Circulation pumps have long been used in the organization of heating systems in homes. They are necessary to improve the temperature regime of the boiler, use complex heating schemes and make it possible to hide communications in the floor or walls. This equipment is now installed even in those places where the natural circulation of the coolant was quite enough earlier.

Users noticed that thanks to the pump, the heating system becomes more efficient and economical: the pipes warm up better and the load on the boiler decreases. In the modern market, you can find a wide variety of this type of equipment from different manufacturers. For example, you can purchase a Grundfos circulation pump that has good characteristics.

A little about the brand

If you translate the word Grundfos from Danish into Russian, then it will sound like "Spring". The concern was founded in 1945. Now the brand is represented in 45 countries, the company occupies a leading position as a manufacturer of pumps for heating, hot water supply and sewerage.

The main function of the manufactured equipment is the efficient delivery of water, both drinking and household water, for various needs. The brand is constantly researching new materials and technologies, which makes it possible to produce innovative equipment that meets all modern quality standards. As a result, the user receives efficient, reliable, energy-saving devices.

Repair of borehole pumps Grundfos and Speroni

provides repair services for pumps and pumping stations in the Moscow region. Our office is located in Solnechnogorsk, so if necessary, you can come to us to discuss the problem that has arisen.

We will not tell you now that we have qualified masters who will repair pumping equipment with high quality, inexpensively and in 1 day. That's what everyone says. And it is not always possible to complete this work in 1 day. Therefore, we just give you a guarantee: if we get down to work, then we will repair the borehole pumps conscientiously. And your well will supply water to the house again.

You can order repair, replacement and service from us all types of pumps Grundfos and Speroni

:

We also carry out repairs of pumping stations Grundfos (MQ 3 35, MQ 3 45) and Speroni Marina (Marina), CAM, APM, etc.

Additionally, you can purchase spare parts for pumps and pumping stations from us, as well as order the repair of the pressure switch of the pumping station or other elements of the water supply system.

Thus, you can order from us the repair of sewage pumps and pumping stations (for example, Grundfos Sololift), as well as any models for wells and household models for water supply of a private house.

Features of circulation pumps "Grundfos"

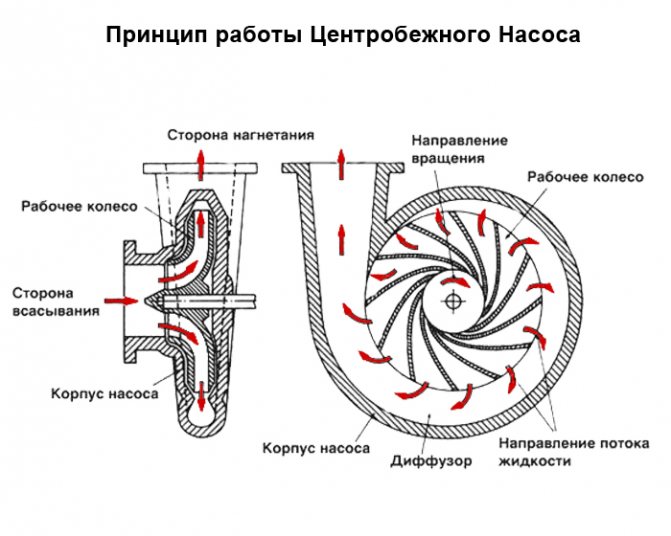

This is the name of compact devices built into the heating circuit in a certain area. Their functional task is to increase the fluid pressure in the system. Grundfos brand products compare favorably with similar pumps in many respects, which makes them popular and in demand.

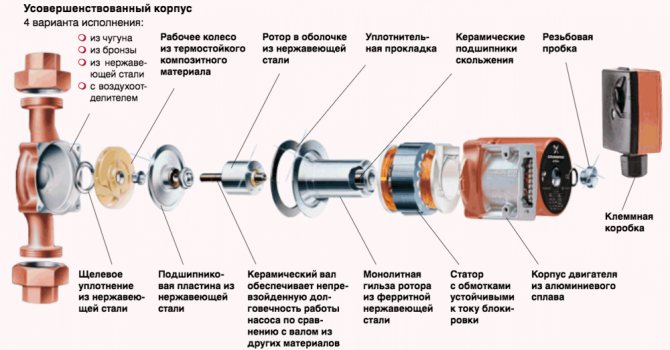

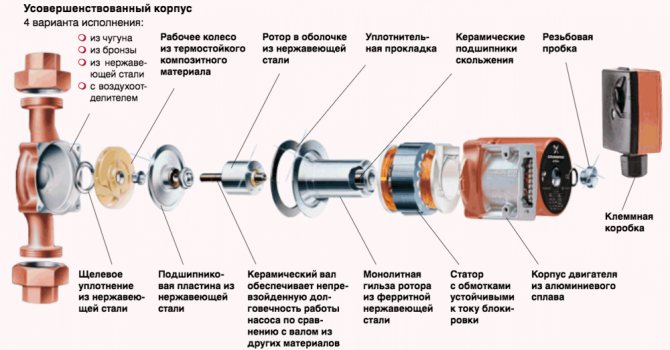

Device

Consider what the pumping equipment consists of and how it works.

The body of the devices is made of the following materials:

- stainless steel;

- aluminum;

- brass;

- bronze.

In the inner part of the body there is a rotor, which can be ceramic or steel. A shaft with a technopolymer impeller is connected to it. When the pump motor starts, the blades begin to rotate, resulting in the pumping of the coolant. It is thanks to this process that the liquid circulates intensively through the system.

Benefits

Danish brand devices are very popular among consumers due to some positive qualities.

Among the main advantages are:

- High performance despite low power. Here it should be borne in mind that this parameter does not depend on the distance.

- Conservation of heat carrier energy. This effect was achieved due to the fact that the circulation occurs due to the frictional force in the system.

- Economical power consumption. The fact is that pumping units from "Grundfos" can operate in an autonomous mode, constantly maintaining the required temperature of the coolant.

- The ability to set the desired temperature. For this, there is a special regulator on the body of the device. If the pump is installed in a system with already heated water, it will automatically maintain its temperature.

- Simple construction. This facilitates the installation work, which you can handle yourself, without the help of specialists.

- Wide range of pumps. Each user will be able to select a unit for a specific heating system, which entails cost savings.

- Use of high quality construction materials. As a result, the reliability and practicality of the equipment is increased. In addition, the pumps have all sorts of functions and components, which reduces their final cost and makes them more durable.

- Warranty. Grundfos provides a 2-year warranty for all pumping equipment. Additionally, each model comes with an instruction manual, which indicates the features of installation and operation.

Products of this brand have 3 operating modes, when switching them, the pumping speed of the liquid changes.

Repair of control cabinets

Modern pumping systems are highly automated. Control cabinets solve several problems at once: energy saving, protection of pumps and electric motors, automatic maintenance of system parameters, accounting and dispatching system. In control cabinets, frequency converters and soft starters are used to control the pump electric motor. Malfunctions in the operation of systems can occur in the event of erroneous programming of the above devices or their failure. The service conducts diagnostics of control cabinets and frequency converters and their repair, if necessary.

Types of pumps for circulation

These devices installed in the heating circuit can have a different design, which affects their operation. There are Grundfos pumps with wet and dry rotor. Each species has its own characteristics, strengths and weaknesses.

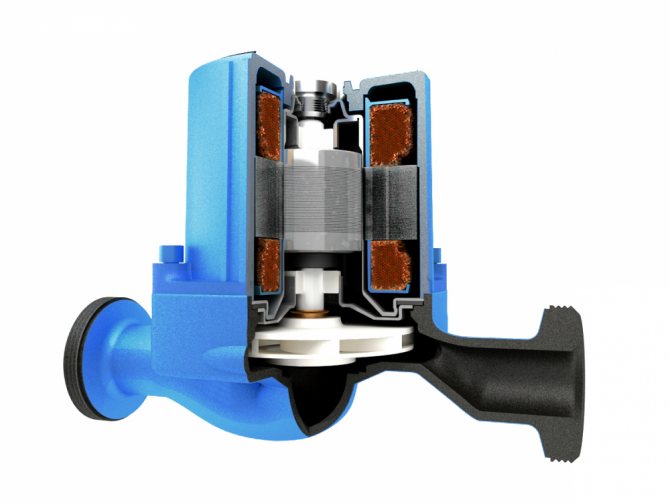

Wet rotor

Such devices are best suited for heating country houses and are installed in small boiler rooms. Thanks to their optimized design, they are compact and quiet in operation.

They are called "wet" due to the fact that they use a water-cooled electric motor. The coolant pumped by the pump additionally lubricates the equipment parts.

Such devices do not require additional maintenance, and their efficiency is 50%. They are capable of effectively performing their task for 8-10 years. A "wet" pump is quite sensitive to the quality of the coolant. For this reason, it is not recommended to install it if there are foreign inclusions in the water. Also, the device is not suitable for circulating cold liquid.

The regulation of such pumps can be manual or automatic. The second option is considered more economical, since the unit independently adjusts to the characteristics of the heating network. Products with automatic adjustment are also distinguished by their quiet operation. The air is also removed by itself, without the intervention of the owner.

If we compare the appearance of pumps with a wet and dry rotor, then the fins are not provided on the casing and impeller of the former.

Dry rotor

This type of equipment appeared somewhat later than units with a wet rotor. The key difference is that the pump motor does not come into contact with the liquid during operation.

The efficiency indicator reaches 70%. As a rule, such equipment is in demand when pumping significant volumes of coolant. Therefore, it is most often installed in large rooms for domestic and industrial purposes. Special seals are provided between the rotor and the fluid in the system.

The disadvantage of dry rotor devices is that they are quite noisy, so they should be installed in a special room or installed with special insulation. To prevent the equipment from overcooling during operation, a fan is provided in the design. Devices of this type serve for about 6 years.

Prices for a range of Grundfos circulation pumps

Grundfos circulating pumps

Maintenance of sewer systems

The service center is ready to provide professional support to the owners of pumping units by offering a complex that allows you to maintain the uninterrupted operation of the system. The decision to entrust the maintenance of the installation to our company will justify the expectation, because our qualified specialists perform operative intervention "on business", eliminating the discomfort caused by a long wait at the time of repair and maintenance work.

Our company is the official partner of Sololift, so we know everything about pumping units and are ready to make professional repairs and maintenance, delighting with terms, guarantees and attractive prices. Do you have any questions about the operation or are you looking for a reliable and competent specialist who provides service to maintain the unit in working order? Without hesitation, contact us and you will be able to understand that you have made the right choice.

Pump manufacturers such as Grundfos produce quality pumps that are characterized by high performance and long service life. But even high-quality equipment is susceptible to breakdowns in case of non-compliance with the norms of use or when periodic maintenance is not carried out. As a result - partial or complete cessation of the functioning of the apparatus.

Grundfos pumps are usually repaired by specialized workshops, which charge a substantial fee for their services. At the same time, the problem itself is not always worth the money spent. The solution may be to repair the Grundfos pump with your own hands, which is quite possible with certain knowledge.

How to choose the right pump

When choosing pumping equipment, it is necessary to take into account the parameters of both the equipment itself and the heating circuit. If you make a mistake, then the efficiency of the device will noticeably decrease, that is, the money will be "thrown into the wind."

When choosing, the following parameters should be taken into account:

- the size of the heated area;

- indoor temperature;

- functionality;

- temperature difference between supply and return;

- pressure;

- network characteristics;

- the quality of the coolant.

If the choice is made correctly, taking into account all the requirements, the room will always have a comfortable temperature. When choosing a power, you need to take into account the volume of the room and the indicators to which the coolant in the system should be heated. There are many formulas for calculating the required pump performance.

Calculations taking into account averaged indicators:

- In order to find out how efficient the unit is, temperature differences are taken into account - from +30 to +35 ° C. The boiler power must be divided by the resulting figure, and the result will show the consumption, that is, the productivity.

- 0.6 m of head is enough for a pipe with a length of 10 m. For each model, this indicator is regulated and indicated in the passport.

- Heating pipes must have the same diameter as the pipes of the connected equipment. With the help of one pump, pumping of up to 80 meters of the circuit is provided.

The temperature of the pumped heat carrier must be taken into account. Pumps installed in heating systems operate with a liquid that heats up to +110 ° C.

If the circulation circuit is long and the pipes have a large cross-section, then a more powerful installation will be needed. Again, increased power is required if not water is used as a heat carrier, but another, more viscous liquid.

Modern pumps have a protection class of IP44. This indicates that the ingress of foreign objects larger than 1 mm into the device and water spray is excluded.

Repair of pumps Grundfos

The specialists of our service centers have received theoretical training at Grundfos and have extensive practical experience in the repair of pumping equipment. The pumps can only be repaired with a Grundfos repair kit (manufacturer's recommended spare parts).

Delivery and sale of spare parts at manufacturer's prices allows timely and efficient performance of all repair procedures. In our warehouse we always have a constantly growing assortment of spare parts for the equipment included in the Grundfos Service 24 hours program. Warranty for all Grundfos spare parts and components is 12 months.

Repair of pumping equipment in the tower

"Empire" of the complex "Moscow-City"

Review of popular models

The devices manufactured by this company have gained popularity all over the world. They are used in heating systems for country houses, cottages and industrial premises. At the moment, "Grundfos" produces several lines of equipment with different parameters and features.

UPS 25-60 180

The Grundfos UPS 25 60 180 is a circulation pump with a two-material housing. The cast iron version is used in heating, and the stainless steel device is used for the hot water system. The design includes an induction motor, a 3-speed switch and a sleeve that separates the rotor from the starter.

It is mounted both vertically and horizontally. With the help of this model it is possible to pump heat carrier of various temperatures: from +2 to +110 ° C.

Benefits:

- suitable for closed and open circuits;

- made of quality materials that are resistant to wear and corrosion;

- economical - consumes 60 W;

- low noise - no more than 43 dB;

- compact - 18 × 13 × 13 cm;

- has a low weight - 2.6 kg;

- protected from overheating, thanks to the "wet" rotor, cooled by the coolant;

- easy to install and maintain;

- has a long service life - up to 10 years.

The performance parameter of this unit is 4.3 m3 per hour. The maximum head is 5.6 m. The device consumes 0.06 kW of electricity.

This range of pumps, like the UPS 25 80 180, is used in heating and air conditioning systems. Units with bronze and stainless steel bodies are also suitable for hot water supply.

Circulation pumps Grundfos UPS 25 40 180 mm and 25 60 180 are sold at a price of 9020 rubles.

UPS 32-40 180

This equipment is suitable for heating and hot water systems. It should be noted that the design does not provide for a prefilter, therefore, the coolant must be of high quality: free of foreign particles, not viscous and not aggressive.

UPS 32-40 180 is a single-stage, three-speed model. The user can, if necessary, change the shaft speed, thereby adjusting the performance of the device. In order for the pump to work normally, it needs to constantly pump liquid - it is the coolant that washes and lubricates its ceramic-graphite bearings.

The model is equipped with a wet rotor. It is very easy to install and does not require additional protective elements - the unit is resistant to current blocking. The almost silent operation of the pump will not distract the user from business.

Key benefits:

- easy installation;

- easy adjustment of the shaft rotation speed;

- built-in protection module;

- no maintenance required;

- a thermal relay is provided in the design;

- high quality and durable parts;

- profitability.

This is a compact device that can work for 10 years without causing problems during operation.

Specifications:

- throughput - 2.72 m3 per hour;

- power - 25 W;

- head - 3.9 m;

- dimensions - 12.6 × 14.1 × 18 cm;

- weight - 2.6 kg.

The circulation pump for heating Grundfos UPS 32-40 180 has a price of 7200 rubles.

UPS 32-60 180

Thanks to its innovative design, the model is considered universal for all systems: heating, hot water supply, air conditioning. The body of the equipment is made of various materials, selected depending on the operating conditions. In addition, the device is suitable for pairing with the "warm floor" system.

All structural parts are made of high-quality, corrosion-resistant materials. Even if the pump works around the clock, it can last at least 10 years. Users note the noiselessness of the device - this is an important advantage in household use.

Specifications:

- power - 50 W;

- throughput - 3.35 m3 per hour;

- head - 5.75 m;

- maximum coolant temperature - up to +95 ° C;

- weight - 2.6 kg;

- installation - vertical or horizontal.

UPS 32-60 180 has proven itself well for household purposes. Its power is sufficient for the efficient operation of the heating circuit.

Benefits:

- easy connection to the network;

- silent operation is ensured thanks to ceramic bearings;

- long service life, for which high-quality structural elements and materials are responsible

- there is a winding of the electric motor, which protects it from blocking the current;

- the ability to set the desired speed;

- on start-up, unnecessary air is removed from the pump.

You can buy this model at a price of 7740 rubles.

UPS 40 120 F

It is a small-sized flange model with quiet operation and economical power consumption. The motor of the device has a wet rotor and a protected stator. Instead of oil seals, 2 O-rings are used.

The pumped liquid serves as a bearing lubricant. To make the design more reliable, the manufacturer has minimized the number of parts. UPS 40 120 F is suitable for heating and air conditioning applications.

Features:

- it is easy to choose the right model for various parameters;

- 3-speed electric motor;

- ceramic bearings (radial);

- the thrust bearing is made of carbon;

- cast iron body;

- built-in thermal relay on the stator.

Like the rest of the products, this line, despite its high power, operates almost silently.

Specifications:

- power - 470 W;

- throughput - 19 m3 per hour;

- head - 12 m;

- coolant temperature - up to +120 ° C;

- weight - 19.1 kg.

This model is suitable for connection to the heating circuit of a large country house or cottage. Price - from 33,060 rubles.

UP 15-14 BUT

This compact unit circulates the liquid for the hot water system. The UP 15 14 BUT pump has a built-in timer and thermostat. Using the timer, the user can program the operation of the device. The task of the thermostat is to automatically maintain the set temperature.

A distinctive design feature is a spherical electric motor that does not use bearings.

Benefits:

- if service is required, the electric motor can be easily removed;

- for the manufacture of the impeller, a corrosion-resistant material is used;

- body made of bronze;

- heat insulating casing included in the kit.

The single-phase electric motor of this unit does not require additional protection, it is already provided by the manufacturer.

Specifications:

- power - 25 W;

- maximum pressure - 10 bar;

- protection class - IP42;

- weight - 1 kg;

- head - 1.2 m;

- liquid temperature - up to +95 ° C;

- throughput - 0.5 m3 per hour.

The cost of this model for hot water supply starts from 7080 rubles.

UPA 15–90 N

The scope of this unit is heating, heating, air conditioning and hot water supply. The design is such that the impeller of the device comes into contact with the coolant, allowing it to react more quickly to changes in the system.

Features:

- 3 steps of speed regulation;

- built-in thermal protection;

- compact size;

- resistance to corrosion formation.

The functional task of this model is to increase the pressure in the system. The device turns on and off automatically, as soon as you open or close the tap. Due to its quiet operation, it can be installed even in an apartment.

Specifications:

- power - 0.118 kW;

- head - 8 m;

- productivity - 1.8 m3 per hour;

- pressure - 6 bar;

- protection - IP 42.

The price of UPA 15 90 N is from 7,500 rubles.

ALPHA2 L 25-40 180

It is not only comfortable, but also a high-performance model on the market today. In addition to its compact size, the device is characterized by excellent performance. Thanks to its innovative design, the unit is suitable for heating and domestic hot water as well as air conditioning and cooling.

Benefits:

- easy installation;

- consumes a minimum of electricity;

- high efficiency, which is achieved thanks to the frequency converter, the most compact stator and permanent magnets;

- technical indicators of the device are automatically adapted to the features of the system;

- easy control - just one key;

- the presence of a display on the case, which is needed to monitor the work.

Any user can install this pump as it comes with a proprietary plug designed specifically for this range. Automation of equipment assumes operation in "night mode", which significantly saves energy consumption.

Specifications:

- power - from 5 to 22 W;

- head - 4 m;

- productivity - 2.4 m3 per hour;

- pressure - 10 bar;

- weight - 2.3 kg;

- protection - IP42.

The price of ALPHA2 L 24-40 180 - from 7600 rubles.

ALPHA3 25-40 130

This is an updated version of the previous model, which has become even more functional and technologically advanced. The pump supports two-way communication function and 2 mobile apps. That is, through a smartphone, the user is able to set the operating parameters of the device, which greatly facilitates its use.

There are 3 control modes for different circuits: with radiators, "underfloor heating" and with a combined circuit. ALPHA3 automatically adjusts to the heating circuit, optimizing energy consumption. Thanks to the mobile application, you can set the schedule for the device.

Benefits:

- simple remote control;

- night and summer modes of operation for various systems;

- dry running protection;

- energy efficient and reliable permanent magnet motor;

- built-in thermal protection;

- connection by means of a special plug;

- the equipment is completed with threaded connections.

Thanks to innovative hydraulic balancing, this model saves up to 20% fuel, which significantly reduces operating costs.

Specifications:

- power - 18 W;

- head - 4 m;

- productivity - 2.6 m3 per hour;

- pressure - 10 bar;

- weight - 2 kg.

The price starts at 19,580 rubles.

Magna

This range includes small, medium and large pumps for commercial applications. Each model is equipped with communication and variable speed motors.

Setting up the equipment is very simple - for this you just need to connect it and leave the factory settings, additionally activating AUTOADAPT mode. As a result, the pump will automatically adjust its own settings, taking into account the characteristics of the system. This will allow you to achieve an optimal level of comfort and minimum energy consumption.

Magna is flexible and reliable equipment with long life and maintenance free.Thanks to the built-in IR communication system, expansion modules can be connected to the device, thereby simplifying its operation.

Features:

- regulation of pressure and temperature;

- various operating modes;

- the electric motor does not require external protection;

- complete with heat-insulating casing;

- profitability;

- TFT display;

- convenient control panel;

- the ability to connect multiple pumps.

At the moment, the Magna line includes several models with different characteristics. In one hour, the equipment is capable of supplying up to 70 m3 of water with a maximum pressure of up to 18 meters. Working pressure indicator - no more than 16 bar.

The price of Grundfos Magna3 25–40 is from 39,700 rubles.

DIY step-by-step installation instructions

In order for the unit to perform its task effectively, it must be installed on a horizontal plane. Equipment with a wet rotor is placed on the supply circuit, and with a dry one - on the return. The fact is that in the "dry" version, rubber or paronite gaskets are used, which deteriorate rather quickly under the influence of high temperatures.

It is advisable that a coarse filter is installed in front of the heating pump. It is necessary to protect the equipment from the ingress of small impurities into it. This will extend the service life of the equipment.

It happens that in the territory where the equipment is installed, the electricity is cut off. In order for the pump to work continuously, an additional bypass must be installed.

Some users during installation cannot determine the correct direction of the nozzles. The manufacturer took this feature into account, therefore, on the body of the pressure equipment, you can see an arrow showing in which direction the rotor rotates, and, accordingly, the coolant.

As a rule, circulation equipment is sold without fasteners, so they will have to be purchased separately. When connecting the device to the network, professionals recommend using a separate cable coming from the switchboard.

The main stages of the work:

- All liquid is drained from the heating circuit. If it has been in operation for a long time, a high-quality flushing is recommended.

- Bypass sections are cut to connect equipment. A bypass is placed between the inserts, which must complement a check valve or ball valve. This will protect the plastic inserts during the welding process.

- The bypass pipeline is equipped with shut-off valves.

- A coarse filter is mounted.

- In the upper part of the bypass, a Mayevsky valve or an automatic air valve is installed.

- The pump crashes. If the model is equipped with a "wet" rotor, then it should be placed horizontally.

- It is best to use a separate grounded outlet for the mains connection.

- The pump is filled with a coolant, its performance is checked.

At first glance, it seems that the installation is not difficult. But this is for advanced users only. In practice, various problems may occur, therefore it is recommended to carefully study the instructions supplied with the equipment. If experience is not enough, it is best to invite a specialist who will take into account all the requirements and correctly configure the unit. Read the wood burning stoves on our website.