When carrying out construction work, it is often necessary to compare the properties of different materials. This is necessary in order to choose the most suitable one.

After all, where one of them is good, the other will not work at all. Therefore, when carrying out thermal insulation, it is necessary not only to insulate the object. It is important to choose insulation that is suitable for this particular case.

And for this you need to know the characteristics and features of different types of thermal insulation. This is what we'll talk about.

What is thermal conductivity

To ensure good thermal insulation, the most important criterion is the thermal conductivity of heaters. This is the name of the transfer of heat inside one object.

That is, if one part of one object is warmer than the other, then the heat will pass from the warm part to the cold one. The same process takes place in the building.

Thus, the walls, roof and even the floor can give off heat to the outside world. To keep the house warm, this process must be minimized. For this purpose, products are used that have a small value of this parameter.

Thermal conductivity table

The processed information about this property of different materials can be presented in the form of a table. For example, like this:

There are only two parameters here. The first is the thermal conductivity coefficient of heaters. The second is the thickness of the wall that will be required to maintain the optimum temperature inside the building.

Looking at this table, the following fact becomes obvious. It is impossible to construct a comfortable building from homogeneous products, for example, from solid bricks. After all, this requires a wall thickness of at least 2.38 m.

Therefore, to ensure the required level of heat in the premises, thermal insulation is required. And the first and most important criterion for its selection is the above-mentioned first parameter. For modern products, it should not exceed 0.04 W / m ° C.

Advice! When purchasing, pay attention to the following feature. Manufacturers, indicating on their products the thermal conductivity of the insulation, often use not one, but as many as three values: the first is for cases when the material is operated in a dry room with a temperature of 10 ° C; the second value is for cases of operation, again, in a dry room, but with temperature 25 ºС; the third value is for the use of the product in different humidity conditions. It can be a room with humidity category A or B. For an approximate calculation, use the first value. All the rest are needed to make accurate calculations. How they are carried out can be found in SNiP II-3-79 "Construction heat engineering".

Optimal indoor climate: dream or reality?

Polyurethane foam sheet

Most of the country is in difficult climatic conditions, therefore, developers of architectural projects pay special attention to the thermal insulation of residential and industrial facilities with the further prospect of minimal heating costs. A comfortable environment is the optimal range of temperatures, humidity, the absence of noise irritants and other factors that negatively affect the health and psycho-emotional state of a person.

A comfortable room temperature can be maintained due to increased energy consumption or by arranging effective, permanent thermal insulation with Rockwool insulation.

The second option is economically attractive, since the cost of heating and air conditioning has a steady upward trend.

The range of modern heaters includes a large list of thermal insulation materials with different properties - in particular, vapor permeability or its absence. The last group includes inexpensive insulation based on foamed polymers: expanded polystyrene, polyurethane foams and polyethylene foams.

Other selection criteria

When choosing a suitable product, not only thermal conductivity and the price of the product should be taken into account.

You need to pay attention to other criteria:

- volumetric weight of insulation;

- shape stability of this material;

- vapor permeability;

- flammability of thermal insulation;

- sound insulation properties of the product.

Let's consider these characteristics in more detail. Let's start in order.

Volumetric weight of insulation

The volumetric weight is the mass of 1 m² of the product. Moreover, depending on the density of the material, this value can be different - from 11 kg to 350 kg.

The weight of the insulation must certainly be taken into account, especially when insulating the loggia. After all, the structure on which the insulation is attached must be designed for a given weight. Depending on the mass, the method of installing heat-insulating products will also differ.

Having decided on this criterion, you need to take into account other parameters. These are volumetric weight, dimensional stability, vapor permeability, combustibility and sound insulation properties.

In the video presented in this article, you will find additional information on this topic.

First of all, it must be said that about vapor-permeable (breathable) and vapor-permeable (non-breathable) walls, I will not argue in terms of good / bad, but I will consider them as two alternative options. Each of these options is perfectly correct if performed with all the required requirements. That is, I am not answering the question “do we need vapor-permeable walls”, but I am considering both options.

So, vapor-permeable walls breathe, let air (vapor) pass through themselves, and vapor-permeable walls do not breathe, do not let air (vapor) pass through themselves. The vapor-permeable walls are made only of vapor-permeable materials. Vapor-NON-permeable walls contain at least one layer of vapor-NON-permeable material in their structure (this is enough for the entire wall as a whole to become vapor-NON-permeable). All materials are divided into vapor-permeable and vapor-NON-permeable, this is not good, not bad - this is such a given :-).

Now let's see what all this means when these walls are included in a real house (apartment). We do not consider the design possibilities of vapor-permeable and vapor-permeable walls in this matter. Both such and such a wall can be made strong, rigid, and so on. The main differences are obtained in the following two issues:

Heat loss.

Naturally, additional heat loss occurs through the vapor-permeable walls (heat also escapes with the air). I must say that these heat losses are very small (5-7% of the total). Their size affects the thickness of the thermal insulation and the heating power. When calculating the thickness (wall, if it is without insulation, or the insulation itself), the vapor permeability coefficient is taken into account. When calculating heat loss for the selection of heating, heat loss due to the vapor permeability of the walls is also taken into account. That is, these losses are not lost anywhere, they are taken into account when calculating what they affect. And, moreover, we have already done enough of such calculations (for the thickness of the insulation and heat loss for calculating the heating power), and this is what you can see: there is a difference in numbers, but it is so small that it cannot really affect either the thickness of the insulation or the power of the heater. Let me explain: if with a vapor-permeable wall you need, for example, 43 mm of insulation, and with a vapor-permeable wall - 42 mm, then this is still 50 mm, in both versions.The same is with the boiler power, if in terms of overall heat loss, it is clear that a 24 kW boiler is needed, for example, only because of the vapor permeability of the walls, the next boiler in power will not work.

Ventilation.

Vapor-permeable walls participate in air exchange in the room, and vapor-permeable walls do not. There must be an inflow and an exhaust in the room, they must correspond to the norm and be approximately equal. In order to understand how much inflow and exhaust should be in the house / apartment (in m3 per hour), a ventilation calculation is made. It takes into account all the possibilities of inflow and exhaust, the norm for this house / apartment is considered, the realities and the norm are compared, and methods of bringing the inflow and exhaust power to the norm are recommended. So this is what happens as a result of these calculations (we have already done a lot of them too): as a rule, there is not enough inflow in modern houses. This is because modern windows are vapor tight. Previously, no one considered this ventilation for private housing, since the inflow was normally provided by old wooden windows, leaking doors, walls with cracks, and so on. And now, if we take new construction, so almost all houses with plastic windows, and at least half with vapor-impermeable walls. And there is practically no air flow in such houses (constant). Here, you can see examples of calculations for ventilation, in the topics:

Specifically, these houses show that the inflow through the walls (if they are vapor-permeable) will be only about 1/5 of the required inflow. That is, ventilation should be properly designed (counted) for anyone, no matter what the walls and windows would be. Only vapor-permeable walls, and that's it, still do not provide the required inflow.

Sometimes the question of vapor permeability of walls becomes relevant in such a situation. In an old house / apartment, which lived normally with vapor-permeable walls, old wooden windows, and with one exhaust duct in the kitchen, they begin to change the windows (to plastic ones), then, for example, the walls are insulated with foam plastic (outside, as expected). Wet walls, mold and so on begin. The ventilation has stopped working. There is no inflow, the hood does not work without the inflow. From here, as it seems to me, the myth arose about the "terrible foam", which, as soon as the wall is insulated, mold will immediately begin. And the point here is in the complex of questions on ventilation and insulation, and not in the "horror" of this or that material.

Regarding what you write "it is impossible to make hermetic walls." This is not entirely true. You can completely make them (with a certain approximation to tightness), and they are made. We are currently preparing an article about such houses, where completely sealed windows / walls / doors, all air is supplied through the recuperation system, and so on. This is the principle of the so-called "passive" houses, we will talk about this shortly.

Thus, here is the conclusion: you can choose both a vapor-permeable wall and a vapor-permeable wall. The main thing is to competently solve all related issues: on correct thermal insulation and compensation for heat loss, and on ventilation.

To create a favorable indoor climate, it is necessary to take into account the properties of building materials. Today we will analyze one property - vapor permeability of materials

.

Vapor permeability is the ability of a material to transmit vapors contained in the air. Water vapor penetrates into the material due to pressure.

They will help to understand the issue of tables that cover almost all materials used for construction. After studying this material, you will know how to build a warm and reliable home.

How to properly attach a drywall vapor barrier

Drywall is the undisputed leader in the construction market in terms of frequency of use in interior finishing works. With its help, you can completely re-plan the premises and change it beyond recognition.

Plasterboard finishing

This finishing material can be used in any premises, apartment buildings or country houses. When planning construction work, especially in rooms where it is necessary to carry out thermal insulation, the question of the need for vapor barrier is relevant.

Vapor barrier is the process of applying a special vapor barrier film to walls and ceilings. This process is carried out in order to insulate and protect the roof, external and internal walls, as well as ceilings from the penetration of water vapor into the interior of the room. Installing such a film prevents condensation from forming in the house during cold weather. Particularly relevant is the vapor barrier of the walls from the inside.

Installing a vapor barrier will allow you to:

- insulate a pitched roof with a metal coating (seam roof, profiled sheet or metal tile);

- insulate a pitched roof, consisting of a non-metallic coating (slate, "soft" bituminous roof, natural tiles);

- insulate walls with external insulation;

- insulate attic rooms, as well as basement floors;

- create insulation in baths or saunas;

- make the floor vapor barrier.

Although many are rather skeptical about the need for a vapor barrier procedure, you should not neglect it. Of course, without it, repairs will cost a little less. But installing a vapor barrier will allow you to avoid condensation. The presence of condensation in the house during the cold season negatively affects the appearance of the repair carried out.

Because of it, wallpaper can peel off, paint deteriorates, and mold and mildews appear in places where condensation forms. Vapor barrier will allow you to keep the house warm and finally get rid of condensation.In addition, such a film will increase the thermal insulation capabilities of the floors, which, again, will only play into your hands.

The procedure for installing a vapor barrier under drywall is relatively easy, and the material itself is not very expensive. Therefore, this procedure is still worth carrying out, since the advantages from it will be much greater than the disadvantages.

Installation of insulation

- eliminate the shortcomings of insulation outside;

- to increase the efficiency of insulation outside;

- make the room warmer;

- prevent the appearance of mold and mildew. This is especially true for window openings;

- reduce heat loss, which will save on heating, the prices of which are constantly growing.

Of the relative disadvantages of insulation and vapor barrier, carried out under drywall, we can mention a slight decrease in free space in the room. But drywall, in most cases, already requires the installation of frame floors, which lead to a decrease in space.

So if you went for this at the very beginning, then it will be much more effective to use the space under the sheets to install insulation and vapor barrier film. So you will kill three birds with one stone: take up free space under the sheets, additionally insulate yourself, and also prevent condensation.

We suggest that you familiarize yourself with What are bumblebees

Therefore, it is not only necessary to do vapor barrier and insulation, but also advisable.

Filling cracks

- cleaning walls and ceilings from old finishes;

- cleaning the premises from construction debris so that it does not get tangled underfoot during work;

- then all cracks should be covered with putty so that they do not crumble and interfere with work;

- we process the walls with a deep penetration primer;

- after the primer has dried, we apply an antiseptic to the walls. It will prevent mold and mildew growth.

Note! Treatment with antiseptic agents before vapor barrier is mandatory, since mold or fungus spores falling behind the film can lead to their multiplication already inside the room.

Also at this stage, you can draw up a diagram for the frame and apply markings on the prepared surface.So it will be much more convenient to carry out installation work. After carrying out the above steps, you can fasten the frame elements.

Installing a vapor barrier on drywall will require the following tools:

- puncher and drill;

- building level;

- drawing accessories - pencil, tape measure and ruler;

- hammer;

- sandpaper;

- spatula.

In addition to tools, you will also need the following materials:

- vapor barrier film;

- drywall sheets. If it is planned to finish rooms with a humid microclimate, it is necessary to use a moisture-resistant type of drywall;

- metal profiles or wooden slats;

- screws, dowels;

- serpyanka;

- insulation.

Having all this will allow you to implement your plans without any problems.

Installing the frame

Drywall can be installed on two types of frame elements:

- wooden slats. When installed in rooms where there is moisture, all frame elements made of wood must be treated with special protective agents in order to extend the life of the wood;

Wooden frame

- metal profiles. For drywall, it is often preferred to mount just such profiles. They are easier to install than wooden slats, and the service life is much longer.

Metal carcass

Of course, drywall can be installed without a frame. But this is rather an exception to the rule, since the frameless method is possible only with flat walls. In addition, in this case, it will be impossible to install heaters and a vapor film under the sheets. The frame performs several functions:

- evens out the curvature of walls and ceilings;

- allows you to easily install a heater in the formed niches of the frame;

- is an excellent base not only for drywall sheets, but also for a vapor barrier film.

Note! To perfectly align the wall, you need to find the largest bulge and orient the installation of all profiles or wooden slats along it.

The installation of the frame is carried out as follows:

- first, we make the lathing of the walls and ceiling around the perimeter using guide profiles. We attach the profiles to the ceiling and walls with dowels from the outside;

- further, using rack-mount profiles, we make an internal lathing using horizontal jumpers.

After completing the installation work to create the frame, you can start installing the insulation.

To keep it warm

Of course, a vapor barrier film also has certain thermal insulation properties. But this will clearly not be enough, especially if insulation was not carried out outside the house. Therefore, experts recommend installing an additional layer of insulation under the steam film. Two materials are especially popular today as insulation:

- mineral wool. It is used most often. Fasten it with a special stapler;

Mineral wool in the frame

- Styrofoam. It is slightly inferior in popularity to mineral wool. It is simply installed between the frame elements.

Styrofoam in the frame

Note! Whatever material you use for insulation, it should form a monolithic layer. All cracks should be sealed with either special tape, or foam or silicone sealant.

The insulation procedure itself is not difficult. It can be dealt with in just a couple of hours if the room is large. Therefore, you should not neglect such a procedure, since you will appreciate the advantages of insulation on cold winter evenings. After the insulation comes the turn of the vapor barrier film.

Installing a steam film

We suggest you familiarize yourself with Herring for vodka

Compared to insulation, everything is much simpler here. The installation process includes the following steps:

- unwinding the film from the purchased roll;

- stretching it along the perimeter of the walls and ceiling;

- it is attached to the profile or wooden slats using small brackets.

Note! Corner sealing takes a special place in this process. The main thing here is to prevent steam from entering the interior of the room. Therefore, all joints should be sealed with special tape. In the same way, you need to seal the joints of the film with the walls and ceiling.

Compliance with all the recommendations and rules will allow you to properly install the vapor barrier and make your room really warm and protected from unwanted penetration of excess moisture. That's all. After the vapor barrier film has been installed, you can mount the drywall onto the prepared frame.

Installing Sheets

Drywall is attached at the very end, when the insulation and vapor barrier were installed. Sheathing with frame sheets, subject to all the rules, will be just as easy and quick.To get an excellent result at the output, you will need to do the following manipulations:

- let the material lie for a day in the room in which it will be further mounted;

- you first need to fasten solid sheets, and only then cut the pieces that are not enough for sheathing;

- the sheets are installed in such a way that their edges fall into the middle of the profile;

- try to arrange the plates so that gaps do not form between them. We fasten the sheets as tightly as possible to each other;

- we fix the plates with self-tapping screws. The installation step of self-tapping screws is 20-25 cm;

- we deepen the screws into the drywall by 1 mm. Avoid raising the hats above the sheets, otherwise you will not be able to carry out the final finishing normally and efficiently in the future.

We finish what we started

After all the manipulations carried out, only the following steps will remain to be done:

- close up all the gaps between the sheets with a serpyanka;

- putty all the screws on top. Putty also needs to be applied over the serpyanka;

- after the putty dries, wipe all irregularities with sandpaper;

- then prime all walls and ceiling and let the solution dry.

Plastered walls

After that, the resulting structure can be given its final look. You can paint it, put ceramic tiles on it or simply paste over with wallpaper. As you can see, installing a vapor barrier on a frame base for drywall with its subsequent installation is not difficult. You just need to follow the instructions above, and you can achieve complete vapor barrier, as well as thermal insulation of your room.

Dealing with the property

It is believed that "breathing walls" are beneficial for the home and its inhabitants. But all builders think about this concept. "Breathable" is a material that allows steam to pass through in addition to air - this is the water permeability of building materials. Foam concrete, expanded clay wood have a high rate of vapor permeability. Walls made of brick or concrete also have this property, but the indicator is much less than that of expanded clay or wood materials.

Steam is generated during hot showers or cooking. Because of this, high humidity is created in the house - an exhaust hood can correct the situation. You can find out that vapors do not go anywhere by condensation on pipes, and sometimes on windows. Some builders believe that if the house is built of brick or concrete, then the house is "hard" to breathe.

In fact, the situation is better - in a modern dwelling, about 95% of the steam leaves through the vent and the hood. And if the walls are made of "breathing" building materials, then 5% of the vapor escapes through them. So residents of houses made of concrete or brick do not particularly suffer from this parameter. Also, the walls, regardless of the material, will not allow moisture to pass through due to the vinyl wallpaper. The "breathing" walls also have a significant drawback - in windy weather, heat leaves the dwelling.

The table will help you compare materials and find out their vapor permeability index:

The higher the vapor permeability index, the more the wall can accommodate moisture, which means that the material has low frost resistance.If you are going to build walls from foam concrete or aerated concrete, then you should know that manufacturers are often cunning in the description, where vapor permeability is indicated. The property is indicated for a dry material - in this state it really has a high thermal conductivity, but if the gas block gets wet, then the indicator will increase 5 times. But we are interested in another parameter: the liquid tends to expand when freezing, as a result, the walls collapse.

How to lay a vapor barrier when insulating walls

Both sides of the vapor barrier are equally impervious to moisture and steam.

Let's figure out how to properly lay the vapor barrier on the walls. There are two options for insulation:

- internal;

- outdoor.

Of course, it is preferable to install the thermal insulation outside the room, but in this case, a vapor protection film is not required. The material that is used for insulation also matters. The film is needed only when it is necessary to protect the thermal insulation from moisture and steam. To figure out how to properly lay a vapor barrier film, you need to understand by what principle the air circulates. It always moves from a high pressure area (where the temperature is higher) to a low pressure area (where the temperature is lower). It turns out that the air, together with moisture, tries to leave the warm room and end up on the street.

Which side to put the vapor barrier to the insulation does not matter, since it does not allow moisture to pass through in any form in both directions. Those who ask such questions are most likely confusing a vapor barrier film with a waterproofing (diffusion membrane).

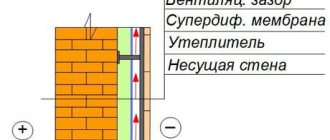

The scheme of laying the vapor barrier on the wall from the inside.

Therefore, in numerous forums, when asked which side to attach the vapor barrier to the insulation, the experts allegedly answer that it is rough. Where is the rough surface of the vapor barrier? It is completely smooth on both sides. As it turned out, even the builders themselves confuse these concepts. In our previous article, we clearly explained how vapor barrier differs from waterproofing.

Another frequently asked question regarding how to properly lay a vapor barrier is the need for a ventilated gap. Some film manufacturers write that the ventilation gap is not needed at all, but it is still not worth making hasty conclusions. When installing an insulation cake for the walls from the inside, a ventilation gap is needed between the film and the finish, but it is optional (although it does not hurt) between the film and the insulation. Here we are somewhat substituting the concept of ventilation gap, since in the space between the film and the finish (all the more so, with insulation) it is not always possible to achieve the necessary air circulation.

Let's leave these subtleties for now and call the buffer air zone between the materials a ventilation gap. Layers of insulation cake for the walls, starting from the inside:

- finishing;

- ventilation gap;

- vapor barrier;

- insulation;

- wall.

The ventilation gap will keep the finish dry, mold free and last as long as it should.

On one load of 20 kg of coal, the Lachinyan pyrolysis furnace, the drawings of which are already in the public domain, works for up to seven days.

You will learn how to make a long burning stove from a barrel with your own hands from this article.

Vapor permeability in a multi-layer construction

The sequence of layers and the type of insulation - this is what primarily affects the vapor permeability. In the diagram below, you can see that if the insulation material is located on the front side, then the indicator of pressure on moisture saturation is lower.

If the insulation is located on the inside of the house, then condensation will appear between the supporting structure and this building. It negatively affects the entire microclimate in the house, while the destruction of building materials occurs much faster.

How the correct vapor barrier should work

Water vapor can pass through building materials in several ways, including direct transfer and heat transfer, but research shows that a full 98 percent of moisture transfer through walls occurs through air gaps, including cracks around electrical fixtures and outlets, and gaps along baseboards.

Note that a poor vapor barrier installation can be worse than no vapor barrier at all.

The main purpose of vapor barrier is to prevent moisture build-up and deterioration of building materials. An improperly installed vapor barrier can actually trap moisture inside a wall, while a more porous wall can breathe efficiently and be less susceptible to long-term exposure to moisture. This condition is especially problematic where vapor barriers are installed on both the inside and outside of the wall.

We offer you to familiarize yourself with How to make a blind area around the house: insulation and do-it-yourself device

Once considered essential throughout a home or office, vapor barrier installation is now highly recommended only for certain conditions, and vapor barrier installation methods must be adapted to the climate, region and type of wall construction. For example, the recommended vapor barrier in a brick-built house in a humid southern climate differs significantly from creating a vapor barrier in a cold climate in a house built with wood siding.

Avoid installing an internal vapor barrier where the outer wall structure already contains vapor barrier material.

In areas with high humidity — such as greenhouses, spa or pool rooms, and bathrooms.

In very cold climates, the use of polyethylene plastic vapor barriers between the insulation and the inner wall can be helpful if all air gaps in any cavity of the wall and ceiling are also insulated. The outer surface of the wall or floor cavity must remain permeable in order to dissipate moisture entering the wall cavity.

In very hot and humid climates, you can also benefit from an external vapor barrier that prevents moisture from entering the external wall.

Walls and floor slabs transfer ground moisture through concrete walls or slabs. It is generally recommended to install a vapor barrier against a specific surface prior to installing wood materials.

Vapor Barrier Installation Tips

Homes must have adequate ventilation before installing vapor barriers. Modern homes that are hermetically sealed for high energy efficiency must also have good ventilation or other solutions to provide a good exchange of fresh air.

Understanding the coefficient

The coefficient in this indicator determines the amount of vapors, measured in grams, that pass through materials 1 meter thick and 1m² layer for one hour. The ability to transmit or retain moisture characterizes the resistance to vapor permeability, which is indicated in the table by the symbol "µ".

In simple words, the coefficient is the resistance of building materials, comparable to the air permeability. Let's analyze a simple example, mineral wool has the following vapor permeability coefficient

: µ = 1. This means that the material passes moisture as well as air. And if we take aerated concrete, then its µ will be equal to 10, that is, its steam conductivity is ten times worse than that of air.

Features of the

On the one hand, vapor permeability has a good effect on the microclimate, and on the other hand, it destroys the materials from which houses are built. For example, "cotton wool" perfectly permeates moisture, but as a result, due to excess steam, condensation can form on windows and pipes with cold water, which is also indicated in the table. Because of this, the insulation loses its quality.Professionals recommend installing a vapor barrier on the outside of the house. After that, the insulation will not let steam through.

If the material has a low vapor permeability, then this is only a plus, because the owners do not have to spend money on insulating layers. And to get rid of the steam generated from cooking and hot water, an extractor hood and a vent will help - this is enough to maintain a normal microclimate in the house. In the case when a house is built from wood, it is impossible to do without additional insulation, while a special varnish is required for wood materials.

The table, graph and diagram will help you understand the principle of this property, after which you can already decide on the choice of a suitable material. Also, do not forget about the climatic conditions outside the window, because if you live in an area with high humidity, then you should generally forget about materials with a high vapor permeability index.

There is a legend about a "breathing wall", and a legend about "healthy breathing of the cinder block, which creates a unique atmosphere in the house." In fact, the vapor permeability of the wall is not large, the amount of vapor passing through it is insignificant, and much less than the amount of vapor transported by air when it is exchanged in the room.

Water vapor permeability is one of the most important parameters used when calculating insulation. We can say that the vapor permeability of materials determines the entire construction of insulation.

What is vapor permeability

The movement of steam through the wall occurs when there is a difference in partial pressure on the sides of the wall (different humidity). In this case, there may not be a difference in atmospheric pressure.

Vapor permeability - the ability of a material to pass steam through itself. According to the domestic classification, it is determined by the vapor permeability coefficient m, mg / (m * hour * Pa).

The resistance of the material layer will depend on its thickness. It is determined by dividing the thickness by the vapor permeability coefficient. Measured in (m2 * hour * Pa) / mg.

For example, the coefficient of vapor permeability of brickwork is taken as 0.11 mg / (m * hour * Pa). With a brick wall thickness of 0.36 m, its resistance to vapor movement will be 0.36 / 0.11 = 3.3 (m2 * hour * Pa) / mg.

What is the vapor permeability of building materials

Below are the values of the vapor permeability coefficient for several building materials (according to the regulatory document), which are most widely used, mg / (m * h * Pa). Bitumen 0.008 Heavy concrete 0.03 Autoclaved aerated concrete 0.12 Expanded clay concrete 0.075 - 0.09 Slag concrete 0.075 - 0.14 Fired clay (brick) 0.11 - 0.15 (in the form of masonry on cement mortar) Lime mortar 0.12 Drywall , gypsum 0.075 Cement-sand plaster 0.09 Limestone (depending on density) 0.06 - 0.11 Metals 0 Particleboard 0.12 0.24 Linoleum 0.002 Polyfoam 0.05-0.23 Solid polyurethane, polyurethane foam 0, 05 Mineral wool 0.3-0.6 Foam glass 0.02 -0.03 Vermiculite 0.23 - 0.3 Expanded clay 0.21-0.26 Wood across the grain 0.06 Wood along the grain 0.32 Silicate masonry cement mortar bricks 0.11

Data on vapor permeability of layers must be taken into account when designing any insulation.

How to design insulation - for vapor barrier qualities

The basic rule of insulation is that the vapor transparency of the layers should increase outward. Then, in the cold season, it is more likely that water will not accumulate in the layers when condensation occurs at the dew point.

The basic principle helps to determine in any case. Even when everything is "turned upside down" - they insulate from the inside, despite the insistent recommendations to make insulation only from the outside.

In order to avoid a catastrophe with wetting the walls, it is enough to remember that the inner layer should most stubbornly resist the steam, and on this basis, for internal insulation, use extruded polystyrene foam with a thick layer - a material with very low vapor permeability.

Or do not forget to use even more “airy” mineral wool outside for very “breathing” aerated concrete.

Separation of layers with a vapor barrier

Another option for applying the principle of vapor transparency of materials in a multilayer structure is the separation of the most significant layers with a vapor barrier. Or the use of a significant layer, which is an absolute vapor barrier.

For example, insulation of a brick wall with foam glass. It would seem that this contradicts the above principle, because moisture accumulation in the brick is possible?

But this does not happen, due to the fact that the directional movement of steam is completely interrupted (at subzero temperatures from the room to the outside). After all, foam glass is a complete vapor barrier or close to it.

Therefore, in this case, the brick will enter an equilibrium state with the internal atmosphere of the house, and will serve as an accumulator of humidity during its sharp jumps inside the room, making the internal climate more pleasant.

The principle of separation of layers is also used by using mineral wool - insulation is especially dangerous in terms of moisture accumulation. For example, in a three-layer construction, when the mineral wool is inside the wall without ventilation, it is recommended to put a vapor barrier under the wool and thus leave it in the outside atmosphere.

International classification of vapor barrier properties of materials

The international classification of materials for vapor barrier properties differs from the domestic one.

According to the international standard ISO / FDIS 10456: 2007 (E), materials are characterized by a coefficient of resistance to steam movement. This coefficient indicates how many times more material resists the movement of steam compared to air. Those. for air, the coefficient of resistance to steam movement is 1, and for extruded polystyrene foam it is already 150, i.e. expanded polystyrene passes steam 150 times worse than air.

Also in international standards, it is customary to determine vapor permeability for dry and moist materials. The boundary between the concepts of “dry” and “humid” is the internal moisture content of the material of 70%. Below are the values of the coefficient of resistance to steam movement for various materials according to international standards.

Steam resistance coefficient

First, the data is given for dry material, and comma separated for humidified material (more than 70% humidity). Air 1, 1 Bitumen 50,000, 50,000 Plastics, rubber, silicone -> 5,000,> 5,000 Heavy concrete 130, 80 Medium density concrete 100, 60 Polystyrene concrete 120, 60 Autoclaved aerated concrete 10, 6 Lightweight concrete 15, 10 Artificial stone 150, 120 Expanded clay concrete 6-8, 4 Slag concrete 30, 20 Fired clay (brick) 16, 10 Lime mortar 20, 10 Drywall, gypsum 10, 4 Gypsum plaster 10, 6 Cement-sand plaster 10, 6 Clay, sand, gravel 50, 50 Sandstone 40, 30 Limestone (depending on density) 30-250, 20-200 Ceramic tiles ?,? Metals ?,? OSB-2 (DIN 52612) 50, 30 OSB-3 (DIN 52612) 107, 64 OSB-4 (DIN 52612) 300, 135 Chipboard 50, 10-20 Linoleum 1000, 800 Laminate underlay plastic 10,000, 10,000 Substrate cork under the laminate 20, 10 Styrofoam 60, 60 EPS 150, 150 Solid polyurethane, polyurethane foam 50, 50 Mineral wool 1, 1 Foam glass ?,? Perlite panels 5, 5 Perlite 2, 2 Vermiculite 3, 2 Ecowool 2, 2 Expanded clay 2, 2 Wood across the grain 50-200, 20-50

It should be noted that the data on resistance to the movement of the pair in our country and "there" are very different. For example, foam glass is standardized in our country, and the international standard says that it is an absolute vapor barrier.

Where did the legend of the breathing wall come from?

A lot of companies produce mineral wool. This is the most vapor-permeable insulation. According to international standards, its coefficient of resistance to vapor permeability (not to be confused with the domestic coefficient of vapor permeability) is 1.0. Those. in fact, mineral wool is no different from air in this respect.

Indeed, it is a "breathable" insulation. To sell as much mineral wool as possible, you need a beautiful fairy tale.For example, that if you insulate a brick wall from the outside with mineral wool, then it will not lose anything in terms of vapor permeability. And this is absolutely true!

An insidious lie lies in the fact that through brick walls 36 centimeters thick, with a humidity difference of 20% (on the street 50%, in the house - 70%) about a liter of water will leave the house per day. While with the exchange of air, about 10 times more should come out, so that the humidity in the house does not build up.

And if the wall is insulated from the outside or from the inside, for example, with a layer of paint, vinyl wallpaper, dense cement plaster (which, in general, is "the most common thing"), then the vapor permeability of the wall will decrease significantly, and with complete isolation - tens and hundreds of times ...

Therefore, a brick wall and households will always be absolutely the same - whether the house is covered with mineral wool with "raging breath", or "dull sniffling" foam.

When deciding on the insulation of houses and apartments, one should proceed from the basic principle - the outer layer should be more vapor-permeable, preferably at times.

If for some reason it is not possible to withstand it, then you can separate the layers with a continuous vapor barrier (apply a completely vapor barrier layer) and stop the movement of steam in the structure, which will lead to a state of dynamic equilibrium of the layers with the environment in which they will be located.

We supply building materials to the cities: Moscow, St. Petersburg, Novosibirsk, Nizhny Novgorod, Kazan, Samara, Omsk, Chelyabinsk, Rostov-on-Don, Ufa, Perm, Volgograd, Krasnoyarsk, Voronezh, Saratov, Krasnodar, Togliatti, Izhevsk, Yaroslavl , Ulyanovsk, Barnaul, Irkutsk, Khabarovsk, Tyumen, Vladivostok, Novokuznetsk, Orenburg, Kemerovo, Naberezhnye Chelny, Ryazan, Tomsk, Penza, Astrakhan, Lipetsk, Tula, Kirov, Cheboksary, Kursk, Tver, Magnitogorsk, Ivanovo, Ulanovo Ude, Nizhny Tagil, Stavropol, Surgut, Kamensk-Uralsky, Serov, Pervouralsk, Revda, Komsomolsk-on-Amur, Abakan, etc.

08-03-2013

30-10-2012

The volume of wine production in the world in 2012 should fall by 6.1 percent due to a poor harvest in several countries of the world,

We compare and select materials for thermal insulation of houses

The differences and similarities of thermal insulation products should be considered in the context of the following characteristics:

1. Strength. The strength indicators of the material for the insulation of facades directly depend on its density:

- for the arrangement of external walls, polystyrene foam is used with a density of 16.0 to 18.5 kg / cu. meter, plate thickness - from 80 mm, 100 mm. Regulated compressive strength at 10% linear deformation not less than 100 kPa, ultimate strength in bending not less than 180 kPa, ultimate tensile strength in the direction perpendicular to the surface not less than 100 kPa

- tensile strength perpendicular to the front surfaces more than 15 kPa. The issue of choosing mineral wool for arranging external walls is solved as follows: if a ventilated facade is installed, then slabs with a density of 45-100 kg / cubic meter are used. meter; for the "wet" facade system - 145-165 kg / cu. meter.

2. Water vapor permeability. If, apart from a specific facade system, we compare that it is better to pass steam through mineral wool or foam plastic, then mineral wool slabs will benefit. The vapor permeability coefficient of foam is at least 0.05 mg / m * h * Pa, while for mineral wool it is 6 times higher. But if the wall outside is finished with synthetic coatings, then the characteristics of the mineral wool deteriorate sharply due to the inability to remove condensate outside. In combination with plasters with a high vapor permeability index - silicone and silicate-silicone, it is optimal to use mineral wool boards in combination with plaster mixtures with a high vapor permeability index - silicone and silicate-silicone compounds.

3. Heat resistance. If we approach the choice of thermal insulation materials from the standpoint of assessing the level of thermal conductivity, then these values for stone wool and PPS are approximately equal.Mineral wool - no more than 0.0475 W / mK, PPS - no more than 0.041 W / mK.

4. Resistance to fire. The materials used for insulating facades should be classified as non-combustible or low-combustible raw materials. Basalt fibers, of which the mineral wool slab is composed, melt at temperatures above 1000 degrees Celsius, therefore, the insulation based on them is highly resistant to fire. PPS burns at a temperature of 110-120 degrees. It is subdivided into classes - G (combustible), G1-G4 weak and highly combustible products, respectively.

5. Load on supporting structures. The optimal choice of wall insulation depends on the materials correctly selected by weight. Expanded polystyrene is 3-4 times lighter than mineral wool board

Another important indicator for comparison is durability. The service life of mineral wool insulation is 20-40 years. Polyfoam is also characterized by high reliability, but a slightly shorter service life. The use of vapor barrier and waterproof layers in facade systems increases the operational period at times.