Soft roof (bituminous shingles)

Shingles can be called differently. These are bituminous, soft and composite shingles. It is also called roofing tiles or shingles. Outwardly, it is represented by flat sheets, the size of which is mainly 100 cm by 34 cm. Shingles have curly cutouts dividing the sheets into petals. The roof resembles a tiled roof as a result of the fact that the sheets are stacked by displacing two adjacent rows relative to each other.

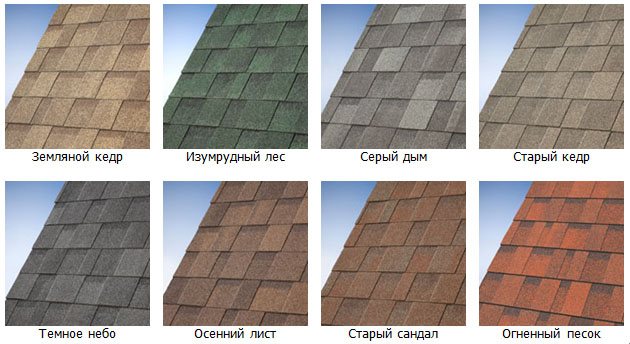

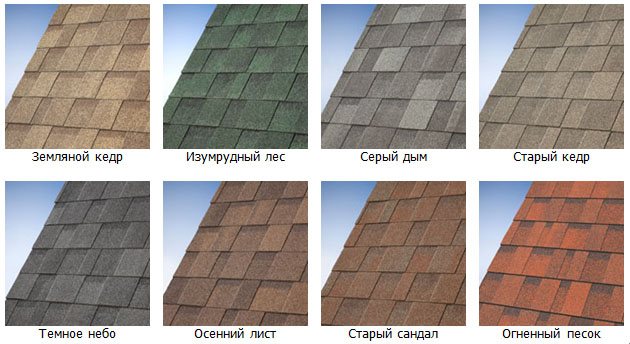

Today, soft roofing can have different petal shapes: rectangular, triangular, oval, wavy, etc. In addition, there is a large selection of colors. But, regardless of the large selection of shades and shapes, each version of the soft roof has an identical composition and structure.

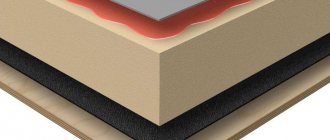

- The top layer is decorative, it creates the desired color of the roof. Consists of mineral chips. Its main task is to protect the remaining layers from the negative influence of external factors.

- Bituminous polymer material. Provides flexibility to the shingles and protects them from deformation.

- Substrate impregnated with bituminous fiberglass or organic cellulose.

- A layer of bitumen-polymer resin.

- Self-adhesive composition of bitumen-polymer mass.

- Siliconized film that protects the adhesive layer.

If we compare flexible shingles with other types of roofing, then the first has many advantages. They are due to the optimal size of the material and modern manufacturing technology:

- easy to install;

- profitability - little waste during installation;

- weighs little;

- absorbs sound well;

- low and high temperatures, its sharp drops are not terrible;

- condensation does not form on the inside of the OSB;

- can be installed on any roof, even with the most complex structure;

- resistance to sunlight;

- bacteria and corrosion are not terrible;

- the material has a dielectric capacity;

- a large selection of shades;

- long service life (20-50 years, depending on the manufacturer);

- high level of water resistance, minimum water absorption.

Expert opinion

Konstantin Alexandrovich

But it is important to remember that the use of shingles involves spending money on creating a solid foundation. It cannot be installed if the outside temperature is freezing. But these disadvantages are insignificant compared to the huge number of positive aspects.

Laying roofing material

The roofing material can be laid on the prepared roof base.

Laying of welded roofing

On flat roofs, roll materials are often used, which are laid by fusion. The technology itself for arranging a soft roof made of deposited materials is not difficult, however, it will be necessary to acquire a gas or liquid fuel burner to heat the material. Basic installation rules:

- The coating is laid in at least two layers.

- For the bottom layer, you can use a cheaper version of the roll material. For the top, you need to choose the strongest samples that have a coarse-grained dressing.

- Laying begins from the lowest section of the roof.

- It is recommended to first roll the material to ensure that it fits correctly, then roll the material back into a roll and proceed with fusion installation.

- First of all, you need to fix the end of the roll on the roof, then start heating the bottom of the roll.

Advice! When heating the material, it is recommended to move the burner along a trajectory that resembles the letter "G". This provides additional heating of the future joint.

- The heated material is rolled out, and from above they pass over it with a roller in order to better press it to the base.

- The second layer of material is laid in the same way, but it is necessary to ensure that the joints of the second row fall in the middle of the strips of the lower one.

Laying shingles

If you plan to install a roof made of soft tiles, then the work should be carried out as follows:

- The tiles are laid in rows parallel to the eaves.

- The rows are arranged so that the shingle petals of the upper row overlap the attachment line of the previous one.

- Before laying the next shingle, the protective film is removed from its lower part.

- The tiles are fastened with special roofing nails. For one shingle, 4-6 nails are spent, depending on the steepness of the slopes.

Junction device

Regardless of the material used, the arrangement of abutting a soft roof is one of the most difficult tasks:

- The vertical surface is well cleaned and covered with bitumen mastic.

- At a height of 25-30 cm from the roof surface, a triangular bar made of wood treated with an antiseptic solution is fixed on a vertical wall.

- The soft roof covering is raised to a vertical surface, leading to the installed beam.

- On top of the mastic, a strip of roll material with a coarse-grained dressing is glued. This strip should overlap the installed block, and the other side should lie on the horizontal surface of the roof.

So, having understood the rules for constructing a roofing pie and having studied the instructions for laying soft roofing material, you can independently perform roofing work and create reliable protection for your home.

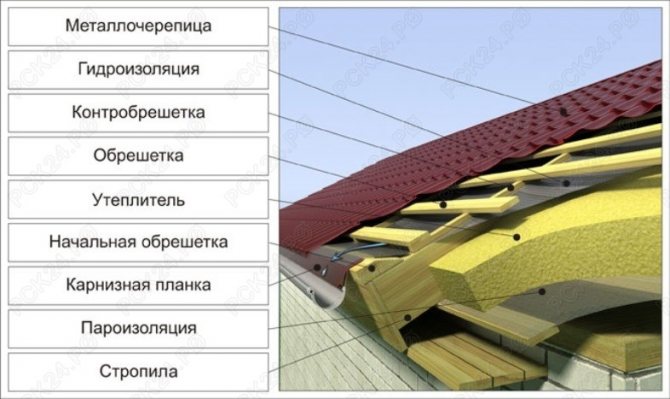

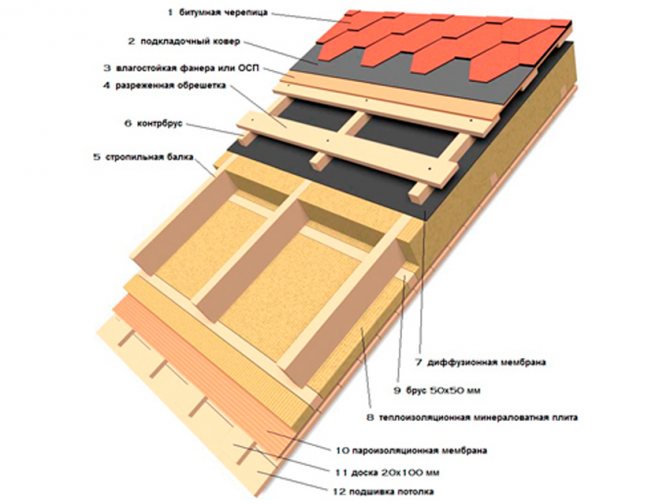

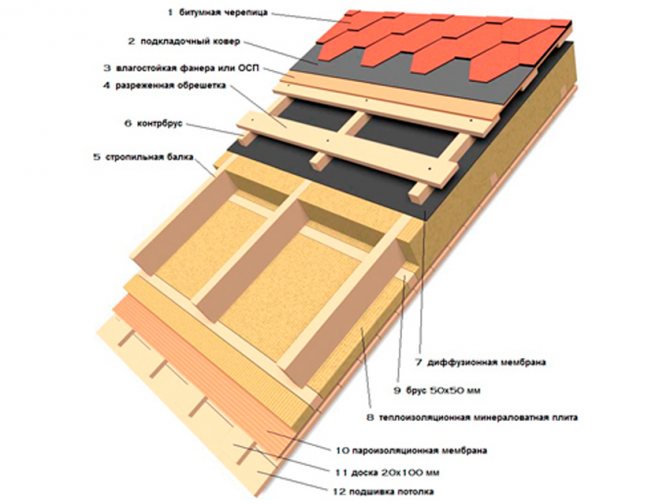

The Right Roofing Pie

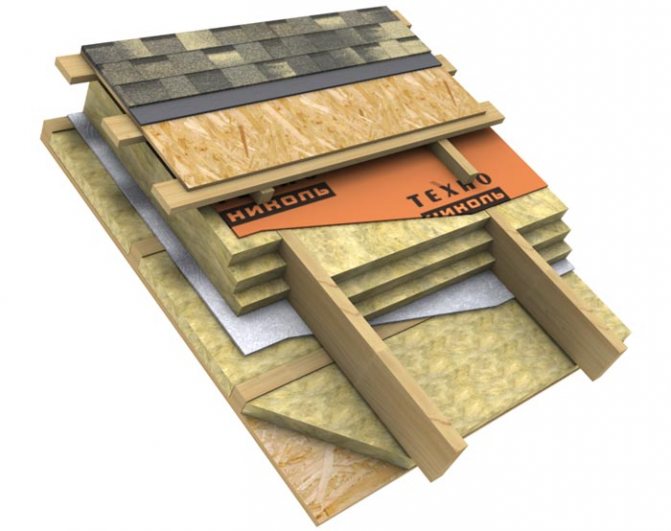

The design for soft tiles is complex. So that he does not lose his qualities, during installation it is necessary to follow all the rules specified by the manufacturer. Thanks to a warm roof, you can insulate a cold attic, as well as increase the area of the room, while incurring small material costs.

But if during the repair work break the device "pie", then this can worsen the thermal insulation characteristics of the roof. As a result, the microclimate indicators in the room will deteriorate. There is a high chance of leaks, which will lead to many other problems. In order for the roof to meet the necessary indicators, it is necessary to take into account everything that affects it.

- Precipitation. The roof must be free of leaks. The installation method directly depends on the angle of inclination of the slopes. It is also worth taking care that snow does not penetrate into the space under the roof.

- Dynamic loads. They are temporary (wind, snow, etc.) and permanent (roof weight). When calculating the rafter system and the choice of covering materials, it is important to take into account the maximum values of the complex loads. A special safety factor must be added to this indicator.

The microclimate in the attic must be stable. It should not be influenced by external factors. If the temperature difference between the indoor and outdoor air is large, then this will cause increased heat transfer and heat loss. To avoid this, an insulated roof is created, consisting of a large number of layers.

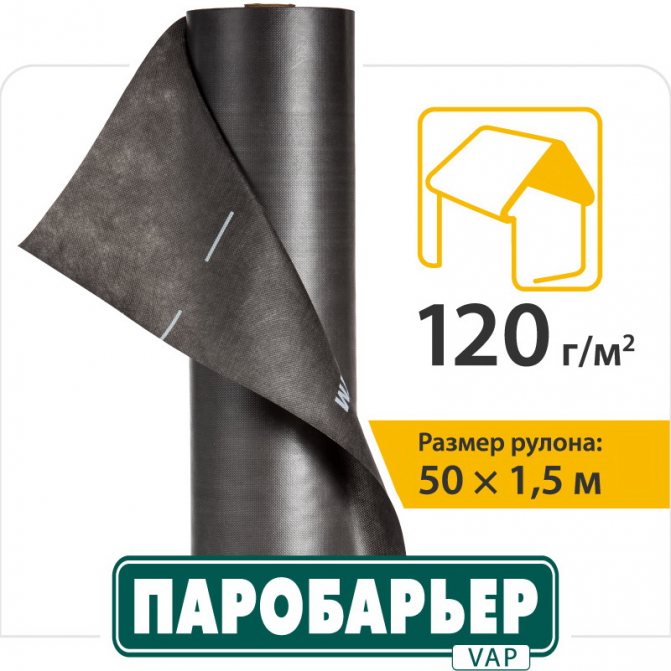

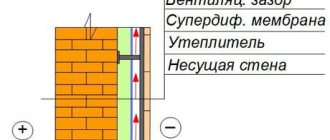

Vapor barrier

Indoor installation. Its main task is to prevent mineral wool from wetting. Modern membranes (an expensive option) or a simple plastic film can serve as a vapor barrier. If you use polystyrene or expanded polystyrene, then you can do without a vapor barrier. These materials are resistant to moisture, do not absorb it, thermal conductivity indicators do not increase due to them.

Moisture can penetrate into the structure of the "roofing cake" if there is a difference in the partial pressure of water vapor in the room and outside. The materials from which the vapor barrier is made must be highly durable and practically impermeable to steam. This minimizes the risk of humid air entering the insulation.

If the vapor barrier is carried out incorrectly, then moisture will condense in the thickness of the cotton wool. If the temperature is low, then the water in the state of steam is much less than if the temperature is high. Condensation starts to form in the top layer of the cotton wool, where the dew point is. But further, due to the action of gravity, water penetrates downward. As a result, all mineral wool gets wet. Because of this, the heat protection index decreases, and decay processes begin to develop.

Installation of a cold roof made of soft tiles

The basic rule for cold attics does not depend on the coating: a full-fledged pie is made in the attic floor, otherwise the house will be cold.

note

On the overlap, there are more insulation options than on a pitched roof: expanded clay, sawdust-clay mixture can be used as a heat insulator. The layer will turn out to be thick, but for an unexploited attic this does not really matter. But it's cheap.

The rest of the cake is made according to all the rules: vapor barrier, waterproofing, the floor is sewn up with boards on top.

The second feature concerns ventilation. Differences in materials are already evident here. Soft roofs (unlike profile metal) do not have waves that would serve as ventilation. The bituminous coating is completely sealed, does not breathe.

note

The ridge aerator for shingles should be installed in any case, it does not depend on the roof structure or on its insulation.

Otherwise, the technology of a cold roof made of soft tiles differs from an insulated one: on cold roofs, a solid sheathing can be placed directly on the rafters (without a counterbeam). The entire attic serves as a ventilation gap. The crate and rafters are not covered from the inside.

Materials and tools for installing a soft roof

As stated above, soft roofing is easy to install. And there is. If you strictly follow all the technologies, then you can mount a two-layer warm roof yourself. The main thing is to have at least a little experience in construction. In addition, you will not need to incur additional material costs for the purchase of additional materials and tools. Any home craftsman can always find everything you need.

Before proceeding with the installation of shingles, you need to prepare the following set of tools:

- saw on wood;

- jigsaw;

- a hammer;

- pencil, chalk;

- level;

- knife for cutting shingles;

- putty knife;

- roulette;

- Master OK;

- nail puller.

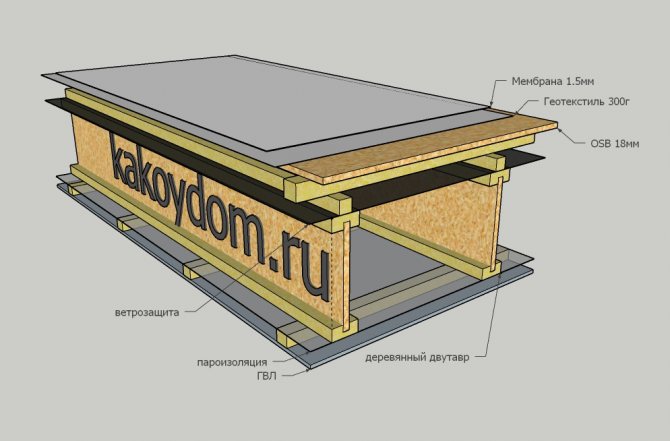

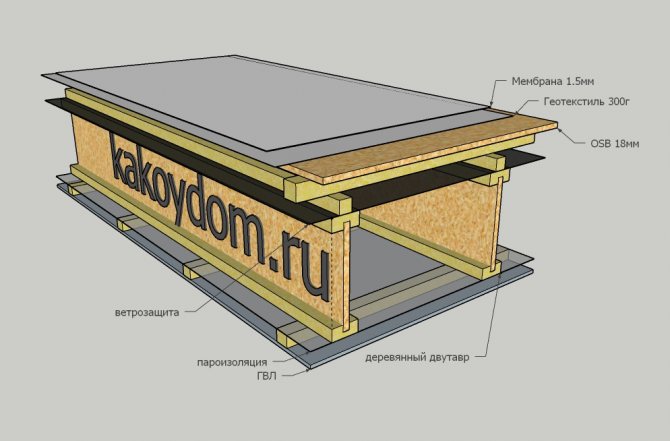

Roofing cake

Top down:

- plastfoil membrane 1.5mm

- geotextile with a density of 300g needle-punched (membrane cannot be without it)

- OSB 18mm

- counter grill 50mm

- lathing bar 40mm

- windscreen

- beams 350mm and between them insulation with ecowool

- vapor barrier

- reiki

- GVL

Ivan builds a frame house with his own hands. Not a professional builder. However, in my opinion, this is the type of self-builder that others can match. Therefore, the solution can be taken into your projects.

Partitions inside the house

The internal thermal insulation cake of a frame house involves the insulation of the internal walls for better heat retention. It also allows individual living rooms to be heated if an autonomous heating system is installed.

The structure of the internal walls is similar in concept to the external one, however, there is no external finishing layer. The inner wall cake is collected in the following order:

At the stage of building the frame of the house, cells for insulation are created. The inner walls are the same thickness as the outer ones (15-20 cm).

On one side of the wall, an OSB board or ordinary drywall is mounted on a vapor barrier layer. It is not difficult to stretch the plastic film on the wall, the installation of large plates will press it well against the common box.Insulation is put into the cells and after a few hours the wall is sewn up with a vapor barrier membrane plus a sheet of OSB or drywall. Decorative wall decoration is carried out at the final stage of preparing the house.

In the case of internal walls, cold bridges are not dangerous, therefore, there is no need to create cross-insulation and complicate the structure with several types of protection. It is better to impregnate wood with compounds against decay and burning.

You can also often find the use of SIP panels when arranging the interior walls of a building. This significantly speeds up the assembly of the structure, depending on the region and the price of materials, you can also save well on the use of various materials.

For houses built using Canadian technology, the space for a kind of creativity is large. By combining different types of materials, you can achieve an optimal price-quality ratio of the built housing.

Insulation of the roof from the inside: installation features

After the preparatory work, the method of laying the insulation boards (mats) should be indicated. They should be pressed against the waterproofing as much as possible if a special diffusion membrane is used, or fixed with an indent of 2 cm in cases where polyethylene is used as insulation from moisture. The required clearance will ensure the natural drainage of steam droplets resulting from condensation.

Plates of insulation should be laid in a pre-made crate (by cells). The material must fit snugly against the wooden battens to prevent cold bridges. But do not overly influence the insulation, otherwise its structure will be damaged.

Plates are stacked in a checkerboard pattern. The number of layers and the thickness of the insulation determine the calculations of heat losses and the peculiarity of the roof structure.

Roof insulation materials

To insulate the roof from the inside, you will need to choose a suitable material. They can be:

• expanded polystyrene;

• mineral wool;

• glass wool.

When choosing a heater, it is worth considering the parameters that it must correspond to:

• low weight, so as not to overload the roof structure;

• thermal conductivity index within 0.04 W / m С;

• fireproof;

• environmentally friendly;

• resistance to external factors.

According to experts, preference should be given to one of the types of mineral wool - basalt. Its properties and qualities are fully consistent with the requirements for thermal insulation material for the roof.

Advantages of the structure of the operated roof

· Modern waterproofing materials exclude the penetration of melt water and precipitation to the ceilings and into the premises.

· Pie of the roof includes insulation, which increases the thermal insulation of the building, allows you to save on heating in cold weather and air conditioning - in the summer.

· Improving the soundproofing of the building.

· Protection of roof waterproofing from mechanical damage, ultraviolet radiation and temperature extremes.

· Possibility of installation at any time of the year, but in dry weather.

· Durability of the structure - from 50 years.

An exploitable roof is being installed on the roofs of residential, industrial, public buildings, entertainment and business centers.