A boiler thermometer is a device that has a simple and at the same time reliable design. If, when buying modern boilers, the thermometer is already included, then for old ones it will have to be purchased additionally.

A thermometer, sometimes a temperature sensor, has two functions:

- Displays the reading of the operating temperature of the heat carrier inside the boiler or heating system. Thanks to this, the owner of the heating system determines the stability of the boiler and, if necessary, changes the operating mode. For example, if the thermometer shows a drop in the temperature level, this indicates a malfunction in the heating system, and it is turned off to find out the reasons;

- Modern boilers rely in their work on automation, and she rely on the operation of measuring sensors, including a temperature sensor. Thanks to the well-coordinated interaction between automation and sensors, it is not necessary to constantly go to the boiler and regulate it in order to ensure the desired temperature regime.

There are two types of thermometers: submersible and remote.

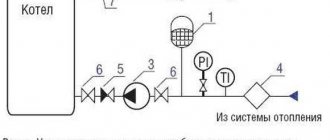

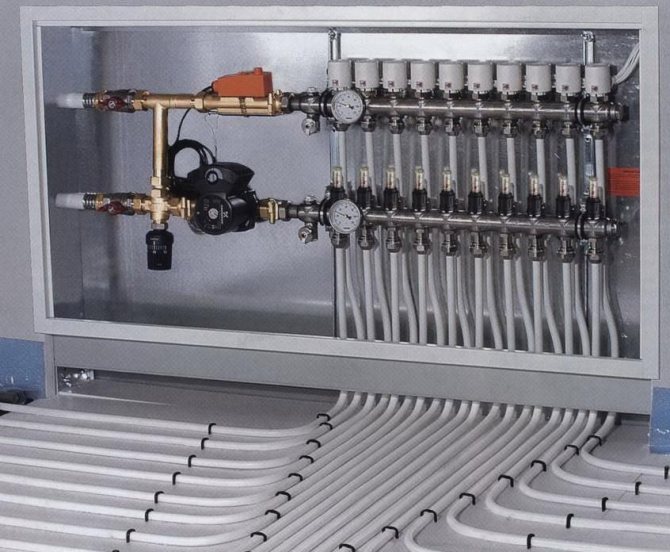

Thermometer installed in the heating system

Immersion thermometers

Designed to read information about the temperature of the heat carrier. They are installed on some segments of the system or on the boilers themselves. Depending on the working material, bimetallic and alcohol devices are distinguished.

- Bimetallic... A thermometer of this type consists of a metal plate, for the manufacture of which two different metals were used, and an indicator arrow with a scale. The work is based on the difference in the coefficients of thermal linear expansion, due to which, when heat is supplied, one of the metals is deformed and exerts pressure on the indicator arrow, which will show the temperature value on the scale.

Despite the simple operation scheme and simple design, this type of thermometer provides accurate readings.

Their only drawback is inertia. If the temperature of the heat carrier inside the boiler or in the system changes abruptly, it will not become known immediately, but after a short period of time.

Bimetal thermometer

Bimetallic thermometers, in turn, are divided into axial and radial. The difference between these two types of products is the position of the dial axis. The axis of the radial thermometer is parallel to the sensor, while that of the axial thermometer is perpendicular.

The most reliable devices come from Watts, Dani and Introll.

- Alcohol... This type of thermometer is a vessel made of thermal insulating material with a degree scale, which is printed on the surface. The principle of operation is impossibly simple. When heated, alcohol or alcohol-containing liquid expands and moves through the vessel along the scale. The alcohol level shows the current temperature of the heat carrier inside the boiler.

There are few differences between this type of thermometer and a conventional thermometer, and hence a small drawback in working with it - visual inconvenience when taking readings.

And here the most reliable devices are manufactured by Watts.

Read the user manual first before installing the immersion thermometer. From it you will learn the upper limit of the temperature values of the product, the dimensions that are needed for connection, recommendations from the manufacturer regarding operation.

Alcohol thermometer

Main characteristics and principles of operation of the pressure gauge

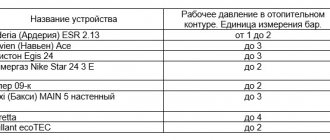

There are devices for different pressure levels.For convenience, buy a device with an intuitive scale that does not require additional calculations. There are usually two arrows on it: red and black. The allowed mark is adjusted in red. For home boilers, manufacturers recommend 2 atmospheres (the exact value is indicated in the passport). If the black one "ran" behind the red one, something is broken. A decrease in the value by 0.02 MPa (0.2 atm) means that you need to look for a coolant leak or check the sufficient pressure level in the expansion tank.

The pressure gauge usually has two scales: pressure in atmospheres and bar. Sometimes the device is combined with a thermometer, therefore it also has a temperature scale. The principle of operation of pressure gauges is based on balancing the value of the desired pressure with another force. According to this characteristic, devices are divided into:

- liquid;

- spring;

- membrane;

- electrocontact (EKM);

- differential.

Advice. Since the pressure in a conventional closed heating system fluctuates between 2-3 atm, choose a pressure gauge with a scale of up to 4 atm. If the upper value of the pressure gauge is, for example, 50 atm, the divisions will be small. You will not register a small pressure drop that can become critical to the system.

It is undesirable to install the device when:

- it does not have a seal or other mark on the passage of the verification;

- the period for checking the pressure gauge has expired;

- it has visual damage, such as a crack in the glass;

- after disconnection, the arrow does not return to the "0" indicator.

Pressure gauge

Remote sensors

They are placed outside the heating system. Despite this, they are connected either directly to the boiler or to a programmer, which is responsible for regulating the parameters of the system. Recently, wireless sensors have gained popularity. With the help of auxiliary electronics, they transmit the temperature readings of the heat carrier to the automation, so that they are installed in the place where it is convenient.

In simple circuits, it is reasonable to install temperature sensors that transmit a signal to the control unit via electrical wires. Due to this, the likelihood of transmission failure or data loss is significantly reduced in comparison with wireless models.

Types of pipe routing schemes

There are many pipe layouts for households. The most popular are the combined ones, which increase the productivity of the system and allow you to evenly heat the house.

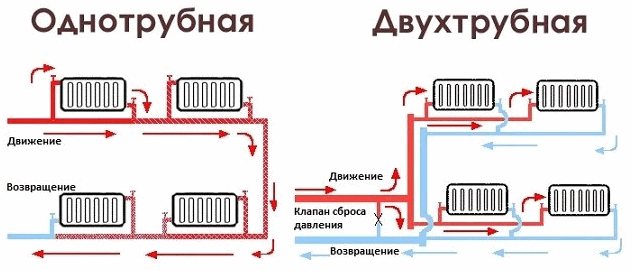

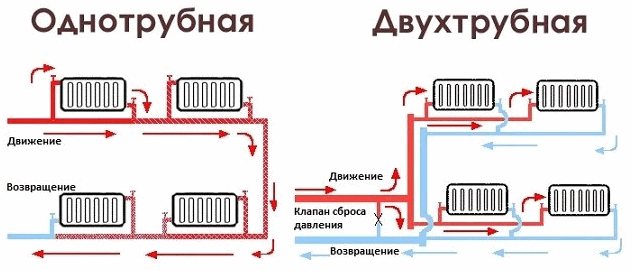

Single pipe

The one-pipe scheme provides for a systematic flow of water into each radiator. That is, the liquid comes out of the boiler, penetrates into one battery, then into another, and then into a third, and so on.

Having reached the end of the system, the coolant unfolds and is sent back through a solid pipe.

The advantages of the scheme:

- Ease of installation - it is required to pass the liquid through the radiators in order and return it back.

- Minimal material consumption.

- Low pipes - installed either at floor level or under floors.

Disadvantages of the scheme:

- The limited length of the horizontal section is about 30 meters.

- The farther from the boiler, the colder the radiators.

Two-pipe

The two-pipe system consists of two pipes - supply and return. Batteries are mounted between them - the input is connected to the supply pipe, and the output is connected to the return pipe.

What it gives:

- Even distribution of heat throughout the premises.

- Possibility of temperature regulation in rooms by blocking some batteries.

- The possibility of heating multi-storey private houses.

There are two main types of such a system - with bottom and top wiring.

Bottom wiring is used in many homes, as it makes it possible to equip heating discreetly. The supply and return pipes are joined together under the radiators or in the floors. Air passes through Mayevsky's taps.

Characteristics of a two-pipe system with bottom piping:

- the ability to mask pipes;

- the ability to use batteries with bottom mounting - this somewhat simplifies installation;

- heat losses are minimized.

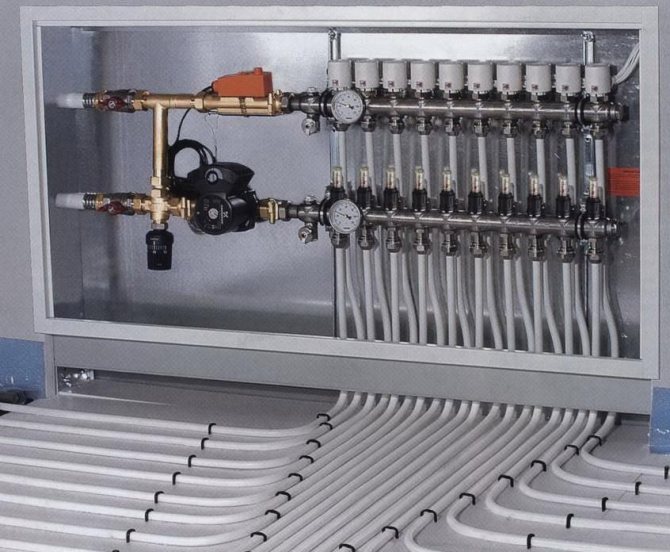

Beam with collector

This scheme lays an individual line to all heating devices. In the system, the supply and return collectors are mounted, from which straight pipes are supplied to the radiators. Such a project provides flexible adjustment of the system parameters and allows you to connect underfloor heating.

Beam wiring is used in many modern homes. Pipes can be laid anywhere (mostly in floors). To adjust the temperature and turn on / off devices, small lockers are mounted in the dwelling.

There are many positive qualities:

- The ability to completely hide all pipes in the walls and floors.

- Convenient system setup.

- Possibility of creating remote separate adjustment.

- Minimum number of connections: they are located in the control cabinets.

- It is convenient to repair individual parts without shutting down the system.

- Almost perfect heat distribution.

There are also a couple of disadvantages:

- High price - this includes equipment and installation costs.

- Difficulty in implementing the plan in an already constructed building - the scheme must be laid down at the design stage of the building.

What to consider when choosing

The operating parameters of the heating system influence the selection of a suitable thermometer. Pay attention to the following:

- Working range of measurements... Affects the accuracy of the readings. A temperature sensor that has an incorrectly selected upper limit of readings will display data with an error or stop working altogether;

- Connection method... When you need to determine the level of heating of the heat carrier with a minimum error, choose among those models of thermometers that are immersed in the medium of the heat carrier. Their installation is carried out only in the heating system itself or on the boiler;

- Reading method... The method of measurement affects the speed of bringing the readings of the device to the real level (in other words, the inertia), the appearance and type of the indicator.

Remote temperature sensor

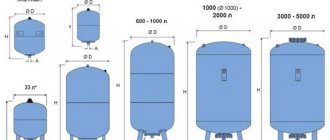

When choosing among immersion thermometers, be sure to consider the length of the well, which is from 120 to 160 mm. And when choosing among wireless sensors, pay attention to the signal transmission range, measurement error and the possibility of autonomous operation from batteries.

Why is it important to control the pressure in the system

Individual heating is a closed system with water as a heat carrier. The liquid is static when the boiler and pump are off. As soon as you light the burner, the water becomes mobile, hydrodynamic pressure appears in the system. It can be of 3 types:

- Natural circulation. When the boiler is turned on and the pump is turned off, the water still moves in the pipes, because in different places in the system it has different temperatures.

- Forced circulation. The pump "drives" the water in a circle.

- Expansion of liquid from heating, which in the process displaces air and takes up the vacated space.

All these types of pressure, which add up to one indicator, are intended to be measured by a pressure gauge. Together with an automatic air vent and emergency relief valve, it is a guarantee of the safety of your system, as going out of range means that your heating is not working properly. It may even cause the equipment to explode.

Closed heating system

The installation of these 3 elements (they are also called a safety group) is required only for solid fuel boilers (wood, coal). If the device is purchased complete with a boiler, then it is compatible with it, but you can assemble a group separately.Installation of a pressure gauge, an emergency valve and an air vent is not necessary for a closed system with a gas or electric boiler, because they can stop heating themselves if excessive pressure or temperature is generated. However, in this case, the pressure gauge and its “helpers” are recommended for convenience and additional protection. Moreover, the devices and their components are inexpensive.

What you need to find out before purchasing

Before purchasing a thermometer, find out some points:

- Find a place on the boiler drum for mounting the thermometer and determine the mounting method. Make sure that the selected device complies with the received data and that the installation is available.

- Determine if a pressure gauge is installed in the system. If it is not included in the original package, either purchase it separately, or purchase a thermometer with a pressure gauge in one case.

- Determine the required temperature measurement range. Do not take devices with a higher boundary temperature than necessary, since with a higher division value, the result is a large error. This will reduce the reliability of the purchased device.

Step by step instructions for connecting

Usually there are no difficulties during installation, so it is quite possible to do all the work yourself... So that the pressure gauge can be changed at any time without shutting down the system, a crane is installed in front of it.

The location does not play a special role, but usually they choose a place near the boiler. The main thing is convenience. The pressure gauge must be directly accessible so that the pressure readings can always be viewed.

If there is no tap, install the device only on a disconnected system. This will require:

- choose a place;

- take a wrench;

- if there is no gasket on the pressure gauge, you need to wind up the thread;

- tighten the device with a wrench.

It is worth noting that you cannot twist the pressure gauge holding on to the case. Thus, it can be damaged. It is better to use a special nut on the union.

The pressure gauge is part of the heating safety group. This also includes an automatic air vent and a safety valve. If the group is not yet installed, you can buy it in assembly... Only it will have to be connected to the highest point of the pipe, since the air vent should be located exactly there.

Post-purchase check

If a submersible device was purchased from one of the above companies, feel free to install it on the boiler or in the heating system. If not, then first check it for accuracy. What for? The low accuracy of readings inherent in cheap products will lead to an inaccurate display of the real picture of the boiler operation, to a decrease in the efficiency and reliability of operation.

This verification process is shown in detail in the video:

How to check? Take a purchased thermometer and a probe with an external spike for water. Bring the purchased thermometer and then the control probe to an open fire for 10 seconds. Given the inertness of the readings, allow a little time for the thermometer to display the actual temperature reading. Then compare the reading of the thermometer with the control sensor. The lower the difference, the more accurate the temperature measurement and display is.

Why check for leaks?

In order for the system to work properly during the heating season, it is important to check the condition of its equipment and identify all the weakest and worn out places. This check is carried out regularly and is called crimping.

The check is usually carried out at the end of the season by pumping fluid into the system using special equipment that raises the pressure above the working pressure by 1.2-1.5 times.

Pressure testing reveals all weak, breaking or leaking parts of the structure that require inspection and preventive maintenance. After checking and repairing, the heating is restarted.

Check out the video that explains why the pressure in the heating system may drop and what to do in such a situation.

Pressure sensors as a complement to thermometers

In a diagram of a heating system with forced circulation, pressure sensors indicate the level of expansion of the heat carrier from heating. For this reason, experts recommend installing pressure meters in the heating system together with thermometers.

Appearance of the spring pressure gauge

The limiting pressure value is the main indicator for manometers and cannot be lower than the maximum pressure reading in the system. As practice shows, it is better to install devices with a maximum pressure of 6 MPa.

Pressure sensors are of two types: spring-loaded and electro-contact.

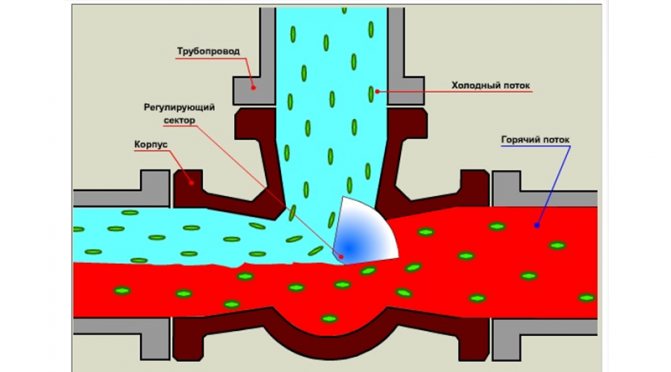

Spring loaded... The role of the sensing element is played by a tube of round or oval cross-section. When a heat carrier is supplied, it shifts, and from this the arrow on the dial starts to move.

The visible advantages of this type of sensors are high operational reliability and reasonable price.

No special skills are required to mount this type of sensor.

The video will tell you about the operation of the minimum pressure sensor:

Electrical contact... Upgraded version of spring type sensors. In addition to the arrow, which indicates the main readings, there are two additional ones, they are set to the lower and upper pressure limits. When the pointer reaches one of the additional readings, the contact closes, and then an electrical signal is sent to the control device. It is advisable to install devices of this type only in autonomous systems of large objects.

Electrical contact pressure sensor

As you can see, there is a choice among the devices for monitoring the operation of the heating system, which depends on a number of factors, such as the place of installation, the operating range, the accuracy of determining the temperature or pressure of the heat carrier. Remember: a properly selected device will allow you to accurately control the operation of the heating system and ensure the durability of its operation.

What to take to the boiler room

In the boiler room, as a rule, spring pressure gauges are used. As we mentioned above, these are fairly simple and sturdy devices.

Having bought and installed correctly once, you can easily control the operation of the equipment. Before going to the store or ordering online, we advise you to find out the connection dimensions. Previously, it was possible to find models with a nominal bore of 3/8 inch on sale, now manufacturers have taken for standard 1/2 and 1/4... If there are no other options, then tees and other fittings can be used for the transition.

Also, understand the following characteristics in advance.

- diameter

- brand

- protection class

- body material

Combined execution, combining thermometer and manometer functionality, many masters do not recommend ordering. One will break, followed by another. However, it all depends on who the manufacturer is.

Products of a German company Watts deservedly in demand among both professionals and beginners. Impeccable quality, attention to detail made Watts manometers a real classic, without which almost any installation of a heating system can do.

Different types of temperature sensors

To take temperature readings, devices with a different principle of operation are used. Among the most popular are the devices listed below.

Thermocouples: Accurate Reading - Difficulty in Interpretation

A similar device consists of two wires soldered to each other, made of different metals. The temperature difference that occurs between the hot and cold ends serves as a source of electric current of 40-60 μV (the indicator depends on the material of the thermocouple).

A thermocouple is considered a high-precision temperature sensor, but it is difficult to get an accurate reading. To do this, you need to find out the electromotive force (EMF) using the temperature difference of the device.

For the result to be correct, it is important to compensate for the cold junction temperature, using, for example, a hardware method in which the second thermocouple is placed in an environment of a predetermined temperature.

The software compensation method involves placing another temperature sensor in an isochamber together with cold junctions, which makes it possible to control the temperature with a given accuracy.

Certain difficulties are caused by the process of reading data from a thermocouple due to their nonlinearity. For correct readings, polynomial coefficients are introduced in GOST R 8.585-2001, which make it possible to convert EMF to temperature, as well as to perform reverse operations.

Another problem is that readings are taken in microvolts, which cannot be converted using widely available digital instruments. To use a thermocouple in designs, it is necessary to provide accurate, multi-digit converters with minimal noise levels.

Thermistors: easy and simple

It is much easier to measure temperature using thermistors, which are based on the principle of dependence of the resistance of materials on the ambient temperature. Such fixtures, for example, made from platinum, have such important advantages as high accuracy and linearity.

An important characteristic of a resistor is its base resistance at a certain temperature. According to GOST 21342.7-76, this indicator is measured at 0 ° C. In this case, it is recommended to use a number of resistance values (Ohm), as well as Tc - the temperature coefficient.

The Tx indicator is calculated by the formula:

- Re- resistance at current temperature;

- R0c - resistance at 0 ° С;

- Te - operating temperature;

- T0c - 0 ° C.

The GOST also lists the temperature coefficients provided for various measuring devices made of copper, nickel, platinum, and also indicates the polynomial coefficients used to calculate the temperature based on the current resistance indicators.

You can measure resistance by connecting the device to the current source circuit and measuring the differential voltage. The indicators can be monitored using integrated circuits, the analog output of which is equal to the supplied voltage.

Thermal sensors with similar devices can be safely connected to an analog-to-digital converter, digitizing it with an eight or ten-bit ADC.

Digital sensor for simultaneous measurements

Digital temperature sensors are also widely used, for example, model DS18B20, whose operation is carried out using a microcircuit with three outputs. Thanks to this device, it is possible to take temperature readings simultaneously from several sensors operating in parallel, while the error is only 0.5 ° C.

Among other advantages of this device, one can also note a wide range of operating temperatures (-55 + 125 ° С). The main drawback is slow operation: for the most accurate calculations, the device requires at least 750 ms.

Non-contact Irometers (thermal imagers)

The action of these proximity sensors is based on the detection of thermal radiation emanating from bodies. To characterize this phenomenon, the amount of energy released per unit time from a unit surface is used, which falls on a unit of a wavelength range.

A similar criterion reflecting the intensity of monochromatic radiation is called spectral luminosity.

There are the following types of pyrometers:

- radiation;

- brightness (optical);

- color.

Radiation pyrometers allow making measurements in the range of 20-25000 ° C, however, to determine the temperature, it is important to take into account the coefficient of incompleteness of radiation, the effective value of which depends on the physical state of the body, its chemical composition and other factors.

Brightness (optical) pyrometers designed to measure temperatures of 500-4000 ° C. They provide high measurement accuracy, however, they can distort the readings due to the possible absorption of radiation from bodies by the intermediate medium through which the observations are carried out.

Color pyrometers, the action of which is based on the determination of the radiation intensity at two wavelengths - preferably in the red or blue part of the spectrum, are used for measurements in the range of 800 to 0 ° C.

Their main advantage is that the incompleteness of the radiation does not affect the measurement errors. In addition, the indicators do not depend on the distance to the object.

Quartz temperature transducers (piezoelectric)

To take readings of temperatures within -80 + 250 ° C, you can use quartz converters (piezoelectric elements), the principle of which is based on the frequency dependence of quartz on heating. In this case, the function of the transducer is influenced by the location of the cut along the crystal axes.

Piezoelectric sensors are distinguished by fine sensitivity, high resolution, and they are able to work reliably for a long time. Such devices are widely used in the manufacture of digital thermometers and are considered one of the most promising devices for future technologies.

Noise (acoustic) temperature sensors

The operation of such devices is provided by removing the acoustic potential difference depending on the temperature of the resistor.

The method of measuring with such sensors is quite simple: it is necessary to compare the noises produced by two similar elements, one of which is at a known in advance, and the other at a determined temperature.

Acoustic thermal sensors are suitable for measuring the interval -270 - +1100 ° C. The complexity of the process lies in the too low noise level: the sounds emitted by the amplifier sometimes drown it out.

NQR temperature sensors

The essence of the operation of nuclear quadrupole resonance thermometers consists in the action of the field gradient, which is formed by the crystal lattices and the moment of the nucleus, an indicator caused by the deviation of the charge from the symmetry of the sphere.

As a result of this phenomenon, a procession of nuclei arises: its frequency depends on the gradient of the grating field. The value of this indicator is also influenced by temperature: its rise causes a drop in the NQR frequency.

What should you pay attention to?

What should you pay attention to?

Before purchasing a pipeline device, it is worth clarifying a few points:

- The cut-in should take place exactly in the place that is intended for the installation of the device. That is why it is necessary to first find a suitable place near the steam boiler and find out the method of fastening.

- Find out what the appropriate temperature range is. Experts advise to select the appropriate product, its upper limit should not be too high. The larger the scale of divisions, the greater the error may be. This error can reduce the reliability of the product.

- It is necessary to find out in advance whether a pressure gauge is installed in the system. If it is not provided in the system initially, then it can always be purchased.

Types of devices for taking temperature

Thermal devices can be classified according to a number of important criteria, including the way information is transmitted, the location and conditions of installation, and the reading algorithm.

By the method of information transmission

According to the method used for transmitting information, sensors are divided into two broad categories:

- wired devices;

- wireless sensors.

Initially, all such devices were equipped with wires through which the temperature sensors connected to the control unit, transmitting information to it. Although now such devices have replaced wireless counterparts, they are still often used with simple circuits.

In addition, wired sensors are more accurate and reliable.

Nowadays, wireless devices have become widespread, which most often transmit information using a transmitter and receiver of radio waves. Such devices can be installed almost anywhere, including a separate room or open air.

Important characteristics of such temperature sensors are:

- the presence of a battery;

- measurement error;

- signal transmission distance.

Wireless / wired devices can completely replace each other, however, there are some peculiarities in their functioning.

Submersible water temperature sensors

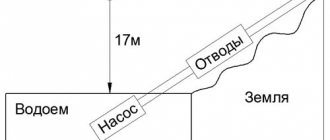

These measuring devices are designed to take readings of the temperature regime inside the pipes. They are installed at specific locations in the piping system. The direct choice of one or another modification depends on the preferred method of recording the readings.

Bimetallic sensors

The operation of this device is based on the principle of metal deformation during heating, which causes pressure on the indicator arrow. This gives a high accuracy of the readings obtained, but is characterized by a high degree of inertness.

Alcohol sensors

The principle of operation is similar to that of a conventional thermometer. Alcohol enclosed in a sealed flask is used as an indicator. When heated, it expands and the arrow points to the corresponding division of the flask scale. The advantage of the design is the low inertia, the disadvantage is the inconvenience of fixing the readings.

Installation of immersion sensors implies careful selection of the sleeve length depending on the pipe diameter, it is also very important to take into account the installation dimensions and the range of measured temperatures.