerable weight, and it will have to be lifted to the attic. Due to the described nuances, this type of equipment was almost supplanted by closed-type tanks.

Closed

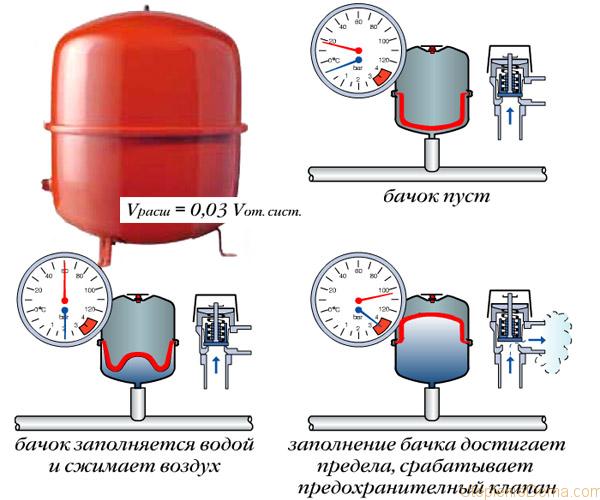

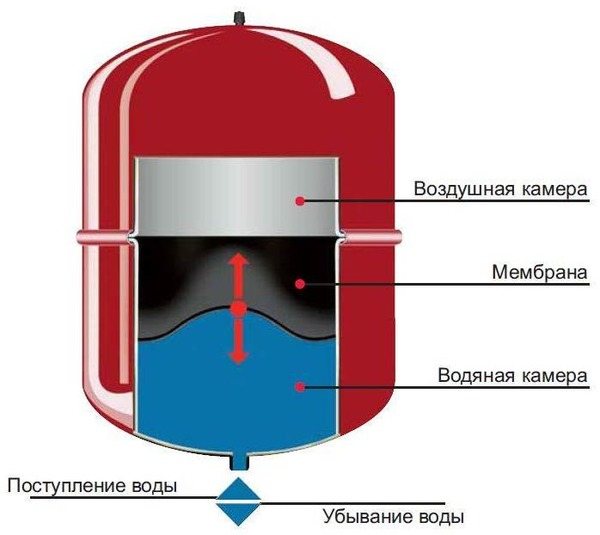

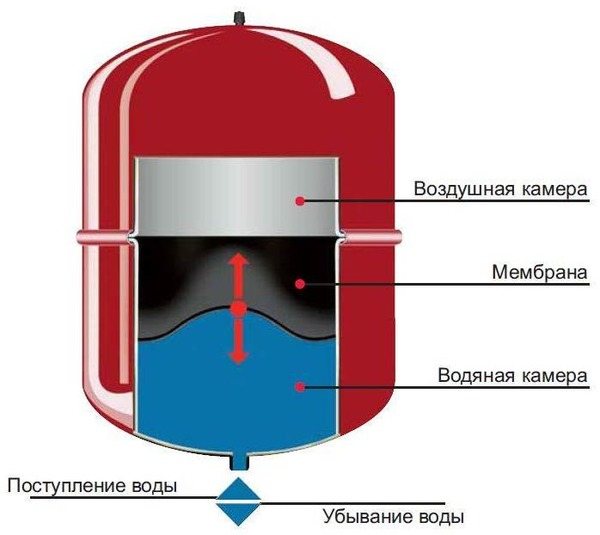

Design spherical or oval with two chambers inside: one for air and one for water coming from the heating system. They are separated from each other by a membrane, which is a bag-shaped rubber reservoir that expands and contracts.

When water enters the first chamber the membrane stretches and air comes out of the second chamber through a special valve. When the liquid cools down, the membrane begins to return to its original position and squeezes the water back into the heating system.

Photo 2. A fairly simple device of a closed expansion tank. Arrows indicate the components.

Depending on the type of membrane, there are two types of closed expansion tanks:

- Equipped with a non-removable diaphragm diaphragm

The design is highly durable due to the production by cold stamping. In addition, tanks of this type have anti-corrosion protection of the surface from the outside and inside. The tank cavity is divided into two chambers by an elastic membrane. The coolant flows from the system to the lower chamber. When the diaphragm is in the desired position - it is on the surface of the liquid - the device is ready for operation.

- Flanged

The diaphragm is connected to the inlet pipe by means of flange fasteners, which allows you to replace a worn out membrane with a new one... The coolant is inside the membrane and does not come into contact with the walls of the tank, which makes it possible not to resort to anti-corrosion measures.

Closed expansion tanks often mounted next to heating boilers. The second option is installation near the boiler, if you plan to install a double-circuit heating system providing hot water supply.

Volume selection

Let's consider separately how to calculate an expansion tank for heating sealed and open types. Since the design and principle of operation of such tanks are completely different, although both perform the same function.

Open tank

The dimensions of the expansion tank for an open heating system, by and large, determine its volume, since the design of such a tank is quite simple.It is made from sheet metal. It has a hole through which the coolant enters the inside and goes back into the pipes. They can also be equipped with an overflow hole through which excess water is discharged into the drain.

It happens that an automatic make-up is brought into the tank. But the main thing is how the expansion tank in the heating system is calculated, or rather, its volume. Let's take the same system with one hundred liters of water. After heating, the liquid will increase by five percent, maybe more, depending on the temperature in the circuit. It turns out that the volume of the expansion tank for this open heating system should be at least five liters, preferably more. And the calculation of the expansion tank for the heating system is reduced to the following algorithm:

- five liters is the expansion of the water;

- a couple of liters should always be in the tank - this is to prevent air from entering the circuit;

- three liters must be made in reserve.

Based on the calculation of the volume of the expansion tank for heating, it receives ten liters. By the way, this is the simplest and most common selection method - ten percent of the amount of water in the circuit.

The easiest way to calculate the volume of an expansion tank for heating is to calculate a tenth of the total amount of coolant. This is a value with the necessary margin, at which everything will work like clockwork.

For closed systems, in addition to the simple, popular, method for calculating the volume of the expansion tank of the heating system, there are more accurate methods. To take advantage of them, you need to know several meanings. These include:

- how much the volume of water (RH) increases when heated. Answer: five percent. The value has been rounded to the nearest whole number without fractions for convenience. If an anti-freeze liquid circulates in your circuit, then this value will be higher;

- how much water is in the circuit (VC). Such data should already be available from the design stage. Since the selection of the heater is based on this value. If it so happens that you do not know how many liters there are, all that remains is to measure. The first thing that comes to mind is to completely drain all the liquid from the circuit and refill it. The number of liters can be measured in buckets, or you can use a special counter that is installed on the stream;

- what is the maximum pressure the circuit and the boiler (DK) are designed for. This value can be read on the heater documents, or on the heater itself. It is unlikely that it will happen that there are neither documents nor information on the boiler body. But if it really happened, then the Internet will help you;

- what is the pressure in the air chamber of the expansion tank (DB). This is also indicated in the technical documentation.

To calculate how much volume of the expansion tank is needed for heating, a simple mathematical calculation should be performed:

OV x VK x (DK + 1) / DK - DB

Based on the results of calculating the capacity of the expansion tank for heating, you will receive an accurate value. The question of the expediency of such complex calculations remains open. Undoubtedly, according to the results of this formula for calculating the expansion tank of the heating system, a lower value will be obtained than according to the results of the "folk" method. But a larger margin of error is not an error. If the tank is larger than what you need, it's okay, you just need to set it up correctly.

Selection of the device according to the calculation

Before proceeding with the calculation of the membrane, you need to know that the larger the volume of the heating system and the higher the maximum temperature indicator of the coolant, the larger the volume of the tank itself.

There are several ways in which the calculation is carried out: contacting specialists in the design bureau, making calculations yourself using a special formula, or calculating using an online calculator.

Formula

The calculation formula looks like this: V = (VL x E) / D, where:

- VL is the volume of all trunk parts, including the boiler and other heating devices;

- E is the coefficient of expansion of the coolant (in percent);

- D is an indicator of the effectiveness of the membrane.

To what level to pump the air chamber

It is important to correctly adjust the expansion tank for closed-type heating. The calculation of the capacity is, of course, a serious aspect, but even if it is done correctly, the tank can still work in an inappropriate way. To deal with this, let's briefly dwell on its design. It consists of two compartments with a rubber gasket between them. There is no connection between cameras. There is a nipple in the air compartment.

During operation, water fills the volume of the tank chamber, while the membrane is stretched. If the pressure in the air chamber is too high, it will simply prevent the elastic from deforming. As a result, the tank does not work. The air chamber must be two tenths of an atmosphere less than the operating pressure of the boiler. Alternatively, use the manufacturer's recommendations for customization.

Types of tanks

All tanks are divided into types according to two criteria: the method of installation and the material of manufacture. According to the method of installation, the tanks are:

- built-in;

- portable;

- samovar type (mounted on the chimney).

By material of manufacture:

- cast iron;

- made of stainless steel;

- made of enamelled steel.

Each type has models that differ in shape, volume, wall thickness. Most containers are equipped with standard taps and have shower outlets, but there are also those from which water is drawn through the top with a ladle. In order not to be mistaken when choosing, you should familiarize yourself in detail with the advantages and disadvantages of all these types.

The most economical and convenient option. The tank is installed in the process of laying the oven. Its lower part is located inside the firebox, due to which the water is heated directly by the flame. Hot water is drawn from the top with a ladle or with a built-in tap.

Due to direct contact with fire, the walls and bottom of the container should be as thick as possible, therefore the most preferred material for such a tank is cast iron with a thickness of 5 mm or more. No less popular are stainless steel tanks with a wall thickness of 1 and 1.5 mm. Enamelled steel containers are not suitable for this installation method. Cast iron tanks are in the shape of a bowl, made of stainless steel, usually in the form of a cube or cylinder.

Benefits of built-in tanks:

- water heats up quickly;

- the water temperature is maintained for a long time;

- free space is saved, since the tank does not protrude beyond the stove;

- simple installation.

Disadvantages:

- the heat transfer of the furnace decreases, since the bulk of the heat goes to heating the water;

- the dimensions of the tank are limited by the dimensions of the furnace;

- the tank must have thick walls, which increases its weight and cost.

Metal tanks for sauna stoves

This method is convenient in cases when no more than 4 people are steaming in the bath at the same time, or people wash themselves separately. For example, if 3-4 people take turns steaming in the bath, this takes a lot of time, respectively, and it will take longer to maintain the water temperature by throwing up firewood. The built-in tank saves on fuel by staying hot for a very long time. But for large companies this option is not the most optimal, since it does not provide the required amount of water.

The remote tank is located at a distance from the furnace and is connected by pipes with a heat exchanger built into the furnace. Without this, its exploitation is impossible. Most often, such a tank is installed in a washing room or mounted on the wall of the steam room next to the stove, if its dimensions are larger than the area of the firebox. When choosing a place for a container, it must be borne in mind that the length of the pipes should not exceed 2.5-3 m. Remote tanks can be made of stainless steel and enameled, cylindrical, rectangular and even triangular in shape - for installation in the corner of the room.

Benefits:

- the tank is installed where it is more convenient;

- large containers can be used;

- there is no direct contact with fire, so the tank can be enameled and with thinner walls.

If 6-8 people regularly take a steam bath, this is an excellent option.

Disadvantages:

- without maintaining the fire in the firebox, the water cools quickly;

- the oven cannot be used without water in the circuit;

- more complex installation compared to the built-in tank.

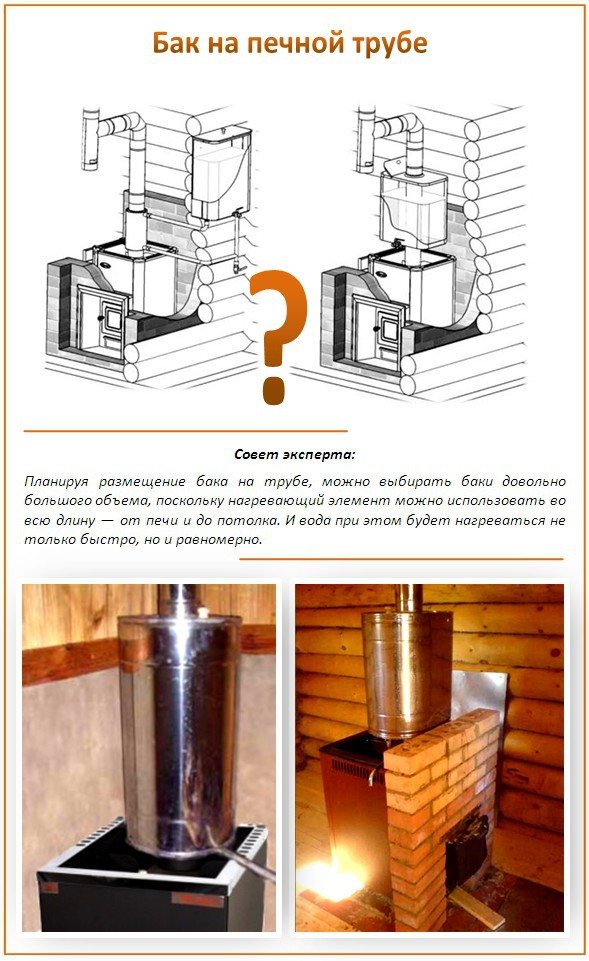

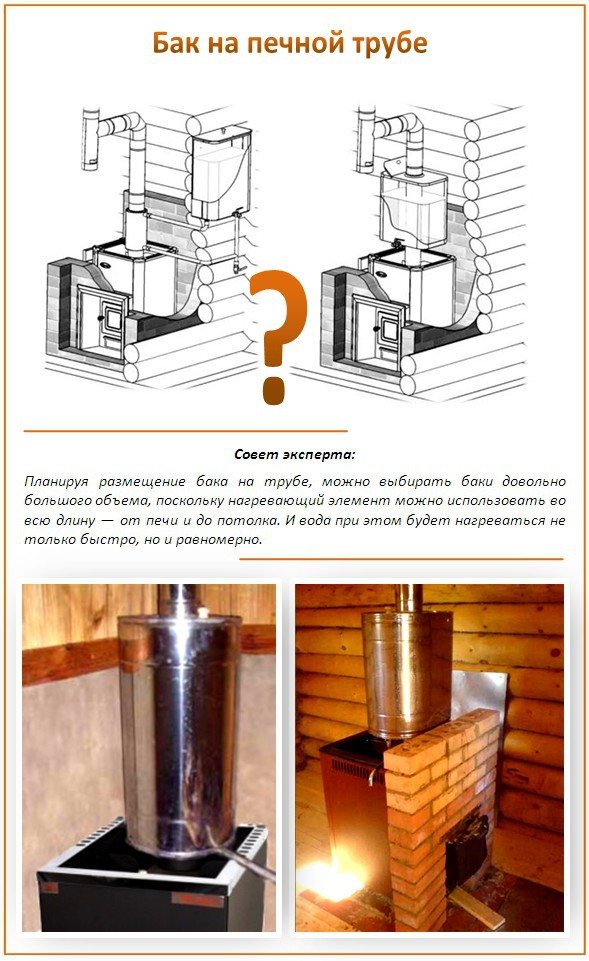

Tank on a pipe or construction "Samovar"

This option implies the installation of the tank around the chimney, and in some models the pipe is located outside the tank, in others - inside.

In height, the tank can occupy the space from the stove to the ceiling, partially go out into the attic, or be attached only to a small section of the chimney above the stove. The most convenient shape of the container is cylindrical, but there are many models of rectangular, triangular and oval sections. The water is heated by the smoke passing through the pipe, which has a very high temperature.

Benefits:

- fast and uniform heating of water;

- does not reduce the heat transfer of the furnace;

- saving space;

- you can install a container of any volume;

- the water stays hot for a long time.

Such a tank is suitable for any bath and any number of people. It all depends on the size of the container.

Disadvantages:

- the complexity of the installation;

- increased deposition of soot on the walls of the chimney.

When installing the tank, it is necessary to select the correct fasteners in order to securely fix the tank in an upright position. In addition, you will need to install pipes for supplying cold water and removing hot water, install a tap.

What is an expansion tank for?

As we know, water tends to expand during heating. As well as any other liquid in general. The coolant in the heating system is no exception. When the liquid expands, its excess needs to be put somewhere. For these purposes, expansion tanks were invented in heating.

First of all, let's recall the basic law of physics: when they heat up, bodies increase, and when they cool down, they decrease. The circulating heat carrier (water) in the system when heated increases in volume by an average of 3-5%. For the prevention of accidents and maintaining the operability of heating equipment, a container is needed, which will smooth out the temperature difference and, as a result, the pressure and volume of water. That is, when heated, the tank will take over the excess liquid, and when cooled, it will lower it back into the system. Thus, the pressure in the boiler remains within the permissible limits. Otherwise, the automatic protection is triggered and the system rises. What can be unsafe in severe frosts.

How to put the tank correctly

When installing an open tank in the attic, a number of rules should be observed:

- The container should stand directly above the boiler and be connected to it with a vertical supply pipe.

- The body of the product must be carefully insulated so as not to waste heat by heating the cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify the level control and make-up, it is recommended to bring 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

Note. It is customary to direct the emergency overflow pipe to the sewer network. But some homeowners, in order to simplify the task, take it out through the roof directly onto the street.

The installation of a membrane-type expansion tank also has its own characteristics. Considering how this product works, it can be placed vertically or horizontally in any position. Small containers are usually fastened to the wall with a clamp or suspended from a special bracket, large ones - just put on the floor. There is one point here: the performance of the membrane tank does not depend on its orientation in space, which cannot be said about the service life.

A closed vessel will last longer if it is mounted vertically with the air chamber facing up. The fact is that sooner or later the membrane will exhaust its resource, which is why cracks will appear in it. The internal structure of the tank is such that with a horizontal arrangement, air from its half will quickly penetrate through the cracks into the coolant, and that will take its place. We'll have to urgently put a new expansion tank for heating. The same result will quickly appear when the container is hanging upside down on the bracket.

In a normal vertical position, air from the upper part will not rush to penetrate through the cracks into the lower one, just as the coolant will reluctantly go up. Until the size and number of cracks increases to a critical level, the heating will work properly. This process sometimes takes a long time, you will not notice the problem immediately. But no matter how you place the vessel, you should adhere to the following recommendations:

- The product must be positioned in the boiler room in such a way that it is convenient to service it. Do not install floor standing units close to a wall.

- When wall-mounting the heating expansion vessel, do not place it too high, so that you do not have to reach the shut-off valve or air spool when servicing.

- The load from the supply pipelines and shut-off valves should not fall on the tank branch pipe. Fasten the pipes together with the valves separately, this will facilitate the replacement of the tank in the event of a breakdown.

- It is not allowed to lay the supply pipe across the floor through the passage or hang it at head height.

How can you beautifully place equipment in a boiler room?

Specialist recommendations

The closed expansion vessel does not need to be installed at the highest point in the system.

The main advantage of membrane expansion joints lies precisely in the possibility of placing it in a place most convenient for installation and operation.

Small tanks with a volume of 20-25 liters are usually installed in systems with a circulation pump, whose power is 1.2 kW. Increasing the capacity to 20-60 liters will increase the pump power to 2.0 kW.

Compensating devices with a volume of 100-200 liters are on sale. In addition to their direct purpose, they can play the role of a storage tank for warm water. True, they can be used in this way only if the main source of hot water supply is turned off for a short time.

Sizes of expansion tanks cover a fairly wide range. Among them, there are models with dimensions so large that standard doorways do not allow them to be brought into the room. In such a situation, it is better to replace one huge container with several small ones. The main thing is that their total volume is equal to the calculated one.

What is an expansion tank for?

Depending on the weather conditions and the climatic regime in the room, the coolant that circulates through the heating pipes heats up to a greater or lesser extent. With intensive heating, it expands and forms an excess volume, which can create a pressure exceeding the maximum allowable for the operation of the system. The installation of an expansion tank in the heating main is just needed to temporarily remove these excess liquid.

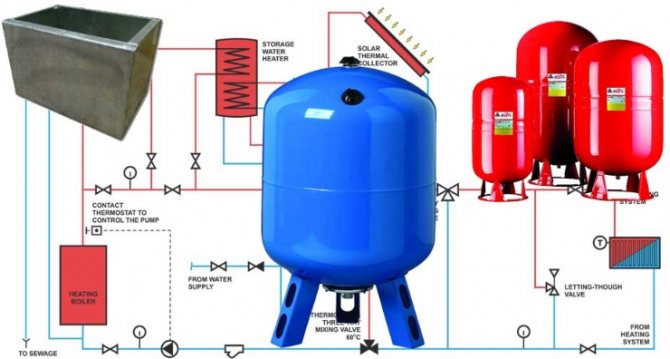

Closed heating system with an installed expander

A double-circuit boiler usually has its own tank for removing the coolant, the capacity of which is quite enough for average operating conditions.

But if your house has a lot of heated rooms, and at least some of them use metal pipes as batteries, then much more fluid is required in normal mode, which means that the increase in volume during expansion will be more noticeable. Therefore, the built-in expansion tank may not be enough, and then an additional tank will need to be installed.

Open tanks

These tanks are used for an open heating system (otherwise - gravitational, gravity) and represent a metal tank with an open top of arbitrary shape. A branch pipe is welded to the upper part of the side wall for connecting a hose or overflow pipe, the coolant is supplied to the tank from below. The element is installed above the entire system on the supply pipe, usually in the attic of the house.

Any expansion tank for open-type heating performs 2 functions:

- serves to compensate for the expansion of the coolant;

- removes air from the system, since its top communicates with the atmosphere.

This is its advantage, but it is not the only one. An open container can also successfully and permanently serve in systems with forced circulation, since the tank structure is very simple, there is nothing to break there. However, it also has a lot of shortcomings:

- a tank installed in the attic requires good insulation;

- during the season, it is necessary to constantly monitor the water level in the tank and replenish it in a timely manner;

- the coolant is constantly saturated with oxygen from the atmosphere, which makes the metal parts of the boiler corrode faster;

- additional consumption of materials and complexity during installation.