Features of a septic tank

The main element of this design is a rectangular plastic tank. It consists of several interconnected chambers through which waste water flows. Here it is filtered clean and also clarified due to the presence of bacteria.

At such a septic tank there are several important pluses:

- non-volatility, because power supplies are not needed during operation;

- the similarity of the main characteristics with the popular Tank equipment;

- resistance to various external factors due to the presence of stiffeners and significant wall thickness;

- no need to use additional fasteners or concreting of the pit;

- increased productivity;

- the tightness of the body, possible due to the absence of seams;

- affordable price;

- the need for pumping out only once a year, which makes the operation of the system quite convenient;

- strength and durability of the structure.

Among the shortcomings, it is worth noting the lack of a system deep cleaning and odor filtration... However, this is what makes the autonomous operation of the equipment possible.

New on alldoma.ru

LLC "TT" - "Thermal Insulation Technologies" - manufacturer extruded polystyrene foam (XPS) THERMIT (Krasnoyarsk Territory). New modern production makes a significant contribution to the development of both the economic and social spheres of the region: modern construction technologies become more accessible, new jobs are created.

Today, technological solutions in construction can no longer be imagined without the use of lightweight thermal insulation materials. Extruded polystyrene foam (XPS) is a new qualitative step in the development of thermal, hydro and sound insulation. The reliability and durability of buildings is significantly increased, which plays a special role in the harsh climatic conditions of our region.

Our products are intended primarily for local, regional consumers. By reducing transport and storage costs, THERMIT panels are more affordable than other similar materials.

With the commissioning of a factory for the production of extruded polystyrene foam, our company contributes to the solution of the fundamental issue of heat preservation, energy saving, contributes to the development of construction technologies.

We invite enterprises, organizations on the territory of our region and other regions to cooperate.

In our joint work, we prioritize partnerships based on the principles of long-term cooperation.

WHAT IS THERMIT Extruded Polystyrene Foam Is a high-quality thermal insulation material for use in conditions of high temperature extremes, physical exertion, and humidity. The production of extruded polystyrene foam originated in the middle of the last century. The uniqueness of the technology lies in the fact that the extrusion of polystyrene made it possible to obtain a material with a closed cellular structure.

Thermal insulation boards THERMIT are made of extruded polystyrene foam (XPS). THERMIT is similar in its characteristics to such long-established brands of this material as Penoplex, Timplex, Styrofoam.

The main characteristics of the new material are minimal water absorption, high strength and excellent thermal insulation properties.

The manufacturing technology of THERMIT thermal insulation boards provides for the use of various components, which allows it to be used in various areas of construction to solve a wide range of tasks.The signature color scheme gives the garments a unique warm yellow color.

MAIN PROPERTIES OF THERMIT Due to its closed cellular structure, THERMIT has the lowest water absorption rate in comparison with other thermal insulation materials.

Low thermal conductivity.

High strength, resistance to long-term mechanical stress.

Resistant to combustion.

Not subject to decay.

It is not assimilated by animals and microorganisms, therefore it is not used by them as feed and does not create a breeding ground for fungi and bacteria. Unique properties of THERMIT boards provide material resistance to temperature extremes. Maintaining performance characteristics when exposed to low temperatures allows THERMIT to be successfully used in permafrost conditions. The costs associated with the construction and heating of buildings and structures in the Far North are significantly reduced.

Long service life.

Ease of use, simplicity of design solutions.

The possibility of using the material in various other areas.

ADVANTAGES OF THERMIT PLATES When selecting a heat-insulating material, it is necessary to pay attention to the basic physical, technical and operational parameters. Comparison of extruded polystyrene foam with other types of thermal insulation materials clearly demonstrates the advantages of THERMIT boards.

Extruded polystyrene foam has the lowest thermal conductivity (0.03 W / mooC) in comparison with other thermal insulation materials.

Possessing a closed cellular structure, THERMIT boards absorb 20 times less moisture compared to other types of materials. Due to such a low level of water absorption, the thermal insulation properties of the material remain unchanged - the extruded polystyrene foam is guaranteed to maintain operational qualities for 50 years.

An important advantage of THERMIT boards is resistance to any kind of biological attack and chemical decomposition. According to the experience of builders, in humid environments, mineral wool can be susceptible to rotting and mold.

Possessing high moisture resistance and strength characteristics, THERMIT boards are not subject to subsidence and other types of physical deformation. Under significant mechanical loads, THERMIT retains its properties, withstanding an average of 50 tons per m2.

Modern requirements for efficiency, reliability, and an increase in the service life of buildings determine the use of advanced technologies in design and engineering developments. Due to their unique performance characteristics, THERMIT thermal insulation boards are used in a wide variety of construction areas.

The use of extruded polystyrene foam does not involve any environmentally hazardous consequences.

MAIN APPLICATIONS OF THERMIT Thermal insulation of foundations of low-rise and multi-storey buildings;

Thermal insulation of floors, including floors with a built-in heating system;

Basement insulation;

Thermal insulation of walls, external and internal, elimination

"Cold bridges";

Thermal insulation of roofs, replacement of outdated thermal insulation, construction of inverted roofs;

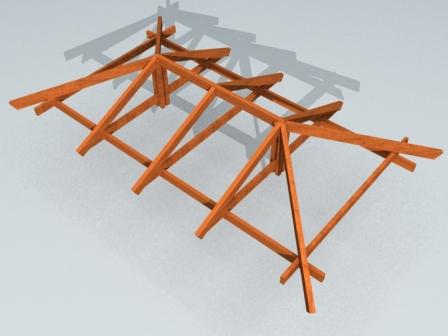

Rafters - common construction name of the roof truss system, which is a set of struts and struts, as well as battens and counter battens that rest on the base. Rafters are supporting structures that provide the location of the pitched roof. Structures include vertical posts, inclined "legs" and inclined struts. The reliability of this entire system determines how long and how effectively the roof (and the whole house) will serve you.And competent design in this case is not easy at all, because this part of the building has a great variety of very different loads. Among them are the effects of wind, rain, snow loads (this item is especially important if the building is located in a cold climate zone). The roof must be able to confidently support the weight of the person, as well as the placed equipment (for example, antennas) It is impossible not to take into account the relatively rare, but capable of having a serious destructive effect of the phenomenon, in particular, hail.

Roof truss system involves the active use of wood. This material is easy to process, reliable and can last a very long time, however, to achieve maximum performance, the design must include a number of protective measures of the design plan. In addition, certain operating conditions must be observed, due to which the rafter system of the attic roof is maintained in working order.

Construction of roads and railways;

Construction of runways and other airport facilities.

APPLICATION OF DIFFERENT TYPES OF THERMIT THERMIT MATERIAL- 35 can be rationally used for external and internal insulation of walls, floors, in industrial and residential buildings. THERMIT-45 is mainly used in the construction of roads and railways, for thermal insulation of foundations in heaving and permafrost conditions, as well as for the installation of inversion operated roofs.

INSULATION OF FOUNDATIONS At the heart of any construction is the process of setting up a foundation, therefore, when designing, it is necessary to take into account all aspects that will ensure its long-term operation. Reliable thermal insulation of the foundation will avoid that part of the problems associated with movements and heaving of the soil under the influence of humidity and low temperatures.

According to experts, during the operation of the building without the use of effective thermal insulation of the base of the building, up to 20% of heat is lost. Thus, modern thermal insulation technologies used in the construction of the foundation can significantly reduce the level of heat loss in a building.

The use of THERMIT slabs prevents the soil from freezing, as a result of which deformation of the supporting structures is excluded during intense temperature changes.

The best option, both from a structural and financial point of view, is complete external thermal insulation of the underground part of the building along the perimeter. This solution protects the foundation from adverse factors and significantly improves the operating conditions of the foundation walls.

INSULATION OF BASEMENT SPACES INSULATION OF FOUNDATION OF LOW-RISE BUILDINGS, COTTAGES The use of THERMIT thermal insulation boards avoids a number of problems associated with the construction and operation of basements:

sharp changes in the temperature regime in the room;

the effects of soil water and the need to artificially maintain an optimal moisture regime;

mechanical damage to the waterproofing layer during construction;

the need to protect building elements from the effects of other destructive factors.

Technological solutions using slabs of extruded polystyrene foam can significantly increase the service life of reinforced concrete structures, basement walls.

The creation of a stable microclimate increases the level of comfort and opens up additional possibilities for using the basement. Construction costs are significantly reduced by lowering the depth of the foundation base. This possibility is due to the fact that the use of THERMIT slabs prevents the soil from freezing.

Foundations with a low level of burial have become widespread in connection with the development of low-rise construction.When erecting cottages, as well as buildings from light metal structures, due to the use of THERMIT plates, the penetration of cold through the base of the foundation into the interior is prevented. Thus, the use of THERMIT boards can significantly reduce the cost of heating buildings.

INSULATION OF FLOORS The level of heat preservation in the room largely depends on the way in which the flooring is designed in the building. The use of THERMIT slabs allows not only to reduce heat loss indicators, but also makes it possible to use the heat capacity of materials, accumulating heat in load-bearing building structures. Another important advantage of THERMIT boards is the reduction in the thickness of the thermal insulation layer, which makes it possible to increase the height of the interior.

Depending on the design tasks, there are several directions for using THERMIT boards for floor insulation:

Thermal insulation of the floors of the first floors. The quality of the floor insulation largely depends on how successfully the heat preservation is ensured in the building structures mating with the floor: basement walls, basement. Basement floor insulation. It is especially relevant in conditions of high soil moisture and in the immediate vicinity of groundwater. Heat and sound insulation of intermediate floors. Thermal insulation of floors with built-in heating system. For heated floors, the presence of a thermal insulating layer is a prerequisite. Otherwise, the level of energy consumption increases significantly to maintain a given temperature regime. An additional layer of vapor barrier is excluded.

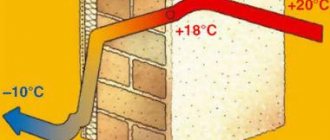

APPLICATION OF THERMIT BOARDS FOR WALL INSULATION Almost half of the heat losses of a building can be associated with insufficiently effective thermal insulation of the outer walls. The use of THERMIT slabs allows not only to significantly reduce heat loss rates, but also provides protection of external structural elements from the effects of adverse environmental factors.

Facade insulation is the most common way to insulate walls. THERMIT boards are located on the outside of the supporting structure. Thus, the wall is operated in more favorable conditions, since due to the outer heat-insulating layer, the wall is in the zone of positive temperatures, which allows it to accumulate heat and, thereby, reduce the cost of heating the room.

Thermal insulation boards THERMIT can be successfully used for insulation in the inner layer of the wall. In this case, the main requirement for the insulating material is durability. Such a structure cannot be repaired, since the service life of the thermal insulation is higher than that of the enclosing material.

Extruded polystyrene foam is increasingly being used instead of foam in precast concrete panels in high-rise buildings.

THERMIT IN INVERSION OPERATED ROOF DEVICE Today, inversion roofing is becoming more and more popular in construction. The main difference from the traditional installation method is that the waterproofing layer is located under the insulation layer, directly on the concrete base. This approach allows you to protect the roof structure from mechanical damage, protect the waterproofing membrane from the effects of temperature extremes, and prevent flooding of the building in the event of a large amount of precipitation. An important advantage of an inverted roof is the possibility of faster installation, reducing the weight of the structure due to the absence of a concrete screed.

The construction of an inverted roof is successfully used for exploited surfaces: arrangement of pedestrian zones and roadways, planting of green spaces.At the same time, this technology puts forward increased requirements for the performance characteristics of the heat-insulating material: resistance to prolonged mechanical stress, resistance to humid environments. Extruded polystyrene THERMIT fully meets the specified requirements.

ROOF ROOFS, SUPERSTRUCTION OF ATTACHMENT FLOORS In recent years, attic floors have become increasingly popular in the field of low-rise construction. They are more architecturally effective and also allow for additional living space in the attic area. Plates from extruded polystyrene foam THERMIT are successfully used in the construction of cottages, summer cottages, and other low-rise buildings with a sloping roof.

Use of THERMIT boards for insulation of the attic floor.

LIGHTWEIGHT ROOFING For industrial buildings, warehouses, sales areas, the technology of construction of a lightweight roof with a base of light profiled metal structures is used. The use of THERMIT boards allows an order of magnitude to reduce the load on the supporting structures in comparison with the use of thermal insulation materials of the previous generation.

FORMS OF DELIVERY OF THERMIT PLATES The material is supplied in the form of plates packed in a special film. The low weight of the material, high strength and resistance to mechanical damage makes it possible to choose any convenient mode of transport for delivering the material to the consumer.

EDGE SHAPE AND PROCESSING The smooth surface of THERMIT boards greatly facilitates the installation of the thermal insulation material. In order to avoid the formation of cold bridges, to simplify the laying and concealment of inter-tile joints, various edge options are provided: straight, "selected quarter", tenon-groove. Plates are easy to process. The necessary adjustments can be made with a conventional cutting tool.

In addition to the applications described, THERMIT can be used as a support base for other materials. The surface of the extruded polystyrene foam can be faced with various decorative materials: plastic, wood, fabric or metal. Such products can be used both for interior decoration of premises and for decoration of the outer part of the building.

Separately, it is necessary to note the use of THERMIT plates for finishing and thermal insulation of refrigeration equipment, refrigerated cars. https://www.thermit-tt.ru/

The main types of construction

Septic Termit has an extensive range of models, which makes it possible to select equipment taking into account certain technical characteristics.

- Termit-Profi for 1.2 m³ is installed in houses, the area of which does not exceed 100 m². This design is suitable for a family of 2-3 people. The product serves not only shower, toilet and sink, but also household appliances such as a washing machine or dishwasher.

- Termit-Profi for 2 m³ is suitable for a dwelling with an area of 100-200 m². Thanks to this design, it will be possible to clean the drains coming from several toilets and sinks, as well as a bath, shower and washing machine.

- Termit-Profi 5.5 m³ is considered the most powerful septic tank, as evidenced by numerous reviews. This design is distinguished by increased productivity and the presence of 3 chambers, so that it will be possible to service not only plumbing fixtures and a washing machine, but even a jacuzzi. Moreover, each chamber is provided with a sealed cover, pumice stone, and fibers with anaerobic bacteria.

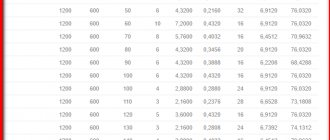

Insulation THERMIT XPS 1200 * 600 * 50 mm - 8 pieces

The price is indicated for 1 package: 8 plates in the package (0.278m3. = 5.5458 m2), 1 plate - 1200 * 600 * 50 mm

Areas of use:

Extruded polystyrene boards THERMIT XPS, THERMIT XPS 35, THERMIT XPS 40, THERMIT XPS 45 are intended for use in industrial, housing and communal and agricultural construction, as thermal insulation of zero cycles, basements, wall fences, ceilings, roofs and the elimination of "bridges cold ".Also, plates are used in the refrigeration industry, in the construction of roads and railways, in the construction of gas and oil product pipelines and airfields. It is possible to carry out thermal insulation of both under construction and already erected buildings and structures.

The use of extruded polystyrene foam plates THERMIT XPS, THERMIT XPS 35, THERMIT XPS 40, THERMIT XPS 45 as thermal insulation can significantly save energy spent on heating insulated buildings, structures and structures; reduce the weight of building structures; reduce the consumption of other building materials and increase the service life of building structures. The use of THERMIT extruded polystyrene foam boards as an insulating layer contributes to an increase in the energy efficiency of insulated buildings, structures and structures, which meets the requirements of the Federal Law RF No. 261-FZ "On energy saving and on increasing energy efficiency"... Thus, extruded polystyrene foam boards THERMIT XPS, THERMIT XPS 35, THERMIT XPS 40, THERMIT XPS 45 can be called a highly effective thermal insulation material.

Extruded polystyrene foam boards THERMIT are chemically inert, do not emit substances harmful to the health of living organisms. They fully meet the hygiene requirements of residential and public premises, in confirmation of which there is an appropriate sanitary and epidemiological conclusion.

Specifications:

| Indicator name, unit of measurement | Values for boards "THERMIT" brands | |||||

| Board grade THERMIT XPS | XPS | XPS 35 (G3) | XPS 35 (G4) | XPS 40 (G4) | XPS 45 (G3) | XPS 45 (G4) |

| Density, kg / cu. m | 25.0…28.0 | 28.0…35.0 | 28.0…35.0 | 35.0…45.0 | 38.0…48.0 | 38.0…48.0 |

| Thermal conductivity at (25 ± 5) ° C, W / m ° C, no more | 0.033 | 0.033 | 0.033 | 0.034 | 0.034 | 0.034 |

| Compressive strength at 10% (** 5%) linear deformation, MPa, not less | 0.15 | 0.25* | 0.25* | 0.45** | 0.5 | 0.5 |

| Ultimate strength in static bending, MPa, not less | 0.25 | 0.35 | 0.35 | 0.7 | 0.4 | 0.4 |

| Water absorption in 24 hours,% by volume, no more | 0.4 | 0.4 | 0.4 | 0.2 | 0.2 | 0.2 |

| Flammability group | G4 | G3 | G4 | G4 | G3 | G4 |

| Flammability group | AT 3 | AT 2 | AT 3 | AT 3 | AT 2 | AT 3 |

| Smoke production coefficient | D3 | D3 | D3 | D3 | D3 | D3 |

* for THERMIT XPS 35 plates with a thickness of 20 mm and 30 mm, the compressive strength at 10% linear deformation is not less than 0.18 MPa

** - for THERMIT XPS 40 boards, the compressive strength is indicated at 5% linear deformation

The permissible temperature range of application is from -50 to +75 C. THERMIT XPS insulating boards can have two types of edge processing: smooth edge (N) and L-shaped edge (L) (with a thickness of over 20mm), Z-shaped edge.

You can buy THERMIT XPS insulation at low prices with delivery in Novosibirsk, Berdsk, Iskitim, NSO in the Novostroy online store. Specify details by phone. 310-75-90 and 310-76-90

How the device works

The design assumes availability of 2-3 reservoirsconnected through the appropriate channels. Wastewater flows through them, being filtered clean.

In general, the functioning of the Termit septic tank is carried out in 5 stages.

- First, the drains enter the primary tank. Here, all insoluble particles fall to the bottom in the form of sediment.

- The liquid enters the second chamber, while the floating sediment does not penetrate here. Mechanical cleaning is carried out in the second tank. It is about settling the liquid.

- In the third chamber, anaerobic bacteria enter the water, causing decomposition and partial dissolution of wastewater. The remaining liquid passes through a suitable element, which ensures filtration at the level of 75%.

- After purification and partial clarification, the liquid passes into the irrigation system.

- Already in the soil, additional treatment of effluents takes place, because bacteria continue to break down organic matter. As a result, the water will become completely safe, since it is filtered clean.

THERMIT SP ROLL

Thermal insulation for pipelines THERMIT SP ROLL can be used for thermal insulation of pipes where technological processes require high cleanliness: in the pharmaceutical, food, microbiological industry, production of high-precision electronics. Unlike segments and half-cylinders, each THERMIT SP ROLL slab wraps the entire pipe and is conveniently secured with a plastic tape or steel ring. It can be removed and reused if necessary.

This thermal insulation is convenient for loading and unloading operations and takes up less space in the warehouse and during transportation.Works on thermal insulation of pipelines using THERMIT SP ROLL can be carried out in the winter, this insulation allows you to shorten the installation time, requires fewer hands. THERMIT SP ROLL qualitatively protects pipes from freezing, performs a protective function due to the structural rigidity of the surface layer, thereby increasing the service life of engineering structures as a whole.

THERMIT SP ROLL can be used for thermal insulation of pipes with a diameter of 58 to 630 mm, used for transporting products with temperatures from -50 to +75 degrees Celsius, with external, semi-buried and fully buried laying.

Installation and maintenance of a septic tank

As mentioned earlier, during operation of the Termit equipment bacteria are used, which are responsible for the processing of organic matter and its splitting into carbon dioxide, as well as water and minerals. Accordingly, after cleaning, the wastewater needs additional filtration in the soil. It is for this reason that it is important to carefully select a suitable installation location. So, it is necessary to take into account not only the composition of the soil, but also the level of groundwater.

For the installation of a septic tank several tools are required:

- 2 pipes;

- fitting;

- sand with cement;

- insulation.

The installation of a septic tank is carried out in 4 stages..

- First, you should prepare the pit. Its width should exceed the dimensions of the septic tank by about 25 cm.

- The device is immersed in the dug hole. For this purpose, it is better to use a special technique.

- Then you need to make a mortar of sand and cement in a 3: 1 ratio. The mixture is poured into the pit until the pipes are completely covered.

- Next, the installation of the pipeline necessary for the discharge of wastewater after cleaning and the filter is carried out.

In order for the septic tank to serve for a really long time, it is worth taking care of proper care. So, the sewer system needs remove silt at least once every 2 years. For the best functioning of the septic tank and the decomposition of waste, the appropriate bacteria must be used.

Material specifications

The technical parameters of the foam allow it to be widely used in many industries. The most important of them are:

- good thermal insulation characteristics. As you know, the lower the thermal conductivity, the better the material retains heat. The thermal conductivity of foam is about 1.2 times lower than that of mineral wool, and 4 times lower than that of wood. By this criterion, dry foam concrete and brick are much inferior to foam;

- availability of material. It is advisable to use polystyrene as a heater due to its price acceptability. The cost depends on the thickness of the slabs. Homeowners choose extruded polystyrene foam, reviews confirm that it has the best ability to retain heat, but it also costs a little more;

- manufacturability. It is important that the foam is lightweight, easy to cut, it is very convenient to work with it, even one person can do it. In addition, this material does not make the structure of the house heavier, which is a significant advantage.

Owner reviews

I ordered Termit for a summer cottage, designed for 2m³. I installed the structure together with a friend, and I had to order special equipment, because it turned out to be unrealistic to load the septic tank on my own. Connection and installation of all communications did not cause any difficulties.

Igor, Kazan

We have been choosing a septic tank for a very long time. As a result, we purchased Termite for 5.5 m³. Volume was the deciding factor. In addition, the compact shape and significant wall thickness won over. Very happy with this septic tank.

Sergey, Barnaul

I took the Termit septic tank for the dacha. Installed it together with her husband. Installation is quite simple, moreover, instructions were attached to the equipment. The device has been in operation for six months already. It does not clog and cleans drains perfectly. I added bacteria only once in the spring and will add it in another six months.

Elena, Pskov

Among all the septic tanks on sale, special attention should be paid to the Termit design. Its advantages are non-volatility and affordable price. You can install the structure yourself, which is an additional advantage of the equipment.

General information

Features of the treatment plant

The design is based on a plastic container made in the shape of a rectangle. The device has several cameras connected to each other. The waste liquid is purified through the sections. At the outlet, the drains are cleaned up to almost one hundred percent; bacteria are used during cleaning.

The advantages of this septic tank

The septic tank has positive characteristics. These include:

1.The devices are not dependent on power supply.

2. The septic tank has similar technical characteristics as the Tank treatment plant.

3.The design is resistant to negative factors, because it has stiffening ribs, significant wall thickness.

4. does not require concrete pouring under a septic tank, any special fasteners.

5. high level of performance.

6.There are no seams on the case, so it is sealed.

7. the septic tank has an affordable cost.

8.The septic tank needs to be cleaned once a year, this makes it easier to operate the device.

9.The septic tank lasts a long time, the device is durable.

Attention! The disadvantages include the inability to deeply clean the drains, eliminate odors. But these qualities are at the same time its advantage: the equipment can function autonomously.

Varieties of cleaning facilities

Termit septic tanks include a line of different models. This allows you to choose the right equipment,

which is distinguished by its technical characteristics:

Variety Termite - Profi, which has a volume of 1.2 cubic meters, is suitable for installation in a house with an area of up to one hundred square meters. The septic tank is well suited for two, maximum three people living in this house, with a washing machine and dishwasher.

Variety Termite - Profi with a capacity of two cubic meters are installed on plots with a house up to two hundred square meters. The device copes with the load, which includes several bathrooms, washbasins, shower stalls, bathtubs, and appliances.

Variety Termite - Profi with a volume of 5.5 cubic meters has a high power. Reviews of the device prove this property. The septic tank has three sections, copes with numerous plumbing fixtures and fittings, including a jacuzzi. The chambers are closed from above with high-tightness covers; inside there is pumice and fibers with anaerobic bacteria.

Consumer Disadvantages

The level of functionality of the septic tank "Termit" is extremely rarely characterized negatively, but the wrong choice of model or illiterate installation of the structure often causes the following negative reviews:

- lack of a deep cleaning system and filters that eliminate unpleasant odors (read reviews on the use of the drug "Doctor Robik 509" here);

- sometimes, there is an uneven distribution of the load on the plastic case;

- a rectangular shape without rounded corners provokes the accumulation of stresses and deflection of the walls;

- the installation of a septic tank involves the obligatory cementing of the pit and the use of a high-quality anchor device;

- there is no possibility to perform cleaning at a temperature of -10 ° C and below;

- it is necessary to apply waterproofing in the winter;

- operation requires application a cesspool machine once or twice a year;

- high financial costs for installation in comparison with biological treatment structures;

- labor-intensive land and installation workassociated with equipping the sprinkler, filtration pit and post-treatment system.

The disadvantages also include the complexity of the septic tank wiring diagram and self-installation of the device.