Types of drywall and its application

Drywall can be used to insulate walls inside a building. Use either moisture resistant or wall.

Moisture resistant can be used in summer cottages or for rooms with a high degree of humidity: bathrooms and kitchens.

Important! Moisture-resistant drywall, the best solution for rooms where heating is not provided.

This material is not threatened by cyclical jumps in temperature. It is only necessary after mounting the sheets to apply a waterproof primer or protective paint to the front part. You should also do the treatment of drywall with an antiseptic, which allows you to kill harmful microbes and bacteria.

Wall types are suitable for living rooms where the humidity is no more than 70%. Sheets are marked in blue on a gray surface.

As for the size of the sheets, it is best to purchase products 2.5-3 meters long and 1.2 wide. In terms of thickness, 12.5 mm canvases are perfect (9.5 mm is the ceiling view).

- normal;

- moisture resistant;

- moisture and windproof;

- reinforced strength;

- fire resistant.

Frame method of insulation

There are 3 methods of insulation:

- Glue method. Sheets are attached directly to the wall using gypsum or polymer-cement glue. With this finish, the area of the room does not become smaller. The only drawback of this method is that it is impossible to make a laying of thermal insulation, and the walls must be strong.

- Frame method with a thermal insulator.

- Frame method without insulation.

The last two methods of installing drywall are used most often. In order not only to insulate the room, but also to achieve good sound insulation performance, you will need to use a profile. The only drawback is that the room is significantly reduced in size.

Which drywall is better to use

The length and width of all sheets is standard (length 2.5 m -3 m, width 1.2 m). In terms of thickness for the walls, you need to take sheets of 12.5 mm (9.5 mm is a ceiling drywall). But the type will need to be determined depending on the room and functions. There are:

- standard;

- moisture resistant;

- increased strength;

- windproof and waterproof;

- fire resistant;

- types of material.

There are three methods of insulation using this technology:

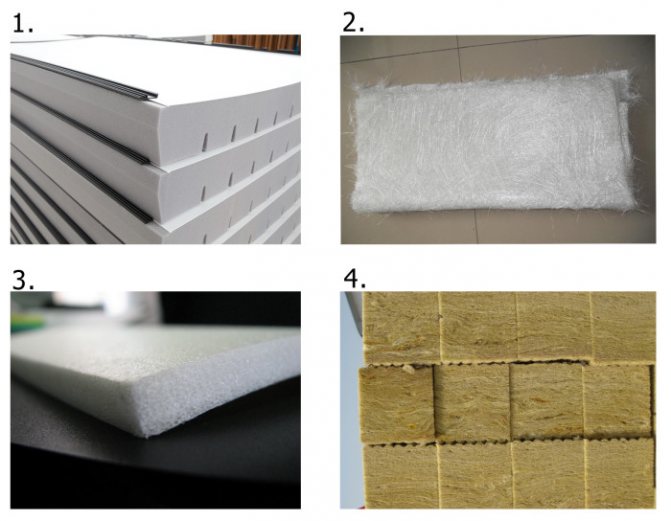

Insulation types

Warming the surface under the drywall is best done with mineral wool or foam. You can also use Isolone or Penoplex. These insulators differ in installation methods, cost, strength.

Studies have shown that styrofoam and polystyrene are unhealthy. In residential premises, it is rarely used. Another disadvantage is that some types of foam are eaten by rodents. But it has a low cost, and is also available in many densities and sizes.

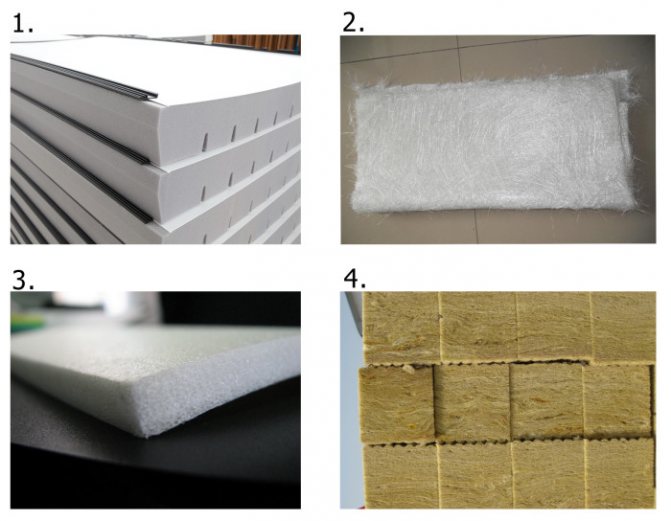

An example of insulation with plasterboard and mineral wool

As for mineral wool, the advantages include low weight (especially important for insulating old buildings), as well as low thermal conductivity. There is only one significant minus of mineral wool - hygroscopicity. Therefore, when insulating partitions and walls, it is necessary to prevent the accumulation of condensation. For this, steam insulation should be used.

There are several types of mineral wool. All of them differ between the method of production, composition and technical indicators. Among the types of wool on the market, the most popular is fiberglass-based basalt wool.Like other types of insulation, they have both advantages and disadvantages.

The main negative sides of glass wool:

- The indicator of thermal conductivity is higher than that of stone, respectively, heat disappears faster.

- At elevated temperatures, it forms a solid glass mass.

- It is inconvenient when working (glass wool fibers can cause itching, requires the use of protective glasses, gloves, a respirator, wearing a tight suit).

Important! For greater efficiency, it is necessary to lay mineral wool in 2-3 layers.

Despite the external similarity, basalt and glass wool differ significantly. Glass wool is made from very thin fiberglass, while basalt wool is made from volcanic rock. They also differ by an indicator of thermal conductivity, which is less in basalt, and, therefore, it retains heat better.

The cost of materials for insulation:

- The cheapest way would be to insulate the walls of the house with polystyrene, the price of which ranges from 70-90 rubles. for 1 sq. m.

- As for mineral wool, it costs a little more - 90-150 rubles. The price of the material depends on its density, thickness and manufacturer.

- Penoplex, which is extruded foam, but with increased strength and density, costs 1 sq. meter about 200 rubles.

Isolon (foamed polyethylene) can also serve as an insulator. Its cost will be 280-300 rubles per 1 square meter.

Varieties of material

Today on the market you can find a huge number of insulation products that differ in their quality characteristics.

When choosing insulation for drywall, you first need to study the characteristics of each.

Heaters include the following materials:

- Styrofoam;

- expanded polystyrene;

- mineral wool;

- reflector (isolon);

- coconut and cork plates.

Each of them has a specific structure and parameters.

To choose the right insulation, you must initially know the characteristics of each of them.

Features of foam and polystyrene foam in insulation

These funds have been used in finishing work for a long time. They have earned recognition for their optimal cost and excellent quality characteristics.

Advantages of materials:

- Low weight, which avoids additional loads on the metal-profile frame.

- Moisture resistance - products do not absorb moisture, and under its influence they are not able to deform.

- High thermal resistance - heated air masses will not be able to pass through their structure.

- Safety - materials can be used without additional hand protection.

- Durability - the service life of polystyrene and polystyrene is the same and is more than 25 years.

- Practicality - the products are easy to cut and also easy to assemble.

Polyfoam or polystyrene helps to make the process of building insulation faster and of better quality. Despite the large number of advantages, the materials also have disadvantages. These include the following characteristics:

- Low strength during physical exertion.

- Immunity to fire - Styrofoam does not burn, but can melt.

- Toxicity - the manufacturing process of materials involves the use of synthetic raw materials.

In addition, polystyrene and expanded polystyrene act as vapor barriers. This negatively affects the insulation of rooms with high air humidity and high temperature conditions.

Mineral wool and its characteristics

There are several types of this material. These include the following products:

- glass wool;

- basalt wool;

- stone wool;

- slag wool.

Each of them has certain advantages and disadvantages.

The most popular insulation is glass wool. It is made from natural raw materials - sand, borax, soda and limestone.

The advantages of mineral wool are its non-toxicity and fire resistance.

The advantages include the following characteristics:

- Non-toxic - the material does not emit harmful substances.

- Good thermal conductivity.

- Resistant to aggressive environments.

- Fire resistance.

Also, the material is an excellent soundproofing agent.

The disadvantages include the fragility of the fibers in the structure, as well as low heat resistance. Glass wool loses its properties when exposed to a temperature of 450 degrees.

Today, this type of insulation is effectively used to insulate drywall interior walls.

Basalt wool is less popular due to its cost. It is made on the basis of basalt raw materials. She has excellent heat and sound insulation performance. It is also heat-resistant and stands out among similar materials for environmental friendliness.

Rock mineral wool is a relatively new type of insulation. It is made of volcanic rock. Due to this, it has a dense structure. The material is not able to absorb moisture and perfectly absorbs noise. Its main advantage is environmental friendliness.

Plasterboard wall decoration: a new look at the space of the house

Slag waste is a raw material for the production of slag wool. This type of thermal insulation is less popular than all the others. This is due to its technical performance. It is capable of absorbing moisture, does not withstand exposure to low and high temperatures, does not absorb sounds so well and is not environmentally friendly. The only advantage is the low cost.

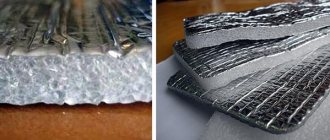

Reflector in thermal insulation of structures

This tool has appeared on the market recently, but has already gained recognition. It is made with foil and rubber base. Thanks to this, the material reflects heat well and does not transmit it through the wall. It is also unable to absorb moisture.

The main qualitative characteristics of the reflector include the following:

- noise absorption;

- environmental friendliness;

- durability;

- resistance to low and high temperatures.

In addition, it is safe for human health. The rubberized base of the material increases its elasticity. This insulation for plasterboard partitions is also called isolon.

Coconut and cork plates

The products are made from coconut fiber and balsa wood using special products. The materials are environmentally friendly and have good technical characteristics.

If you need to make high-quality heat and sound insulation of the structure, coconut and cork plates will be indispensable.

Benefits of funds:

- high structure density;

- elasticity;

- moisture resistance;

- heat resistance;

- durability;

- practicality.

The structure recovers quickly after compression. The service life of cork insulation reaches 30 - 40 years. It should be noted that the material does not rot or deform when exposed to alkalis, which cannot be said about coconut plates. They are able to absorb moisture during a certain cycle of exposure. A variety of bacteria are formed in the structure, with the help of which mold develops.

If coconut insulation is used, it is necessary to additionally make layers of hydro and vapor barrier.

The cost of the material is quite high due to the use of natural raw materials in its production.

Stages of thermal insulation of a wall

In order for the work process to proceed quickly and properly, the necessary tools should be prepared. This will significantly speed up the work of protecting the walls with insulation.

The following materials will be required:

- drywall sheets;

- self-adhesive tape;

- insulation;

- membrane to ensure the maximum degree of vapor barrier;

- screws, nails;

- hammer, screwdriver, hacksaw;

- yardstick;

- metal profiles or wooden slats for the construction of the frame;

- fastening materials.

1 sheet requires about 30 pieces of self-tapping screws. It is best to buy screws with a length of 20 mm.

As for the manufacture of the frame, the profile must be taken in 2 types: with the CD and UD markings. The length is chosen based on the size of the room.

Frame design

It consists in tracing the perimeter and thinking over how the frame will be located on the wall. A simple pencil and a building level are enough.

Advice! For the best insulating effect, the structure must be positioned 3-10 cm from the wall.

- surface cleaning;

- even out all irregularities and putty chips and grooves;

- drying with a heater or stroyfen;

- getting rid of mold and mildew.

Sometimes it is necessary to treat the walls with a special waterproofing putty to prevent dampness. First, the layer is applied vertically, then horizontally.

Frame construction

According to the pre-made marks, you need to mount the frame. To avoid contact of the metal structure with the wall, a tape prepared in advance is glued to the profile sole. Fastening of frame parts to the wall is carried out using self-tapping screws and dowels.

Before laying the insulator, the surface is prepared in advance. Remove or restore fragile plaster areas. To exclude the possibility of the formation of fungus and mold, it is necessary to do the treatment with a primer with an antiseptic.

Plasterboard sheets are installed on a frame made of metal profiles or wood. A metal frame will serve significantly longer than a bar.

In the area where the batteries are located, where the installation of thermal insulation is difficult, penofol can be used.

For drywall, you can make a frame from bars

Assembling the frame begins with the installation of the guides created from the UD profile. The slats are attached to the ceiling and floor with an indent from the walls of 50-60 mm. The section of the rack profile is inserted into the guides. The ends are fixed with small self-tapping screws ("flea beetles"). The edges of the suspensions are bent from the sides and connected to the slats. The step between the profiles must be observed so that there are 3-4 slats per sheet.

Important! When the frame is constructed, the insulator begins to be laid.

To improve the rigidity of the structure, it is necessary to make transverse jumpers from the CD profile. The profile is cut in such a way that its length overlaps the adjacent strips by half. Shears are cut off the shelves with metal scissors. Then the workpieces are fixed with “flea beetles” on the frame.

Thermal insulation of walls in damp and unheated rooms

In such cases, moisture resistant drywall is used. It is more expensive than usual, but not worth saving! Wall cladding with such material is carried out both in rooms where the humidity is high, and in very wet ones. Already at the production stage, the ability to resist moisture is laid - gypsum plasterboards undergo a special heat treatment, which helps to exclude the appearance of mold and mildew.

The product is pigmented with green dyes to distinguish it from other types of sheets. Special water-repellent and antifungal additives enable this material to retain its unique characteristics even at high humidity. This does not preclude the need to combat humidity in the bathroom. Such a room must necessarily have forced ventilation. It should not be tied to turning off / on lighting. It is advisable to use a humidity sensor in the electric fan control system.

Moisture-resistant drywall is recommended for use where there is no constant heating. For example, in the country. It is able to withstand cyclical changes in temperature.It is necessary only after installing the sheets in rooms that are not heated, to apply a waterproof primer or protective paint to the front side. It is also recommended to treat drywall with an antiseptic, which contains components for the destruction of harmful microorganisms.

Thermal insulation of walls with drywall has a significant advantage over other methods. This is a great way to insulate walls and, at the same time, reduce the noise level in a house or apartment. This indicator is of particular importance if the house is located on a large street, tram lines or a railway pass nearby.

It is not always possible to insulate a high-rise building; you need special equipment. However, wall insulation from the inside with mineral wool plus drywall gives a good result, heat losses are reduced by 20-30%. It is only important to make a thermal insulation layer in the apartment according to the technology.

Do-it-yourself wall insulation with drywall requires the correct selection of materials. Saving and choosing components that do not match technology will make thermal insulation useless and money wasted.

To make high-quality insulation you will need:

- Wall drywall.

- or wooden slats.

- Insulation.

- Fastening materials.

Drywall and profile

Plasterboard can be used to insulate walls from the inside of the room, either wall or moisture resistant. The latter type is used for rooms with a high level of humidity: kitchens or bathrooms.

Wall types of drywall are suitable for living rooms where the humidity does not exceed the 70% threshold. marked in blue on a gray surface.

The main types of drywall Foam insulation

Penoplex is extruded foam, but with high density and strength. Wall insulation with penoplex will cost more, the price per square meter is about 200 rubles.

Penoplex insulation

Another good option for insulation is izolon, or foamed polyethylene. Its price is 280-300 rubles. per square meter.

Thermal insulation performance when using a particular type of material will depend on the observance of the installation rules and the thickness of the insulation.

Insulation with isolon

You will need to purchase from fasteners for fixing, and for connecting the guide rails to each other (fleas).

The assembly of the frame begins with the installation of guides, which are made from the UD profile. These slats are fixed to the floor and ceiling in parallel, stepping 50-60 mm from the walls. The space under the frame will be used for laying the heat insulator.

Fixation of the guides is carried out through the use of a nail-type dowel, which ensures reliable fastening to brickwork and any other.

After installing the profiles on the floor and ceiling, proceed to the installation of the rails from the CD profile. These slats are the basis for. So that they are rigidly fixed to the wall, they mount straight hangers, as well. For a standard apartment with a ceiling height of 2.5-2.6 meters, 3-4 suspensions are enough for one profile.

Installation of the main frame rails is carried out as follows. The segment is inserted into the guides. The ends are fixed using small self-tapping screws "flea". From the sides, the edges of the suspensions are bent, which are also connected to the slats. The step between the frame profiles is observed so that there are 3-4 slats per drywall sheet.

To strengthen the rigidity of the entire structure, it is necessary to make transverse jumpers from the same material (CD profile). This is done according to the following algorithm.

Jumper to strengthen the structure

The profile is measured and cut so that its length overlaps the neighboring rivers by half. Shears are cut off the shelves with metal scissors. The resulting blanks are fixed with "flea beetles" on the frame.

When the frame is completed, they begin to lay the heat insulator.

Balcony wall insulation

As for the insulation of balconies and loggias, such structures require compliance with certain rules.

The material for thermal insulation should be:

- waterproof (since there is a high probability of water appearing on the balcony);

- drywall you need to buy only moisture resistant;

- walls should be treated with an antiseptic.

For the insulation of balconies, a frameless method is often used. This is due to the fact that such a space has a small area. The insulator creates a higher degree of structural reliability despite different influences: tension, moisture and other loads.

Initially, the walls are prepared for fastening the sheets. All fragile areas are restored, and the surface is treated with an antiseptic agent.

As soon as the walls are prepared, they begin to install the sheets. Initially, they need to be cut into the required pieces. It is not recommended to cut the sheets right away, it is better to do this during work.

Once the material is prepared, you can start fixing it. This should be done using an adhesive. This is the easiest way to attach hl. When carrying out such work, you need to ensure that the layer of the mixture is the same everywhere.

Thermal insulation allows you to protect the house from dampness, drafts and provide a favorable and comfortable microclimate. After all, a heater, like a shield, can be fenced off from the harmful effects of the environment.

Posted on 03.07.2016 in category Building materials // 0 comments // Posted by Admin

- 5

- 4

- 3

- 2

- 1

(1 vote, average: 5 out of 5)

Plasterboard is a modern building material for interior decoration. For several years, he gained immense popularity among both builders and ordinary people.

Benefits of drywall

Drywall, unlike brick or foam block, does not limit the imagination of designers in anything, and anyone who knows how to hold the simplest tools in their hands can handle the installation of a drywall partition. Plasterboard partitions are lightweight, so they do not create a tangible load on the floors and the building structure itself.

Drywall sheets themselves have excellent sound and heat insulation properties, and the empty space between them further enhances this effect. Therefore, if you revet the walls facing the street with plasterboard, this will make it possible not only to prevent the cold from getting into the room in winter, but also prevent the heat from penetrating inside from the walls heated by the scorching sun. In this case, it is advisable to mount the sheets on a metal frame, not immediately on the wall. The space between the drywall and the wall provides additional thermal insulation.

Insulation materials

Installation of insulation

How to properly insulate walls inside under drywall

More often the walls are insulated using drywall, because:

- the thermal conductivity of this material is 10 times lower than that of reinforced concrete - therefore, even simply glued to the wall, it gives a noticeable thermal insulation effect;

- since flat surfaces are required for its sticker, then with defects existing on them, the sheets have to be mounted on special frames, which creates an air gap between the drywall and the wall - this also helps to preserve heat in the room;

- the space between the drywall and the wall is more efficiently used, if insulating materials are laid between them, which will greatly increase the possibility of keeping heat in the house;

- in the summer, such insulation will not let heat into the room from the heated walls;

- the ideal geometry of the material allows, simultaneously with improving the microclimate, to perform one more task - to level the surface of the walls, hide defects and communication installations.

Wall insulation with plasterboard

Installation of drywall sheets is one of the most popular ways to install thermal insulation material.In some situations, 1 layer without additional insulation is sufficient to increase the heat level in the room.

Insulation for GKL partitions does not require special conditions or properties. Drywall has tremendous advantages over other interior decoration methods. It is easy to cut and install, and the thermal insulation is aesthetic and inexpensive.

Insulation for plasterboard partitions

Insulation for GKL partitions does not require special conditions or properties. Drywall has tremendous advantages over other interior decoration methods. It is easy to cut and install, and the thermal insulation is aesthetic and inexpensive.

- installation by means of the frame “eats up the area of the room;

- the material is very fragile, not suitable for hanging heavy objects;

- GKL does not differ in mechanical strength, it breaks easily upon impact;

- untreated sheets give off dust that is harmful to health.

Foamed polyethylene film coated with aluminum foil is ideal as a vapor barrier gasket that prevents condensation from forming inside the partition. For information on how to insulate walls with drywall, see this video: The self-adhesive tape is made of polystyrene components and has a thickness of 3-4 mm. It is glued to effectively absorb sound from the ceiling, walls, floor and even from the frame itself from profiles.

With this method of installation, a thermal insulation material is laid in the chamber between the wall and the gypsum board sheets. The height of the guides in this case is equal to the thickness of the insulation material.

Material characteristic

Moisture resistant gypsum plasterboard painted green

GKL are produced with a thickness of 12.5 mm for walls and partitions and 9.5 mm for ceiling sheathing. Standard sheet sizes are 2.5 * 1.2 m.According to additional characteristics, the material is divided into:

- regular or standard;

- moisture resistant;

- increased strength;

- fire resistant.

It is still recommended to lay a layer of thermal insulation between the wall and the gypsum board

GKL has a low level of thermal conductivity ten times lower than that of concrete. The value of the indicator ranges from 0.14 to 0.15. It is thanks to this value that the sheets do an excellent job of retaining heat inside the room without the use of an additional layer of insulation.

Nevertheless, thermal insulation is usually laid under the gypsum board with a thermal conductivity value of 0.03. A decrease in thermal conductivity is possible when installing the gypsum board on the frame guides. This design significantly increases the thermal insulation properties of walls and floors.

Wall insulation with plasterboard from the inside is used both in office or utility rooms, and in living rooms. Such insulation is most relevant where it is difficult to arrange the outer layers of thermal insulation, especially in corner rooms.

GKL is often mounted on a metal frame

Experts consider the device of a thermal insulation system from drywall sheets to be one of the simplest and fastest methods. Any technology has its own specifics, wall insulation from the inside with plasterboard is no exception.

Depending on the area of the room and the required level of thermal insulation, you should choose one of the installation methods.

Methods for fixing the installation of gypsum board:

The sheet is glued directly to the wall using gypsum or cement-polymer mortar. With this method, the gypsum board itself is used as a heater. This installation method does not reduce the area of the room. The disadvantage is the inability to lay the thermal insulation material. The wall covering must be absolutely strong without delamination.

GKL sheets are attached to metal guides or a wooden frame beam. The service life of a metal base is much longer than a wooden one. In addition, the tree is prone to deformation, especially in the regime of temperature changes.The air chamber between the wall and the sheet, even without laying the insulation material, provides a good level of thermal insulation

Frame with insulation

With this method of installation, a thermal insulation material is laid in the chamber between the wall and the gypsum board sheets. The height of the guides in this case is equal to the thickness of the insulation material.

Using the frame method with the use of insulation material, the movement of convection air flows is prevented and the level of thermal insulation is increased.

Insulation material

When installing mineral wool, use a vapor barrier

Internal insulation of drywall partitions is made with various materials. The most common heat insulators for laying under drywall are:

- Mineral wool. The material has a very low weight, so that the load on the load-bearing walls of the building does not increase. This property is especially important when insulating old buildings. The main disadvantage is that it easily absorbs moisture, therefore, vapor barrier films should be used during installation.

- Glass wool. It is possible to work with the material only in protective clothing, goggles and a respirator. As the temperature rises, it becomes a single glass mass. Has a budget price tag, but fits in 2-3 layers.

- Styrofoam. According to some reports, it is not safe for health, therefore, it is not recommended for use in living rooms. Small rodents "love" it very much, which eventually causes a persistent specific smell. Available in various thicknesses and densities on the market.

Foamed polyethylene film coated with aluminum foil is ideal as a vapor barrier gasket that prevents condensation from forming inside the partition. For information on how to insulate walls with drywall, see this video:

The use of the film will save 95% of heat. At the same time, sound insulation in the room will significantly improve.

The choice of thermal insulation filler

Experts consider the insulation of external walls to be more effective. But in multi-storey residential buildings, it will be almost impossible to carry out work on your own. But the use of drywall as insulation allows you to significantly save on hired labor and achieve high thermal insulation properties. At this stage, the most important issue will be the choice of insulation. Currently using:

- Styrofoam;

- glass wool;

- isolone;

- basalt (stone) wool.

Foam plastic remains relevant in the insulation market. However, in living quarters, it is better to avoid wall insulation with this material. Firstly, rodents love it, therefore, over time, the insulation layer will lose its properties, warm air will begin to leave the room through the holes that appear. And to replace the foam, you will have to open the finish, i.e. relive the renovation again. Secondly, the foam has low sound insulation and does not "breathe" at the same time. A residential apartment will require additional ventilation. If you nevertheless chose it, then you will be pleased that it is very simple and easy material to work with.

Glass wool also has low thermal conductivity, but this is a specific material that attracts only by its low price. Its main disadvantage for internal wall insulation with drywall is the presence of glass fibers, which, when in contact with the skin, cause itching and burning. It is necessary to work with glass wool only with gloves, protective clothing and a respirator. Such inconveniences, as a rule, repel buyers, therefore, it is practically not used in residential premises.

Isolon is much more popular. This material has several advantages. It not only retains heat, but also does not allow noise to pass through, which saves on sound insulation. Do-it-yourself wall insulation work from the inside takes not only time, but also the useful area of the room. Izolon has a small thickness, which allows the owners not to worry about the meters "eaten" by the heater.

Often, basalt wool is involved in the thermal insulation of walls. In terms of its properties, it is most similar to glass wool, but differs in composition. In its manufacture, rocks are used, which gives it fire resistance and hypoallergenicity. But its disadvantage is the price, it is more expensive than glass wool and foam.

Each apartment owner must answer the question himself how to insulate the walls with plasterboard. You need to build on your financial capabilities and your preferences. I would like to give only one piece of advice: if possible, then purchase insulation in the form of plates, not rolls. This will make your work easier and faster. The slab insulation has a standard width of 60 cm, which corresponds to the step of fastening the frame profile.

Back to content ↑

Advantages and disadvantages

When installing the gypsum board on the frame, the area of the room will slightly decrease

The main advantage of using drywall sheets as insulation is the high efficiency of the material.

At the same time, the surface of the sheets does not require additional leveling and is ready for laying the finishing decorative layer of the design.

- installation by means of the frame “eats up” the area of the room;

- the material is very fragile, not suitable for hanging heavy objects;

- GKL does not differ in mechanical strength, it breaks easily upon impact;

- untreated sheets give off dust that is harmful to health.

How to putty drywall for painting

Which is better: gypsum plasterboard and drywall on the walls

Correct wall insulation in a foam concrete house

Wall insulation with foam or mineral wool

Insulation of external walls with sawdust

How to properly insulate aerated concrete walls from the outside

Warming of drywall partitions. Material selection

Today, the choice of heaters for drywall structures is simply huge. In this article, we will consider the most common of them.

The following materials are distinguished:

- mineral wool;

- coco cork wood and combination board;

- expanded polystyrene;

- Styrofoam;

- rockwool.

- reflector.

To achieve maximum sound insulation in gypsum partitions, builders most often use mineral wool. It is important to remember that this soundproofing material comes in different shapes, sizes and thicknesses.

The most common type of mineral wool can be called roll "mats". They have the following widths: 40, 60 and 120 cm. This is exactly the width of the horizontal step of the plasterboard frame. Rolled "mats" are of the following thickness: 50, 75, 100 mm. This is the thickness of the metal profile for the installation of plasterboard walls.

It is important to remember that when laying mineral wool in the profile of a drywall structure, at least a minimum air space must remain.

In addition, mineral wool can be in the form of slabs. Dimensions: 60x100 cm. The thickness is the same as that of roll-up mats.

What insulation to use

To prevent convection air currents and increase the thermal stability of the walls, the cells of the frame are filled with heat-insulating material.

The most common types of insulation used as insulation for gypsum plasterboard sheets:

To prevent moisture from being absorbed into the insulation, you need to use a special vapor barrier film. Penofol is also suitable for these purposes - a special foamed polyethylene covered with aluminum foil.

This material allows you to save up to 96% of heat. It has good sound and vapor barrier properties. There are small holes in the penofol membrane, through which moisture particles are able to move in only one direction. Flexible material, low thickness, easy to use. The vapor barrier layer is installed after the mineral wool, from the inside.

Insulation is available in rolls or slabs 50 and 100 mm wide. In work, undoubtedly, plates are more convenient, they do not need to be cut and their width is 60 cm, which is often equal to the distance between the frame posts. The advantages of roll material include lower cost.

How to properly install mineral wool

Before laying the mineral wool, you need to have a respirator, construction gloves, and a hat.

When the frame is fully assembled, the mineral wool is cut into strips of certain sizes using a drywall knife. The cut strips are laid tightly along the frame racks. If you are joining the ends, it is better to lay an overlap of 10 to 15 cm.

Coco-cork wood and combination board

If it is important to achieve maximum soundproofing of the plasterboard partition, balsa and coir slabs can be used. You can combine these soundproofing materials. Then the maximum permissible soundproofing effect can be achieved.

Expanded polystyrene plates are perhaps one of the best thermal insulation materials used in the insulation of gypsum plasterboard partitions. Expanded polystyrene boards have different sizes, as well as density. Usually it is 120x60 and 100x50 cm with a thickness of 2 to 5 cm. In terms of density, they differ into soft, semi-rigid and hard. They are connected using grooves.

They also speak well of polystyrene as an insulation material. High heat transfer, a wide range of sizes and shapes, allows you to insulate any wall made of plasterboard construction.

If it is decided to carry out insulation exclusively with the help of mineral wool, then Rockwool will be an indispensable insulation. After all, it is no worse than the same foam. As an advantage, it is worth emphasizing the fact that Rockwool can have a heat reflector. It should be remembered that ROCKWOOL mineral wool comes in both slabs and rolls. If it is a roll, then it can have a thickness of 30, 40, 50 cm; length 5, 8, 10 m, standard width 1 m. If it is a plate, then dimensions: 100x60 cm with a thickness of 5 to 20 cm. This insulation is able to withstand a large temperature difference, has good water-repellent and fire-resistant characteristics.

Polymer heat reflectors are used to keep the temperature in a particular room. They are usually sold in rolls with dimensions: 2-5 mm thick. width - 1 m. long - 30 m. The thickness of the heat-reflector foil itself can also be different.

Insulation of drywall partitions with mineral wool

It is not difficult to carry out competent insulation and sound insulation of drywall partitions. By itself, drywall has good soundproofing characteristics. It is possible to increase the heat and sound insulation in the room thanks to the stitching in two layers.

Mineral wool is considered one of the most used insulation materials. Important: before installing the metal frame on the profile guides, self-adhesive insulating tape must be glued to the floor, ceiling and walls.

The self-adhesive tape is made of polystyrene components and has a thickness of 3-4 mm. It is glued to effectively absorb sound from the ceiling, walls, floor and even from the frame itself from the profiles.

The insulating tape is also glued to the U-shaped brackets. It (insulating tape - ed.) Is nailed to the wall, after which the rack profiles are aligned and screwed to the brackets. Then the distance from the indent from the wall to the metal frame is measured. Rolled mineral wool is cut into strips 10-15 cm larger than the size we need. It is recommended to overlap the mineral wool from above by 10-15 cm, as this will allow the insulation to be fixed more rigidly between the frame and the wall.

Having secured the first layer, you can proceed with the installation of the second. It is worth remembering that the second layer should be overlapped (10-15 cm). Remember, the denser the mineral wool is, the better the sound insulation will be. However, do not forget about the minimum gap (2-3 mm).

After the mineral wool lies well in the metal frame, everything is sewn up from both sides with plasterboard sheets.

How to insulate a drywall wall

- GKL sheets have a thermal conductivity coefficient of 0.15 - this is a fairly low indicator, which indicates a good ability to heat insulation (the lower it is, the better the material retains heat);

- gypsum plasterboard is able to improve the microclimate in the house, which will ensure the preservation of heat in winter and will not let the heat in summer.

Insulation of walls with plasterboard from the inside allows not only to insulate the room, but also to level the surface of the walls. This issue can be solved immediately by using only one material - drywall, because it is excellent for both insulation and sound insulation. The final stage of getting rid of the mold from the walls is filling them with waterproofing putty, which will prevent re-infection, after that you will need to wait for it drying. Only after that you can proceed with the installation. It is worth noting that during repairs it is better to use insulation, which is made in the form of sheets, they are especially suitable for independent work (their standard width is 60 cm, it is optimal for installation between the frame posts).

The choice of insulation directly depends on what degree of insulation must be achieved, if the housing is in a sufficiently warm climatic zone, then strong insulation is not needed, in this case, you can use glue for fastening. If the housing is located in a cold, harsh climatic zone, then the issue of insulation will need to be taken as seriously as possible and the best materials should be chosen, because this will largely influence the comfort and health of the whole family. Types of heaters:

What insulation is better for drywall

To create comfortable living conditions, it is important to choose the right not the heating system, but the insulation for the walls. This allows you not only to keep warm, but also to save on utility bills. It should be noted that the use of drywall for this process is best suited. It allows you to create a pleasant microclimate, while perfectly leveling the walls, creates an almost finished surface for finishing. Consider the insulating qualities of drywall, which filler to choose for it in order to create warmth and comfort in the house.

Thermal insulation properties of gypsum board

The use of gypsum plasterboards allows you to create high thermal and sound insulation not only due to the pores that form inside it, but the air gap behind the slab. Therefore, for a relatively warm climate, you can not use additional insulation. As for the gypsum board itself, the level of thermal insulation is determined by the coefficient of thermal conductivity. For example, drywall has a thermal conductivity coefficient of only 0.15, which is significantly lower than reinforced concrete. This allows not only to create warmth in the winter, but also in the summer there will be coolness.

It is worth noting that the method of installing drywall affects the level of thermal insulation. To achieve a greater effect, it is recommended to use a frame version rather than glue. The resulting layer under the frame creates additional wall insulation. But, one way or another, insulation will be needed to create a warm atmosphere.

Wall insulation from the inside

The first thing to decide with is where the insulation will take place. For private houses, it is better to choose outside insulation, this is a more effective option. If the process is carried out in an apartment, then you will have to carry out internal insulation. For it, the following materials are used for drywall:

- Styrofoam. It is suitable for plasterboard construction, but its use is rare. There are several important disadvantages that will cause the rejection of foam: exposed to rodents, they can create a hole and create "tunnels" for living, it is also not fully proven how harmful foam is for home improvement;

- Polystyrene.Has the same disadvantages as the previous version;

- Glass wool. Also used as insulation for plasterboard walls. Main advantages: low price, good protection from cold. But there is also such a disadvantage as the complexity of the work. The process itself is easy, but glass fibers during processing, getting on the human skin, cause irritation, inflame the mucous membrane;

- Izolon. This insulation has no particular drawbacks. It has a low price, a low level of thermal conductivity, and it is easy to work with. This is ideal for insulating small buildings, since isolon is a thin material that does not take up space;

- Basalt wool. By its main qualities it resembles glass wool, only work with it takes place without harm to human health. Due to the fact that it is made from rocks of magmatic origin, it has a high level of fire resistance. More expensive than glass wool.

So, in order to choose the right insulation for drywall, you need to decide what price for insulation, where exactly the building will be insulated (inside or outside). Isolon and basalt wool are best suited for internal insulation. The latter option is more common, it is easier to purchase at different prices, while it is completely safe during operation.