Today the construction market presents a very wide range of floor coverings. The combination of a reasonable price and high quality is what distinguishes linoleum from other coatings. Most of the linoleum is of artificial origin. This material is easy to install and maintain, which to some extent provides such a popularity of the coating. However, if the floor in the room is cold, it will have to be additionally insulated before laying the linoleum. This article will help you figure out what kind of insulation to put under linoleum on wooden floors, as well as on a concrete base.

Types of linoleum

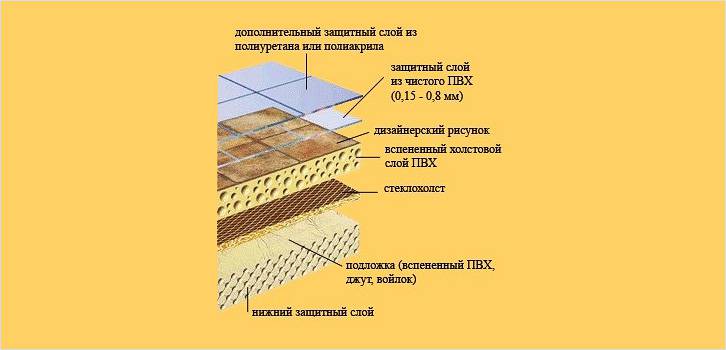

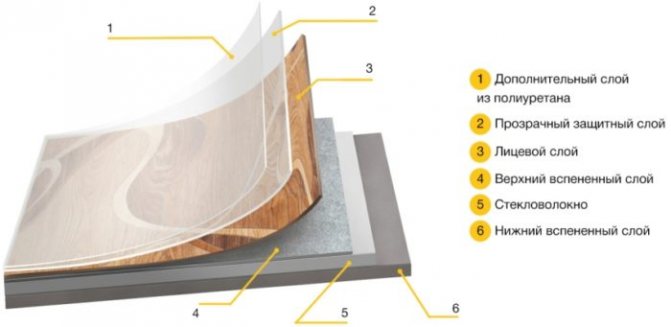

Linoleum structure

Linoleum can be base or baseless. Baseless linoleum is very thin and requires special preparation before laying, as it tears and wipes quickly on an uneven surface. Such a coating will last up to five years, but it must be borne in mind that it has absolutely no sound and thermal insulation properties.

If there is a base, there are:

- Foam base... It has a small thickness of about 1.5–3 mm. The foam backing retains some heat and absorbs sound. It is very soft and elastic, easily glued in the corners. The base can be supplemented with fiberglass, which will protect the coating from deformation and dents. The top decorative layer is covered with a protective film that will extend the life of the linoleum.

- Warm base... It consists of natural or artificial jute or felt, protected by a polymer layer. The soft and elastic coating up to 5 mm thick is perfect for bedrooms and keeps enough warmth. The disadvantages include insufficient strength of the top layer. It requires special care and is not suitable for rooms with high air humidity.

Jute-based linoleum

Linoleum with a base will protect your feet from the cold to some extent, however, if the floor is too cold, it still needs to be insulated.

Insulated plywood floor

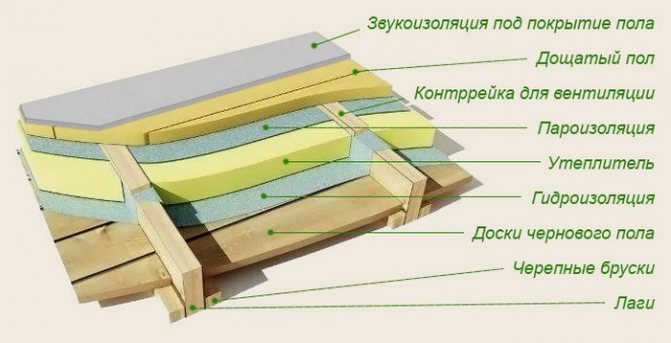

Installation of logs and insulation

High-quality insulation of the base can be carried out by installing an insulated plywood floor along the logs. Lags can be used regular or adjustable. Adjustable joists are convenient to use if there are uneven floors. If the irregularities are small and ordinary logs fit, the differences can be leveled with a wedge lining.

Note!

This option is suitable for rooms with high ceilings.

Plywood can be laid on a flat concrete surface without logs, however, if the room is located above an unheated one, this option will not save in winter in frost.

Installation of plywood

Installing a plywood floor:

- Logs are installed on the screed at a distance of 300–600 mm from each other.

- If the insulation does not tolerate moisture, waterproofing is laid.

- Then carry out the installation of thermal insulation between the lags.

- Plywood is sawn into squares and laid with small gaps between the sheets, both between each other and against the walls.

- The sheets are fixed with self-tapping screws, sinking them into the thickness of the plywood.

- The gaps and caps of the screws are putty with elastic putty.

Video: installation of a plywood floor with foam insulation

Benefits:

- Environmental friendliness.

- Low price.

- Strength.

- High degree of thermal insulation.

Disadvantages:

- Moisture instability.

- Not installed in rooms with low ceilings.

Note!

About the technology of leveling the bases using plywood, read our article on leveling the floor with plywood with your own hands.

Popular types of substrates with thermal insulation properties

When starting the choice of insulation, it must be borne in mind that the main selection criterion should be the material of the floor to be insulated. It can be either concrete or wood. You need to study the list of suitable materials that are better combined with the main floor material, find out the nuances of installing the substrate, familiarize yourself with the list of advantages and disadvantages.

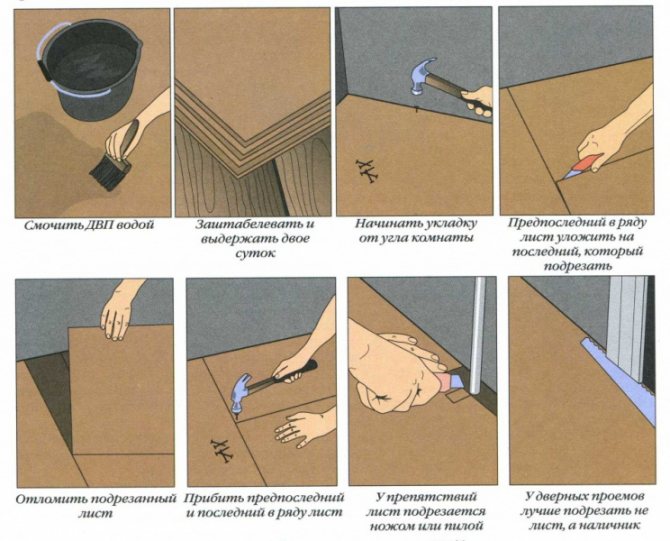

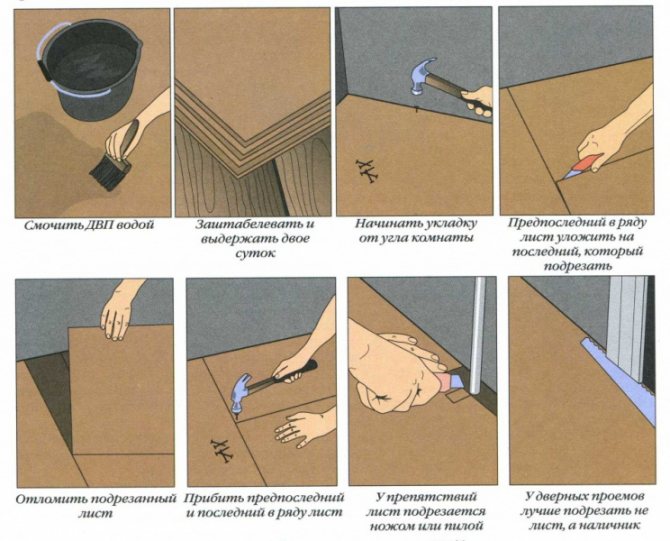

Fiberboard and plywood

The use of fiberboard or plywood sheets for floor insulation is one of the most budgetary ways of floor insulation. In addition, the installation of this type of coating will allow you to make the surface smoother. Sheets of the selected material must be laid on the floor, marked according to the required dimensions and cut by sawing.

For fastening to the concrete surface, you will need to use dowels, to the tree - theirs, plus screws.

Multilayer linoleum

This type of linoleum is called warm. This coating is characterized by the presence of a heat-insulating substrate consisting of jute or felt fibers. By choosing such linoleum, you will get rid of the need to equip an additional insulation layer and reduce the amount of costs. The surface to be insulated should be flat and not have noticeable flaws and level drops. The material is convenient and recommended for use in dwellings located on the upper floors of apartment buildings.

Benefits: The material has several layers and can simultaneously serve as a heat insulator and a finishing coating. It is easy to install, the flooring can be done without the use of glue. The coating turns out to be warm, soft, and comfortable to walk on.

The disadvantages are as follows: high level of hydroscopicity - felt or jute substrate absorbs moisture well. It is unacceptable to lay the material where there is a high level of humidity. The multilayer coating is not resistant to mechanical damage and stress. It can quickly deform and lose its original properties and visual appeal.

Cork floor insulation

Cork insulator is deservedly considered the best type of insulation for both concrete and wood floors. It has high thermal insulation properties. The material can be found on the market both in rolls and in panel versions, with various sheet thicknesses.

ATTENTION! Before laying the cork, you will certainly need to level the floor surface. You can use plywood, fiberboard sheets or equip a screed. Between the insulation itself and the base of the floor, you will need to lay a waterproofing layer of polyethylene. The sheets should be tightly butt-to-side, so the coating will be solid and there will be no heat leakage.

Dignity: The material is fireproof and resistant to high humidity. It is produced on the basis of natural raw materials, which ensures high environmental friendliness. A long service life is guaranteed if the installation is done correctly, and the operating conditions meet the standards, the insulation will work effectively for 20 or more years.

Jute underlay for linoleum

For the production of insulation, exclusively natural materials are used, such as linen and wool. The principle of installation of jute covering is similar to laying a cork. It is imperative to provide for the presence of a waterproofing layer. The most commonly used plastic wrap. For concrete substrates, liquid waterproofing can be applied. A brush is used for this.

Advantages of jute insulation: It is lightweight and easy to install. The material is environmentally friendly and resistant to the influence of aggressive substances.

Disadvantages: Differs in a high level of cost. It is easily deformed in places of high traffic or from furniture standing on it, it becomes uneven and loses its appearance.

Extruded polystyrene foam

This material makes it possible to insulate all types of floors, both in apartments and in a private house.EPPS is distinguished by its porous structure, which determines its insulating properties. It is produced in the form of sheets.

Installation is carried out either on the surface itself, or logs are equipped, between which sheets of insulation are tightly laid. The plywood sheets laid on top will provide the necessary level of rigidity for further laying of linoleum.

Advantages: Foamed extruded polystyrene is versatile. It can be placed on both concrete and wood floors. It is resistant to possible deformations, is not afraid of moisture, does not support the development of molds. It has a long service life and is inexpensive.

disadvantages: Requires arrangement of a screed layer or installation of a lag, which reduces the usable area. With a standard ceiling height in an apartment of 2 meters 70 centimeters, the installation of such a coating is not very practical.

Insulation of the floor with a cork

Cork roll

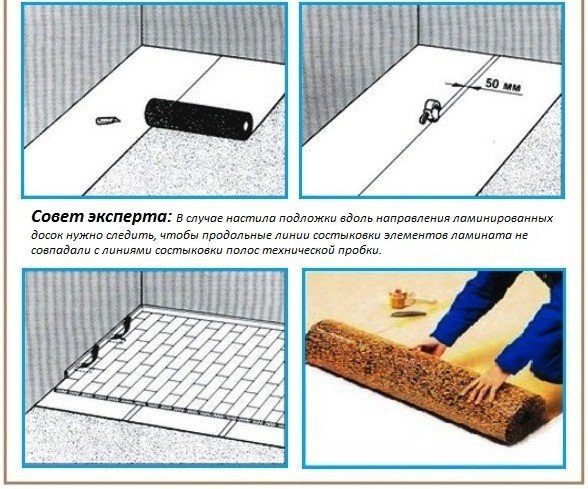

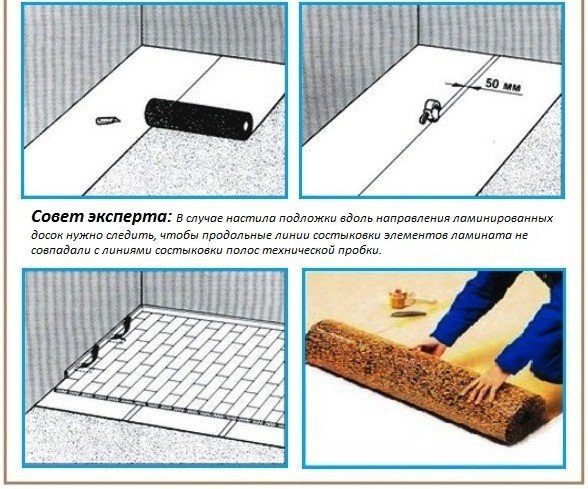

Cork is made from the bark of a cork tree and is considered an environmentally friendly product. Installation is carried out in two ways:

- By floating method. The roll material is rolled along the surface joint to joint. The sheets are connected with construction tape.

- With glue. When laying cork boards. Cork flooring can also be used as a finishing floor.

Video: installation of a cork backing

Pros:

- Naturalness of the material.

- High sound and heat insulation.

- Wear resistance.

- Resistant to moisture.

- Can also be used for laminate and carpet.

Minuses:

- High price.

How to insulate the floor: the order of work

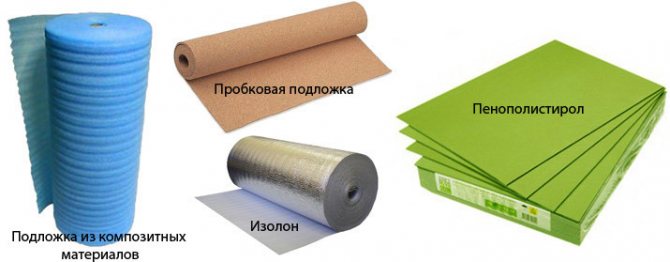

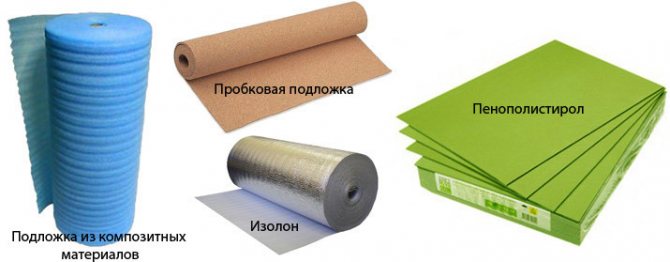

Types of substrates for linoleum.

If you have decided to make your floor, on which the flooring has already been laid, warmer, then before starting work you will need to remove it and inspect the floors under it. If the board is well preserved, is not rotten and there is no mold, you can start to work on insulation.

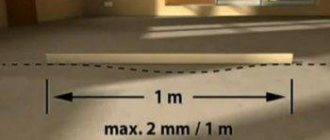

Decide on the height to which you can and want to raise the floors, do not forget to pay attention to the doors, so that in the future there will be no problems with opening and closing.

You can start by laying the linoleum underlay. If you are a connoisseur of natural materials, then when choosing a substrate for linoleum, pay special attention to the base of bundled fibers, which is a natural and environmentally friendly material. But it is worth considering the fact that such a base is considered short-lived, it will gather dust and wear off quickly enough, and besides, moths and other insects often start in it.

This problem can be solved with the help of foam or izolone, such a material has a foil on one side of it.

Laying the underlay under the laminate along the direction of the boards.

Before you cover it, you need to cut it into pieces of the size you need, after that you can lay it out on the surface and fasten all the joints with tape.

Next comes a layer of plywood sheets, which must be fastened between the foam or isolon and the plywood with screws or self-tapping screws. It will contribute to the hardness and rigidity of the surface, and will not allow the flooring to fall through.

If you are satisfied with plywood as a heater, then you can stop at this, only you will first need to apply special glue or mastic to the plywood, with the help of which it will be glued to the inside of the linoleum and will not allow it to slide and slide out in the future.

The procedure for laying fiberboard under linoleum.

It is very good to achieve warm floors by resorting to the help of extruded polystyrene foam (foam), of course, it is intended for external cladding of buildings, because it will emit vapors that contain harmful substances and have a bad effect on your health and your family members.

Related article: Do-it-yourself installation of an entrance metal door: instructions, photos, videos

They also use fiberboard as insulation, which will also allow this flooring not to protrude and fall through, such material is very tough and even. It is important to carry out waterproofing so that it does not swell in the future.

For this, it will be sufficient to lay a plastic film under it, and it is important to putty (prime) the fiberboard layer in advance. Next, you need to cover another layer of polyethylene from the top side.

To get rid of moisture penetration down, you can use special skirting boards for rectangular linoleum.

Seal all joints well, if possible, purchase flooring sheets of such a width that they do not have joints.

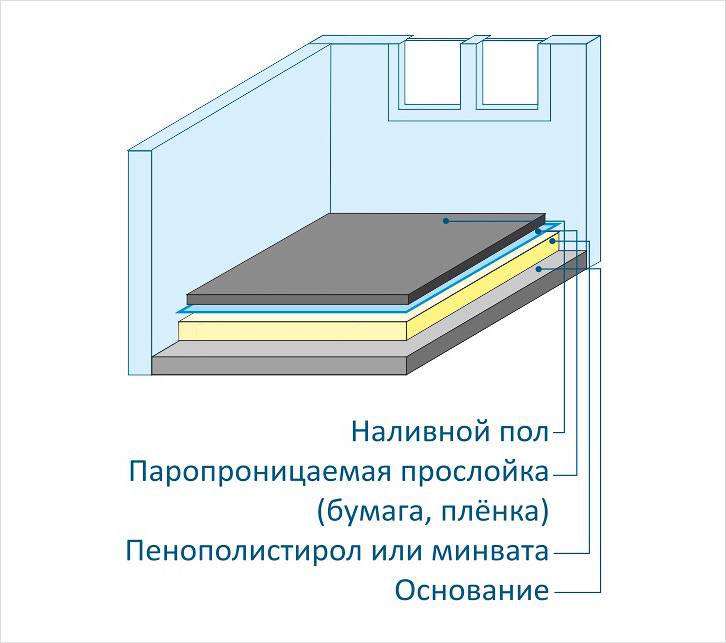

Expanded polystyrene for linoleum

Floor insulation scheme with expanded polystyrene

Expanded polystyrene has a porous structure, which is a great advantage.

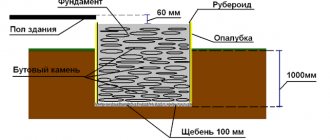

Method of installing expanded polystyrene under the screed:

- Expanded polystyrene can be laid on concrete or ground. When laying on the ground, the surface is covered with crushed stone and sand in layers of 10-15 cm.

- Expanded polystyrene plates are laid out.

- Beacons are being installed.

- A screed with a thickness of 5–8 cm is poured.

Expanded polystyrene plates can be fixed with nothing

Benefits:

- High thermal insulation.

- Durability;

- High heat and sound insulation.

- Security.

No waterproofing required

Disadvantages:

- Flammable material.

- Poor air permeability.

- Housing for rodents.

Video: floor insulation with expanded polystyrene

Insulation for linoleum on a wooden floor - All about insulation and energy efficiency

Over time, wooden floors lose their original appearance, the boards deform, and gaps appear between them.

Such a deteriorating coating ceases to retain heat and requires mandatory repair and insulation.

Many homeowners prefer to lay linoleum on top of the boards, but it does not solve the issue of insulation if the wooden base is not properly prepared.

Laying linoleum on a wooden floor

Laying linoleum on a wooden floor is the simplest solution to tidy up the interior of the room. But in order for the renewed floor to serve for a long time, the work process must take place in stages, in compliance with all the rules and technological recommendations.

Before buying linoleum as a new flooring, you need to find out which type is optimal for wood flooring.

Positive qualities of the material

Linoleum has always been popular as a topcoat for floors with any base. This is a consequence of its numerous advantages over other materials.

The following properties can be safely attributed to the positive qualities of linoleum: durability and elasticity, water resistance and strength, a variety of shades and patterns, simplicity and speed of installation, which can be done independently, without calling and paying specialists, and, of course, an affordable price, which for many it is a decisive factor when choosing.

Covering the floor with a jute backing

Jute backing for linoleum

Jute backing consists of primary refined fiber.

Pros:

- Naturalness.

- Heat and sound insulation.

- Coating strength.

- Smoothing out concrete imperfections.

- Durability.

- Easy to install.

Minuses:

- Expensive.

- Sagging under the influence of heavy objects exerting a load over time.

Foamed polyethylene: insulation under linoleum

Foamed polyethylene

Foamed polyethylene has a closed-porous, lightweight and elastic structure. A certain degree of insulation can be provided by dense and fairly thick types of foamed polyethylene. If you buy an inexpensive thin substrate with large cells, it will not cope with the tasks assigned to it.

Pros:

- It is not toxic.

- Moisture resistant.

- Easy to install.

Minuses:

- May wrinkle under load.

- Only dense and thick types of substrate can be used as insulation.

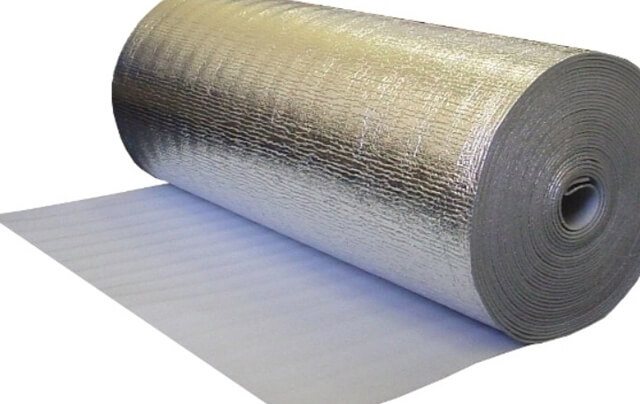

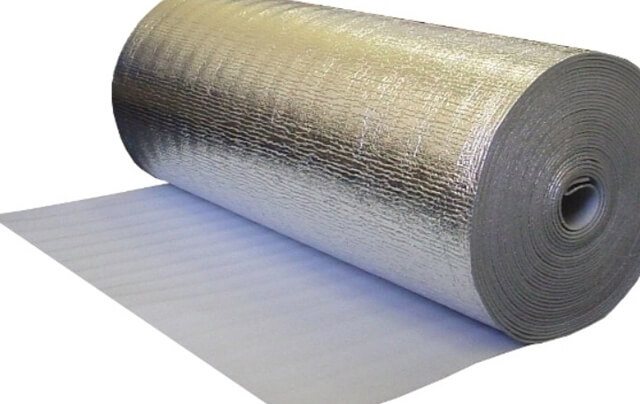

Foil insulation

Foil insulation consists of a foam base and a reflective foil surface.

The installation technology is very simple. The material is rolled over the surface. The joints are sealed with aluminum tape.

Advantages of the material:

- Reflectivity.

- Resistant to temperature extremes.

- Easy to install.

Disadvantages:

- Cannot be used for finishing with building mixtures.

- Additional insulation is required.

Insulation types

You can use the following types of insulation to insulate the floor under linoleum:

- penoplex;

- isolon.

Insulation penoplex

stands out for its strength and long service life. This material is often used to insulate various surfaces. The thickness of these slabs is small, so the rise of the floor level occurs to an insignificant height (for more details: "How to insulate the floor with penoplex - proven methods").

This insulation for linoleum on a concrete floor has a significant advantage - ease of installation, if necessary, you can cut it with an ordinary knife. Among heaters it is most popular; floor insulation in a private house is most often done with this material.

Izolon

Is a closed cell polyethylene foam. Possesses excellent characteristics:

- high rates of thermal insulation;

- vapor barrier qualities;

- waterproof;

- safe;

- durable.

In addition, the cost of isolon is low.

There are two types: non-foil and foil-lined insulation for linoleum.

Thermal insulation paint for insulation

Heat insulating paint

The components of the paint are: water, acrylic dispersion, additives of glass fiber, perlite, foam glass or ceramic microspheres.

Paint is applied to the surface with a thickness of 2–4 mm with a spray gun or a paint brush. The thickness of the paint layer affects the effectiveness of the thermal insulation.

Pros:

- Resistant to high temperatures and atmospheric influences.

- Low heat dissipation.

- Ability to last up to 50 years.

- Does not require special equipment for application.

- Thermal insulation.

- Corrosion protection.

- Fire resistance.

Minuses:

- Cannot be used as a primary heat insulator.

- The high price of paint.

Video: technology of using thermal insulation paint

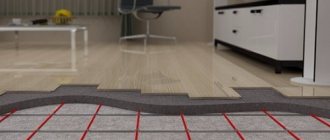

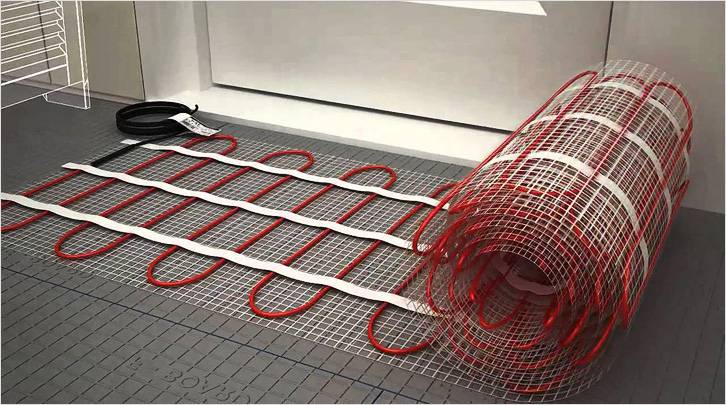

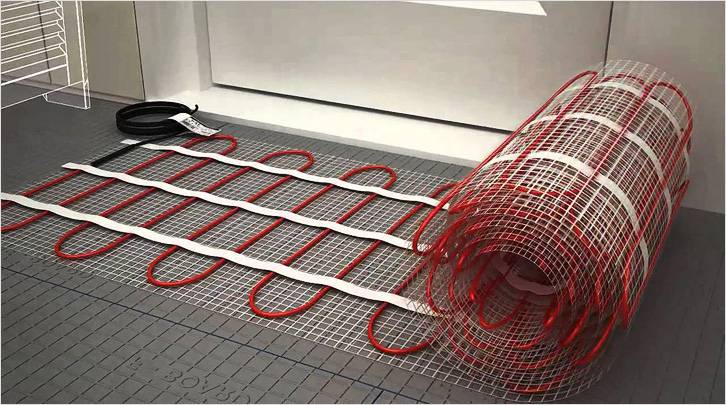

Warm floor

Water heat-insulated floor

In addition to the above options, underfloor heating systems are widely used to insulate cold substrates for linoleum. They can be water or electric. Thanks to such a system, you can provide a comfortable temperature regime.

Advantages of water systems:

- Creation of a comfortable temperature.

- The ability to adjust the temperature.

- Profitability.

- Security.

Disadvantages:

- The possibility of breaking through pipes with a coolant.

- Time consuming installation.

Video: instructions for installing a warm water floor

Electric underfloor heating

Benefits of electrical systems:

- Does not dry the air.

- Warms up quickly.

- Long lasting.

Disadvantages:

- Increased power consumption.

You can use any of the insulation methods you like. Each of the insulation options can be mounted independently. If you have any questions, you can ask them on the site.