Glass wool is a popular material used by humans for thermal and sound insulation since the distant 1873.

it one of the cheapest and most widely available types of insulation.

Let's figure out what qualities, characteristics and features glass wool has, and why it has been popular for the second century.

About the material

This is a special case of mineral wool - insulation based on mineral fibers. Fibers can be of three types:

- glass;

- stone;

- slag.

Thermal insulation is provided by the presence still air between the fibers... Thermal conductivity is in the range of 0.030 - 0.052 W / mK (when measured dry at 10 ° C or 25 ° C).

Sound insulation is obtained by absorption of sound waves by fibers (the sound absorption coefficient of the fibers can be 0.8 - 0.92).

If we compare the thermal resistance of glass wool and brick, then 5 cm of the thickness of the first material corresponds to 1 m of the thickness of the second.

https://youtu.be/CdLJHJPjGIg

Characteristics and properties

Glass wool fibers are located parallel to each other, characterized by significant:

- length - from 15 to 50 mm (this is 2 - 4 times more than stone);

- thickness - from 3 to 20 microns,

This gives products from them strength and resilience - the largest among mineral wool.

Specific strength value of glass fibers exceeds that of steel wire.

The uniformity of the composition determines the high resistance to vibrations, and the low density (11 - 45 kg / m3, compared to 30 - 90 kg / m3 for stone wool) - the minimum impact on building structures.

High compressibility (90%), softness and elasticity make it possible to qualitatively isolate uneven surfaces, structures of complex geometry.

The inorganic base makes the material unsuitable for rodent eating and nesting, is an unsuitable medium for the appearance of mold and mildew.

In addition, glass wool:

- keeps its shape stably;

- does not age;

- does not deform;

- does not cause corrosion of metals in contact with it;

- retains mechanical and thermal insulation properties for decades;

- characterized by frost resistance (used in the range of -60 ° C).

TO disadvantages include:

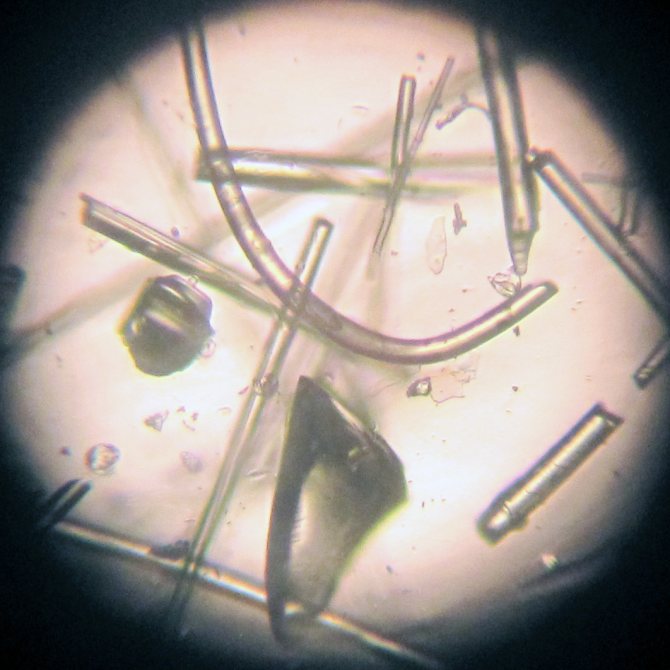

- increased fiber fragility - to protect against the smallest debris, the installation should be carried out in overalls using respiratory protection (for example, respirators), when installed outside, protection from wind is required to prevent fiber migration (for example, the installation of fiberglass);

- excessive moisture absorption (the water absorption coefficient for materials of open porosity can be up to 20% by weight, up to 2% by volume); moisture trapped inside the glass wool irreversibly changes the structure to a more fragile one, leading to a loss of more than 40% of its thermal insulation properties;

- shrinkage over time.

To reduce exposure to moisture, cotton wool impregnated with special compounds (oils, silicon organic compounds), water-repellent additives are introduced.

Harm to eyes

As you know, glass wool is characterized by increased fragility. Sharp and fine debris can penetrate the eyes and cause serious injury. During repair work using glass wool without special glasses, particles can get into the eyes.

Symptoms of getting into:

- acute pain in the eyes;

- lacrimation;

- feeling of discomfort;

- increased painful sensations.

What to do if glass wool dust gets into your eyes? In this case, in case of discomfort, you should consult a doctor.

Structure

What is glass wool made of? This material contains both the main components that ensure its properties as a heater and binders, which allow it to maintain its strength and integrity.

Basic:

- glass or glass broken;

- natural quartz sand;

- limestone (chalk);

- soda ash;

- boric acid;

- borax (sulfate);

- dolomite;

- fluorite.

Binders:

- polymer resin;

- clay;

- spar;

- other substances.

Binder components can be 2.5 - 10% by weight.

The question that arises for some, why is glass in glass wool, can be answered as follows. The presence of this component determines the important properties of the material, namely:

- incombustibility;

- unattractiveness to rodents and mold;

- strength and durability.

If glass wool was in place of glass, say, wood fibers, all these advantages would be reduced to zero.

Does glass wool burn?

Glass wool does not support combustion, belongs to the class of non-combustible materials (NG).

Such materials withstand exposure to high temperatures while maintaining the integrity of the structure, strength and other properties, they do not ignite.

The material is sintered at temperatures from 500 to 550 ° C.

The temperature range of use is determined by the composition, more precisely, by the organic resins included in the composition as a binder. For glass wool, the upper limit is 250 to 450 ° C. Exceeding this range can be considered the melting point.

In this case, the upper limit is determined by the temperature of burnout of the resins, as a result of which the material loses its binder, and, consequently, its operational properties.

Under the influence of fire no release of toxic and harmful substances.

Applications

If we talk about the industries of application, then these are:

- building;

- heat supply;

- production;

- automotive industry;

- aviation;

- pipeline transportation of materials.

For every sphere different types are selecteddiffering:

- type of fiber

- their location,

- the presence of additional coatings,

- density (maximum possible - 130 kg / m3).

Most common designs glass wool - rolls and soft mats.

Fiberglass insulation is available in the following form:

- continuous filament (rolls);

- staple (cut) fibers (slabs), including those characterized by increased rigidity with facing;

- soft mats;

- reinforced rolls;

- cached technical insulation, including in the form of foil-clad products.

Rolls for a long time and successfully used for insulation of horizontal surfaces - floors, roofs.

Cached View - for insulation of high-temperature pipelines, assemblies and containers.

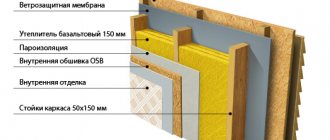

Mats and slabs used for thermal insulation of various premises and structural elements, namely:

- facades;

- window and doorways;

- interfloor and other floors;

- internal and external partitions of buildings;

- sound and thermal insulation of cabins.

Cotton wool should be fastened in such a way as to provide a free position (for maximum expansion) and at the same time a tight fit without gaps.

Non-combustible mineral wool: in what forms it is produced

Mineral wool insulation that does not burn is available in several versions with excellent performance. These include:

- soft;

- semi-rigid;

- tough.

Soft mineral wool slabs do not burn, have average density, a small coefficient of thermal conductivity. Suitable for use in structures that do not require heavy loads.

Semi-rigid mineral wool slabs also do not burn, have a density twice that of soft slabs, and are suitable for insulating vertical structures.

Rigid slabs, like the previous options, do not burn, they have the highest density indicators. They are used for insulating structures of any type, especially relevant for the insulation of roofing systems without a concrete screed.

Non-combustible mineral wool slabs are the most popular insulation. They are followed by mineral wool mats, also with the ability to resist fire. The main difference between the slabs and mats is the structure - fibers stitched with a special thread, forming a canvas similar to a quilt. The thickness and length of the mats vary by brand. The advantage of the mats is the protective foil or mesh layer.

Both slabs and mats from the non-combustible category are indispensable for insulating flammable structures. These can be wooden houses, verandas, baths, etc. Thanks to mineral wool insulation with a melting temperature of 600 degrees Celsius, it becomes possible to protect buildings and structures from fire damage, increase noise absorption and heat conservation.

https://youtu.be/LQFRwJc08u0

Production

Production begins with the introduction of the starting components into the smelting furnace. As a result of the temperature of 1400 ° C, centrifugal forces of centrifuges and steam inflation get glass filaments.

To obtain the finest yarns with the required mechanical properties at the outlet, strict adherence to the recipe composition is required.

The yarns treated with binder solutions of polymers (modified urea, phenol-algid polymers) are sent to a straightening conveyor to be formed homogeneous fiberglass cloth.

This is followed by the stage of polymerization - a temperature of 250 ° C becomes a catalyst for the formation of polymer bonds and removal of excess moisture.

Cooling, cutting with saws and milling cutters, then - pressing (compressed 5-6 times), packaging in polyethylene - we get ready-to-transport rolls and plates.

The use of cullet as the main component deserves special attention.

Modern technologies allow add up to 80% glass powder, obtained by crushing and grinding of commercial glass waste.

The composition of cullet is regulated by national standards - GOST R 52233-2004. According to the provisions of the document, this secondary raw material can be of 1 or 2 grades and one of five grades in accordance with the color (BS, PST, PSL, ZS, KS).

Glass wool obtained as a result of the disposal and processing of household and industrial glass waste meets all the requirements for these products.

At the same time, a product made from recycled materials differs lower production costs in comparison with traditional technology, and, as a result, a more affordable price for the consumer.

Many companies are engaged in the production of glass wool using this technology, including:

- Isover;

- URSA;

- Knauf.

Staple fiberglass: harm to skin and eyes

If the process of laying fiberglass was carried out without overalls and gloves, then sharp particles could get on the surface of the human skin and penetrate inside. This can cause irritation and allergies. Most often, the first signs are itching, redness, and pain at the sites of penetration. It is not worth combing the reddened areas, and first aid consists in rinsing the skin under cold running water.

All work involving the use of fiberglass must be carried out in special clothing and rubber gloves. Tarpaulin mittens may also work.

Everyone knows that glass wool has increased fragility.For this reason, sharp, inconspicuous debris can fall into the eyes of a person. The work should be done exclusively in special glasses, so as not to allow further problems.

Manufacturing standard

Glass wool production regulated by a number of regulatory documents... GOST 19170 2001 is considered the main one.

It describes:

- production methods;

- protective measures when working with material;

- scope of application.

Manufacturing according to our own is allowed, approved in the appropriate order by TU.

How to work with fiberglass

Experts provide some tips for working with fiberglass to help protect your health.

During direct contact of glass wool with human skin, when they work without gloves and overalls during installation, sharp fragments of microparticles penetrate inside and cause skin irritation, at the point of contact it turns red, itching appears

For example:

- When working, use disposable special clothing with a hood;

- Wear safety glasses;

- Cover your hair with a hat or cap;

- Make sure that your hands do not come into contact with the material, use gloves or gloves;

- If the material is loose, work in a cotton-gauze bandage;

- If glass wool gets on an open skin area, take a shower to wash off all microparticles;

- Do not try to wash work clothes if cleaning is necessary - shake off dust vigorously.

But most importantly, in the event of an injury, it is an appeal to a medical institution, since it is almost impossible to alleviate the situation at home. The harm that staple fiber possesses is obvious. The danger can be anything from itching, bronchitis (if inhaled) to a long list of body allergies. How dangerous vata is, and what to do to get rid of the consequences, you can learn from a special video. How to work in such conditions, how to cleanse the skin of small particles, whether it will be enough to simply wash, and what to eat in case of poisoning, you can find out all this in the video format.

Pros and cons as insulation

Based on the properties of glass wool, we can distinguish both positive and negative qualities.

The pluses include:

- good heat and sound insulation properties;

- fire safety;

- resistance to biological influences (pests, bacteria);

- light weight;

- ease of transportation;

- low cost (700 - 2100 rubles).

By cons:

- hygroscopicity (the need for additional vapor barrier);

- inconvenience of installation (the need to use protective equipment);

- the appearance of shrinkage after 8 - 10 years of service.

Is there any harm to human health?

In this question, there is information chaos.

Manufacturers selling glass wool talk about its harmlessness, while competitors offering other insulation materials talk about adverse effects.

We will not argue, we will only report the facts.

Glass wool can be dangerous and pose a threat only during its installation - there is a possibility contact of glass dust on the skin and in the respiratory system.

For protection, it is necessary to use protective clothing, respirators.

There is good news in this matter - modern technologies allow the production of materials that do not spread glass dust.

At the end of the installation, glass wool insulation becomes completely harmless.

Overalls are cleaned:

- shake off;

- vacuum cleaning;

- wash with 3-4 rinses;

- re-vacuuming after drying.

If glass wool particles come into contact with your skin, take a cool, strong shower without using detergents.

Why cool? Because hot water expands the pores, and therefore the penetration of glass particles.

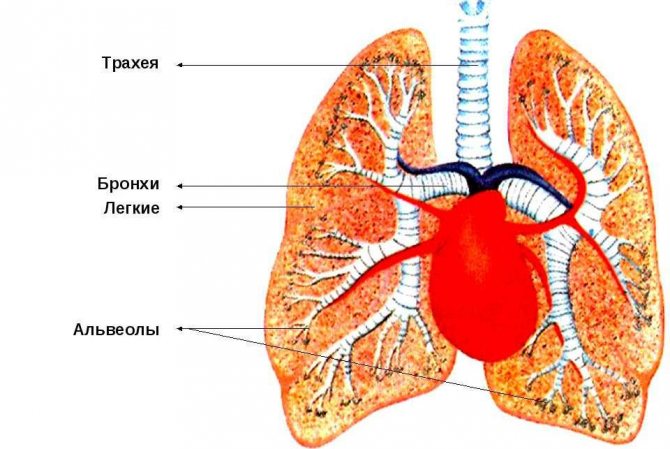

Consequences of getting basalt dust into the lungs

It is widely believed among many users that the greatest threat from stone wool lies in the ingress of microparticles from its fibers into the human lungs. It is especially dangerous if the material is used indoors, and not for external insulation. The concentration of such dust in the room will be essential for harm to the body.

When it enters the respiratory tract, the basalt fiber permanently settles in the human lungs. Subsequently, favorable factors are created for the development of various microorganisms, cysts are formed. The latter, in turn, are dangerous with trematodes, which are dangerous by malignancy, leading to the development of malignant formations.

There were cases when patients with oncology in the lungs lived or worked for a long period in rooms with particles of asbestos or basalt fibers in the air. That is why many European construction organizations refuse to use these materials.

Recycling

Glass wool can be obtained by recycling cullet. And how is it disposed of itself?

Today there are three options:

- Burial at special landfills.

- Pure grinding and reuse in road construction, brick making.

- Use in the form of a charge - a solid residue formed during waste incineration. In this case, the glass component can reach 78% of the total volume, almost 20% is clay, 2% is sodium silicate.

The price of the recycling service for the disposal of glass wool ranges from from 400 to 1,000 rubles per ton.

There are also installations (mills) for processing (deep grinding to a size of 0.1 - 100 microns) of industrial glass fiber waste and its return to the technological process.