Installation of electric floors

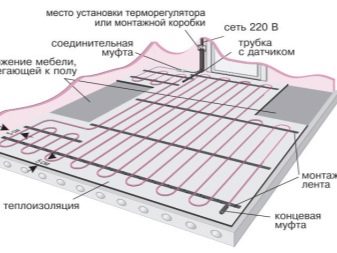

The most difficult is the installation manual for underfloor heating from separate Deviflex cables. However, this is only in comparison with the laying of mats. In fact, the installation is not much different from the usual laying of heaters under the screed.

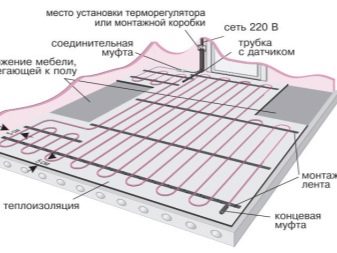

The subfloor should first be thermally insulated and laid with a foil-lined reflective film so as not to waste electricity on heating the floor slab and lower rooms. Alternatively, one layer of Penofol is suitable with gluing all seams with aluminum tape. But only if the neighbors "warm" your floor from below, otherwise you cannot do without an additional layer of thermal insulation.

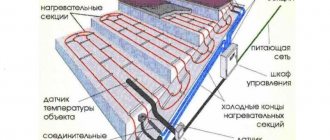

Further, the order of work with Devi will be as follows:

1. Metal mounting tapes are fixed to the floor in advance with a pitch of 200-250 mm - they will fix the heating cable in one position.

2. First of all, the temperature sensor is installed. Only then can the heating elements be laid.

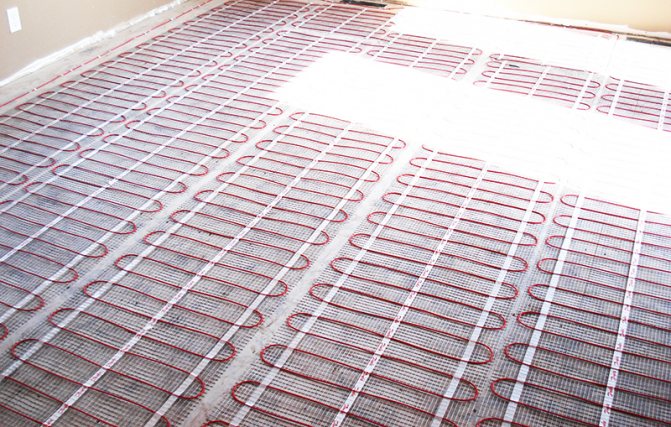

3. Underfloor heating Deviflex is unrolled on the prepared base in even turns. Leave a gap of at least 50 mm between them.

4. Secure the cable with steel tapes. Thanks to them, the heat transfer of the system becomes more uniform, and the distance between the Deviflex turns can even be increased.

5. The last stage before pouring is connecting the temperature sensor to the cable and household network. It should be hidden in the corrugated tube, but not embedded in the floor.

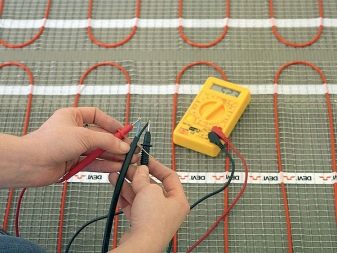

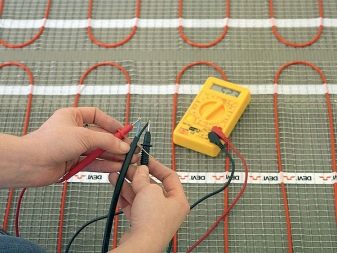

According to the instructions, it is forbidden to cut Devi heating elements, so carefully consider the choice of their length. Also, do not check the work before the solution finally hardens. The maximum that is allowed is to "ring" the installed line with a tester.

When installing a warm floor for pouring and facing with tiles, it is necessary to take into account that building mixtures will undergo thermal expansion. Choose suitable formulations for this parameter. Before pouring the screed, do not be too lazy to take a photo of the Devi system and apply approximate dimensions. Customer reviews indicate that it will be useful to know for the future where exactly the cable runs under the concrete.

Heating mats

For the equipment of the heating system in the premises, it is recommended to install heating mats. They are thin, 3 mm. A single-core or two-core cable is fixed on the surface of the mesh made of heat-resistant plastic.

An adhesive layer is applied on the base of the mat, which makes it possible to quickly carry out installation work. Mats are laid on any surface: on wooden logs, concrete screed, on old tiles.

- "DEVImat" has a power of 150 W, operates from a voltage of 230 V. The product is used in rooms with any temperature and humidity conditions. A two-core cable is located on the mesh with a snake.

- DEVI mats have one more modification - DEVIheat DSVF 150 S. The system is manufactured with a single core cable. Two cold ends of the conductor are connected to the thermostat. The system is not recommended to be laid under the screed. Tile adhesive is used for the heater. The mats are adapted for installation on wooden joists. Cable diameter 2.5 mm; suitable for thin floors. The system is placed under the laminate.

- "DEVIcomfort DTIR-150" - equipment power 150 watts. A two-core cable is attached to the mats. Devimat operates on 220 watts. It is recommended to lay the mats under the ceramic tiles. A layer of tile adhesive no more than 2 cm.

The mats are placed on the surface with the cable facing up. The net should be fully extended. Thanks to the adhesive base, it adheres well to the floor. Additionally, you can strengthen it with tape. If there is a need to turn the mat, then cut the mesh, do not touch the cable.It is not recommended to violate its integrity. The product is turned by 1800 and installation work is continued.

The bending radius of the cable must be equal to 6 conductor diameters. The distance between the turns is maintained at 2-4 cm. A thermal sensor is placed on the mesh between the turns of the conductor. The wires from the mats and the sensor are connected to the thermostat. They are preliminarily placed in corrugated tubes.

Since the mats are designed for thin floors, the system is vulnerable to mechanical stress. Heating is established only on the usable area of the room. According to the instructions, it is not recommended to lay the system under cabinets and a sofa, which fit snugly to the floor.

Locking of the cable may occur. Carpet or carpet is not laid on the warm floor. Ceramic tiles are used as cladding.

It will take time to warm up the systems, up to 48 hours. In order to always have a comfortable microclimate in the house, it is recommended to connect the sensors to the software and control the heating system through a computer. DEVI has a representative office in Moscow and other large cities throughout the CIS.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- How to calculate the distance between underfloor heating pipes?

- How to check underfloor heating?

- How to make a dry warm floor?

- How to calculate the power of the underfloor heating?

- How to make a warm water floor in a private house with your own hands?

- How to install Eastec underfloor heating?

Installation

Thermostat for underfloor heating

The principles of installation work for some categories of underfloor heating are briefly described below:

- For a heating cable, the installation principle is quite simple. Installation is carried out by the snake method into the floor screed, then the connection to the temperature controller is performed. When plugged into the network, the cable heats up, which leads to the appearance of heat in the premises. The heating time is rather short, which allows you to get a warm, comfortable floor in a short time interval.

The most common option at the present time is the self-regulating version of the cable, due to which heat is accumulated.

- The installation of the heating mat is not too difficult, as well as its adjustment. You need to connect the mat according to the scheme provided by the manufacturer. To do this, you need to roll out the roll onto the base and connect the cable to the socket, which has a temperature regulator. This option is considered the best for tiles, as it can be laid directly on the cable system.

Installation of underfloor heating devi

How to choose a thermostat for a warm floor

The technology of underfloor heating is quite simple, and therefore, the installation can be done independently. Otherwise, if there is no experience in such matters, then it is better to call a specialist who can carry out a high-quality installation of a Devi warm floor, thereby ensuring the maximum efficiency of the system during its operation.

Several popular mistakes that occur when installing a warm floor:

- When planning, the area that will be covered with furniture and household appliances is also taken into account. When developing a scheme for the further installation of a warm floor, it is necessary to take into account only the area that will be in the public domain. If the furniture is without legs, and under it there will be a warm floor, this can disrupt heat regulation, which will lead to overheating of the heating cable and failure of the entire system;

- A branded cable has a certain length. If the cable was chosen longer than the required size, then later it will not be possible to shorten it, since this is prohibited by the instructions for the underfloor heating technology;

- The first test of a warm floor can be carried out only after the screed and the mortar that was used for laying the cables have dried;

- Before installing the underfloor heating, it is recommended to thoroughly clean the surface, and, if necessary, priming the base, which will allow you to achieve an even floor level;

- It is forbidden to walk on the heating cable in solid shoes, as it has a small tensile strength;

- The temperature sensor should be installed in a corrugated pipe. It must be remembered that it must be freely available, and therefore it is strictly forbidden to hide it under the wallpaper, and even more so to fill it with concrete;

- When installing a warm floor, from the very beginning to the end of the installation, the resistance indicator is monitored. The results obtained must be verified with the data in the system passport. Consumption between indicators should not be higher than 10%;

- The warm floor is insulated without air gaps. Their presence can disable an individual cable or system completely;

- It is strictly forbidden to turn on the warm floor, thinking that this will help speed up the drying of the heavy. In almost all cases, this leads to a breakdown of the warm floor.

Calculation and installation

Installation of Devi underfloor heating can be performed only after calculations. At the first stage, it is necessary to determine the heat loss in the room. Since the calculation of this value is complicated, it is customary to take the average value of the required power of the warm floor per 1 m2:

- Rooms, kitchen - from 110 to 150 W / m².

- Glazed balconies - from 140 to 180 W / m².

- "Wet" rooms (bathroom, shower, toilet) - 130-450 W / m².

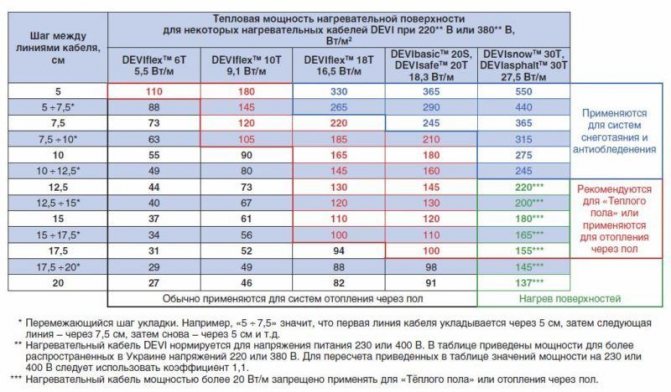

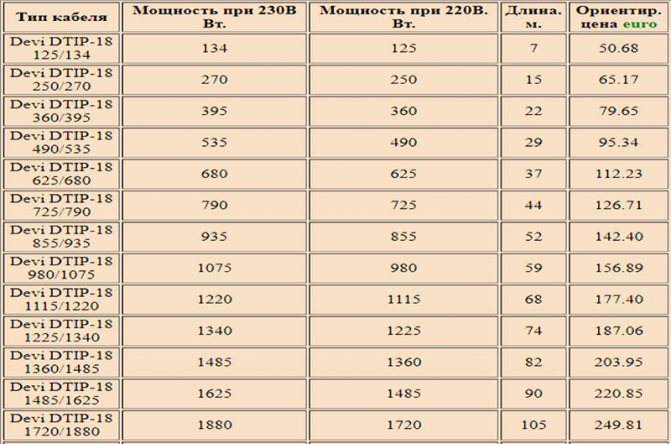

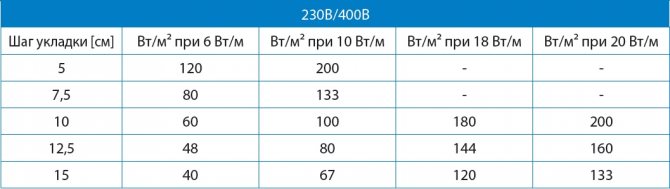

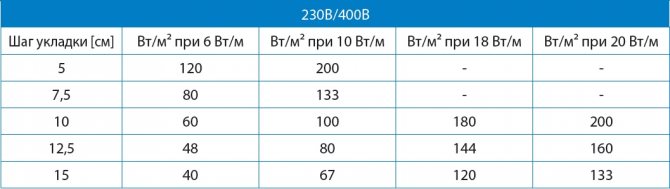

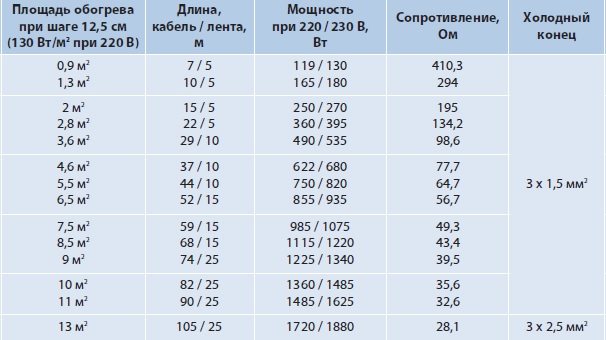

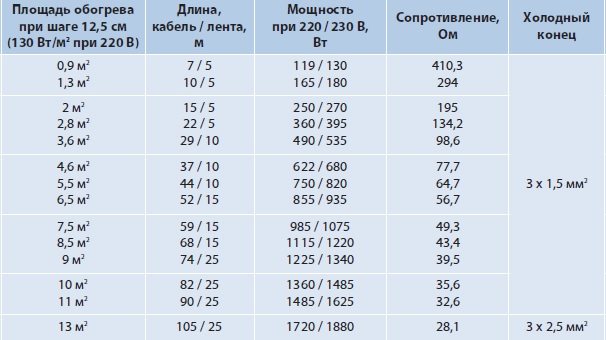

Having determined the type of room, an approximate calculation is performed. Devi underfloor heating can be completed with cables of different power. The main indicator is the amount of energy per 1 lm. It depends on the thickness of the cable and the number of cores. The company currently offers products with a power of 6, 10, 18 and 20 W / m. Depending on the required heating power, the laying step is regulated.

Before starting work, it is recommended to draw a working sketch of the room. It will display the location of the Devi underfloor heating sensor, heating elements and thermostat.

Advice

It is important to prepare separate power wiring in advance.

It is strictly forbidden to plug the system into an outlet without installing the safety switches. You should also take into account the location of the furniture - it should not be on the structure, as this can cause the reflection of thermal energy and overheating of the cables.

Depending on the area, the optimal model is selected - laying cables with the desired laying step, or installing ready-made mats. The latter scheme will be convenient if the width of the room is a multiple of the dimensions of the mats. Underfloor heating Devimat is a Teflon-coated polymer mesh.

Advice

The standard mat width is 50 cm and the thickness is 5 mm. Depending on the model, the paving area can be from 7 to 12 m². The set includes a protective sleeve for mounting a temperature sensor.

Different installation schemes are used depending on the type of floor. Consider the most common installation option on a concrete floor with further installation of floor tiles.

The main functions of the underfloor heating thermostat

Thermoregulator for water underfloor heating

The system under consideration consists of a thermostat and a special temperature sensor. This sensor is installed in the required location. It is installed using the supplied corrugated mounting tube. In the case of a warm floor, it is placed in a conventional cement-sand screed.

Selecting functions on the thermostat

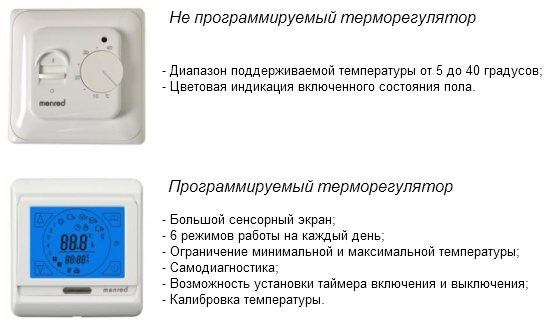

Most often, such devices are equipped with underfloor heating systems that work with a heating cable. Thermostats are commercially available that can be programmed. This allows additional energy savings.

Thermostat for underfloor heating

For example, the user can program the thermostat so that in the absence of tenants, the system will operate in the minimum mode, and shortly before they return, it will switch to normal operation in order to have time to warm up the room to the required level.

Types of thermostats

Programmable thermostats are more expensive than their non-programmable counterparts, but, as practice shows, the existing price difference pays off in no more than 1-2 seasons.

Principle of operation

The main feature of heating the floor surface using electric cables is the ability to smoothly adjust the temperature, depending on the current settings of the thermostat. The principle of operation is the transfer of thermal energy from electrical cables to the floor covering, which serves as a heat exchanger. The air in the room is heated from its surface.

The step-by-step process of increasing the temperature is as follows:

- The Devi underfloor thermostat connected to the cable receives data from the sensor about the current floor temperature.

- Depending on the set mode, a current of a certain value is supplied to the thermoelements to heat the surface.

- When the desired mark is reached, the power is turned off.

As soon as the temperature drops below the set value, the process is repeated. The company supplies several types of thermostats. The most popular is the Devilink control system. It consists of several elements, the central of which is DevilinkCC (centralcontroller).

The convenient touch control panel can control the operation of not only the warm floor, but also all electrical heating elements. Thanks to the wireless connection (radio channel), it is possible to connect additional temperature sensors, an electric boiler, radiators, etc.

How to choose

Below are a few rules for choosing a warm floor:

- When buying an electric heating element, you should pay attention to the compliance of this brand with the floor covering, under which the warm floor will be laid. It is not difficult to find out: you need to pay attention to the pictograms indicated by the manufacturer on the packaging.

- The power of the heating elements is also an important factor. There is a relationship between the flooring and this indicator. It is necessary to consult the seller.

- Indoor wiring. It is important to know here whether the existing wiring can additionally take the load from the warm floor.

- Calculation of the required power. To do this, you need to know the characteristics of the building, glazing zones and much more.

- Manufacturing firm. The emphasis should be on branded products: even if they are more expensive than analogues, the consumer will be calm about the quality of the product. After all, such a system should last for several decades.

Devi heating mats and their modifications

Such products are easier to install, but they are only suitable for rooms with right angles. If the geometry of the room is non-standard, it will be much more difficult to bring them into oblique corners. It does not require an independent step layout and respecting the distances. The heating elements are already built into the foil with mesh. All that is required is to place the strips on the floor of the room and lay the floor covering on top.

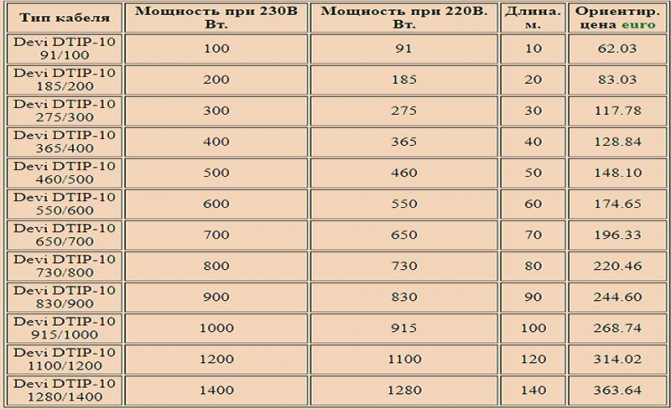

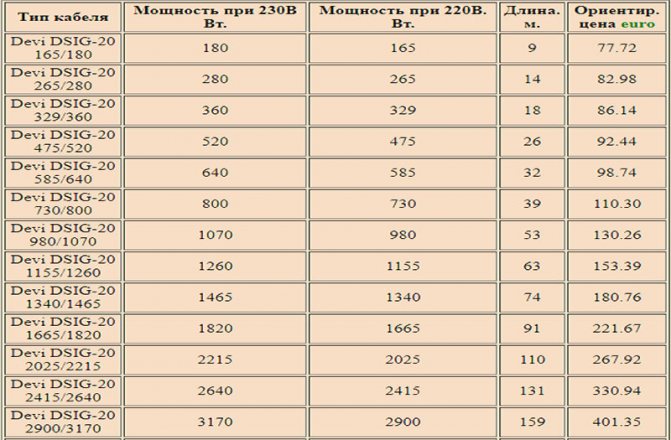

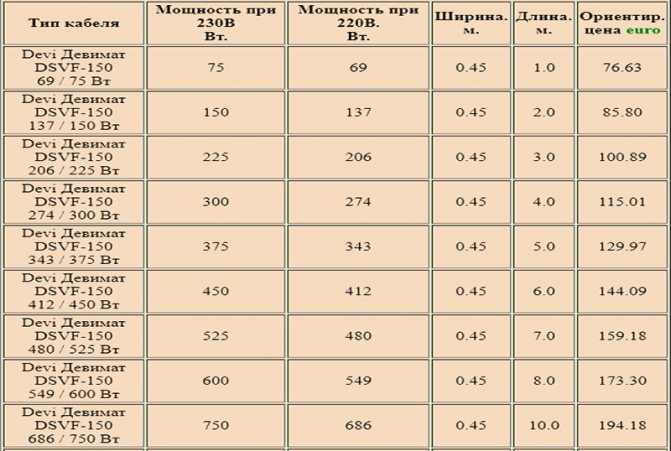

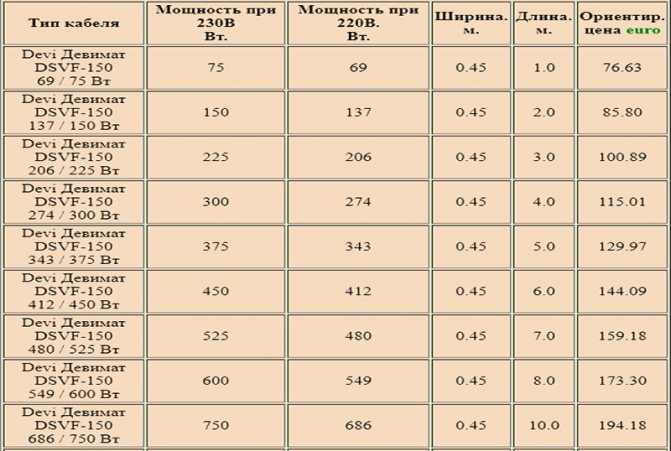

There are only two models in this line, the characteristics of which can also be found from the tables.

Single-core heating Devimat DSVF. Its maximum temperature is 90 ° C. It fits directly into the tile adhesive. The indicators of such mats are as follows.

Single core heating Devimat DSVF PHOTO: otopleniye-sam.ru

Two-core heating Devimat DTIF. Also able to warm up to 90 ° C. The characteristics are practically no different from the previous version. The only difference is the screen, which here consists of copper and aluminum (the single-core has no aluminum)

As for the warranty for all models of heating mats and cables, the manufacturer stopped it at the 10-year mark. Naturally, in the absence of violations of transportation and installation by the buyer.

Devimat DTIF - two-core cable on a substrate PHOTO: devi.market

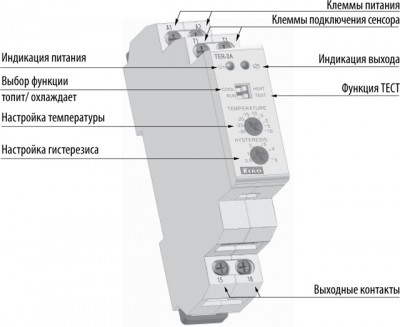

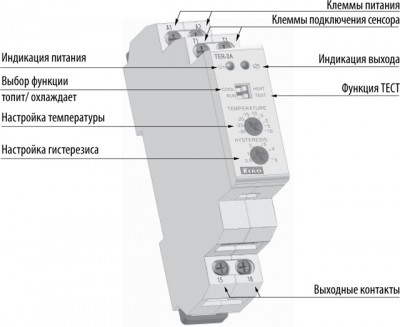

Devireg D 610 connection

To connect the D 610 regulator, you need to unscrew two screws for a Phillips screwdriver on the upper (front) housing cover.

The front cover opens easily, but it is solid, like an armored front door, and the regulator itself resembles a small safe.

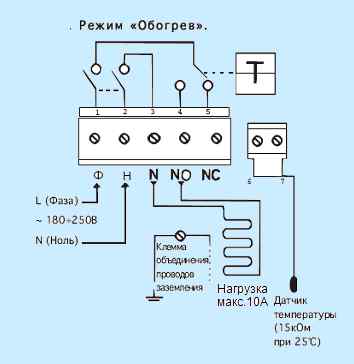

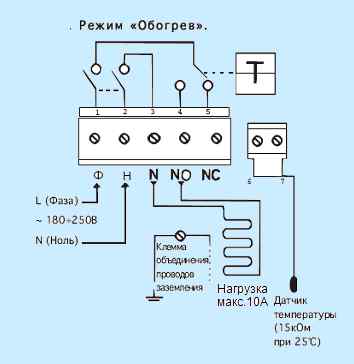

The connection of the load conductors, temperature sensor and 220 Volt power supply is carried out to the terminal blocks, they are marked with letter markings "L", "N", "NO", "NC", "NTC". According to the electrical diagram given here, the wires are connected as follows:

1) To control heating systems (underfloor heating, electric heating systems, heating cables):

- the wire supplying 220 Volt power is connected to terminals "L" and "N" ("L" - phase, "N" - working zero);

- heating cables are connected to terminals "NO" (normally open) and "L";

- a temperature sensor is connected to the small “NTC” block.

2) To control cooling systems (air conditioners, ventilation):

- supply wire, 220 V is connected to terminals "L" and "N" (phase to "L", working zero to "N");

- the cooling system is connected to the "NC" (normally closed) and "L" terminals;

- a thermal sensor is connected to a small block "NTC".

The braided shield from the heating cables and the shield from the cooling systems are connected to the grounding conductor of the supplied power (yellow-green wire).

After connecting and installing the front panel in place, do not forget to make sure that the jog wheel is in place and has full stroke from -10 ° C to + 50 ° C.

It will also be useful to remind that all connections and electrical connections can only be made by qualified electrical personnel with an electrical safety group of at least 3 to 1000V as repair or operational-repair personnel.

Connection diagram

Errors when installing DEVI underfloor heating

Despite the fact that the installation of underfloor heating (and heating mats for tiles and heating cables in the screed layer) is not an extremely difficult process and simple adherence to the installation instructions will allow you to enjoy the comfort of a warm floor for many years, many working roofing felts by virtue of their own carelessness, roofing felts from the "big" mind make mistakes, from which the client then suffers. Unfortunately, failure of a heating mat or cable is fraught not only with the installation of a repair sleeve on the heating element, but also with the loss of one or two expensive floor tiles, which have to be broken to get to the place of cable damage. And who knows, maybe this collection of tiles has already been discontinued?

Here are the most common mistakes made by installers when installing underfloor heating (not only DEVI, but also from other manufacturers).

- A common mistake when installing a heating mat, when the cold end (the supply cable that goes to the regulator in the wall) is not removed into the gouged groove in the screed, with a smooth transition from the wall to the floor, but simply thrown from above onto the screed. The wire at the wall-floor junction sticks out, and when laying the tiles, the tiler cuts or damages the supply wire of the heating cable with the sharp edge of the tile, breaks the external insulation, lowering the insulation resistance, which eventually leads to the failure of the entire heating element.

- A common mistake when laying heating mats in the kitchen is to move away from the kitchen furniture. When laying a warm floor, as a rule, an indent from the walls is made 10-15 centimeters. This is done to reduce the heating area and is permissible, since, as a rule, no one is standing close to the wall. However, it is completely wrong to make such an indent from the kitchen (cutting table, sink, hob, etc.) in this case, the person stands exactly close to the furniture and, the heels are in a warm zone, and the toes feel all the coldness of the tiles near the cabinet. This causes discomfort. The heating element should be positioned along the line of the kitchen cabinet work wall.

- When laying tiles, craftsmen sometimes damage the outer insulation of the heating element. If any damage occurs to the heating cable, its outer sheath, and even more so to the screen or cores, do not wrap this place with electrical tape. Over time, especially quickly in humid rooms, the heating cable will begin to deteriorate, its insulation resistance will decrease and, in the best case, the protective automatics will start to work. In the worst case, the heating cable will burn out and you will have to break the tiles when the repair is finished to install the repair sleeve. It is better to immediately contact a specialized service that will install a repair heat-shrinkable adhesive sleeve with a quality guarantee. The cost of such repairs is much lower than the subsequent search for the place of damage and repair. And it's almost impossible to buy one or two tiles to restore the floor after renovation (especially if several years have passed since the release of the batch). It is optimal to preserve several tiles of different patterns after repair, since damage to the heated floor when installing door stoppers, trimming tiles in place, and also completely eliminating factory defects.

- It is necessary that during laying the junction of the heating cable and the "cold" (supply) wire should be laid flat. Do not allow the heating cable to turn sharply immediately after the bushing. During the operation of underfloor heating, permanent deformation of the outer sheath of the cable occurs. As a result, after a few years, with constant mechanical stress at the junction at the turn, the internal heating conductors can simply be pulled out of the bushing sleeves, which leads to the failure of the heated floor.

- If you need to drill a hole in the floor where the heating element is laid, it is better to call a specialist with a thermal imager, who will accurately indicate the location of the cable so that later expensive repairs are not required.

Warm floor Devi. Annotation for installing heating mats on your own

Initial step:

- The possibility of an electric supply is checked for connecting a warm floor. The power of all devices connected to the network is summed up.

- The permissible current value of the machines is checked. Remarkable mats that consume more than two kW are connected with a separate connection and an automatic machine is installed for them.

- Without unrolling the mat, measure the resistance of the cable. Check the result with the passport data for the material. An error of +/- 10% is allowed.

- They control the condition of the surface for laying the mat. In the presence of cracks, protrusions or depressions, level drops, the screed is made with a self-leveling substance.

- On the prepared surface, clean of debris, make the layout of the placement of furniture, devices, plumbing. Make an indent of 50-100 mm from these areas. Perform the same indent from the wall. It is not allowed to install furniture and office equipment on the Devi heating mat.

- Lay out the mat on the marked area. At the point where the material is turned to the other side, the mesh is cut, and later a turn is made. The cable is not cut.

- Making sure that the reversal of the mat allowed the material to adhere accurately and perfectly to the surface, mark the area for the corrugated pipe with the temperature sensor. Place the beginning of the groove strip in the heating zone, in the center of the cable turns on the mat. Continue the line to the location of the sensor. Lead out the current wire in advance.

- Roll up the mat and cut a 20x20 mm groove and a section for the back box along the marked strip.

- Remove trash.

- Prime the surface of the base.

- Close the end of the corrugated pipe with electrical tape or tape and stick it into the groove.

- Install the back box for the thermostat.

Installing the mat:

- Spread the surface with an adhesive, glue the prepared mat.

- Measure the insulation resistance of the heating element, check it with the initial readings, make an entry in the warranty card of the technical passport.

- In the coupon, in the laying scheme, enter the placement of the main and auxiliary parts of the mat, indicate the indentation from objects and walls.

- Connect the thermostat and check the operation of the heating mat.

- Switch off the system before installing the top finishing coat.

- Proceed with the installation of tiles. It will protect the cable and electronic parts from accidental mechanical damage.

Description Devireg D 610

Dust and moisture resistant Devireg D 610 regulator is designed both for control of Devi heating cables in systems such as electric underfloor heating, in snow melting and anti-icing systems, heating pipes, tanks, tanks (frost protection), and for control in cooling systems (ventilation , air conditioners).

The Devireg D 610 thermostat can be installed outdoors, the operating temperature of the environment is from -30 ° C to + 50 ° C. In addition to installation on a street wall of a house, the Devireg D 610 regulator can be fixed with clamps on a heated pipe, and, of course, can be installed inside warm rooms, incl. and in damp rooms.

In essence, this D 610 regulator is analogous to simple mechanical ones: D 130 regulators controlled by a temperature sensor, and is also similar to the principle of operation of D 330 regulators, which are mounted on a DIN rail.

Airframe Devireg D 610

The dust and moisture-proof housing of the B 610 regulator is made with a high degree of tightness, and in accordance with Russian standards it complies with IP44. The on / off button is protected by a transparent rubber strip. A rubberized seal is installed under the temperature control wheel. A protective rubber gasket is laid around the perimeter of the opening cover.

From the ends and from the bottom of the regulator, there are holes for entering wires from the sensor, from the heating cable and 220 V power supply, the holes are drilled with a crown (do not knock out with a screwdriver). The kit includes rubber seals, which are inserted into the holes made by the installer and the wires are passed through them. Alternatively, instead of rubber seals for wire entry, you can screw in a cable gland (purchased independently). Diameter of holes to be punched - 20 mm 3 pcs (one on the side and two on the bottom) and 10 mm 1 pc (top).

With all the listed advantages, this regulator is not devoid of a relative disadvantage, namely, it is a small current load power that the D 610 can pass through its own relay contacts. The connected load (power of heating cables) should not exceed 10A, which corresponds to 2.2 kW at Russian 220V.

Features and characteristics

Underfloor heating from well-known manufacturers Devi is very popular in interior decoration. The materials produced by this brand are manufactured to high standards and qualities. Anyone who decides to install floor heating comes across this brand.

Devi underfloor heating differs from other manufacturers in that it produces not only heating cables, but also special equipment - regulators, connection elements, thermostats with an LCD display. Cooperation between heating systems has been created. Thanks to this, this brand is recognized as the safest and most environmentally friendly device: it received the ISO 14001 class certificate.

The main advantages of Devi underfloor heating:

- Heating of the house takes place in a fairly short period of time. Due to the installed Devireg thermostat, a certain constant temperature can be set without the risk of fluctuations. You can control the system using a PC. It is possible to set a different temperature in each room.

- Energy streams are transferred to the surrounding air. They go up, and heat passes through the legs. Due to the fact that the energy does not rise to the ceiling, it is not wasted, as with conventional heating of the apartment. Therefore, the heat dissipates evenly throughout the room.

- Works independently of the main central heating.

- Does not emit foreign odors and harmful vapors.

- Warranty of the manufacturer of the warm floor is 10-20 years, but the real terms are much longer.

- Installed under any floor covering and in a specific area that needs to be heated.

- Does not take up space in the apartment, thus the interior of the house does not change.

- Suitable for families with small children. Thanks to its automated system, if a human touch is detected on the cable, the system will automatically shut down.

Like many other types of underfloor heating, the Devi product has its drawbacks:

- High cost of production.

- In case of chronic diseases of the legs, the use of this heating is prohibited.

- The operation of an electric floor requires special attention. If the structure breaks down, it will be difficult to find out where the failure occurred.

- Heat dissipation near the walls is much higher than in the middle of the floor. Therefore, it is necessary to install an electric floor so that the heat transfer is evenly distributed.

- Electricity can damage rooms that have high humidity.

Underfloor heating Deviflex - screed heating sections

Advantages: by changing the step of laying the heating section, you can change the power of the heating system, laying is possible with any configuration of the heated surface, due to its large thickness, the system is inertial - it heats up for a long time, but also keeps heat for a long time after that. minimum increase in floor level 3 cm, inertia of the heating system

Under the general name DEVIflex, a whole series of different heating sections for electric underfloor heating systems is presented. A heating section is a section of a heating cable of a certain power and length, to which an electrical power cable is connected (power, "cold" end). They are connected using a special sealed coupling. Heating cable thickness is 6-9 mm. For example, the diameter of DEVI's most popular underfloor heating cable - Deviflex 18T - is 6.9 mm.

Therefore, it must be taken into account that the use of heating sections for laying a warm floor entails an increase in the floor level by at least 3 cm.When working with heating sections, you must remember a few rules:

- It is forbidden to directly connect the heating cable to electricity (connection is made only through the "cold" wire)

- It is forbidden to shorten or lengthen the heating cable (if necessary, you can shorten or extend the "cold" power cable)

- It is forbidden to crush, strongly bend the heating cable during installation (this leads to local overheating and further cable burnout)

- In case of local failure of the heating cable, a special repair sleeve is installed

- If a sufficiently large section of the cable has burned out, it must be replaced with exactly the same cable to maintain the power characteristics of the heating section.

As a rule, in systems "electric underfloor heating" heating sections are installed in a screed layer (DSP) with a thickness of 3 centimeters. DEVIflex sections are fixed to the subfloor using a special mounting tape, or with plastic clamps to the mounting mesh reinforcing the screed. The heating section is laid in a "snake" pattern. The distance between the cable turns (laying pitch) is calculated depending on how much power the heating system needs to be made. For example, on balconies or loggias, it is recommended to mount a system with a capacity of 180-200 W / sq.m. Those. to heat 3 square meters of the balcony, you will need a heating section with a capacity of 550-600 watts. In this case, the laying step can be calculated using the formula:

h (laying step, cm) = (S area, m * 100) / (L cable length, m).

Underfloor heating with a power of 130 W / m from DEVIflex 18T sections under the screed at a laying step of 12.5 cm

For installation in concrete floors, the Deviflex 18T cable line is available under the Devi brand. This is one of the best underfloor heating cables.The warranty period for it is 20 years.

Varieties of "warm floors" Devi

Single-core, two-core resistive and self-regulating cables from Devi are used not only when installing "warm floors", but also on pipelines (as protection against freezing), in heat storage systems, in greenhouses and other agricultural premises, in heating systems for entrances, lawns and open areas ...

Resistive cables consist of a heating core, copper braid and sheath. When buying, you need to take into account that they cannot be cut. Self-regulating products change the heating temperature depending on the room temperature, which saves up to 30% of electricity. This type of "warm floor" can be cut during installation.

For laying underfloor heating under tiles or stone in residential premises, there are three types of cable:

- Deviflex DSIG - the simplest single-core cable, it is used not only indoors, but also in open spaces, segments of various lengths are sold, the cost is low, for example, a segment of 9 m can be bought for 3000 rubles;

- Deviflex DTIP - two-core PVC-insulated cable, can be used both indoors (for installing a complete heating system) and outdoors (on ramps, stairs), power 10 or 18 W / m. It comes to stores in bays of various lengths, a 10 m segment costs from 3100 rubles;

- Deviflex DTIE - an improved version of a two-core cable with special Polyolefin insulation, which facilitates installation. The manufacturer positions this product as a bioproduct, so it can be used in preschool and school educational institutions, in medical institutions. It is sold in segments of 9-170 m, a segment of 7 m costs from 2600 rubles.

Devi Mats multilayer, consist of a cable (single or two-core with a diameter of 2.5 - 4.5 mm, which is fixed in a mesh with foam plastic. For interconnection, the mats are equipped with connectors. using a thermostat.

Warranties and equipment

In this moment, the Devi firm keeps the brand. On their heating cables, they give a 20-year warranty, subject to the integrity of the insulation. A very bold statement requires tight control over the products released. Therefore, Devi cables are sold only in single pieces! In other words, you will not be sold 50 meters of cable in a store. There are sections of 40 m, and there are 60. Take any. And if you shred it, then the guarantee is removed.

There are a lot of standard sizes, and it is unlikely that it will be possible to find some kind of length grading system. Some series have a step of 5, 7 or 14 m, some 3 and 6 m. If you wish, you can choose it to suit your needs. But the prices are quite high. The "cheapest" heating cable, will cost ≈ 170 rubles / r.m. Subject to the purchase of a bay of 198 m.

Heating mats are even more expensive. With a single standard of width (50 cm), the lengths of the mats vary from 1 to 24 meters. At the same time, a mat with an area of 0.5 m2 will cost ≈ 5.5 thousand rubles, and 12 m2 at 26 thousand rubles.

That is why, on sale there are no ready-made sets "Heated floor Devi". For each room, an individual set is made. Considering that the products of this Danish company are sold in specialized centers, you can count on the full help of consultants.

Heated floors electronic Devi. The cost of installing the system and individual materials

- The Devi set for underfloor heating with a two-core Deviflex cable is used for laying on a cement surface and installing full or local heating. The average unit cost of a cable per meter is $ 12.5. The manufacturer produces kits with a short length of seven meters. A long cable length of 100 70 m.

- Heating with mats is used for narrow floors, under the cover. 1 m2 of a two-core mat costs $ 100 40 6. The size of the mats starts from 0.5 m2 and ends with a large area of twelve m2.

- Devidry special heating mats for wood flooring are available with plug connection, switch box, extension cable from two hundred 50 to two thousand mm.The cost of heating surfaces depends on the area and on the connection method. On average, one m2 costs $ 100 twelve.

- Devi thermostats average unit cost $ sixty-two.

- Installation of Devi underfloor heating by professionals costs the client $ 200-235 per sq. M.

You should not close the topic of floor heating to yourself. Just divide the installation cost by the number of days to be heated. You will notice the difference in favor of electronic floor heating: the cost of communal heating is 15-20% higher than that of personal heating.

Overview of Devi thermostats for underfloor heating

Thermostats that control underfloor heating operate basically according to the same principle: activation and deactivation of the heating cable by a temperature sensor.

The algorithm for triggering the underfloor heating for all controllers is as follows: the sensor, sensing the temperature drop on the floor, changes its resistance, and when the floor temperature drops below the set value, the thermostat closes the contacts of the enabling relay and starts supplying 220V power to the underfloor heating heating cable, and this heating the cable, accordingly, heats up, and with it the floor structure heats up.

The floor temperature sensor under the influence of heating begins to change its resistance in the opposite direction, and when it reaches the temperature set in the regulator (i.e. when the floor heats up to the one you defined in the temperature regulator), it gives a command to turn off the relay. The warm floor begins to cool down.

The cycle is repeated an infinite number of times. The only difference between programmable regulators: they control the time of day and day of the week, and if you and your household are not at home or you are sleeping, and the regulator knows about this through the settings you have set, then the heated floor will not turn on. In addition, some controllers have a built-in air temperature sensor.