Deepening the external sewage system deeper than the level of soil freezing is a troublesome job, especially if the work is carried out in winter. An alternative option for frost protection is a heating cable for sewer pipes. It's worth familiarizing yourself with the peculiarities of its styling, don't you agree?

From the article we have proposed, you will learn everything about the device for cable heating of the sewer pipeline. We will tell you how a heating cable works and how to choose the best option correctly. For independent owners, a step-by-step installation and fastening guide is provided.

Why does the sewer freeze?

The problem of freezing of the sewer pipe is not immediately detected. Unlike water pipelines, here the flow of liquid is not constant and does not completely fill the cross-section of the pipe.

In addition, sewage entering the sewer system usually has a higher temperature than, for example, water from a well. Therefore, the freezing of effluents occurs gradually.

At first, only a small part of the contents of the sewer can freeze, then another layer of frozen sewage appears, etc. Gradually, the entire lumen of the pipe is filled with a dense frozen mass, after which the problem becomes obvious. Faulty plumbing, such as a leaking faucet or cistern, can aggravate the problem.

Small portions of water enter the sewer system, quickly cool and freeze. Even the correct laying of sewer pipes and the presence of a layer of insulation do not always prevent the freezing of drains. Defrosting frozen sewers is troublesome, in addition, this phenomenon can damage the pipes, some of which will have to be replaced.

Freezing of a sewer pipe can occur gradually, layer by layer, and a little leaking plumbing only increases the danger of this unpleasant phenomenon

Therefore, it is recommended to lay the sewage system below the level of freezing of the soil with the obligatory insulation of communications. If in the southern regions and the middle lane digging a sufficiently deep trench is usually not a problem, then in the north everything is a little more complicated. In this situation, the use of a special heating or hot cable is more than appropriate.

When using this type of system, the amount of earthwork is noticeably reduced, since the depth of the trench can be reduced to an acceptable level without worrying about freezing the soil.

Types of sewer pipes that need heating, and the method of heating pipes

The following types of sewer pipes need heating:

- pipes for laying an external sewage system that drain wastewater to a septic tank or to a local treatment plant;

- pipes designed for the drainage of flushing water from cleaning filters;

- pipes connecting a septic tank with a filtration well or drainage fields.

The most commonly used pipe heating methods are as follows:

- heating of sewer pipes using a special cable;

- laying of sewer pipes equipped with a heating system.

How does a heating cable work?

A heating or hot cable is a heating system for pipes laid in the soil. An electric cable in an insulating sheath is fixed to the pipe and connected to the power supply. The pipe heats up, as a result, the wastewater acquires a consistently high temperature, which reliably protects it from freezing.

A distinction is made between a cable for external heating of a pipe or an internal one. The first is laid outside the structure, and the second inside.It is believed that outdoor installation is easier than indoor installation, so it is more in demand. In addition to the outer cable, a heating film is also used.

Heating with a film for sewer systems is not often used. The material has to be wrapped around the entire pipe, which complicates the installation, but ensures uniform heating

The structure is completely wrapped with this material, then it is fixed. The film provides a more uniform heating of the pipe than the cable, it has a lower power, which makes it possible to somewhat reduce operating costs.

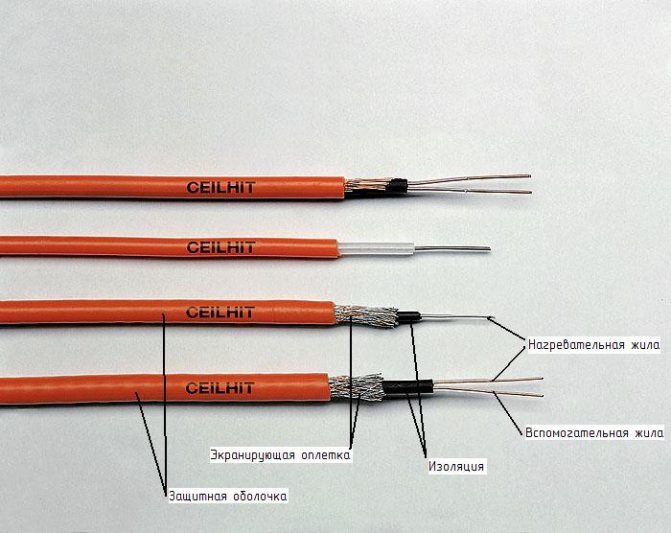

Three types of cable can be used to heat pipes:

- self-regulating;

- resistive;

- zonal.

A self-regulating cable is considered an extremely convenient option, since it can automatically change the heating temperature depending on climatic conditions. The cable resistance decreases as the soil heats up more and increases as the temperature drops.

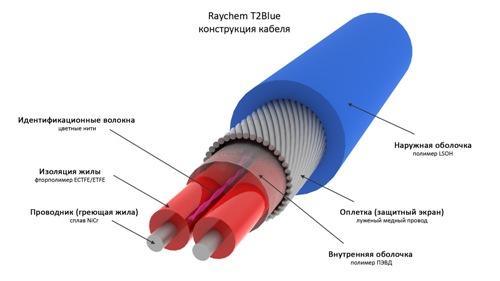

Self-regulating cable is most in demand in modern conditions, since it is easy to lay it, it is more reliable and does not require additional elements for installation

This change in operating mode reduces the overall system power, i.e. allows you to save energy. Moreover, the change in resistance can be different in certain sections of the pipeline. The result is a higher quality of heating, the self-regulating cable itself will last longer, and there is no need to install thermostats.

A resistive cable does not possess such capabilities, but differs in comparison with self-regulating systems at a more moderate price. When installing this type of cable, you will need to install a set of temperature sensors and thermostats to ensure that the system's operating mode changes when the weather changes.

Resistive cable costs less than self-regulating counterparts. If this option is selected, a suitable power density must be carefully calculated to prevent overheating.

If this requirement is neglected, the risk of cable overheating and breakage increases. The zone cable also does not have the ability to regulate the resistance, but this system does not generate heat along the entire length, but only in certain sections. Such a cable can be cut into separate fragments, which is convenient when installing pipelines of complex configuration.

It is also widely used in the installation of metal sewers or for heating tanks. It should be noted that heating structures buried in the ground is not the only area of using the heating cable. It is also used to heat pipes laid on the surface or in rooms that are not heated.

Sometimes the cable is used only for certain sections of the pipeline, for example, parts that come to the surface. Systems that are mounted inside a pipe are relatively rarely used. They are most often used if the pipeline has already been laid in the ground and the installation of the external cable would require extensive earthwork.

So the installation of the internal cable will be much cheaper. But such cables are usually recommended to be used only inside small-diameter pipes, since they have low power.

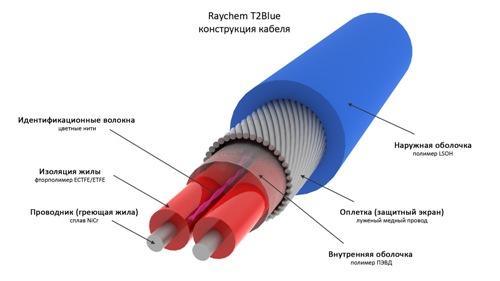

It varies in the range of 9-13 W / m, which is usually not enough for large sewer pipes. The length of such a cable, for obvious reasons, should be equal to the length of the pipe. The internal heating cable is manufactured only of the self-regulating type.

Heating cable reliability

The reliability of a self-regulating cable directly depends on the quality of the heating matrix (semiconductor material between conductors). The lower the quality, the faster it ages - as a result, the specific heat generation and self-regulation decrease. The service life of such a low quality matrix is 3-4 years.

Proven manufacturers that care about their reputation such as Fujikura, Pentair, Devi, Hemstedt use quality materials for production. This, of course, translates into a higher price, but its operation throughout its entire service life (15 ... 20 years) is worth it.

How to find the right cable?

When choosing a suitable hot cable, it is necessary to decide not only on its type, but also to choose the right power for it.

In this case, it is necessary to take into account such parameters as:

- the purpose of the structure (for sewerage and water supply, calculations are performed in different ways);

- the material from which the sewerage is made;

- pipeline diameter;

- features of the site that is supposed to be heated;

- characteristic of the used thermal insulation material.

Based on this information, heat loss is calculated for each meter of the structure, the type of cable, its power is selected, and then the appropriate length of the kit is determined. Calculations can be performed using a special formula, according to calculation tables or using an online calculator.

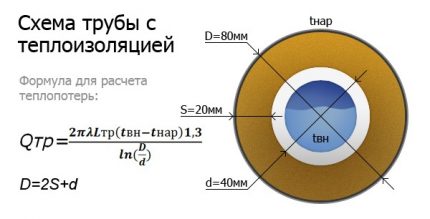

The calculation formula looks like this:

Qtr - pipe heat loss (W); - coefficient of thermal conductivity of the insulation; Ltr - the length of the heated pipe (m); tвн - temperature of the contents of the pipe (C), tout - minimum ambient temperature (C); D is the outer diameter of the communications, taking into account the insulation (m); d - outer diameter of communications (m); 1.3 - safety factor

When the heat loss has been calculated, the length of the system should be calculated. To do this, the resulting value must be divided by the specific power of the heating device cable. The result should be increased, taking into account the heating of additional elements. The power of the sewer cable starts from 17 W / m and can exceed 30 W / m.

If we are talking about sewer pipelines made of polyethylene and PVC, then 17 W / m is the maximum power. If you use a more efficient cable, then there is a high probability of overheating and damage to the pipe. Information on the characteristics of the product can be found in its data sheet.

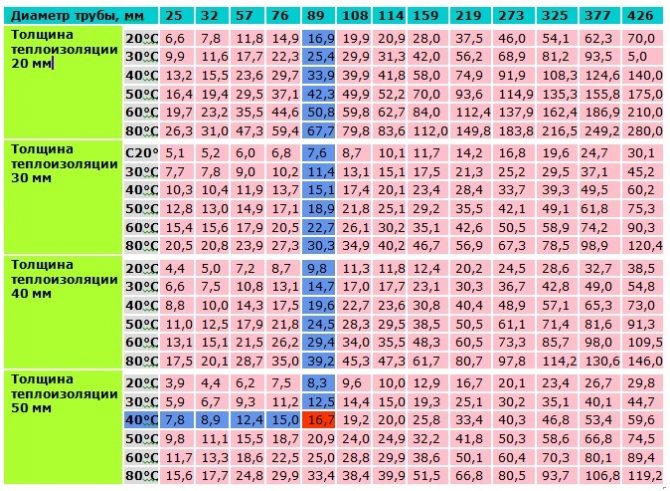

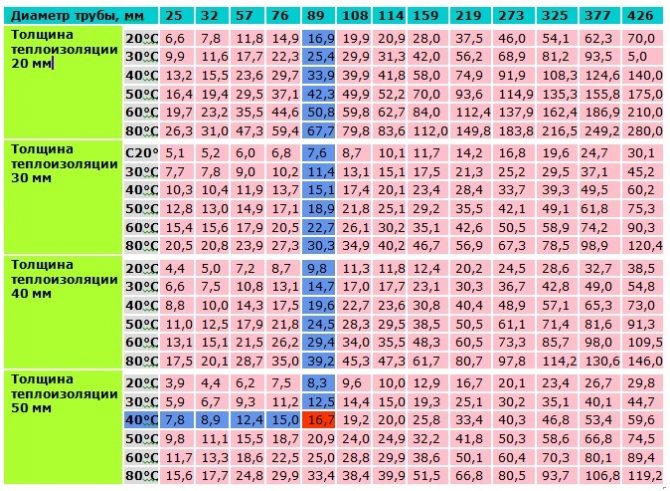

Using the table, choosing the right option is a little easier. To do this, you first need to find out the diameter of the pipe and the thickness of the insulation, as well as the estimated difference between the temperature of the air and the contents of the pipeline. The latter indicator can be found using reference data depending on the region.

At the intersection of the corresponding row and column, you can find the value of heat loss per meter of pipe. Then the total cable length should be calculated. To do this, the size of the specific heat loss, obtained from the table, must be multiplied by the length of the pipeline and by a factor of 1.3.

The table allows you to find the size of the specific heat loss of a pipe of a specific diameter, taking into account the thickness of the heat-insulating material and the operating conditions of the pipeline (+)

The result obtained should be divided by the power density of the cable. Then you need to take into account the influence of additional elements, if any. Convenient online calculators can be found on specialized sites. In the appropriate fields, you need to enter the necessary data, for example, the diameter of the pipes, the thickness of the insulation, the temperature of the ambient and working fluid, the region, etc.

Such programs usually offer the user additional options, for example, they help to calculate the required diameter of the sewer, the dimensions of the thermal insulation layer, the type of insulation, etc.

Optionally, you can select the type of installation, find out the appropriate step when installing the heating cable with a spiral, get a list and the number of components that will be needed for laying the system.

When choosing a self-regulating cable, it is important to correctly consider the diameter of the structure on which it will be installed.For example, for pipes with a diameter of 110 mm, it is recommended to take the Lavita GWS30-2 brand or a similar version of another manufacturer. For a 50 mm pipe, the Lavita GWS24-2 cable is suitable, for structures with a diameter of 32 mm - Lavita GWS16-2, etc.

Complex calculations will not be needed for a sewage system that is not often used, for example, in a summer cottage or in a house that is used only occasionally. In such a situation, they simply take a cable with a power of 17 W / m with a length corresponding to the dimensions of the pipe. A cable of this power can be used both outside and inside the pipe, and it is not necessary to install a gland.

When choosing a suitable option for a heating cable, its performance should be correlated with the calculated data for the probable heat loss of the sewer pipe

For laying the heating cable inside the pipe, choose a cable with special protection against aggressive effects, for example, DVU-13. In some cases, the Lavita RGS 30-2CR brand is used for indoor installation. This is not entirely correct, but a valid solution.

Such a cable is intended for heating a roof or storm sewer, therefore, it is not equipped with protection against corrosive substances. It can be considered only as a temporary option, because if used for a long time in unsuitable conditions, the Lavita RGS 30-2CR cable will inevitably break.

Rules for installing cable on pipes

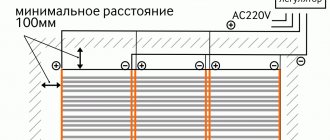

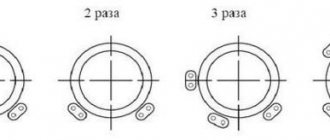

Heating cable installation is a relatively straightforward process. It is simply fixed to the surface of the pipe, usually lengthwise, in one strip. Separate projects include spiral mounting. In this case, it is necessary to accurately maintain the calculated pitch between the turns of the spiral so that the pipe warms up evenly.

After the heating cable is fixed to the sewer pipe, it is recommended to additionally install a layer of thermal insulation in order to improve the quality of heating.

The intersection of individual sections of the heating cable is not allowed. The cable, depending on the type, is fixed with heat-resistant adhesive tape or mounting ties. The distance between the attachment points must be at least 200 mm. To fix the cable in a mineral sheath, metal fasteners are used: tightening tapes or a special bandage.

But most often I still use heat-resistant tape. Fasteners must withstand not only high temperatures, but also be resistant to the influence of natural factors and chemicals. Sometimes aluminum tape is used as an attachment. But in the places of attachment, the thermal power of the cable will increase.

This is not always useful, it can lead to overheating of communications. It is not recommended to use metal fasteners when installing a heating cable enclosed in a polymeric insulating sheath. But in some cases, aluminum tape can even improve the situation.

The heating cable on a plastic sewer pipe can be secured with aluminum tape to increase the heating efficiency and make it more uniform

When laying on a polymer pipe, metallized tape is placed both under the cable and above it. This slightly increases the heat output, and also contributes to uniform heating of the pipeline. Inside the sewer, the heating cable is rarely used.

Usually, small areas of the system that are not in the ground are heated in this way, for example, sewer pumps that stimulate the movement of drains if natural movement is difficult or impossible.

For the installation of the internal cable, you may need a clamping and sealing sleeve, a joint sleeve, a set of washers, and other elements (+)

To install the inner cable into the completed pipe, you will first need to cut a tee into the system. This will make a hole for inserting the cable into the pipeline.

In addition, a special nipple sleeve may be required. Such a solution may slightly worsen the characteristics of the sewer system, for example, at the point where the tee is installed, the pipe clearance will slightly decrease.

This increases the likelihood of debris build-up and blockages. Difficulties with the internal cable are inevitable if the pipeline has several bends, bends, etc. It is not easy to carry out internal work on the installation of a hot cable, as well as in sewer systems of considerable length.

Of course, you should not connect the system to the power supply until the installation work is complete. Before covering the cable with insulation, you should carefully check all the connections. If you use thermal sensors, it will be easier to determine the time of activation and deactivation of the system.

You can automate the process using a relay. If the power of the cable laid in one line is not enough, you can perform a spiral installation or lay two parallel lines. The main thing is that individual sections do not intersect, and there is no overheating. To make the heating of the structure more uniform, sometimes the pipe is first wrapped in foil, then a cable is placed on top.

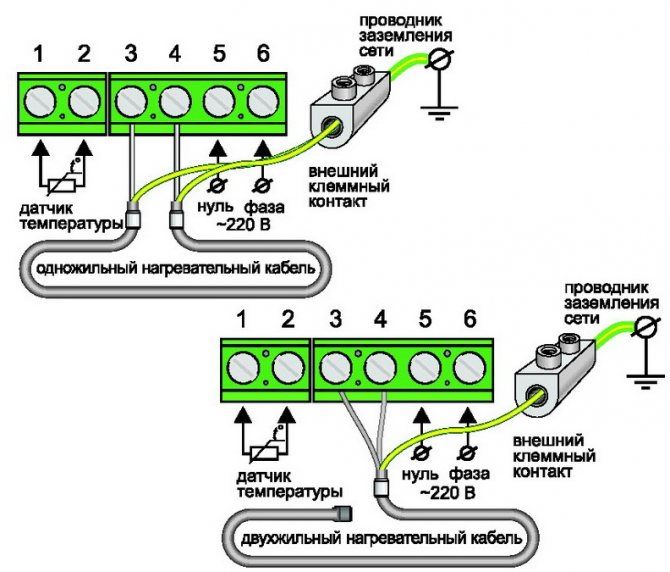

These examples allow you to get an idea of how to correctly connect the supply and heating cable, as well as the order of its insulation (+)

Temperature sensors are installed after the insulation is supplied. Above it is recommended to apply markings that reflect the position of the heating elements. To connect the heating cable to the mains, you will need a piece of heat-shrinkable pipe. Then, about 50 mm of insulation and 10 mm of braid are removed from the edge of the cable.

The separated and stripped ends are protected with pieces of heat-shrinkable tubing of a suitable diameter and heated with a hairdryer. Now you need to strip about 6 mm of the wires, turn them into a spiral and clamp them in a metal tube. Similar manipulations will have to be done with the power cable.

About 80 mm must be stripped of insulation and sheathing and divided into separate wires. The resulting ends are trimmed to 35 mm, but one wire should be left uncut for grounding. 6 mm wires are also stripped here.

The ends of the heating elements and power cables are now connected in a heat shrink tubing fitted with a metal sleeve. It is heated and clamped, the place of contact is wrapped with thermal tape, and then closed with another protection tube.

The following article will acquaint you with the features of the choice of pipes directly for the device of an autonomous sewage system, with the content of which we advise you to familiarize yourself.

About insulated pipes

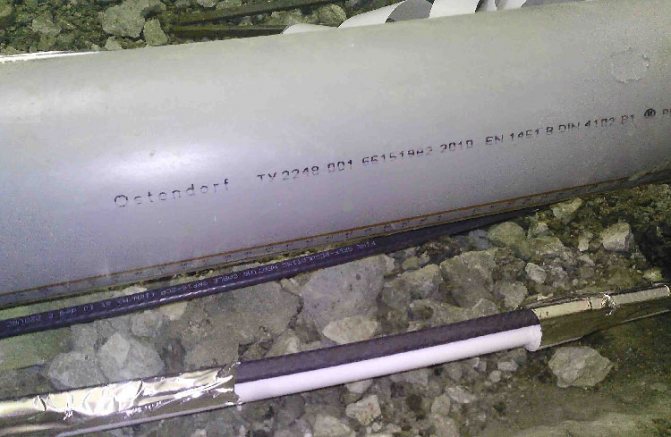

Another modern solution, not only in ensuring sewage insulation, but also in maintaining the temperature of hot pipelines, is the installation of factory-made heat-insulated pipes with heating.

The sandwich system of such pipes includes a plastic pipe directly, equipped with a self-regulating cable system and reliably hidden under a layer of heat and waterproofing material.

Ready-made sewer pipes with heating will allow you to get rid of the laborious self-installation of the system and will provide much greater reliability and durability.