To create a specific microclimate in paired rooms, today it is customary to adhere to the thermos principle, that is, to use reflective properties in combination with low thermal conductivity of insulating materials. On the one hand, the ceiling of the bath is exposed to the same factors as the walls: infrared radiation, convection heat transfer, hot steam. On the other hand, their quantitative ratio is different (warm air moves upward), and the structure of the floors is different from the structure of the walls. Therefore, answering the question "how to properly insulate the ceiling of a bath?", One should take into account not only heat exchange, but the relationship of strength, waterproofing and other functions of the building.

Principles of warming ceilings in steam rooms

In addition to the fact that it is necessary to significantly reduce energy losses, it is required to reach certain parameters for vapor barrier. At the same time, one should not forget about the special requirements for the safety and environmental friendliness of all materials used. Choosing the design of the ceiling lathing for the bath, the types of strength elements, membranes and insulation, one should proceed from the observance of three basic principles:

- quick kindling;

- slow cooling (comfort and heat saving);

- special microclimate characterized by the accumulation of steam (it is required to avoid its condensation).

The classical approach to the arrangement of the ceiling in the steam room provides for the sewing of the rough plane (adjacent to the supporting beams) with wide thick boards - "forty". A thickness of 50 mm is considered excessive. It is known from experience that such flooring begins to accumulate moisture, which does not have time to evaporate between pair sessions. As a result, the likelihood of getting a ceiling prone to condensation increases.

Bath ceiling insulated with expanded clay

When equipping a room with a classic lathing made of "magpie" most often, the ceiling of the bath is insulated with mineral wool, expanded clay or other proven heaters from above - from the side of the roof.

The modern trend is associated with the use of two types of insulation, one of which is reflective, and the second plays the role of the main one. The better to insulate the ceiling of the bath in order to realize the functions of infrared reflection and thermal break will be discussed in the following sections of the article.

How to insulate the ceiling in a bath with your own hands

Before you start insulating the ceiling area, you need to take into account its type.

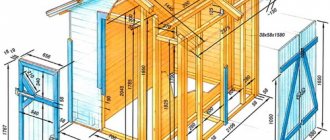

| Varieties of ceilings | Design features |

| Hemming. | It is also called draft. It is nailed directly inside to the attic floor joists. |

| Grazing. | The planks are laid in the attic and the planks in the steam room remain uncovered. On such a structure, it is imperative to make bumpers along the edges for insulation. |

| Panel | It consists of scraps of boards that are nailed tightly to each other. A kind of shields are made, in which the insulation is laid. |

The suspended ceiling is used in small rooms. The insulated ceiling surface is assembled on the ground and then attached to the ceiling. Consider the stages of work when laying the insulator. You can reproduce the whole process yourself, with your own hands.

Insulation of a floor ceiling

First of all, a vapor barrier film is placed on the flooring. We fix it with a construction stapler or nails. Then the insulation comes into play. To prevent expanded clay from scattering around the perimeter, a side is nailed.We cover all this with waterproofing material. At the last stage, the thermal insulation is pressed against the boards, which are laid with a gap of 40-50 cm.

Minvata is used for a flat ceiling quite often. There is the following overlap method. Mineral wool must be insulated on one side with a film or membrane, and on the other with foil. The vapor barrier is placed closer to the steam room, and the waterproofing is placed on top of the insulation from the attic side.

Hemming type works

To insulate a false ceiling, there is the following procedure. Waterproofing with a lower foil part is placed on its boards. Then a layer of thermal insulation materials laid between the floor beams. The last layer is a vapor-tight membrane that allows the ceiling to "breathe" and the attic floor boards.

You can use both basalt wool and expanded clay. First, a vapor barrier film is attached to the ceiling beams, which is best laid in two layers. Insulation also needs a double amount. Then a lining or edged board treated with an antiseptic is nailed to the beams.

It is important to arrange the material so that there are no gaps. The insulation should not reach the top of the beams by 3-5 cm, creating space for ventilation. And the last stage of work: the thermal insulation material is covered with a waterproofing film. On top of all this is a plank flooring.

Features of panel insulation

First, you need to nail on two parallel beams, which should protrude 5 cm on each side. They are treated with a special protective antiseptic. A vapor barrier, insulation (expanded clay or mineral wool) and again a vapor barrier are laid inside. This whole structure is covered with a solid board.

And finally, a few tips.

- The vapor barrier film and foil must be handled with care, as they can tear, which will be a big flaw.

- It is necessary to lay the insulation slightly below the walls, leave space for placing bulk materials or mineral wool. It is necessary to fill small sides along the perimeter of the ceiling.

- If you do not want to spend money on the purchase of steam and waterproofing, then it is best to use a high-tech mineral wool insulation with a foil layer.

- Set to work - do not skimp on waterproofing materials. Cheapness will affect their quality.

To create a favorable climate in the steam room, it is important to choose the right insulation and follow the instructions during its installation. And then your bathhouse will always delight you with its warmth, and your stay in it will become a real rest.

The role of foil-clad materials and vapor barrier films

There are no ideal heaters for baths. It is impossible with one material to equally realize the reflection of heat rays, resistance to heat transfer and vapor barrier. Aluminum foil and foil-coated sandwiches such as foil-insol allow you to select the optimal combination of materials for the equipment of baths of any design.

For example, foil insulation makes it possible to install non-absorbent mineral wool, as it is an ideal vapor barrier.

Thermal insulation of the ceiling of the bath with foil material

The reflective layer is located just behind the decorative headliner. If the main heat-shielding layer is placed further, then an air gap of at least 2 - 3 cm must be provided between it and the reflector.

Related material: installation of foil insulation in a bath, see here

It is advisable to limit the use of polyethylene films to waterproofing in the under-roofing areas. Vapor barrier without condensation is much better provided by foil sandwiches and membrane materials with special microvilli.

Competent insulation technique

Under the insulation, it is supposed to lay a layer of insulating material that will keep the heat inside the room. However, only the insulating layer in the bath is not enough. He will not be able to fulfill his task, since it will become saturated with moisture and deteriorate. In order for the insulation to last for a long time, it is required to lay three layers of insulating materials.

Layer 1: vapor barrier

The main task of this layer is to prevent fumes from entering the inside of the insulation. All vapors rising from the heated room must be contained. As an insulator for this layer, materials such as glassine or roofing that have been tested over the years can be used. Or more modern geosynthetic coatings, various membranes and thermofol. Well, if the coating is foil, then it can also screen heat, returning it to the room.

Bath ceiling insulation

Bath ceiling insulation

Layer # 2: thermal insulation

The second layer of insulating cake should trap heat without letting it out. A wide variety of materials can be used here. Which to choose, will tell you the budget and your own skills in carrying out construction work. It is important that the insulation is as light as possible (then it will not create an unnecessary load on structures that is resistant to moisture) and non-combustible, as simple and convenient as possible to install.

Vapor barrier layer

Vapor barrier layer

Layer 3: waterproofing

For insulation, protection from water only from the side of the room is not enough. Another barrier is required, but from the side of the roof. Water can also penetrate from there. Therefore, a waterproofing layer must be laid on top of the heat insulator. This is a film or membrane. It is optimal that one side of the material is completely waterproof, and the other is vapor permeable. Thus, the insulation will be able to "breathe" and water will not get into it.

An important nuance. If the bathhouse is built without an attic, insulation is done only from the inside. If an attic is present, then thermal insulation can be installed both from the inside of the room and from the outside. The decisive role here will be played by the material that will be used for insulation. For example, slab and roll coverings can be laid in any way, but liquid or bulk coverings can be installed only outside.

Warming with dry ecowool

Warming with dry ecowool

Ceiling insulation with mineral wool

Mineral (aka basalt) wool is used more often than other materials as the main insulating layer. For many specialists involved in the construction of baths, the question "how to insulate the ceiling in the bath" has long been resolved in her favor. The main advantage of stone wool over all other insulating materials is high heat resistance and fire safety. Unlike glass wool, the structure of the fibers based on molten basalt is not harmful to the respiratory system. However, the insulation of the ceiling in the bathhouse with mineral wool also has serious limitations. This is the high hygroscopicity of the material and the presence of hydrophobic impregnations designed to resist moisture penetration. Impregnations are made on the basis of waxy fusible compounds, which are prone to unwanted gas emission when heated above 70 ° C - 80 ° C.

Insulated ceiling with mineral wool

Not all mineral wool is suitable for arranging baths. Use only grades without impregnation with a direct indication of the intended use in spa areas: for example, "ISOVER Sauna" or "ROCKWOOL Sauna Butts". The first material is a roll type, the second is made in the form of slabs. Both are lined on one side with a vapor barrier based on aluminum foil. The ceiling of the bath should be insulated with mineral wool while providing double-sided hydro and / or vapor barrier.When installing foil or other type of protective layers, it is necessary to leave an air heat-insulating gap between the cotton wool and the membrane.

The need for vapor barrier

Whatever the structure, laying a layer of vapor barrier for the ceiling in the wooden floor of the bath is an essential element of insulation. It is laid before installing a layer of insulation. As a vapor barrier in baths without an attic, wax paper, aluminum foil or thick cardboard impregnated with linseed oil are used.

In structures with an attic or attic, it is allowed to use similar materials. However, in practice, wooden floors are most often coated with clay, with a layer of 2 cm.

On the building materials market, you can find several options for vapor barrier:

- Dense plastic wrap - it is rarely used, since it contributes to the greenhouse effect. In this regard, when installing it, it is important to leave technological gaps for condensate evaporation.

- A special polyethylene vapor barrier film with lint to retain condensation.

- All kinds of vapor barrier membranes.

The need for a vapor barrier layer is due to the fact that it allows you to protect the insulation for the ceiling of the bath from the accumulation of moisture contained in the warm air. This is important, since moisture will gradually lead to a decrease in the thermal insulation qualities of the material, reduce its service life and increase the load on the walls as a result of the increase in the mass of the ceiling.

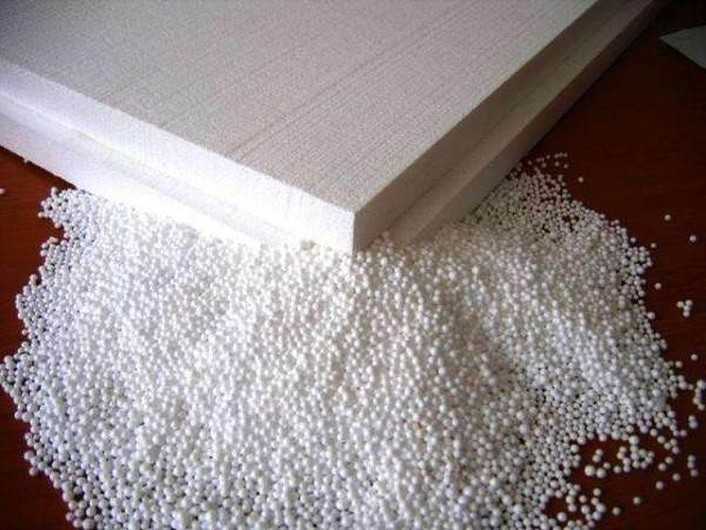

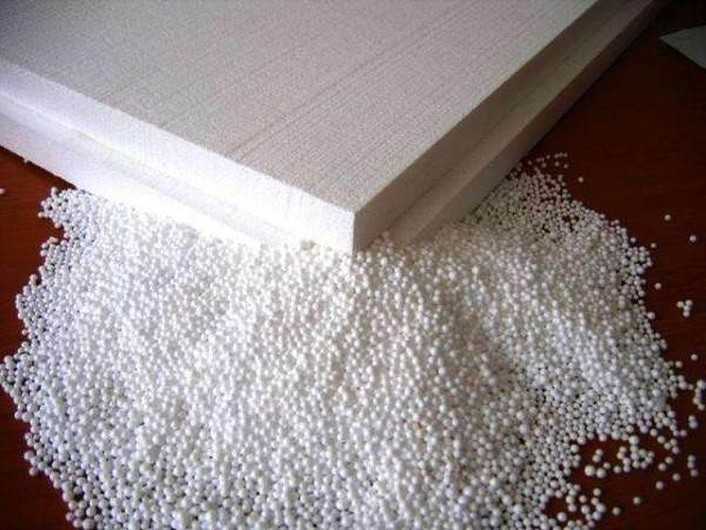

Use of expanded polystyrene

In a number of sources, one can find statements about the inadmissibility of using foams (EPS) and extruded polystyrene foams (EPS) for equipping baths and saunas due to the release of harmful substances by these materials when heated. Others argue that the thermal destruction of this insulation begins at 160 ° C, and the under-ceiling space of a Russian bath can only warm up to 100 ° C - 110 ° C. And therefore, they say, restrictions on lining a steam room with foam or EPS do not make sense.

Let's dot the "i" in this question. The point is that neither the first nor the second position is fully justified. Surface emission of styrene can begin even before thermal degradation (in the range 90 ° C - 130 ° C).

Therefore, the material cannot be used as an inner layer of insulation that is in direct contact with the decorative lining of the ceiling in the steam room. However, provided that reflective two- and three-layer foil materials are used, it is quite possible to place a heat-shielding layer made of PPS or EPSP behind them, since the temperature on the back surface of the sandwich does not exceed 50 ° C.

Expanded polystyrene for the ceiling of the bath is possible only with a reflective multilayer screen

It is advisable to use expanded polystyrene to insulate the ceiling in the bath with your own hands, working alone. It is especially convenient to use EPSP boards if it is necessary to mount a layer of insulation on the lower surface of the rough ceiling. It is extremely difficult to carry out such work with loose materials such as mineral wool without helpers.

Expanded clay

Insulation of the ceiling with expanded clay is used in baths with under-roof rooms (attics, attics). The properties of expanded clay are in many ways similar to those of mineral wool. The same pluses: environmental friendliness, resistance to high temperatures ... and the same minus: the material absorbs moisture too well. From below it must be protected from steam penetration, and from above from the effects of atmospheric and condensation moisture.

In addition, the fired pellets of this heat insulator have a much lower resistance to heat transfer than mineral wool. For this reason, the required thickness of the effective embankment is at least 30 cm.

The option is suitable for large steam rooms.Since the floor beams above the spacious rooms have a significant vertical section, deep natural niches are formed for filling the required amount of expanded clay.

Self-growing foam concrete and other DIY heaters

Ceiling insulation with clay with sawdust, homemade aerated concrete, moss and other exotic materials is advisable if you have access to these relatively cheap or free thermal insulators.

If during the construction process you have a surplus of basic rough materials (for example, cement), then some of them can be used to equip a heat-insulated ceiling in a steam room. The technology of self-growing aerated concrete is based on the interaction of three main components: cement, water and a special gas-forming powder. In addition to the listed materials, density-reducing components such as sawdust and straw can be added to the mixture.

Thermal insulation of the ceiling of the bath with homemade foam

The main advantages of the technology in comparison with expanded clay backfills are lower thermal conductivity and greater moisture resistance. It is enough to fill the resulting cellular material with a layer of 10 - 12 cm. Expansion under the influence of gas-forming additives, in addition to heat-saving properties, helps to obtain a continuous surface without cracks and gaps. In addition, waterproofing is not required with this option.

If you have your own carpentry production, and the roofing area of the bathhouse allows filling in large layers, then you can implement insulation of the ceiling with sawdust, combining them with sand, clay and some other building and natural materials. Clay has good steam and waterproofing properties. Therefore, before backfilling the sawdust, a clay layer is first made about 2 cm thick. Then the sawdust is backfilled with a layer of about 10-15 cm in height. On top of the sawdust, sand, dry earth or moss is laid in a mixture with needles in a layer of about 15 cm. Mixtures of sawdust with clay are also used as masses that have both heat-saving and waterproofing properties.

How to insulate the ceiling of a bath: the best options

Different materials can be used for thermal insulation. Let's consider the most popular solutions.

Mineral wool

A general name for a group of heaters with similar properties. For thermal insulation of the ceiling, you can use:

- Glass wool, which is made from glass fibers.

- Slag wool produced from blast furnace slag.

- Stone wool is made from molten rock.

Mineral wool

Mineral wool

Their common advantages include low thermal conductivity, good resistance to temperature changes and fire resistance. The average service life of materials is 40-50 years, which is due to the high resistance to decay and reproduction of pathogenic microflora. The main disadvantages are considered to be the loss of insulating properties even with slight wetting and brittleness of the fibers, which leads to strong dusting.

Comparative characteristics of mineral wool are presented in the table

| Variety | Coefficient of thermal conductivity | Fiber length, mm | Burning possibility |

| Glass wool | 0,042 | 15-50 | Absent |

| Slag | 0,04 | 16 | High temperature sintered |

| Stone wool | 0,046 | 16 | Absent |

Cotton wool insulation is produced in the form of slabs and rolls. The former are more convenient to lay. Some manufacturers produce foil coatings, which is very convenient, since the metallized layer reflects heat rays and delays evaporation.

Expanded clay of various fractions

Environmentally friendly insulation, available in the form of clay granules of various sizes. The advantages of the material are:

- low thermal conductivity;

- fire resistance;

- immunity to high humidity;

- resistance to mold and mildew damage.

Expanded clay granules

Expanded clay granules

Of the shortcomings expanded clay it should be noted that it is necessary to backfill with a sufficiently high layer of insulation, which can lead to an increase in the weight of the floor. In addition, the top layer of granules is capable of absorbing water, especially if the technology was violated during the production process. Wet material loses its insulating properties and dries for a very long time. Therefore, the presence of hydro and vapor barrier is necessary.

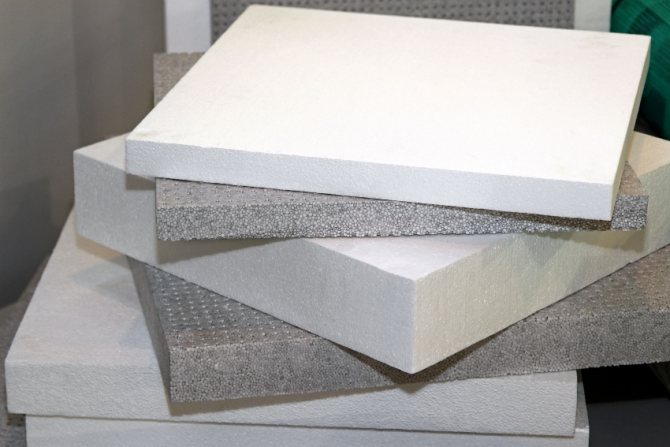

Styrofoam and expanded polystyrene

They are produced in the form of slabs of various thicknesses. Polyfoam is a gas-filled material with low thermal conductivity. Expanded polystyrene is its denser variety. The advantages of insulators include:

- high thermal insulation characteristics;

- light weight;

- low water absorption, especially in expanded polystyrene;

- resistance to the growth of mold and mildew;

- budget cost.

Insulation foam

Insulation foam

The main disadvantage of the material is destruction under the influence of elevated temperatures. The insulator quickly ignites and burns, releasing extremely toxic substances. It is worth thinking about this when choosing this heater for a bath.

Ecowool

Fully eco-friendly insulation based on cellulose impregnated with sodium tetraborate and boric acid. The advantages of using the material are:

- low thermal conductivity of the coating;

- resistance to temperature extremes;

- light weight;

- long service life;

- almost complete resistance to damage by insects, microorganisms, fungi.

Of the shortcomings, it is worth noting the complexity of installation. If it is produced by the so-called "wet" method, and this happens most often, the use of special equipment is required.

Ecowool from cellulose

Ecowool from cellulose

These are not all coatings that are used for insulation. Sometimes, environmentally friendly materials are chosen as an insulator, which have been successfully used by home craftsmen for decades. it clay with sawdust or with leaves. The composition of the mixture may vary. In various proportions, chips, cement, peat, black soil, straw, etc. are added.