Thermal insulation IZOVOL

Izovol company - produces building materials for complex solutions to problems (heat, sound, fire) insulation. Izovol brand insulation is used in systems, structures and structures for various purposes, as well as used for the reconstruction of buildings. Izovol technologies are successfully applied in medicine, energy and mechanical engineering, which makes the company an absolute leader in its industry.

Izovol products are distinguished by an incomparably high level of quality. It is possible to maintain a consistently high level of production at the enterprise thanks to the availability of modern technology and experienced specialists who control the quality of goods at every stage of production.

The latest technologies developed by the best specialists of the IZOVOL laboratory reduce the risk of defects and defects, therefore the company gives its customers a guarantee for each product.

Another of the main principles of Izovol is the production of environmentally friendly insulation, safe for human health. The material underlying the materials is pure basalt fiber, so choosing Izovol, you can be sure that you will not harm yourself.

IZOVOL is proud of its innovations and values every client. The management of the plant is confident that a responsible attitude to production, combined with attention to the consumer, guarantees the success of any product.

Characteristics of Izovol heaters

Thermal insulation of walls is a guarantee not only for the insulation of the outer walls, but also for sound insulation and fire resistance. Insulation for walls outside is produced using an environmentally friendly fiber technology - ECOSAFE, which is why Izovol thermal insulation is used in residential construction. Izovol material density helps to reliably isolate walls from outside noise and drafts.

What insulation is better - insulation Izovol

On the website of Trading House SSKkomplekt we offer you to familiarize yourself with the best Izovol insulation products:

| Izovol 35; |

| Izovol 75 (Izovol Art 75); |

| Izovol 50; |

| Izovol 90; |

| Izovol 100 (Izovol 120 f); |

| Izovol 150; |

| Izovol acoustician. |

It should be noted that Izovol mineral wool is a certified and high-quality building material that does not cause harm and damage to health. The thickness of Izovol insulation guarantees protection from external influences. Thermal insulation of the facade is essential in residential construction. Thermal insulation is suitable for warming interfloor ceilings, rooms with high humidity and warming of basement floors.

Insulation for the house outside Izovol has a warranty period and will not upset the owner of the house. The calculation of the amount of thermal insulation for a construction site is made by architects and technologists when planning a building project. Roof insulation is required to insulate frame walls and floors between floors.

Buy insulation for walls Izovol

You can always buy Izovol insulation inexpensively in the StroyCityKomplekt trading house. An official Izovol dealer is ready to provide you not only with a guarantee from the manufacturer and all the necessary documents, but also offer a favorable price for insulation. Order insulation at StroyCityKomplekt by calling the number indicated on our website and get a free consultation and cost estimate from our managers.

Scopes of IZOVOL insulation:

- residential construction;

- industrial engineering.

- insulation of the roof and attic;

- insulation of floors;

- warming of inter-rafter spaces;

- facade insulation;

- soundproofing.

The use of Isobel thermal insulation boards can significantly save costs on heating and maintenance of buildings and structures.In terms of thermal technical characteristics, this insulation is several times superior to other traditional materials.

The unique IZOBEL basalt insulation technology has no analogues. This allows us to supply high-quality materials for thermal insulation to the Voronezh market.

Among the products of the plant are the following plates

IZOVOL "Noise protection" - designed for soundproofing rooms and buildings, the slabs have a size of 1000x600 mm, thickness from 40 to 250 mm, with a step of 10 mm. Has a flammability group - NG

IZOBEL (IZOBEL) - the lightest slabs, with a density of 25 kg / m3, are used for thermal insulation of unloaded structures (partitions, floors on logs, interfloor floors)

IZOVOL slabs, general construction thermal insulation of already higher densities, the names are quite short, but it is not difficult to understand by the name where the slab is used

- Izovol L-35 - light, non-loaded structures

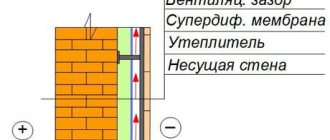

Insulation of external walls under ventilated facades

- Izovol St-50 - density 50

- Izovol St-60 - density 60

- Izovol St-75 - density 75

- Izovol St-90 - density 90

Mineral wool lined with canvas, as an outer layer of insulation in ventilated facades

- Izovol V-50 - density 50

- Izovol B-75 - density 75

- Izovol V-90 - density 90

Insulation under the plaster facade (see article)

Insulation of flat roofs

- Izovol K-100

- Izovol K-120

- Izovol K-150

- Izovol K-175

The upper layer of thermal insulation in flat roofs (KV-roof top)

Factory branding

Izovol produces the following types of insulating materials:

- General construction thermal insulation

- Soundproofing

- Technical thermal insulation

- Fire protection

- Thermal insulation for sandwich panels

Objects where the products of the plant were used. These are mainly the central regions and the south of Russia, this is due to the location of the plant.

Not a single new building will last even a decade if it was built without the use of thermal insulation materials. Thanks to them, maximum heat savings are achieved, there are no drafts and "cold bridges" inside the walls, and the service life declared by manufacturers allows you to forget about major repairs of the building for decades.

Material overview

Insulation panel characteristics

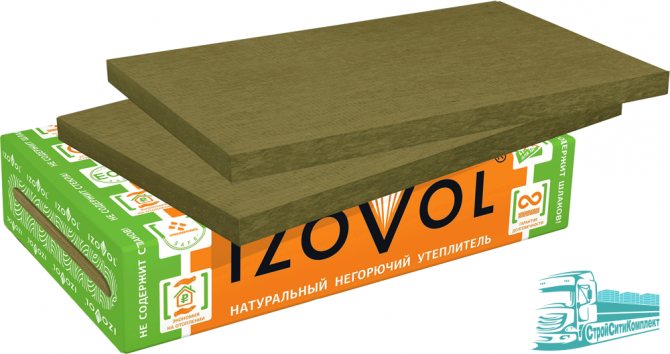

Pressed and glued basalt fiber slabs retain heat well

Isobel is a slab mineral insulation used for thermal insulation of pitched roofs, partitions, floors and other unloaded structures. The material has a fibrous structure, which provides it with high porosity, vapor permeability and a certain elasticity.

The composition of the panels is quite simple:

The structure of thermal insulation grade L25

- The basis of the insulation is basalt fiber. In the production of basalt fiber panels, rectangular slabs of standard size are formed.

During forming, the fibers are laid randomly, which contributes to the formation of multidirectional pores in the thickness of the panel. This not only reduces thermal conductivity, but also improves the sound insulation qualities of the material.

- A special glue is used to connect the fibers. The glue contains phenol-formaldehyde, but in the polymerized state it does not enter the atmosphere, so from an environmental point of view, the insulation is quite safe.

In the production of slabs, basalt fibers are pressed and glued

- Allocate different types of material depending on how strongly the fibers are compressed during production. Isobel L 25 has a density of 25 kg / m3, and Isobel P 75 (PL 75) - 35 kg / m3. The second option is somewhat inferior to the first in terms of heat-saving properties, but it is much less prone to deformation.

Isobel PL 75 is usually produced in such a package.

The characteristics of the insulation are given in the table:

| Characteristic | Value |

| Panel size (length x width), mm | 1000 x 600 |

| Panel thickness, mm | 50 / 75 / 100 |

| Density, kg / m3 | 25 / 35 |

| Flammability | NG (not lit) |

| Thermal conductivity, W / (m * K) | 0,036 |

| Water vapor permeability, mg / m * H * Pa | 0.3 and more |

| Water absorption,% by volume | 1.5 and less |

| Moisture,% by mass | 0.5 and less |

Scope of application

In practice, Isobel is used almost in the same place as ordinary mineral wool. But if you focus on the manufacturer's recommendations, then it is worth using insulation in the following areas:

Scope of insulation - recommendations from the manufacturer

- Thermal insulation of pitched roofs. The material is laid between the battens of the sheathing with the obligatory overlap with a waterproofing windproof membrane. It is imperative to leave a gap for ventilation between the insulating panels and the roofing material. On the inside, Isobel must also be protected with a vapor barrier material.

The material is excellent for the thermal insulation of pitched roofs

- Insulation of floors. We lay the slabs of material between the logs in such a way as to eliminate the load on the basalt fiber. The presence of a vapor barrier and waterproofing on top of the panels is highly desirable.

When insulating floors, it is advisable to protect basalt wool from moisture using vapor barrier films

- Heat and sound insulation of partitions. The porous inhomogeneous structure of the material makes it possible to significantly reduce the volume of sounds - both penetrating into the room and outgoing. When arranging partitions, Isobel is laid in the frame sections and sheathed on both sides with either plasterboard or a board.

When installed inside partitions, not only insulation is provided, but also sound insulation

- Thermal insulation of baths and saunas. The low flammability of basalt fiber makes it possible to use Isobel for decoration of premises with extreme temperature conditions. When installing thermal insulation in the gap filled with insulation, we lay the plates and be sure to cover the material with foil film.

Low thermal conductivity and low flammability make it possible to use Isobel for finishing baths and saunas

Naturally, the scope of use of the material is not limited to this list. So, Isobel can be used wherever effective sound and heat insulation is needed, there is no risk of getting wet, and where the material will not be compacted.

Advantages and disadvantages

Isobel thermal insulation boards have recently become quite popular. This is explained by their operational advantages.

Main pluses:

- Good thermal insulation performance. The thermal conductivity of basalt wool is low, so that even dense modifications (35kg / m3) retain heat well.

An additional plus - almost zero flammability of the material

- No negative impact on the climate. Insulation is characterized by good vapor permeability and low moisture capacity. Therefore, the humidity regime of the room does not suffer when finishing with Isobel.

- Do-it-yourself ease of processing. The slabs hold well in the crate cells due to their own elasticity and are easy to cut when adjusted to size.

Izobel knife is very easy to cut

- Acceptable price. The cost of a cubic meter is in the range of 1100-1300 rubles, which allows the material to be classified as economy class.

The material also has disadvantages:

- Low density at the edges. Sometimes there are panels that crumple strongly, and because of this they do not hold well in the frame.

Uneven density (this is quite obvious from the photo) is one of the significant drawbacks

- Deformation over time. Some builders note that Isobel shrinks significantly, so that after a couple of years cavities form in the insulated wall.

My experience with this material does not confirm this - so far everything has worked out. But, on the other hand, the difference in the density of different parties is noticeable to the naked eye, so someone could not be lucky.

When compressed, the thermal conductivity of the material increases significantly

- The presence of phenolic components... If it is critical for you that the adhesive composition for the insulation does not contain volatile substances, you should consider other options. Yes, phenol-formaldehyde in this insulation is present in an inert state - but still it is!

Insulation features

The area of use of isobel is to reduce the thermal conductivity of buildings for various purposes. In the production of insulation, EcoSafe technology is used, which reduces the amount of moisture absorbed by the material. Izobel slabs are a type of basalt wool (material with the lowest thermal conductivity) and are manufactured without the use of blast furnace slags. Typically, the insulation has a standard size (1000 × 600 mm, 1000 × 1000 mm, etc.).

Isobel can be produced not only from heavy basaltic rocks, but also from lighter ones like limestone or quartzite.

The resulting slabs weigh less and do not hold heat so well, but their density is higher, which affects the durability. A similar izobel is used for cladding places in a house where thermal insulation does not play a special role, and fire resistance and noise absorption are much more important (non-residential attics, ceilings, pitched roofs).

Insulation materials IZOVOL in modern construction

Thermal insulation materials are an integral element in the construction of residential and industrial buildings. The main task of thermal insulation materials is to save thermal energy used for heating buildings.

In modern construction, materials are widely used that can significantly increase the energy efficiency of enclosing structures. Basalt slab is a profitable and effective material for thermal insulation. According to its technical parameters, this material is very reliable in operation.

Basalt heat-insulating slabs are able to withstand temperatures within a radius of –120 ° to +700 ° C. The melting temperature of the fiber is up to 1100 ° C. Due to these excellent performance characteristics, they have a wide range of uses. Our company offers high-quality materials, with which thermal insulation will reach a qualitatively new level.

Features of installation isobel

Due to its ease of use, insulation is used almost everywhere. Thermal insulation with its help will be justified in such places:

- partitions between floors;

- floor;

- sloped roofs;

- attic;

- walls.

The only place that is undesirable to insulate with isobel is the foundation, since the slabs can get wet from interaction with the soil and fail.

Like any other mineral wool, insulation requires two additional layers - hydro and vapor barrier. The first protects the plates from getting wet from the outside, the second - from the inside. When installing Isobel on a sloping roof, it is recommended to make an air gap, the purpose of which is to drain the accumulating condensate.

The key difference between isobel like mineral wool and foam is that it is not mounted directly to the wall with glue, but is placed inside the cells formed by a wooden crate. Plus such a need - additional strengthening of the building frame, minus - financial investments.

Material specifications

Izobel heaters have approximately the same physical characteristics. For example, a plate with a size of 1000 × 600 mm is considered below. Its characteristics will be:

- density - 25 kg / cu. m;

- thickness - from 40 to 250 mm;

- vapor permeability - from 0.3 mg / m * h * Pa;

- flammability class - IV (best);

- thermal conductivity coefficient - 0.03-0.04 W / m * K;

- liquid absorption at full immersion in water - up to 1.5%;

- moisture content by weight - up to 0.5%.

IZOVOL Acoustic "Noise protection"

Izovol "Protection against noise" basalt-based is one of the most effective sound-absorbing building materials in the class.Mandatory quality control of each slab ensures consistently high acoustic and consumer properties of this product.

Research and development of the IZOVOL company have shown that frame partitions made of plasterboard sheets on a metal or wooden frame are the most effective way to protect against noise both during construction and during the reconstruction of buildings and structures for various purposes!

The chaotically directed structure of IZOVOL stone wool basalt fibers is the best barrier to sound waves and completely prevents their propagation, which contributes to a comfortable stay in the room and has a beneficial effect on people's well-being.

IZOVOL materials are indispensable for arranging acoustic interior partitions and coatings of all types. The use of IZOVOL products provides ideal indoor comfort, due to the unique properties of high-performance insulation, its low density and fibrous structure, improves the functional characteristics and hygiene of the premises, and, consequently, improves the quality of life in general.

Application area:

• for sound insulation of walls, ceilings, partitions, floors during construction;

• for sound insulation of air ducts and ventilation systems;

• for sound insulation of industrial equipment.

Specifications:

| Length, mm | 1000 |

| Width, mm | 600 |

| Thickness, mm | 40-250 interval 10 |

| Flammability, class | NG |

| Packing m3 | 0.24 (with a plate thickness of 50mm and 100mm) |

| Water vapor permeability, mg / m • H • Pa, not less | 0,3 |

| Thermal conductivity, W / (m • k) | 0.035 |

Price

RUB / package

476

from

Insulation advantages

Minvata would not have become so popular among consumers if it did not have a number of advantages. With regard to insulation of the Izobel brand, the qualities listed below are considered as such.

- Excellent thermal conductivity - coefficient from 0.03 to 0.04 - one of the smallest among heaters. If you add to this the thinness and elasticity of basalt fibers, you get an almost ideal material that allows you to significantly save on heating the room.

- Fire resistance - isobel belongs to the IV group of fire safety materials. In the presence of a nearby fire site, its physicochemical properties will remain unchanged; also the plates will become an obstacle in the path of the spreading fire.

- Long service life - the insulation made of basalt stone lasts at least 50 years, subject to storage conditions. Excess liquid will not in any way affect the material - the fibrous structure will easily let steam through and evaporate condensate.

- Weak water absorption - basalt is non-hygroscopic; only 1.5% of its volume can be filled with moisture. If water-repellent additives are used in the production, the value is reduced to 1%.

- Good vapor permeability - achieved by the fibrous structure of the material and promotes the use of isobel in baths, saunas or industrial premises.

- Sound insulation - depending on the thickness of the slab, they completely or partially neutralize extraneous noise.

- Resistant to corrosion, fungi, rodents, unattractive to birds.

- Affordable price - isobel is on average 15% cheaper than mineral wool analogues; for a slab with an area of 1 sq. m and a thickness of 50 mm, the consumer will give from 100 to 300 rubles.

- Environmental safety - achieved by a minimum amount of chemical components used to increase water repellency, and even then not always.

The above is only a part of the positive aspects of the izobel insulation. Other benefits are easier to perceive in operation rather than describe.

Technical characteristics of heat and sound insulation Izovol

The technological process for the manufacture of mineral basalt wool, used at the manufacturing plants, is based on strict adherence to standards and GOST.Well-organized work, high-quality raw materials and the experience of technologists are reflected in the manufactured products, namely in their increased demand and popularity in the building materials market of the Russian Federation.

The list of the achieved technical results in the manufacture of Izovol:

- thermal and sound insulation properties Heat and sound insulation characteristics depend on the quality of mineral fibers, on their location in the structure of the mineral wool slabs and on interfiber air cushions. Each type of Izovol product is responsible after the quality control test must comply with GOST 9573-96, the thermal conductivity coefficient is 0.035-0.037 W / mK (λA). This index is achieved due to the density of the product.

Regardless of the size of microscopic air layers, thermal conductivity does not change its properties, this figure remains stable. The only factor that can affect thermal conductivity is the complete immersion of the mineral wool slabs in the liquid. "Wet" cotton wool reduces thermal conductivity by 10%, and inside the premises the temperature drops by 10 degrees.Laboratory and technical studies have proved interesting facts: a mineral wool slab or mats can be leveled in terms of thermal conductivity with masonry materials, that is, a 5cm thick slab can be compared to 45cm thick brickwork. This fact affects the general construction process, in which you can save on masonry material and build walls not in two or four bricks, but in one and a half. The rest of the thickness can be added by means of Izovol mineral wool insulation.

The level of sound insulation of the premises after the laying of rockwool rolls, slabs or mats is noticed immediately after the end of the insulation work. Heat insulator Izovol is able to extinguish all sounds: from high-frequency - to low-frequency. Even the strongest noise phenomena inside the living space are not felt, you can feel a slight vibration. Sound insulation properties are increased due to density, and this is achieved through the addition of sealing additives.

- density

The entire range of Izovol products manufactured in the factory under strict adherence to technology, design documentation, SNiP and GOST9573-96. It is produced with a density index variation of 50kg / m3. - 200kg / cubic meter This density figure is achieved with the use of inorganic sealing additives and product pressing. And also the density directly depends on the acid modulus of basalt fibers, which is 1.8 and the volume of air layers. The higher the density, the smaller the air space and the harder the material. The density index for each Izovol modification is different. - absolute safety

Basalt fibers do not burn or smolder - they melt at a temperature of + 1200˚С. Izovol, according to the flammability class, meets the construction regulatory documents: ISO 1182, DIN 4102 and GOST 30244-94. The incombustibility of the material expands the range of its use. All civil and industrial facilities are insulated with Izovol. Fireproof mineral wool slabs can be used to insulate saunas and baths, as well as garages and car repair shops. - ECO group material

The purity of Izovol products is achieved, firstly, by the use of pure raw materials from natural rock stones, and, secondly, by the quality of remelting in furnaces using natural gas without the use of coke and slags. The environmental friendliness of products has been scientifically and experimentally proven, and approved for use as a heat insulator for residential, public and industrial facilities by the Ministry of Health and Pediatrics of the Russian Federation. - water repellent properties

Izovol basalt fibers do not absorb moisture, but, on the contrary, are repulsive. The fibers themselves are interconnected by means of sealing substances that enhance the hydrophobicity property. The denser the cotton wool, the less likely it is to absorb steam and water.After a series of experimental studies, it was proved that a completely submerged plate in a liquid absorbs 1 kg / sq. (EN1609) within 24 hours. After drying, mineral wool does not lose its zero thermal conductivity coefficient, therefore it is widely used in climatic zones of high humidity. - vapor permeability

The high degree of vapor permeability eliminates the cause of mold and putrefaction. Due to the free "migration" of steam, moisture does not accumulate inside the mineral wool slabs. Good ventilation inside the facade insulation sandwich will quickly eliminate condensation, preventing water vapor from penetrating deep into the wool. Vapor permeability is exactly: 0.035-0.5 mg / mchPa, this coefficient is suitable for any construction project. - resistance to aggressive media

Absolute neutrality of products to alkaline and acidic substances, as well as to fuels and lubricants, ethers, oils, alcohols and paints and varnishes - gives Izovol thermal insulation a wide range of applications in various fields of mechanical engineering and equipment production. - endurance to stress and mechanical stress

Izovol products are used to insulate cellars, basements, basements, cellars and underground communication systems, so the products are made of high density and durability. Density 100 kg / m3 (or 200 kg / cubic meter) is an ideal barrier for destruction of mechanical impact, ruptures, compressions and all sorts of deformations. Dense and rigid slabs are resistant to temporary or permanent vertical loads. This characteristic is achieved by means of a special technology for the manufacture and compaction of the resulting pulp with special additives.The stiffness of the slabs or mats is a direct obstacle to vertical and lateral loads from the ground, groundwater or road surface. Flexibility and compressive strength of Izovol products (30-40-65-80-85kPa), even under the most severe operating conditions, will retain all the technical characteristics and shape of standard modifications without compromising heat and sound insulation requirements.

Disadvantages of thermal insulation material

Alas, even Isobel is not devoid of disadvantages, although there are not so many of them. These include:

- the possibility of loss of thermal insulation properties at the joints of the slabs or in the area of contact with the crate (the joint is not sealed with a sealant or foam, like polystyrene);

- an additional waterproofing layer is required, since with a direct hit of water, the plate will swell and cease to be useful;

- a crate of certain sizes is required (according to the dimensions of the izobel insulation slabs);

- the process is complicated by the use of a mask, gloves and clothing that covers the skin; otherwise, small particles that come off the stove will get on the skin, causing allergies or scabies.

Despite the slight disadvantages of isobel, the material is still recommended for use in almost any room. It is accessible, it is easy for them to sheathe a section of the house, and the next replacement of insulation, subject to the installation technology, will not have to be done earlier than 50 years later. When buying material, the consumer will save a good amount, and during operation he will be convinced of the right choice.

IZOVOL

Insulation "IZOVOL", presented by our company, is produced by the "Belgorod plant of thermal insulation materials" ("BKTM"). Thanks to the latest production technologies, the entire manufacturing process is fully automated and controlled through a central computer - from the supply of raw materials to the packaging of finished products.

Advantages of IZOVOL insulation:

LOW THERMAL CONDUCTIVITY

The most modern production equipment of the plant makes it possible to obtain products from IZOVOL® stone wool with special improved properties that ensure maximum functional efficiency, safety and product reliability.The low thermal conductivity of IZOVOL® stone wool is one of its most important properties and depends mainly on the average fiber thickness. Know-how in the IZOVOL® production technology made it possible to obtain thinner threads of basalt insulation (basalt fiber), therefore, they are more elastic and resist destruction better.

Thermal insulation materials "IZOVOL®" are distinguished by high stable physical and mechanical characteristics, have a low coefficient of thermal conductivity under operating conditions. The use of IZOVOL® basalt thermal insulation in building structures allows minimizing heat transfer between the warm and cold sides, thereby significantly increasing the thermal efficiency of structures.

The use of "IZOVOL®" significantly saves the costs of heating facilities, the operation of buildings and structures.

In terms of thermotechnical characteristics, IZOVOL® is several times superior to traditional materials. To ensure the same thermal resistance as that of IZOVOL® with a thickness of 100 mm (and a density of 100 kg / m3), a wall thickness from hollow ceramic bricks - 1170 mm, from clay bricks - 1600 mm, from silicate bricks - 2000 mm is required, from dry wood - 255 mm.

HYDROPHOBICITY

For the enclosing structures of buildings and structures (walls, roofs, foundations), an unfavorable factor is the destructive effect of moisture penetrating into them. Non-hygroscopic basalt products "IZOVOL®" successfully resist this effect. An increase in water-repellent properties is achieved by adding special preparations at the stage of IZOVOL® production.

Thermal insulation "IZOVOL®" is an integral part of the enclosing structures, and the reliability and durability of the thermal insulation material depends on the level of water absorption, which for "IZOVOL®" is no more than 1% of its volume. This is significantly less than the indicators of most materials used for thermal insulation purposes.

DURABILITY

When choosing thermal insulation materials for various industries, for individual construction, you, first of all, need to take into account the durability of the insulation. The stability of the main technical characteristics of stone wool and slabs based on it during the experiments (2360 cycles), as well as the preservation of the structure of the fibers and the adhesion of the binder to them, made it possible to determine the long (more than 50 years) service life of stone wool in a moderately cold climate zone.

Due to the successful combination of unique properties, IZOVOL®, produced from natural basalt stone, is considered the most promising. BKTM specialists have modeled a uniquely balanced elementary composition of the fiber at the molecular level, which made it possible to obtain an optimal and stable acidity modulus, which significantly increases the durability of the IZOVOL® insulation.

"IZOVOL®" is the most stable heat-insulating material, resistant to external influences, which retains its performance properties for a long time.

HIGH

Vapor permeability

High vapor permeability of IZOVOL® mineral wool products (mineral wool) is a matter of paramount importance. Excess moisture in the premises can freely penetrate through the fibrous structure of IZOVOL® mineral wool boards, and the condensate that falls out, without accumulating in the thickness of the insulation, evaporates from the surface of the boards. This advantage of IZOVOL® products has a beneficial effect on the humidity regime of building structures.

INCREASED

FIRE RESISTANCE

High-quality natural stone materials, which are the basis for the production of IZOVOL®, are classified as non-combustible!

In case of fire, IZOVOL® thermal insulation fully retains its physical and mechanical properties and fire retardant ability. The upper temperature limit for the use of IZOVOL® stone wool is much higher in comparison with most heat-insulating materials (fiberglass, slag wool, etc.). Basalt fibers "IZOVOL®" can withstand temperatures above 11400C without melting.

EXCELLENT SOUND INSULATION

Mineral wool thermal insulation "IZOVOL®" is the best barrier to sound waves and completely prevents their propagation, which contributes to a comfortable stay in the room and has a beneficial effect on people's well-being.

ENVIRONMENTAL SAFETY

The use of "IZOVOL®" products provides ideal indoor comfort due to the unique properties of high-performance insulation, improves the functional characteristics and hygiene of the premises, and, consequently, improves the quality of life in general. CHEMICAL RESISTANCE

IZOVOL® stone wool products are not aggressive. They are chemically resistant to organic substances (solvents, acids, alkalis, etc.); protect the surfaces insulated by it from corrosion, fully comply with sanitary and hygienic standards, are characterized by stability of volume and shape, high accuracy of geometric dimensions, resistant to the effects of house fungi, microorganisms and rodents; harmless to human health. Mineral wool products "IZOVOL®" do not shrink, have a coefficient of linear expansion equal to zero, are easily processed by sawing, cutting with a knife, and are convenient to install.

IZOBEL

Natural non-combustible "economy" class insulation material used in building structures, allows you to minimize the transfer of heat between the warm and cold sides. "IZOBEL" - high quality lightweight hydrophobized thermal insulation boards based on basalt rocks. In terms of thermal engineering and operational characteristics, it is several times superior to traditional materials.

Advantages of IZOBEL insulation:

- high thermal insulation characteristics; - increased environmental safety; - stability of geometric dimensions; - stability of volume and shape; - low water absorption; - high vapor permeability; - high soundproofing properties; - high strength characteristics; - durability; - do not "shrink"; - ease of installation; - frost resistance; - absence of toxic emissions during operation; - resistance to the effects of house fungi, microorganisms and rodents; - protects the insulated surfaces from corrosion; - can be easily processed by sawing and cutting.