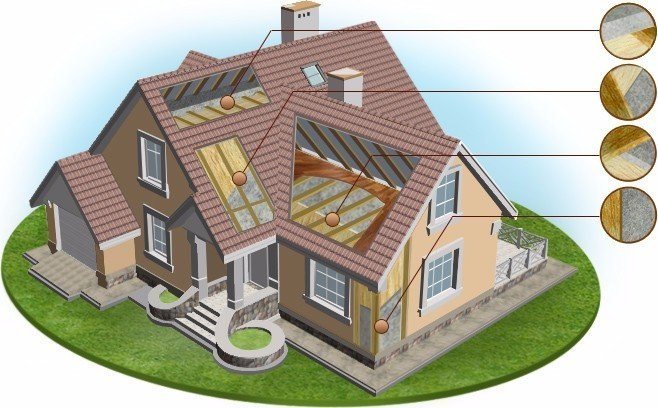

General rules for thermal insulation

In order to properly insulate a wooden outbuilding, certain rules are followed.

- First, we prevent heat loss through the roof - we cover the structure with a special film. Only then can the roof be laid in the form of corrugated board or ondulin.

- To increase heat resistance, MDF panels are used, installed on special profiles. Fill the free space with a heat insulator of your choice.

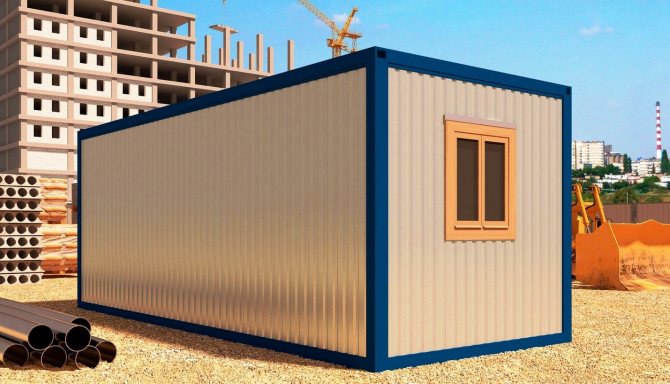

Change houses made of metal are highly resistant to mechanical and other influences. The metal frame is completely protected from moisture by a special flooring. But the roof of a farm building is often subject to corrosive processes. To prevent corrosion, it should be treated with a polymer-based coating or paints and varnishes.

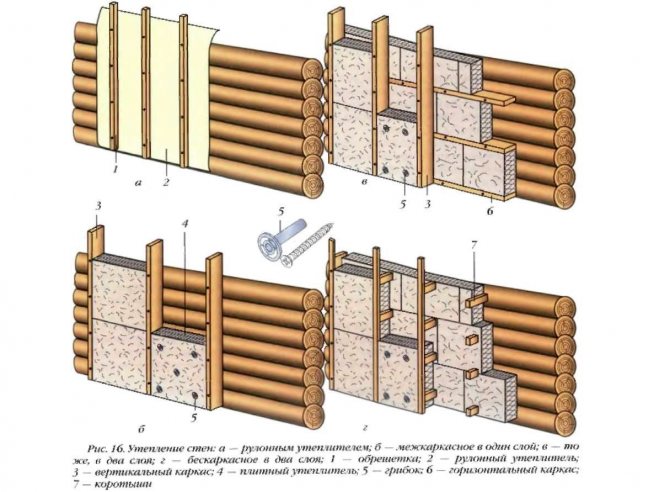

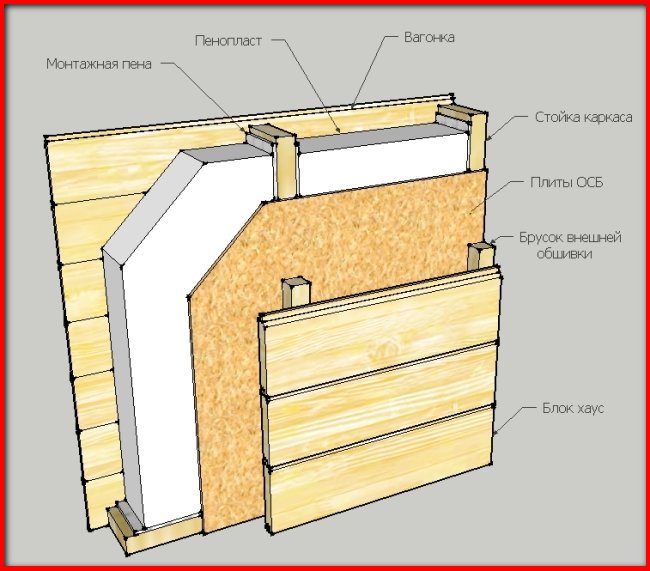

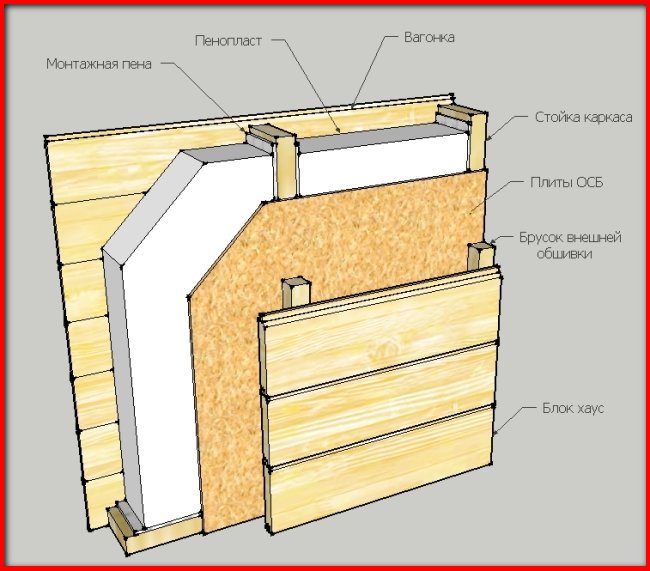

Wall structures are sheathed with clapboard, block house or plastic panels. Thermal insulators are mineral wool or polyurethane foam. To prevent heat loss, slots and joints are sealed with a tongue-and-groove board. Combined outbuildings are insulated in the same way.

Where to start insulating a change house

If you are just going to purchase a change house for winter living, then first of all you need to pay attention to the material from which the structure is made. There are three main types of cabins: metal, wooden and combined.

- The metal structure is a frame sheathed with profiled galvanized iron. The design is resistant to moisture penetration and therefore exhibits better heat retention properties.

- The wooden change house is very vulnerable to the penetration of cold and moisture into the room, therefore it requires more thorough thermal insulation.

- The combined change house is a structure made of several materials. It is necessary to make insulation taking into account the material of the change house in its individual areas.

Floors insulated with expanded clay

The method described above is not suitable for warming the floors of the change house with expanded clay, since the thickness of the heat-insulating layer is limited by the height of the beams (10 cm). Expanded clay must be poured three times more in order to get a good effect. To achieve this, it is necessary to use the space between the change house and the ground, formed after the installation of the structure on a columnar foundation.

When the distance from the ground to the floor of the change house is 30 cm or more, then this cavity can be completely covered with expanded clay. The side gaps under the structure are sewn up with any suitable material that keeps the insulation from spilling. Before filling on the ground, you need to lay a waterproofing layer of roofing material, and cover the improvised basement from the inside with a waterproofing film.

After backfilling with expanded clay, it is not necessary to arrange a subfloor, it is enough to lay and hermetically glue a vapor barrier film, and then lay a finishing coating. As a vapor barrier, you can also use thin foil insulation made of foamed polyethylene, laid end-to-end with gluing with aluminum tape.

What are the cabins

A foundation is not needed to install a wooden change house.

Change houses, insulated for a summer residence, differ both in the material of manufacture and in their design. They are united by one feature - this is the lack of a foundation. In some cases, contractors offer to install a change house on a pile foundation, but often they are placed on low pads. The main thing is that there are no distortions, everything must be done according to the water level.

Wooden cabins insulated for summer cottages are:

- shield;

- frame;

- from a bar;

- from a log.

Cabins for summer cottages made of metal are either a container or a trailer; there are even cabins from old buses. Sometimes the possibilities are limited only by imagination. Such mini-rooms are needed for storing inventory, in order to change clothes and keep warm. Change houses are often equipped with heating. In this capacity, electric heaters, stoves and stoves, gas or liquid fuel heaters are suitable.

The change house, insulated, with a stove, can be operated without problems in winter.

It is an integral part of any construction site. In it, workers not only change clothes and have lunch while on business trips, they live there. Of course, the lack of water, sewerage and a bathroom cannot but create inconveniences, but in the absence of an alternative, the winter insulated change house is quite suitable for temporary residence. If the size allows it, it can be divided into several rooms, in which it is quite possible to create minimal amenities.

Insulation materials

A change house without insulation will not fulfill all the functions and tasks for which it is intended. Therefore, you should carefully consider and select the insulation technology, as well as choose a suitable insulator.

The modern market provides a variety of thermal insulation materials. Let's consider the most common in detail.

Styrofoam

Such a heat insulator is mainly used to insulate the walls of outbuildings. Foam insulation is beneficial when decorating cabins made of wood. The material is resistant to moisture, simple and easy to install. Foam insulation has disadvantages: a short service life and a large volume for good insulation, and with low-quality products, significant heat loss. Several layers of foam will reduce the area of the room, and improper operation of the structure will lead to a fire.

Mineral wool and fiberglass

The advantages of materials are considered fire safety and excellent thermal insulation characteristics, while observing all the requirements of the technological process. If you mount several layers of heat insulator, then the acoustic properties of the rooms will increase. Disadvantages - the constituent components are harmful to health.

Basalt slabs

Such fibers are made by careful processing of basalt rocks. On the construction market, slabs are a common form of material, which can be easily cut to size and laid. The heat insulator is completely resistant to fire and does not lend itself to deformation processes for a long time. The easy-to-use material will not take up a lot of free space, so the area of the cabins will remain almost the same. The disadvantage is called the many seams that remain after the installation of thermal insulation.

Cotton thermal insulator

This substance is the safest for today. It is of high quality and environmentally friendly. It can be used to insulate the walls inside the trailer and does not require special skill during installation. It is often used for thermal insulation of change houses in which it is planned to live. The downside is that the product is hard to cut.

Polyurethane foam

This heat-insulating material is the most widespread and effective for the insulation of utility structures. There are 2 types: liquid and hard. Experts recommend using the second option to increase the heat capacity of the exterior finish of the building. It is great for strengthening roofing systems and outside walls. With the help of the unique structure of polyurethane foam, it is possible to mask possible defects in the roofing system and increase the temperature in the structure.

Step-by-step instructions for insulating a change house

Work can be carried out both inside the trailer and outside. These methods have both positive and negative aspects. Insulation of the change house from the outside will allow you to keep the internal volume in it... It will also protect the walls of the building from external negative factors, which will extend the service life of the trailer. The disadvantage of insulating the change house outside is that then it will have to be trimmed with decorative material so that it looks attractive.

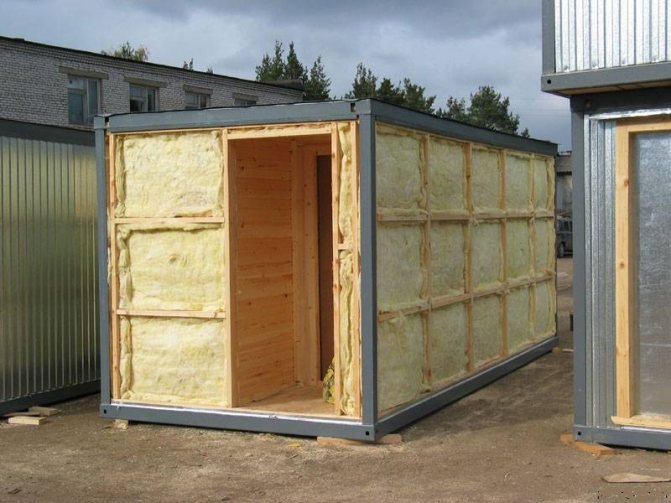

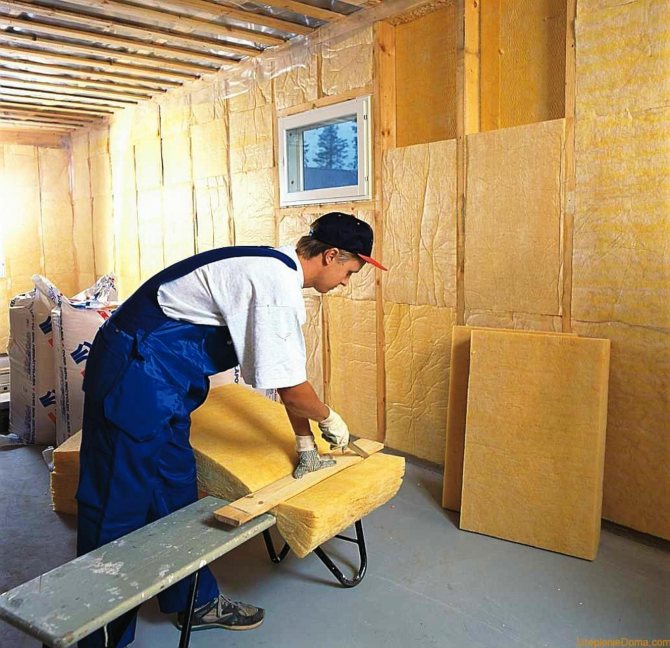

For work inside, it is important to use non-toxic and environmentally friendly materials that do not burn. An excellent option would be to use mineral wool. The installation process consists of the following stages:

- Equipped with a frame on the wall.

- The space between the beams is filled with cotton wool.

- Laying a layer of waterproofing.

- Facing.

Training

You will need to prepare the following materials and tools:

- Steam insulator.

- Minvata.

- Bar.

- Mastic for wood processing.

- A hammer.

- Screws.

- Nails.

Floor insulation

How to insulate the base of a change house with your own hands? For such work, you can use:

- Expanded polystyrene.

- Minvatu.

- Styrofoam.

The instructions say that initially you need to lay a frame made of timber on the floor. Previously, the base will need to be cleaned of dirt. The tree must be treated with antiseptics so that it does not rot and insects do not multiply there. The cells in it need to be made 50x50cm. Insulation is placed in them. A layer of waterproofing is laid on top. Then the surface is covered with boards.

Roof

How to insulate a trailer for winter living from above? Such work is recommended to be carried out outside. To do this, you need to remove the roofing material (slate), lay waterproofing and insulation under it. Then attach the roofing material back.

If it is not possible to do such work from above, then it is necessary to thermally insulate from the inside. To do this, you need to attach beams to the ceiling. Thermal material is placed between them and chipboard is sewn up. It is worth remembering that this can reduce the height of the room.

Frame installation

The walls must first be treated with antiseptics so that they do not rot and rust. It will also help prevent the formation of fungus on the surface. Then slats made of wood are attached to them, to which a heat insulator is mounted with a stapler. The distance between the bars should be equal to the width of the heat insulator.

When carrying out work, it is worth leaving the air vents on the walls at the bottom so that steam does not collect there and condensation does not form. You can also put penofol on top of the insulation, which will create the effect of a thermos in the building.

Window

The windows can be sealed with silicone. To do this, you will have to dismantle the glazing beads and apply a layer of sealant under them. Then the glazing beads are attached in place. This will help keep the room warm. You can, of course, put double-glazed windows.

Materials and methods

Internal or external cladding

There are three ways to position the insulation:

- external,

- interior,

- intra-wall.

The latter is, of course, preferable, but it is possible only in frame structures. In addition, it is advisable to produce it at the construction stage, since dismantling the entire inner lining is very problematic and costly.

If we talk about the remaining two, then it is better to focus on the external location of the thermal insulation, and here's why:

- Firstly, with an internal arrangement, the already limited internal volume of the room will decrease;

- Secondly, the wall structures will not freeze through, which will increase their service life;

- Thirdly, it is undesirable to use many materials for interior work because of their chemical composition and influence on the atmosphere of the room;

- Finally, cladded insulation further protects the walls from weather, corrosion, solar radiation and pests.

Important! It must be borne in mind that the external location of the insulation will require additional cladding with siding, clapboard or blockhouse, and this will require certain costs.

If you do not want to mess with the cladding, or there is no such possibility, you can position the insulation from the inside. In the case of using polystyrene or expanded polystyrene, this completely simplifies the task, since these materials do not need waterproofing and can remain open, but this option is acceptable only as a temporary measure, for example, as insulation of a change house for builders or workers.

Ecowool

If the insulated change house will be used as a country house or other permanent habitat, then additional requirements are imposed on thermal insulation:

- The material must be non-combustible, since otherwise there is a serious danger to the life and health of people, as well as the safety of things and furniture;

- The heat insulator must be non-toxic. The change house will be your bedroom, kitchen and shower at the same time, so it is important that the material does not emit any toxins and chemical compounds harmful to humans;

- The insulation must have a long shelf life. Country houses have been used for years, so it is advisable to use material with an adequate service life.

Best of all, ecowool meets all these requirements - a modern thermal insulation material consisting of 80% recycled waste paper or recycled cellulose, as well as boric acid (12%) as an antiseptic and 7% impregnation with fire retardants.

There are several ways to lay this material:

- Manual;

- Mechanized dry;

- Mechanized wet.

In the case of small volumes (our case), manual stacking is used. This allows you to do the work yourself and significantly reduce costs.

Now about how to insulate a change house with your own hands using ecowool. The installation instructions are quite simple:

- A vertical crate is stuffed onto the wall. Distance between slats - 40 - 50 cm.

- Starting from the bottom, the lathing is sheathed with clapboard to the level 50 cm.

- Ecowool is removed from the package and fluffed up so that its volume is tripled.

- Fluffed cotton wool is poured into the gap between the lining and the wall and tamped down by hand until the material begins to spring.

- Next, the next line of lining is packed, again 50 cm

and the process is repeated. - In this way, the entire wall is closed.

- Lignin, which is part of cellulose, after interaction with atmospheric moisture forms a hard crust that protects the cotton wool from moisture and wind.

Advice! Before installing the lathing, the wall can be covered with a wind barrier, this will also increase the heat resistance of the change house.

Styrofoam

Styrofoam or expanded polystyrene can be glued to the metal on liquid nails, and covered with roofing material on top. As a temporary measure, it is a perfectly acceptable option, and the insulated metal change house is ready.

You can also use this material for interior cladding. You can also use liquid nails for this. After fixing the sheets on the wall, the gaps and gaps between them should be covered with polyurethane foam.

Advice! If there is no foam, you can use scotch tape or electrical tape to isolate the cracks, after having coated the joints with glue.

If we compare polystyrene and expanded polystyrene, then expanded polystyrene will be a more effective material:

- it is stronger;

- has a lower thermal conductivity;

- in addition, the sheets of this material are equipped with locks that will save you from processing the joints with foam.

The price of expanded polystyrene is somewhat higher,

Insulation of the change house outside

Thermal insulation of a structure from the outside can have both pros and cons. The advantage is the preservation of the free space of the room, and the negative is the need to finish the outer part with siding or eurolining.

It can act as a heater Styrofoam

which has a porous structure, light weight and soundproof performance. It retains heat well and is highly resistant to decay.You can also use basalt slabs, slag wool, glass wool. To thoroughly seal the joints and cracks, polyurethane foam is used, which perfectly seals and retains heat in the room.

The order of work

The lag is installed in 2 ways. At the first, the logs are inserted into the grooves of a beam of smaller width, laid on the strapping by the second tier. Then a shelf is formed around the entire perimeter of the change house, where the subfloor boards will subsequently lay. A more popular way is to attach to the strapping beam butt, flush with the top plane. The distance between the lags is adjusted to the width of the slabs of the selected insulation.

The sub-floor does not bear any load and serves for laying insulation. In the first method of installing the lag, the boards rest on the shelves and are nailed. In the second case, the floor is installed in the following order:

Cranial bars are nailed to the beams, flush with the lower plane.

The subfloor boards are laid on the shelves formed.

The areas between the lags are covered with a diffusion membrane, which is aimed at them with a stapler. The membrane indicates which side should face the insulation, do not confuse.

The cavities are filled with insulation and covered with a vapor barrier. Films are laid out over the entire area with an overlap of at least 10 cm and then glued with tape.

To provide a ventilation gap of 2 cm between the film and the floor covering, counter-lattice strips are nailed to the logs from above.

The main flooring is made of boards or chipboard.

The topcoat is laid and the skirting boards are mounted.

During the installation of polymer insulation, all joints and gaps are filled with polyurethane foam, in the case of mineral wool, this is not necessary. Installation of flooring from boards or chipboard is carried out so that there is a small gap between the elements (up to 2 mm), otherwise the floors will subsequently creak annoyingly. The same applies to the ends of the boards adjacent to the walls.

How to insulate a change house for winter living

Temporary often becomes synonymous with permanent, purchasing a change house for the country, you can assume that it will only be needed for the summer season, but in fact it will be needed in winter as well. However, not every house will be cozy during the cold season. That is why, how to insulate a change house for winter living is an important issue that requires consideration. In fact, the correct answer consists of two factors, without each other they will be useless. To live in a shed during the winter cold, you need not only to do insulation, but also to think about heating the structure.

Heating issues

Of course, it is difficult to organize a capital stove in a change house, however, there are several systems that will help make the house much more comfortable and provide a comfortable temperature in it. So:

- Electrical systems. First of all, it can be electric furnaces that have not only suitable power, but also have good fire safety, as well as protection against possible burns. In addition, wall heaters, infrared heaters, electric heat guns are used in change houses;

- Gas systems. This type can work, for example, on liquefied gas from cylinders;

- Heat guns, multi-fuel, diesel, etc.

Having decided which room heating system to give preference to, you can do the second part of the process.

Warm cabins

Our warm cabins

can be used for various cases of doing business: in the construction, trade, in a warehouse. As temporary or permanent housing for employees, as a mobile office or for personal residence. Our

warm cabins

quickly assembled and disassembled, and in order to install them, you do not need to build a foundation.

Warm cabins

allow you to protect your employees and workers from cold weather, makes it possible to organize heating on site and comfortable working conditions in any cold weather.

Insulation of an iron trailer

Before insulating the iron trailer, you need to fix the wooden crate.

Before insulating the iron trailer, the issue of finishing should be resolved. The design of the metal change house is quite simple - it is a frame made of profiled pipes, sheathed with corrugated board or other metal. Finishing needs to be fastened to something, you cannot do without a crate. To do this, you need to securely fasten wooden blocks to the frame made of profiled pipes. Styrofoam is placed between the crate, since it is the cheapest. The foam is attached to metal with adhesive foam, which has good adhesion to almost any surface.

Wall insulation

The cabins are insulated by using the following materials:

- Expanded polystyrene;

- Mineral wool;

- Styrofoam;

- Polyurethane.

The minimum insulation layer should not be less than 50 mm. The thicker it is, the warmer your change house will be. Remember that in addition to a layer of insulation, you need to lay a layer of vapor barrier, usually materials such as glassine or plastic wrap are used for this.

Finnish cabins, as well as other houses with a frame base, are insulated as follows:

- The inner lining of the house is removed, the deterioration of the outer is checked, the general condition of the frame and the existing layer of insulation (if any) is assessed;

- Necessary repairs are being carried out; if required, the outer skin is sealed;

- A waterproofing coating is applied on the inside of the cladding;

- A heat-insulating layer is mounted from the type of insulation that you have chosen. To support it, a lath system is required or it is glue-mounted;

- A layer of vapor barrier made of glassine or polyethylene film is mounted;

- The interior lining is being restored in the room.

When the insulation work is completed, the selected heating devices are installed.

The main methods and their features

There are only three options for insulating such a building - these are:

recommended articles:

- Izospan: versatile insulation material

- Thermal insulation Knauf: application and characteristics of insulation

- application of an internal heat insulator;

- installation of external insulation;

- and placing it in the space between the walls (this option is only possible for frame temporary huts!).

Installation of insulating materials inside the walls is possible only if the change house initially provides for this possibility. It is extremely difficult to change an already finished structure.

Internal insulation reduces the usable floor space. Therefore, this method is not suitable for small buildings. Also, the technical properties of the material do not always allow it to be fixed on the inner surface of the walls. For example, the selected insulation emits harmful substances or is a source of dust.

Insulated change house

External thermal insulation is the best choice for most cases. This method has a number of advantages, such as:

- significant saving of space inside the building;

- providing an additional protective layer outside (bad weather affects the integrity and safety of the entire structure less);

- reducing the likelihood of walls freezing in the cold season;

- environmental safety - no harmful chemical compounds will end up inside the change house.

A significant disadvantage is necessity. The finished layer of insulation must be carefully insulated from any external influences. This point is important to ensure the long-term operation of the material.

Insulation of the building from the inside will be cheaper - here you can use expanded polystyrene or polystyrene (if no one lives in the change house!).The last insulation does not have a long service life and is not suitable for capital buildings that have been used for more than a decade in a row.

Heating shed

The heating of the change house in the cold season is done with devices without an open fire.

Mostly these are oil radiators, closed hearth furnaces and heat guns.

- Heat guns are compact and powerful devices. There are electric, gas, water, infrared, diesel and versatile multi-fuel options.

- The closing oven is safe and economical. Equip it with a protective casing, which improves the conversion of warm air and eliminates heat radiation inside the trailer.

- The oil cooler is energy efficient and has a horizontal position sensor that turns off the device if it falls.

Competent insulation of all elements of the trailer will create comfortable conditions for staying in winter.

How to prepare a change house for winter

A summer cottage, when carrying out competent insulation and the presence of heating, may well be suitable for living in the winter.

How to prepare a change house for winter correctly:

- Floor insulation on sub-floors;

- Insulation of the ceiling base;

- External wall insulation;

- Replacement or improvement of the construction of windows.

As practice shows, the weakest link in the change house is the floor.

Therefore, even during construction, it is important to correctly determine the foundation (it is necessary, to put the change house on the ground - bad manners and the inability to warm it up normally).

To insulate the floor on rough floors, you will need a wooden beam with a cross section of 50x50 mm, mineral wool, a vapor barrier film, a floorboard and a solution against wood insect pests. Initially, the existing floor base is cleaned of dust and a protective emulsion is applied. Also, the entire wooden beam is processed in parallel with the solution. When the floor base dries well, a vapor barrier film is spread on it with the glossy side away from you. Further, stepping back from one of the walls of the change house 10-15 cm, parallel to the wall, the first beam is mounted on top of the film on self-tapping screws.

Having mounted the first beam, 100-120 cm recede from it and the second and all subsequent beams are mounted in the same way. At the next stage, the entire space between the beams is filled with slab or roll mineral wool. On top of the mineral wool, on top of all the bars, a second layer of PVC film is mounted with a stapler. The warming of the floor of the summer cottage is completed with padding on the existing beams of the floorboard.

Of course, it is desirable to insulate the ceiling from the outside. That is, slate or ondulin sheets are dismantled, mineral wool is laid and the roofing material is installed in its place. However, if this operation cannot be performed, the ceiling insulation in the cabins is made from nutria. If the ceiling is upholstered with wooden clapboard on a crate made of a bar of at least 50x50 mm, then the space in the crate can be safely used for filling with insulation. But, if there is no cavity in the ceiling base, the ceiling is insulated in the same way as the floor, followed by finishing with clapboard.

When insulating the walls of a summer cottage, work begins by covering the wall planes with an antifungal solution. When the walls dry out on their surface, a 50x50 mm beam is mounted vertically at a distance of 100-150 cm from each other. Further, mineral wool is mounted between the bars with the help of brackets or a raspor. You can, of course, use expanded polystyrene for insulation, but a wooden building "wrapped" in polystyrene can quickly begin to bloom. Styrofoam is great for insulating any walls, except for wooden ones. Having mounted mineral wool, a film is stuffed on top of it and the front board or wide lining is stuffed.

Choice of materials

The height of the wooden logs is selected according to the size of the strapping beam laid along the perimeter of the structure.Usually, when building a change house with your own hands, a beam of 10 x 10 cm is used for strapping, then a 10 x 5 cm board is suitable for the logs. The number of beams depends on the installation step taken along the width of the insulation plates, equal to 600 mm. For the device of the subfloor, you will need 2 x 2 cm bars and the same thickness of a second-grade board or 18 mm OSB plywood.

The material for the flooring is selected based on the living conditions. If the summer cottage is operated all year round and is heated, then it is easier to lay a finishing floor from chipboard sheets, on top of which any coating is laid - from linoleum to laminate. For summer living, planed boards and simple linoleum, not afraid of moisture, will have to be laid on the logs.

The overlap is insulated with the following materials to choose from:

expanded clay;

mineral wool in slabs or rolls with a density of up to 80 kg / m3;

foam plastic with a density of 25-35 kg / m3;

extruded polystyrene foam 30-40 kg / m3 density.

Each of the heaters has its own pros and cons. Minvata needs protection from moisture and good ventilation to remove it, but it does not burn. Foamed polymers are not afraid of moisture, but they are flammable, and mice eat foam. Expanded clay is cheap, but has low thermal insulation properties, it must be covered with a thick layer (from 30 cm).

For the device of hydro and vapor barrier, special films are required. Waterproofing is done with a diffusion membrane that allows steam to pass through but repels water. Its task is to protect the floors from wind and moisture from below, allowing the steam that forms in the "cake" of insulation to escape. Vapor barrier is a film that prevents steam from penetrating inside the "pie" from the premises.

Insulation of a wooden change house for a summer residence

It is better to insulate wooden cabins with mineral wool, as it allows the wood to breathe.

Insulated cabins for summer cottages are on sale, their price starts from 20 thousand rubles for a room of 1.5 by 2 meters, while thermal insulation is paid separately. Naturally, the larger the area, the more expensive. Making it with your own hands is not so difficult, and even more so to insulate it, so there is no point in overpaying. Regardless of the design, thermal insulation is laid from the inside, only the method differs.

Panel and frame structures are insulated according to the same scheme, since in both cases the thermal insulation is placed in the cavity of the frame. Do-it-yourself insulation of the change house must be carried out with materials that let steam through, since this is important for wood. Any thermal insulation that is applicable for insulating frame houses is suitable:. PPU; penoizol; loose insulation; ecowool; polystyrene in sheets and crumb.

- PPU;

- penoizol;

- loose insulation;

- ecowool;

- polystyrene in sheets and crumb.

Those materials that are afraid of moisture need to be protected with special films (vapor barrier and waterproofing). They must be laid in such a way that the steam from the room does not enter the thermal insulation layer, and the one that nevertheless penetrates could leave the walls without hindrance. Humid air always moves from a warm environment to a cold one, and not vice versa. Carefully look at what is written on the film, it indicates which side it should be laid on. Many films are made in the form of membranes and allow air to pass in only one direction. Incorrect installation is fraught with obtaining the opposite result from the use of protective films.

In addition to wall insulation, work on the floor and ceiling insulation must be carried out without fail, the materials are the same. The only problem that almost all owners of insulated cabins face are mice. I will simply not save from them, especially in such a small area, therefore, perhaps, one should give preference to materials in which rodents do not live.Alternatively, you can insulate with penoizol, but not liquid, but in sheets, so it will be cheaper.

A lot has been said about how convector heaters work, because this method of heating the air is the fastest.

You can read about what is the most compact heater in the room.

A heat gun as a heating device for a change house

It often happens that a change house needs urgent heating due to a cold snap. Temporary housing is not always equipped with oil radiators or convectors, and their frequent use significantly increases energy costs. Heat guns of small sizes are used at the construction site and for change houses. This versatile device can become an alternative to heaters. Heat guns managed to earn respect among consumers, and positive reviews about this powerful, but at the same time compact and inexpensive product persuade us to choose this particular product among others. There are different brands of guns, but their structure and principle of operation remains unchanged, as can be seen from the figures.

Heat guns that heat construction trailers

, differ depending on the source of energy. And they are:

- Electric guns, in which the heating system does not have combustion products. Such a device is lightweight. It is used both in domestic and industrial conditions.

- Gas cannons, which are recommended for indoor use only.

- Diesel and they are applicable only for rooms with good ventilation. There are also indirectly heated diesel devices, which are equipped with closed chambers that allow the removal of combustion products.

- Multi-fuel cannons that are economical because they run on waste oil or a mixture of them. These heat guns are easy to maintain, but very effective.

- Infrared, which uses infrared light as fuel.

- Water. The air is heated by the evaporation of hot water.

The area of application of heat guns divided them into industrial and household guns. The high heating temperature and high power rotation of the fan are provided by industrial devices. They can maintain a constant indoor temperature and humidity.

Nothing is more permanent than temporary. Therefore, warming a change house with your own hands is not only possible, but also highly desirable, because even a short stay in a cold room is fraught with health problems. We will consider how to insulate the change house and how best to do it.

Related work

Reducing heat loss and, as a result, reducing the cost of heating the change house will allow the implementation of additional insulation not only of the ceiling, but also, which is no less important, of the floor and walls. Professional builders also recommend sealing door and window fillings, through which a significant amount of heat is also lost. Only a comprehensive solution to the problem of insulation will lead to the achievement of the necessary energy efficiency and guarantee a positive final result.