Variety of heaters Technonikol

Thermal insulation of a domestic manufacturer is represented by two main classes of insulation: mineral wool and extruded polystyrene foam.

Minvata Technonikol consists of the finest strands of rocks. There are air cells between basalt weaves. This combination provides excellent performance. Stone threads are responsible for the strength, refractoriness of the material, and many air cells give the basalt slabs required heat capacity.

Extruded polystyrene foam (EPS) is produced by combining styrene with special foaming additives. All components are mixed under high heat and pressure. The prepared mass is passed through an extruder - at the exit, smooth surface slabs.

Competitive advantages of EPPS: light weight, easy installation and rigidity... Excellent strength characteristics allow using expanded polystyrene in areas where a soft heat insulator is not suitable. The disadvantages of EPS are flammability, the release of corrosive smoke during combustion.

Meet TechnoNIKOL products

This company, currently on a par with the largest European manufacturers (more precisely, one of the five largest of them), produces not only thermal insulation. She makes the following products.

Roofing materials:

- Roof tiles;

- roofing material;

- membranes made of polymeric materials;

- primers;

- mastics.

Heaters:

- Expanded polystyrene made by extrusion;

- mineral (basalt) wool, made in the form of slabs.

Basalt wool: composition and features

The finest stone fibers of this material consist of processed gabbro-basalt rocks. There are a lot of air spaces between these fibers. As a result, the level of thermal insulation of the material is simply excellent. After all, it is no secret that it is air, being motionless, that has great resistance to heat transfer.

But this is not all the advantages of the insulation - it is good not only in frost, but also with a critical increase in temperature. Such characteristic of Technonikol mineral wool as fire resistance is very impressive. This material does not burn, calmly withstanding temperatures of even 1000 degrees Celsius. However, it does not even melt! Even if, unfortunately, there is a fire, basalt wool will protect your home, preventing walls and ceilings from collapsing. It will block the path of fire, without emitting a single drop of harmful substances in case of fire.

- You can familiarize yourself with the characteristics of the basalt wool insulation in the article: Technical characteristics of basalt insulation, advantages, disadvantages and scope.

Extruded polystyrene foam Technonikol

This type of material is increasingly used for the insulation of houses both in our country and abroad. After all, it keeps warm very well. For example, to achieve an equivalent effect, you need to take a layer of wood 10 times thicker than expanded polystyrene (twenty centimeters versus two). So the EPS is cheaper. And it is much lighter than other heaters, and this reduces transportation costs and facilitates installation. Its strength and rigidity allow it to be used where softer heat insulators cannot cope. But this material is afraid of fire - it not only burns, but also releases toxic substances. So it is necessary to comply with fire regulations, providing adequate protection.

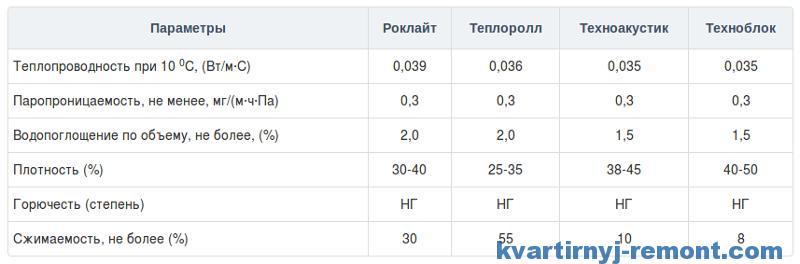

Types and characteristics

The range of mineral wool is quite diverse and is able to satisfy the needs of even the most demanding consumer.

"Rocklight"

This type is characterized by low weight and standard dimensions of min-plates, as well as low formaldehyde and phenol content. Due to its durability, the material is widely used for insulating country houses and summer cottages., allowing for a long time not to worry about the repair of thermal insulation.

Plates are suitable for finishing vertical and inclined surfaces, can be used for insulation of the attic and attic. The material has excellent vibration resistance and is neutral to alkalis. The slabs are not of interest to rodents and insects and are not prone to fungus.

"Rocklight" is distinguished by high thermal resistance: a 12 cm thick layer of minelite is equivalent to a thick brick wall 70 cm wide. The insulation is not subject to deformation and crushing, and during freezing and thawing it does not settle or swell.

The material has proven itself as a heat insulator for ventilated facades and houses with siding finishes. The density of the slabs ranges from 30 to 40 kg / m3.

Technoblock

More dense and incompressible (compared to the listed) mineral wool slabs with a low phenol content in the binder.

- similarly to Technoacoustic plates, they provide both thermal insulation and noise protection;

- can be used for arranging wall layered masonry (unlike expanded polystyrene, these plates are vapor-permeable), both with and without an air gap, as well as frame walls.

"Technoruf"

High-density mineral wool for insulating reinforced concrete floors and metal roofs. Sometimes it is used to insulate floors that are not equipped with a concrete screed. The slabs have a slight slope, which is necessary to drain moisture to the catchment areas, and are covered with fiberglass.

"Technovent"

Non-shrinking plate of increased rigidity, used for thermal insulation of ventilated external systems, as well as used as an intermediate layer in plastered facades.

Technoflor

The material is intended for thermal insulation of floors exposed to serious weight and vibration loads. Indispensable for the arrangement of gyms, production workshops and warehouses. The cement screed is then poured over the mineral slabs. The material has low moisture absorption and is often used in combination with the "warm floor" system.

Technofas

Mineral wool used for external heat and sound insulation of brick and concrete walls for plastering.

Technoacoustic

Slabs with a special arrangement of mineral fibers that provide a high level of sound absorption. In addition to incombustibility and moisture resistance, the following should be noted:

- the main area of application is the arrangement of soundproofing of frame partitions, suspended ceilings and floors between floors with laying on logs, no load;

- can be used both in apartments and office premises;

- the material has a low rate of compressibility, which allows it to work without shrinkage as part of vertical structures for 50 years or more.

"Teploroll"

Roll material with high sound insulation properties and having a width of 50 to 120 cm, a thickness of 4 to 20 cm and a density of 35 kg / m3. It is used in the construction of private houses as a heat insulator for pitched roofs and floors.

TechnoACUSTIC

Thermal insulation boards Technoacoustic - these are non-combustible, sound-absorbing mineral wool slabs based on rocks of the basalt group. The special arrangement of the fibers ensures high sound absorption properties. Recommended for use as a sound absorber in the structures of frame-sheathing partitions and claddings, in the structures of suspended ceilings, as well as in ceilings with a non-loaded installation of insulating material.

The use of TECHNOACUSTIK in the above structures ensures their compliance with building codes and regulations, fire safety requirements and environmental comfort. High physical and mechanical properties ensure reliable operation of the material in vertical structures for more than 50 years.

The use of modern high-performance sound insulation TECHNOACUSTIK provides higher sound insulation values and saves on the supporting structure. The main advantages of TECHNOACUSTIK sound insulation are:

- High soundproofing ability;

- Stability of volume and shape, insulation does not shrink;

- Low water absorption;

- The insulation is resistant to microorganisms and rodents;

- Neutrality in contact with concrete and metal materials;

- Ease of installation of insulation, ease of cutting and processing

- Fire safety (group NG)

| Indicator name | Unit measurements | TECHNOACUSTIK | Test Method | |

| Compressibility, no more | % | 10 | GOST 17177 | |

| Flammability | power | NG | GOST 30244 | |

| Thermal conductivity | λ10 | W / m S | 0,035* | GOST 7076 |

| λ25 | 0,037* | GOST 7076 | ||

| λ A | 0,039* | GOST 7076 SP 23-101-2004 | ||

| λ B | 0,040* | GOST 7076 SP 23-101-2004 | ||

| Water vapor permeability, not less | mg / (m h Pa) | 0,3 | GOST 25898 | |

| Moisture by mass, no more | % | 0,5 | GOST 17177 | |

| Water absorption by volume, no more | % | 1,5 | GOST R EN 1609 | |

| Organic matter content, no more | % | 2,5 | GOST R 52908-2008 (EN 13820-2003) | |

| Density | kg / m3 | 38-45 | GOST R EN 1602 | |

| Sound absorption class with a total thickness of the insulation layer: | 50 mm | NSV | 212 | GOST R - 16297-80 GOST 27296-87 |

| 100 mm | NSV | 211 | ||

| 150 mm | NSV | 211 | ||

| 200 mm | NSV | 111 | ||

Price

RUB / package

887

from

Extruded polystyrene foam - application features

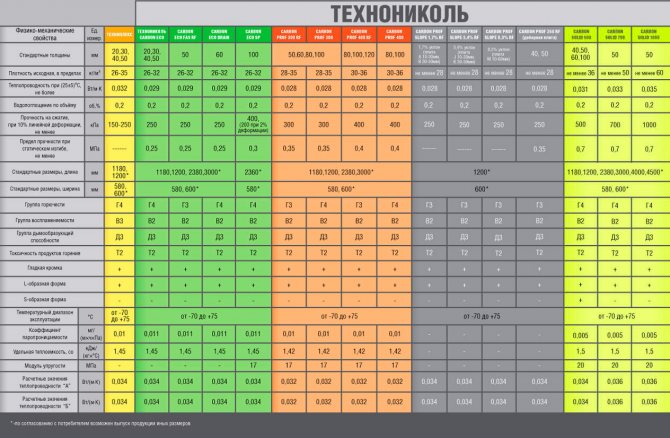

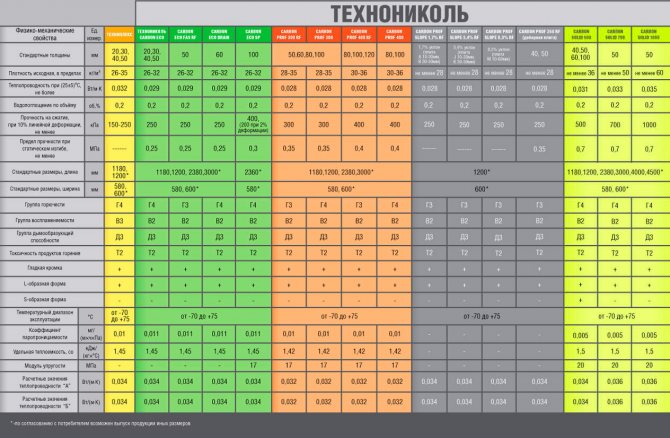

Polystyrene foam insulators are combined into one series - Carbon. The materials have similar characteristics, but differ in the form of release. The type of performance largely determines the scope of use of the EPS.

Material characteristics

Insulation is produced by extrusion. As a result, many sealed cells are formed. The composition and structure of expanded polystyrene endowed the heat insulator with the following properties:

- Low thermal conductivity. An indicator of 0.028-0.035 W / m * C makes the material one of the leaders in terms of thermal efficiency.

- Hydrophobicity. EPPS does not absorb moisture, retains its characteristics in a humid environment.

- Moderate burning. The use of carbon made it possible to minimize the flammability of expanded polystyrene - no burning droplets are formed when the material melts.

- Insulation thickness - 20-120 mm. The choice depends on the area of operation.

- Thermal insulator resistant to fungus, mold, and pests.

- The operating temperature range is comparable to that of basalt insulation - from -50 ° C to + 75 ° C.

Weaknesses of EPS: vulnerability to gasoline, solvents, UV rays, fire.

Carbon: variety of commodity items

Types of TechnoNIKOL Carbon extruded polystyrene foam:

- Eco - slabs of various thicknesses (20-100 mm) for insulating low-rise buildings, cottages.

- Drain - one side of the EPS has drainage grooves. The holes provide improved ventilation when insulating a flat roof or drainage of rainwater when insulating the foundation.

- Eco Fas - arrangement of house plinths, plastered facades. Milling from the outside ensures good adhesion with various surfaces.

- Eco SP - applicable for insulation of foundations using the Swedish plate method. The foundation is laid with communications, a floor heating system. Eco SP has increased rigidity, very low thermal conductivity.

- Prof - maximum strength. Application - insulation of floors on the ground, various foundations, flat roofs.

- Prof Slope is a combination of five panels that form a wedge-shaped insulation.

- Solid - high strength due to closed cells. Used on an industrial scale: insulation of highways, floors under load, railways.

TechnoBLOCK STANDARD

Basalt wool TechnoBLOK STANDARD is one of the many insulation materials produced from basalt rocks under the influence of heat treatment with the addition of a synthetic binder. This type of mineral wool is widely used as heat and sound insulation for various structures in industrial and residential construction. A prerequisite for the use of plates of the Technoblock Standard is the absence of external loads on the insulation.

Technoblock insulation is used to insulate horizontal and vertical surfaces of enclosing structures in buildings of any type, but it found the most widespread use in cottage frame construction.

TECHNOBLOCK slabs have:

- low level of thermal conductivity;

- resistance to high temperatures;

- stability of shape and volume;

- low rate of water absorption;

- high rate of sound absorption capacity;

- resistance to the action of rodents and various microorganisms;

- neutrality when interacting with various building materials and concrete;

- ease of installation;

- ease of processing and cutting (cut with a saw or knife).

Main characteristics of TECHNOBLOCK STANDARD

| Indicator name | Index | |

| Compressibility, no more | 8 % | |

| Flammability | NG | |

| Thermal conductivity | 0.037 W / m | |

| Water vapor permeability, not less | 0.3 mg / (m h Pa) | |

| Moisture by mass, no more | 0,5 % | |

| Water absorption by volume, no more | 1,5 % | |

| Organic matter content, no more | 2,5 % | |

| Density | 40-50 kg / m3 | |

Price

RUB / UP

740

from

Innovative insulation PIR TechnoNIKOL

The mats are made of polyisocyanurate foam. The structure of the slabs is sealed cells, externally the insulation is covered with a layer of foil. This solution improves thermal efficiency - the thermal conductivity coefficient is reduced to 0.021 W / m * C. An innovative polymer is used to insulate the fuel tank of rockets.

A 1.6 cm PIR insulation layer is equivalent in terms of thermal efficiency to a 1.34 m concrete wall.

Polyurethane is considered the toughest elastomer with compressive strength over 120 kPa. The excellent characteristics of the insulation make it in demand when arranging flat roofs. Reviews of PIR insulation are positive - the material is lightweight, easy to install, durable, and the aluminum layer increases its fire resistance.

TechnoNIKOL products are in active demand. Main advantages: wide assortment of choice, high quality and loyal pricing policy.

Insulation features

Thermal insulation "TechnoNicol" is a unique product of its kind. It is distinguished from competitors (Knauf, Isover, Rockwool, etc.) versatility, high quality and reasonable price.

Versatility. It is also expressed in the fields of application and the materials used. So, the company's products can be found in almost all areas of the national economy (in truth, it is more difficult to say where it cannot be found), and in construction there is no such structural element of the building and its type (residential buildings, garages, baths, saunas, summer cottages, etc.) etc.), where it is impossible to use "TechnoNicol" heaters.

This is evidenced by the extensive range of assortment. But the versatility of TechnoNIKOL wedge-shaped insulation, the release of which was one of the first to be mastered by the company, illustrates the most vividly.

If we talk about the raw materials used for the production of insulation, the company produces thermal insulation materials from all the most popular materials: basalt wool, expanded polystyrene, polyurethane foam.

Quality. The manufacturer can find out the most accurately about the quality of its products in various forums. Here the company is in complete order - it is difficult to find a negative review (if desired, it is still possible). The high level of quality is also confirmed by the awards received by the brand at various exhibitions of thermal insulation materials.

Acceptable price. The manufacturer strives to cover all market segments.Therefore, on sale you can find the same type of insulation with a budget price and a cost per 1 m2 of several thousand rubles. Such variability of prices is achieved by changing the density of the material.

Specifications

Physical and mechanical characteristics determine the suitability of a particular material for the specific needs of the buyer. Plates differ in strength, slope, thickness and cost.

Fire resistance

Most of the insulation materials are non-flammable. The flammability group of raw materials has its own marks. For example, heat-insulating boards "Pir" for a bathhouse and a balcony are marked with the G4 mark. Materials with fiberglass and foil lining have indicators G1 and G2.

Extrusion varieties "Eco" and professional insulation with carbon fiber have indicators G 3 and G4. At the same time, smoke generation and flammability are marked with D3 and B2 markings. Techno stitched materials are a non-combustible type of heat-insulating material for any material thickness (from 30 to 80 mm). Basalt-based and basalite-sandwich versions are marked with NG (non-combustible).

Thermal conductivity

The performance of each material is different. For example, the level of thermal conductivity is:

- technical heat insulators - 0.037-0.041 W / mS;

- extrusion analogs in the form of plates - 0.032 W / mS;

- thermal insulation boards "Pir" - 0.021 W / mC;

- basalt-based analogs - 0.038-0.042 W / mC;

- options for shipbuilding - 0.033-0.088 W / mS.

Specifications

Each type of insulation has its own technical and operational characteristics.

Basalt wool

Basalt insulation "TechnoNIKOL" has attractive performance indicators for consumers:

- thermal conductivity - 0.048-0.077 W / (m · K);

- density - 28-210 kg / m3. The value of the indicator depends on the purpose of the insulation. So, for inclined surfaces, the most optimal density will be 35-40 kg / m3, for the facade - 80-100 kg / m3, and under the screed on the floor or on a flat roof - 150-210 kg / m3;

- vapor permeability - 0.25-0.35 mg / m2 * h * Pa;

- strength:

- for compression - 8-60 kPa;

- separation of horizontal layers from each other - 80 kPa;

- bending - 0.15 MPa.

- durability - more than 50 years;

- operating temperature: from -170oС to + 1000oС.

In addition, cotton wool does not burn (flammability class NG) and does not absorb moisture - hygroscopicity is completely absent (water absorption is only 0.095% in 24 hours of soaking). More details about the performance of basalt mats can be found in the work "Basalt slab".

Extruded polystyrene foam

A feature of extruded polystyrene foam produced at the enterprises of the TechnoNIKOL concern is the inclusion of carbon in the form of nanoparticles in the insulation. This significantly changed all the technical parameters of the material: thermal conductivity, service life and physical and mechanical properties. Therefore, the numerical values given below may differ significantly from the generally accepted ones (data taken from the official website of the company www.tn.ru):

- thermal conductivity coefficient - 0.029-0.035 W / (m · K);

- density - 26-36 kg / m3;

- bending strength - 0.025-1.0 MPa;

- vapor permeability - 0.005-0.011 mg / m2 * h * Pa;

- flammability class - G3-G4 (note that the company honestly indicates the flammability class);

- durability - over 50 years.

Liquid polyurethane foam

One-component polyurethane foam has open cells, and therefore its technical characteristics differ significantly from those of two-component polyurethane foam:

- thermal conductivity coefficient - 0.025-0.045 W / (m × ° K);

- vapor permeability - 0.07-0.17 mg / (m * h * Pa);

- density - 8-18 kg / m3;

- moisture absorption - 10.0-60.0%;

- compressive strength - about 1.02 kgf / cm2;

- bending strength - about 17.0 kgf / cm2.

Thermal insulation boards PIR

Polyurethane foam boards have the best technical and operational indicators among all heaters on the market. Among them:

- thermal conductivity - 0.028-0.030 W / (m × ° K). The manufacturer indicates a value of 0.021 W / (m × ° K), which raises reasonable doubts.The work "PPU Plates" explains in detail why;

- density - 40-160 kg / m3;

- vapor permeability - 0.02-0.05 mg / (m * h * Pa);

- strength:

- when compressed to destruction - 200 kPa or more;

- bending to fracture - not less than 300 kPa.

- water absorption when immersed in water for a day - 1-1.5%.

Release form

The company offers two types of insulation: in rolls and in the form of sheet material. The second type is thermal insulation made of rectangular sheets. For ease of transportation, they are sold in packages of several pieces. The number of sheets in a bundle may vary. It depends on the thickness of the insulation and its composition.

For the convenience of the buyer, the manufacturer indicates the number of square meters on the marking. This allows you to perform cladding of roll or sheet material, taking into account the specific parameters of the base.

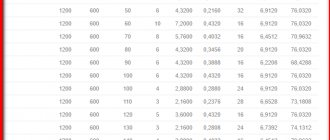

Dimensions (edit)

In addition to the fact that the dimensions of roll and tile materials are different, the brand provides for a flexible approach to each client. On an individual order, you can make insulation in a different format, convenient for the customer. The dimensions of standard slabs are 1200x600x100, 1200x600x50 mm. The thickness of the material varies on average from 1 to 15 cm. The sizes of varieties with an edge are 1185x585, 1190x590 mm with a width of 20, 30, 40, 40 mm. The length range is from 600 to 12000 mm, the width is from 100 to 1200 mm.

How to choose insulation

In the process of choosing a thermal insulation material, regardless of the manufacturer, the user should pay attention to a number of criteria. It is they who will allow you to choose the right insulation, taking into account the climatic zone, external natural factors. Therefore, the following requirements are imposed on the selected material.

- Thermal insulation level. This criterion must correspond to a particular climatic zone, as well as to the material of the insulated surface itself - it is wood or brick, blocks, and so on.

- The weight of the insulation itself - the lower it is, the more savings on fastening, the less weight is given to the wall, the very foundation of the structure.

- The level of vapor permeability - the indicators here should be high, as this will ensure the removal of moisture and the walls will always be dry.

- Long years of service. You shouldn't choose a material that will last only 5-8 years - at least 25 years.

- Environmental indicators are also important, when the insulation does not emit harmful and poisonous compounds into the air.

- Resistant to ultraviolet light, as well as insects, such as bark beetle or rodents.

- The material itself must have low flammability indicators.

- Moisture absorption. The indicator should not exceed from 30 to 60%.

Important! And the last criterion is the cost of the insulation. According to general standards, the cost of insulation should not be more than 10% of all costs for building a house.

Installation features

Among the popular methods of insulation, craftsmen use two techniques - a wet and a dry facade. The method of insulating a wet facade provides for the presence of wet materials during the finishing itself - adhesive mixtures and plaster, and so on. The very same technology of this type of wet installation is as follows.

The insulation itself is simply attached, so to speak, "put" on the adhesive mixture. Then they are fixed with umbrella dowels. This will allow the material itself not to deform during operation, not to slide off the wall itself. With regard to the consumption of the dowels - at least 5 pieces must be used per square meter of area. After that, a reinforcing special mesh is attached at the top and again covered with a layer of glue, then primed with special compounds. Finish the work by applying a layer of decorative plaster and paint.

Insulation installation

Each type of insulation has its own installation technology. At the same time, it can be modified depending on which structure of the building is being insulated. The standard insulation scheme is as follows:

- the calculation of the necessary materials is carried out (insulation, vapor barrier film, lathing timber, fasteners, etc.);

- a set of tools and devices is being prepared, materials are purchased;

- preparatory work is in progress;

- insulation is attached;

- if necessary, vapor barrier works are carried out;

- finishing of the walls is carried out from the outside and from the inside, the ceiling from the inside.

A detailed description of each type of thermal insulation work using TechnoNIKOL insulation can be found on our website Stroy.Guru.Com:

- insulation of roof structures:

- "Is it possible to insulate the roof with foam and how?" - the instructions for insulation are the same for EPS and PIR boards;

- Do-it-yourself PPU roof insulation;

- "Insulation of the roof of a private house with mineral wool".

- ceiling:

- "Thermal insulation of the ceiling with mineral wool".

- facade:

- "Do-it-yourself wall insulation with mineral wool";

- "Do-it-yourself PUU walls insulation";

- "Technology of wall insulation with basalt wool";

- "How to insulate internal and external walls with foam" - the technology is suitable for extruded polystyrene foam and PIR boards.

- gender:

- Do-it-yourself PPU floor insulation;

- "Floor insulation with mineral wool";

- "How to insulate the floor with foam."

Advantages and disadvantages

Manufacturing facility .

Any material has its pros and cons, without considering which its characterization will be incomplete. Let's start with the positives.

Minvata resists fire well.

Advantages of TechnoNIKOL cotton wool:

- Basalt raw materials... Cotton wool is produced only from high-quality raw materials of the gabbro-basalt group, as a result, the material does not burn, does not cause allergies, and has good technical characteristics;

When insulating the floor, the slabs are laid between the logs.

- High quality binder... Any mineral fiber board is impregnated with organic resins containing phenol and formaldehyde. TechnoNIKOL uses only high-quality resins, in which these dangerous toxins are bound and do not escape to the outside;

Fiber does not cause itching and allergies.

- Wide range of... You will be able to choose the kind of insulation that is best suited for your purposes. The manufacturer is constantly expanding its product range for your convenience;

Good sound absorption allows you to lay material for filling walls from gypsum board.

- Exact geometry... Mats and especially slabs have clearly marked dimensions, which are maintained from product to product with millimeter precision. This facilitates the calculation and installation of insulation;

The photo shows - dense mats can withstand the weight of an adult man.

- Simple assembly... Heaters of this brand are distinguished by the ability to do it yourself without the involvement of specialists. As a result, the cost of insulation is much lower;

Basalt wool is successfully used for facade insulation.

- Durability... The company's products are distinguished by a long service life exceeding 50 years (subject to the conditions of use and installation).

The instruction allows you to work with mineral wool on your own, without the involvement of specialists.

Disadvantages of mineral wool:

- Dust emission... Even basalt raw materials cannot completely protect from dust. Although it does not itch and does not prick, inhaling it can be harmful to health, therefore it is recommended to cover the plates with membranes;

It is better to work with mineral wool with gloves and a respirator.

- Vapor permeability... Although the fibers themselves do not absorb moisture, moisture can accumulate inside the cotton wool in the form of steam and drops, increasing its thermal conductivity. It is recommended to use a vapor barrier for laying slabs and mats;

- High price... Basalt wool is more expensive than any similar insulation, it is more expensive than expanded polystyrene and a number of other materials. In return, you get safety and good insulation.

Characteristics of stone wool

In general, the features of TechnoNicol stone wool and its technical characteristics are very similar. Basically, when choosing a material, it is worth considering:

- Manufacturer's recommendations;

- Density (hardness);

- Material type.

The manufacturer initially recommends some types of insulation for specific tasks. For example, Technoacoustic plates are used for soundproofing interior partitions. In the video below, at 6 minutes 31 seconds, the manufacturer recommends Rocklight for insulating the attic.

And, as a front insulation TechnoNicol, Technofas is recommended. If there is a need for insulation of the foundation, TechnoNikol recommends Technoruf. In general, the insulation of the foundation must be carried out with hard mineral wool slabs.

Density, the second important factor that affects the scope of the cotton wool. There are three main types of cotton wool layout:

- Mats (rolls);

- Soft slabs;

- Rigid slabs;

Mats or rolls are used to insulate the ceiling in the attic, or it can be laid between floors. Insulation of walls of balconies and loggias may require the use of hard slabs, if there is no possibility or desire to use the crate.