Optimum temperature parameters

Setting up a water floor heating is carried out depending on individual needs. Someone likes it when the room is warm, while someone prefers invigorating freshness, even in the most severe frosts. But despite this, there are general standards that were developed taking into account sanitary standards, these include:

- floor heating up to 28 degrees;

- in the presence of another source of heat or when living in the room all the time, the ideal level from 22 to 26 is the optimal conditions for a person;

- if this type of heat source is the only one, or it is in the bathroom, corridor, on the balcony, or in a house where they do not live permanently, it is permissible to raise the degree to 32.

Therefore, when regulating water floors, in addition to your preferences, so that the microclimate in the apartment is healthy, these standards should be taken into account.

Thermostats - types of devices

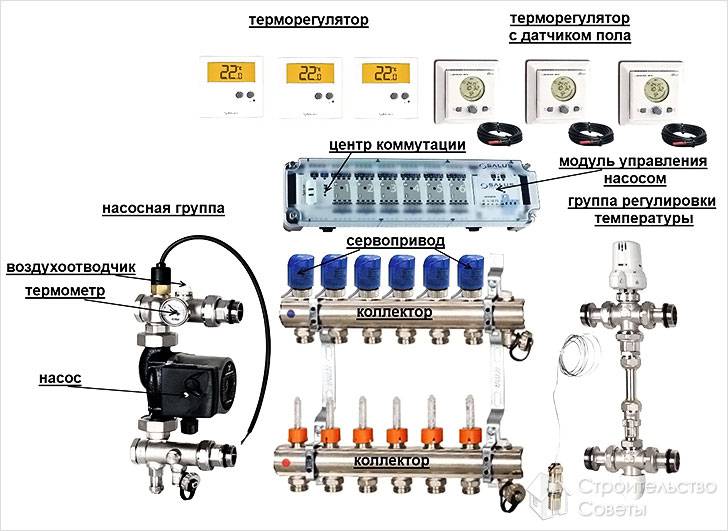

The water floor is a fairly sensitive system. The degree of heating of the coolant, the rate of water supply to the heating circuit and the intensity of the circulation of the coolant are the parameters that determine the efficiency of heating.

From a technical point of view, thermostats are devices that ensure the implementation of certain mechanical actions as a result of a reaction to changes in the set temperature parameters. Thermostats solve the following tasks:

- automated switching on and off of the heating system;

- control and maintenance of the set temperature inside the room;

- programmable devices provide heating at a certain time;

- control over the degree of heating of the coolant provides energy savings.

On a note: in practice, it has been noticed more than once that the installation and adjustment of a thermostat in a room for warm floors can save up to 20-30% of the blue fuel consumed for the operation of an autonomous boiler.

In practice, the following regulator models are used:

Mechanical devices. This category of devices belongs to the budget options. A distinctive feature of mechanical regulators is their reliability and easy maintenance. Adjustment is carried out by simply turning the dial, which is set at a certain value of the scale. In some cases, the front of the device has a mechanical lever that operates on the open / closed principle. In addition to monitoring the temperature of the coolant in the supply pipe, such devices are not designed to perform other functions.

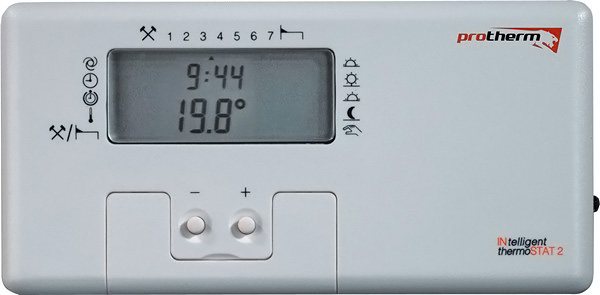

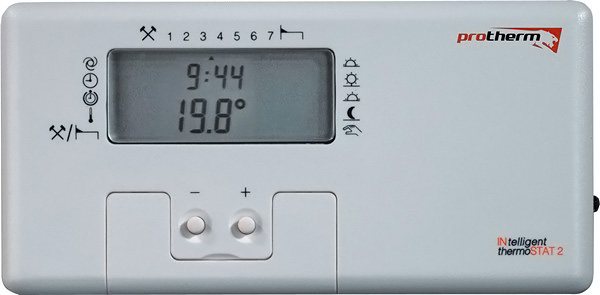

Electronic devices have the same functions, only differ in the way they are implemented. The device is equipped with a screen and has buttons for adjusting. The device displays parameters in real time and programmable data. Push-button control allows you to set the preset parameters and carry out a step-by-step change in temperature.

On a note: electronic devices for adjusting warm floors are three to five times more expensive than mechanical devices.

Among electronic control devices, programmable devices occupy a special place. The presence of software creates conditions for maintaining the temperature of floor heating, temperature conditions inside the room in real time and more. The set temperature parameters and time allow you to change the temperature of underfloor heating over time, adjust the operation of all units and units of the underfloor heating, depending on climatic conditions.

Such functions are very convenient, freeing up a lot of time for the inhabitants of the house. With the help of programmable devices, you can ensure the operation of the heating system in your absence, maintaining a stable and comfortable temperature in the house. Energy saving when using programmable electronic controllers is 25-30%. In modern conditions, when comfortable housing is gaining popularity, programmable regulators are becoming in demand. Such systems can be controlled via mobile devices, remotely. Solving several tasks in a complex at once, regulating the temperature of heating the floor surface and controlling the temperature of the air inside the room, electronic programmable devices are beneficial in all versions. Even taking into account the fact that the cost of these devices is quite high.

Evaluating the types of appliances used in adjusting warm floors, some conclusions can be drawn. In each individual case, one should start from what tasks the regulator should solve.

Connection diagrams

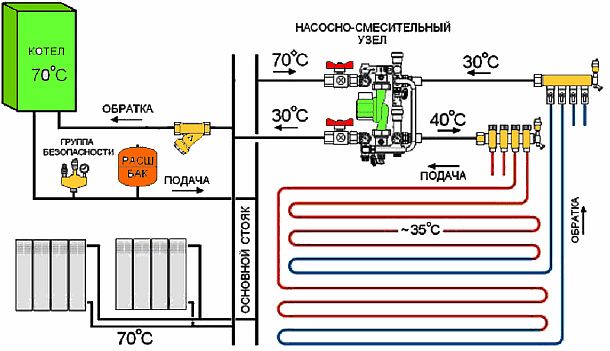

A water-heated floor often acts as an additional source of heat. It is mainly combined with a general heating system or hot water supply. It is on the connection method that the features of adjusting warm floors depend.

There are several schemes for connecting water heating devices.

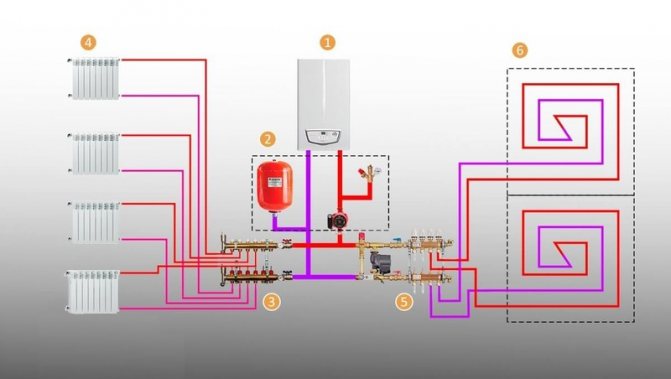

Combined

A popular and technologically sound method is combined heating, which includes a radiator and underfloor heating system. However, to equip this structure, we need:

- boiler;

- pump;

- expansion tank;

- collectors for radiators and underfloor heating;

- radiators;

- pipes.

It is important to combine different heating devices correctly in order for them to function effectively. The main ways of connecting radiators with warm water floors into a single structure:

- Parallel connection of the manifold unit to the heating system. The circuits are cut into the line to the batteries. The circulation of the liquid is provided by a pump.

- Connection by rings, primary or secondary. The pipeline, when laid, forms rings, they cut into the supply system in several places. The coolant temperature depends on the distance between the coil and the heat source.

- Connection to the coplanar collector, to its extreme point. Water moves in the circuit due to the operation of a common house pump located in the generator room. In this case, the underfloor heating has priority when supplying hot heat carrier.

- Using a hydraulic distribution unit is a great option: if there are several heating devices, with a difference in the length of the floor loops and the water consumption in them. In this scheme, you also cannot do without a coplanar collector.

- Local connection of the circuit through a unibox in a parallel circuit. Suitable for rooms with a small area: bathroom, corridor.

Radiator connection

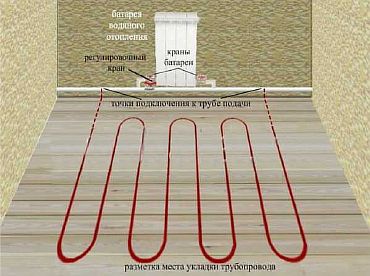

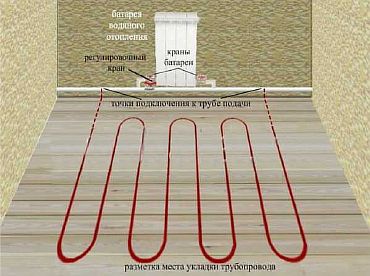

A common way to feed underfloor heating from radiators. With this scheme, the temperature of the liquid in the water floor is directly related to the degree of its heating in the radiator.

For the construction of this system, a line is needed, which has a supply with a return flow, as well as floor pipes and a unibox. Since the water in the batteries heats up to 80 degrees, it is recommended to connect the floor loops to the return line.

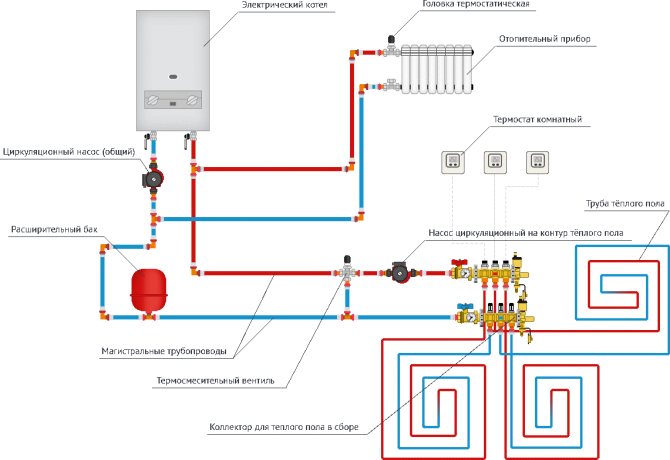

From the boiler

This is a simple option - the installed boiler is designed only for heating water for a warm floor, so no regulators are needed.

In the presence of a modern gas boiler, it is able to regulate the temperature itself, it is enough to set the required indicator on the panel. Even with a two-contact system, when the boiler heats up water for batteries and underfloor heating, the values for each device can be easily adjusted by the boiler automation.

When using a boiler that runs on solid fuel, a compensating barrel is required.The level of temperature and pressure is regulated by installing a safety unit on the barrel, which consists of a pressure gauge, an air release valve and a thermostat.

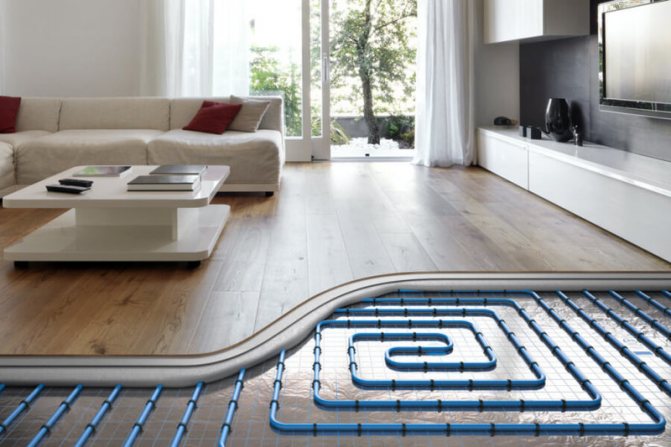

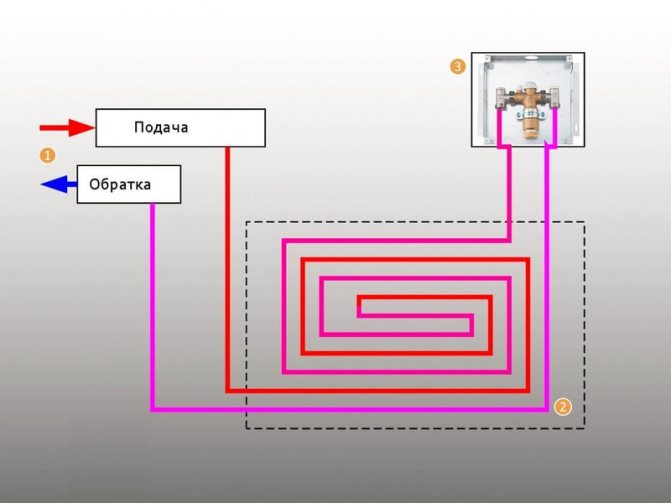

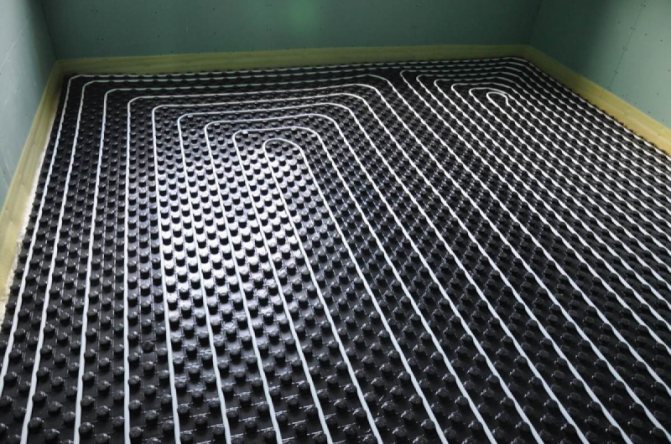

For your information! The functioning of the water heated floor is influenced by the pipe laying scheme - find out what the laying schemes are, as well as how to connect the heated floors. With a "snake", the heating will not be uniform, with cold and hot areas. When placing the contour according to the "snail" scheme, uniform heating is ensured.

Temperature regime

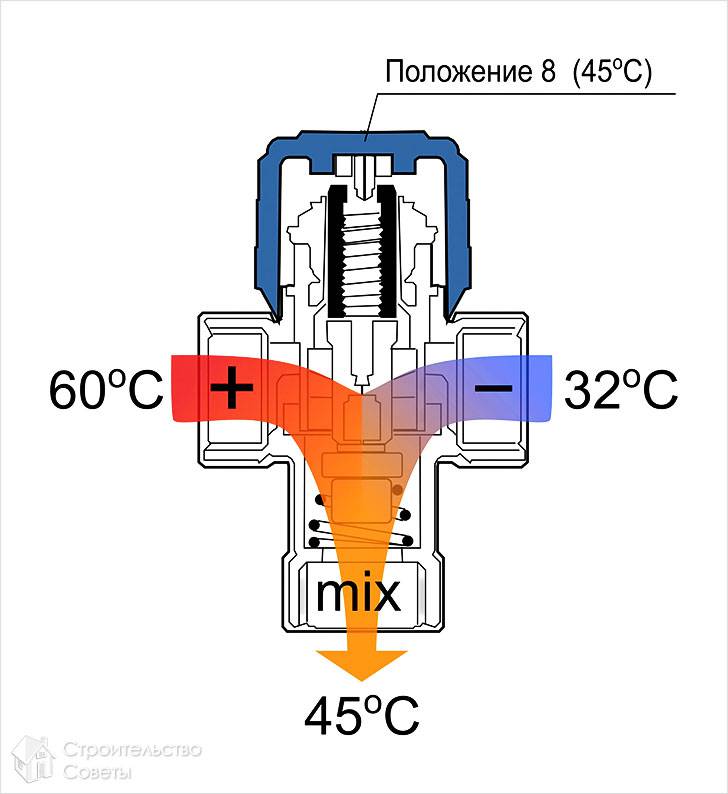

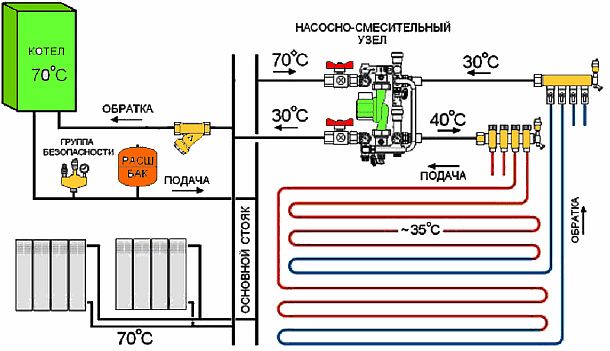

The principle of operation of a water underfloor heating is different from the functioning of other heating devices. The main difference is in the level of heating of the coolant. The radiators are supplied with water heated to 80 degrees, for water floor circuits a maximum of 42 degrees. At this temperature, the heating of the floor covering will reach 26 degrees.

There are two methods for adjusting the temperature of water underfloor heating:

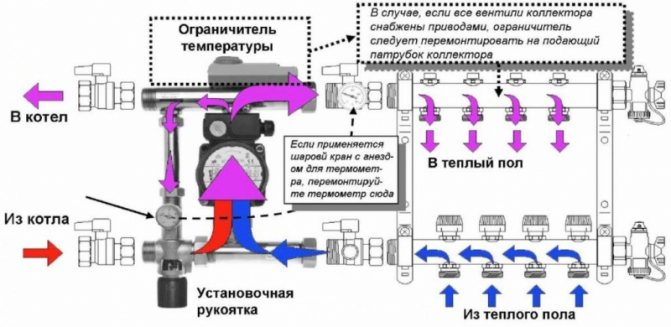

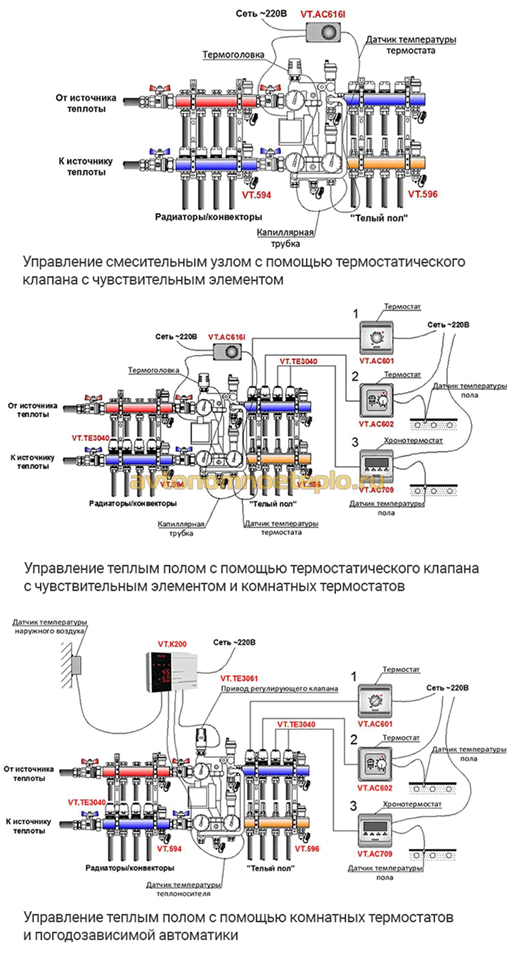

- Exercising control in the collector supply unit, by mixing waste water. This is achieved by equipping a three-way valve with a thermostatic head. When working, the temperature of the water, not the air, is taken into account, and a constant volume of consumed liquid is provided, with a slight fluctuation in its temperature.

- Restricting the flow of heated coolant into the pipes. This also requires a thermal head, which is located on the 3-way valve and is used to shut off the return flow. In this case, the supply and return valves are connected to the bypass, through which the flow is regulated by a restricting valve. Since underfloor heating is inert, water is supplied to the pipes at a nominal temperature, and only its consumption changes.

In both methods, the thermostatic head is repelled in operation from the return temperature.

Heating temperature control

An important parameter of any heating system is the optimal temperature regime of its operation. A ratio of hot and cooled heat transfer fluid of 75/50 or 80/60 is considered suitable. However, this value is not always acceptable for certain parts of the network. How to properly regulate the heating in the house in this case? Installation of special equipment is required. Some of them are designed to adjust heating radiators.

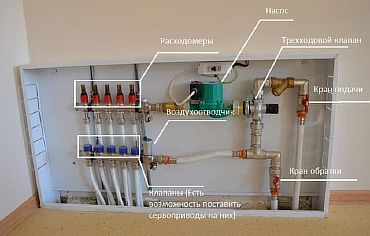

Mixing units

Their main element is a two or three way valve. One of the nozzles is connected to the heating pipe with hot water, the second to the return. The third is mounted on the section of the line, where it is necessary to ensure a low level of the coolant temperature.

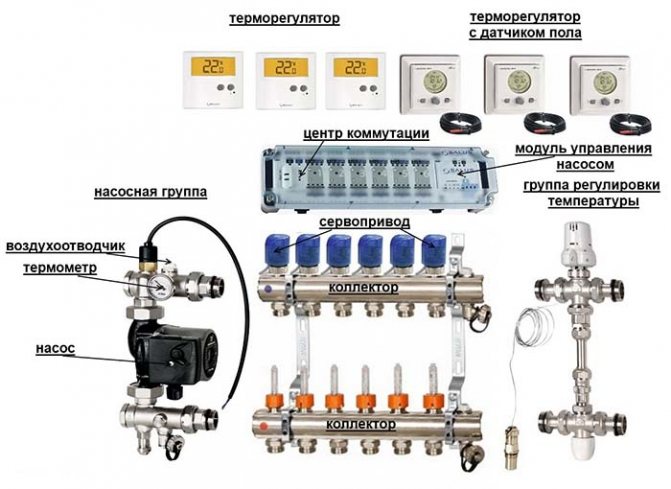

As additional mixing units, they are equipped with a temperature sensor and a thermostatic control unit. The sensor sends a signal about the heating agent heating level and it opens or closes the mixing valve, thereby regulating the two-pipe heating system. Most often, such mechanisms are installed in the collectors of a water-heated floor.

If you need to adjust the heating of a water-heated floor in an apartment building, you need to take into account the temperature regime of the pipes. Most often it does not exceed 45 degrees.

System refueling rules

It is impossible to properly adjust the functioning of the water structure if the volume of liquid in the pipeline changes independently. This can happen if there is air in the system - see the instructions on how to bleed the air from the heated floor yourself. Therefore, it is important to both professionally assemble the structure and fill it in correctly.

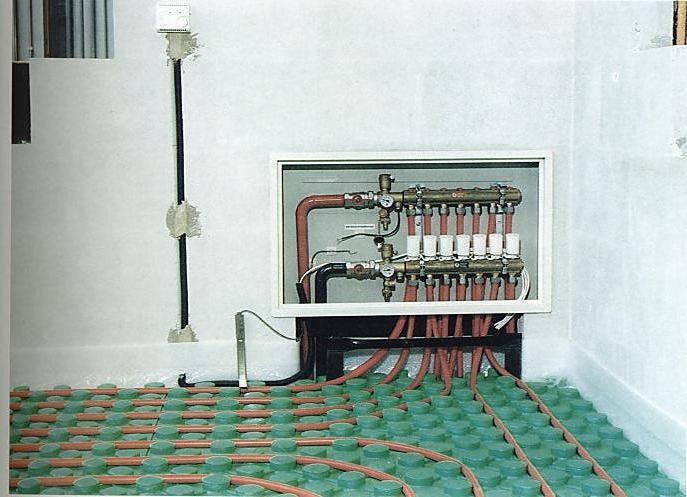

For high-quality filling of the system, both collector branches should be equipped with automatic air vents. The filling of the floor hinges should be carried out separately from other heating devices. The generator and radiators are pre-filled. The manifold inlet valves are closed before refueling.

In order to properly start the floor, you need to connect a hose from a water supply source or pump to the supply tap, and an air outlet hose to the return.

It is necessary to start filling the water floor from the collector and its distribution units. To do this, the flow meters of the supply valve open to full, at this moment the taps on the return should be turned off.

The loops are filled one by one, the water is started up from the bleed hose until it comes out clean and without air bubbles. The water should be started with a small pressure, this will make the process of air exit from the pipes more even. After threading all the loops, the device can be turned on.

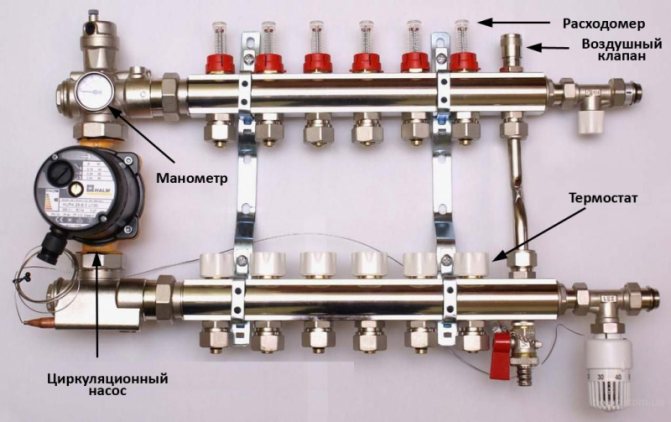

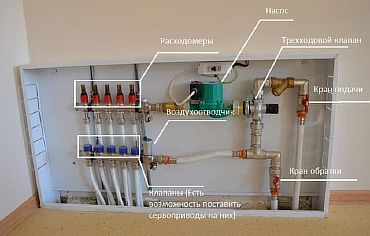

Working with collector flow meters

Underfloor heating balancing means the definition of norms for each loop. Indeed, from the size of the floor branch, so that in the process of passing through it the coolant cools down according to the calculated value, the amount of water is required different. The volume of fluid that the loop passes through is the heat load on it.

Not infrequently, it is recommended to determine the flow rate of the coolant, starting from the power of the pump, that is, the volume of the incoming fluid is divided proportionally by the length of the loops. However, it is worth abandoning this method, since it is not easy to accurately calculate the size of each coil using this method.

In addition, calculations in this way lead to a discrepancy between the pressure in the hinges and the calculated value, which makes it impossible to customize the structure.

The very same regulation process with flow meters is simple - an article with step-by-step instructions. The throughput of the device is adjusted taking into account the model, either by turning the body, or by the stem using a key. The device displays the amount of water in liters passed per minute, you just need to set the desired value.

Basically, always, when adjusting the throughput of one loop, there is a change in others. Therefore, the process should be repeated sequentially with each flowmeter. Significant failures indicate that the valve has poor flow capacity, or that the circulating pump has poor performance.

Ways to adjust the temperature of underfloor heating

To achieve the required temperature values that meet the standard specifications, you need to configure the device.

Correct adjustment of underfloor heating is possible depending on the type of room. A suitable temperature level for residential premises is 20 to 28 degrees. For a kitchen, corridor or bathroom, heating from 19 to 24 degrees is suitable.

For your information! The permissible humidity in the room is 60%, but the optimal indicator is 40 - 50%.

The main purpose of the regulation is to maintain a constant temperature difference when entering and leaving. To determine the temperature difference, the thickness and material of the screed, and the laying spacing of the pipes, are taken into account.

The installed equipment affects the methods of adjusting the structure; it can be mechanical and automatic. The device responsible for the water flow is configured; this can be done by mixing the hot and cooled coolant, or by limiting it.

Automatic adjustment

If the underfloor heating is adjusted automatically, then the main adjustment elements are the RTL thermal head or the unibox valve. The level of floor heating depends on the set indicator, the more it is, the hotter the liquid going through the pipes will be, and therefore the flooring will warm up more.

How to automatically adjust the water heating floor - this can be done in two ways:

- Using a thermostatic self-regulating device, it is adjusted by valves or a valve with heads.

- With the help of an electronic system, it includes an electrothermometer, a controller, and electric drives.

Electronic control devices are expensive, but they can be used to program floor heating and adjust it for optimal and efficient operation.

Electronic regulators are represented on the market by many companies, the most popular are "Uponor" products.

Manual temperature equalization

The manual configuration process is simple but time consuming. The water heating temperature is adjusted by opening or closing the valves. The procedure becomes much easier with a device that doses the feed into each branch.

For your information! Underfloor heating will function effectively when manually adjusted - with intensive water circulation in the pipeline, this can be achieved using a separate heat pump.

Before you start adjusting the temperature level in the water floor, you need to make sure that the system is full and that there are no air locks. Adjustment is the supply of coolant to each coil, and the setting of the level of its flow. The control is carried out taking into account the difference in flow temperature, at the inlet and outlet. This procedure must be carried out annually.

Important! The temperature of the incoming and outgoing heat carrier in all loops should be approximately the same, the permissible difference is 5 - 15 degrees.

Control over the adjustment process of the water floor will facilitate the use of a thermometer, laser or electric. Its presence will significantly reduce the setup time.

How to adjust the temperature

The difference in the temperature of the coolant inside the supply and return risers should be 15-20 degrees. This indicator can be adjusted using special equipment - mixers, taps and servo drives. Mixers are a crane with two or three working positions. The pipe of the supply riser is connected to one of the inputs, the outlet pipe is connected to the second. The third is used to regulate the temperature in a separate section of the line. Mixing units are equipped with a temperature sensor and a control unit. The sensor gives a signal about the temperature of the water inside the riser, and the control unit regulates the valve, due to which the two-pipe heating system is regulated. You can adjust the heating of water in radiators with your own hands, using taps for this. But the servos will eliminate the need to do this, since with their help, the heating of the risers will be automatically adjusted. The servo drive includes a thermostat that sets the desired temperature value. After that, the servo drive will begin to measure the incoming coolant flow and, if necessary, reduce or increase it.

Important! It is impossible to regulate the pressure with the help of thermostats, since they limit the flow of water only in one section of the system, without affecting its general condition and the heating of the remaining risers.

Hydraulic leveling system

Warm water floors are a reliable and safe design. But for it to really be that way, it needs to be configured correctly. How to regulate water underfloor heating in a private house - for this it is better to equip a collector group equipped with flow meters with a working pressure of 6 bar. If the house is equipped with central heating, then this capacity is not enough.

If there are servo drives on the manifold, the water flow is automatically adjusted as needed. However, the preliminary configuration still needs to be done. In the absence of this drive, one cannot do without such an adjustment.

You can calculate the flow rate of the coolant using the formula:

Gsp = Q / (1.163 * Δt), in which

- Gud is the specific volume of water per m2;

- Q - floor power indicator;

- Δt is the difference between the temperature of the heating agent during supply and output;

- 1.163 is the correction factor.

In the future, to calculate the volume of fluid that passes through the loop, the specific flow rate should be multiplied by the surface area.

The simplest option for hydraulic alignment:

- calculate the volume of water for each loop by multiplying the floor area where this contour is laid by 8.6 (average);

- start the pump at first speed;

- set the thermal head to 30 degrees;

- check that the liquid passes freely through the loops, and all the air has escaped;

- adjust the flow device on each circuit so that a value equal to the water flow rate you calculated is obtained.

These actions are pre-adjustment, that is, in fact, during the operation of the warm floor, additional adjustment will be required, taking into account personal preferences for comfort.

Heating regulation of a private house

For owners of private houses, the question is: how to adjust a two-pipe heating system. Unlike district heating, only internal factors affect the parameters of autonomous heating.

The main one is the design of the boiler, the types of fuel used and its heat output. Also, the ability to adjust the parameters of the coolant directly depends on the following system indicators:

- Diameter and material of manufacture of pipes

... The larger the cross-section of the line, the faster the expansion of water will occur as a result of an increase in temperature; - Radiator characteristics

... Before adjusting the heating radiator, it is necessary to make its correct connection to the pipeline. In the future, with the help of special devices, you can reduce or increase the speed and volume of the coolant passing through the heating device; - Possibility to install mixing units

... They can be installed for a two-pipe heating system and with their help the water temperature is reduced by mixing hot and cold streams.

In order to find out how to adjust the heating system in a private house, it is recommended to consider all possible options.

The installation of pressure control mechanisms in the heating system should be foreseen at the design stage. Otherwise, even a small mistake during installation can lead to a loss of efficiency of the entire system.

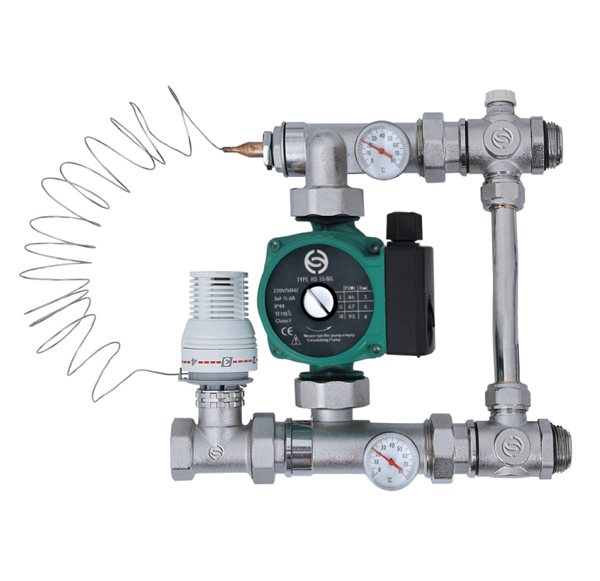

Three-way valve capabilities

If the manifold has a three-way valve, then the adjustment is done using the servo. In this case, the control over the indicators will be carried out by the mixing valve. In the process, the three-way valve can be turned as desired, and as many times as needed. Setting up the mixing valve, however, is more difficult.

Why do you need a comb for a warm floor, we will analyze its structure and principle of operation, how to choose, instructions with photos and videos, how to install and configure or do it yourself.

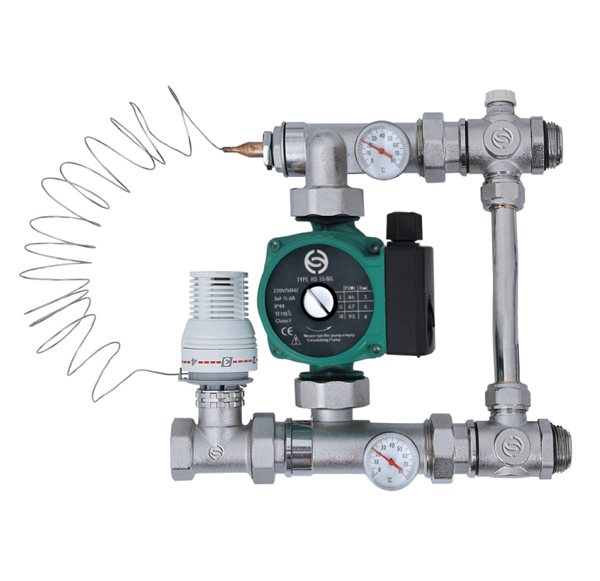

There is another possibility to adjust the heating floors - using a modular mixer, it consists of:

- three-way crane;

- thermometer;

- bypass;

- pump for circulation of liquid;

- thermostatic head;

- relay.

This set costs a lot, but its efficiency is high. There is a prerequisite for the functioning of this module - the European assembly.

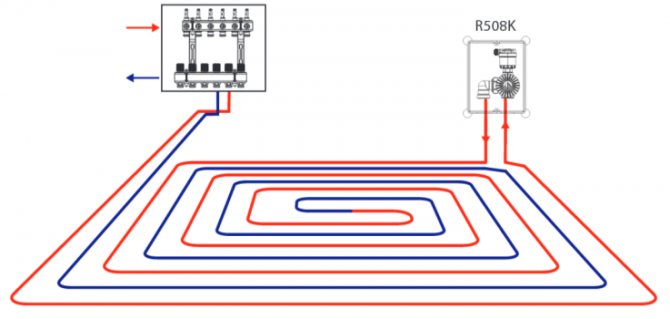

Another method of regulating warm floors is to install a servo drive and a thermostat. The thermostat notifies the servo drive about a decrease in the room temperature, and about the need to supply a heated coolant. This method works even when assembling the collector with your own hands.

A warm water floor is a complex structure, and deciding to build it in your home, you need to be aware that it is not enough to mount the system, it is necessary to periodically adjust it according to the instructions. And it is important to understand this process, otherwise the floor will not meet your expectations.

Types of floor heating control

Water-type floor control means control of 2 parameters: floor temperature and room temperature. Moreover, if the first concept can be set and monitored in the process of work, then the second one directly depends on the temperature of the floor itself.

The principles of regulation represent several methods, which depend on the equipment, devices and instrumentation used for these purposes.

All methods are divided into the following types:

- manual;

- individual;

- group;

- complex.

It might be interesting

Thermal insulation

Distinctive features and variety of ceiling tiles ...

Thermal insulation

How to insulate the ceiling in a wooden house?

Thermal insulation

What is a heating cable?

Thermal insulation

Warm "pie" for a metal chimney

Manual adjustment is carried out using thermal heads installed on the return and supply manifolds. It takes experience and time. The result appears in 3-4 hours. It has been experimentally established that if at the entrance to the system the temperature reaches 40-55 ° C, then the room is 20-25 ° C.

Individual regulation is carried out by installing the sensor in a warm floor. This allows you to control the required temperature in each individual room.

Group control is to obtain the floor temperature, which will be the same in all rooms.

Complex adjustment - a combination of individual and group, as well as competent selection and installation of the necessary equipment.

Temperature control

The temperature of the heating water system is regulated by means of a manifold. It is desirable that it be with a flow meter if the goal is not only to obtain the desired temperature in the room, but also to save. The device controls the flow of water or other heat carrier. When necessary, it triggers and shuts off the fluid supply.

How to adjust depends on the design of the device. Recommendations for adjusting the underfloor heating collector are always indicated in the instructions for use and maintenance of the collector, as well as in the passport data that a bona fide manufacturer always attaches to the product.

The installation of a collector, where radiator heating is used, and at the same time a water underfloor heating system is connected, requires not only correct installation, but also correct adjustment. The temperature of the pipe system installed in the floor cannot be that of the radiators. There it reaches 70-90 ° C, and this should not be in the pipes of the floor heating circuit. It is twice as low. Recommended floor temperature limits are in the range of 30-45 ° C.

The methods for adjusting the underfloor heating collector are as follows:

- from the manufacturer (factory);

- unconventional.

Setting up a floor heating collector from the manufacturer is an option when the temperature is controlled according to the instructions of the factory instructions. Usually this is an automatic method, where heating is carried out automatically or manually by special modules. They are assembled on a three-way valve.

Three-way valve

The module consists of a thermometer that monitors the temperature, a relay, a bypass and a circulation pump. By turning the knob / thermal head of the valve, the temperature can be decreased or increased. A circulation pump is required to run water through the pipe loop and take a part of the coolant from this loop through the valve.

Mixing module

There are more modern models of collectors, in the design of which a thermostat or servo drive is provided.

A special line called a bypass line is used to supply the coolant with the required parameters to the pipe system. It is a bypass line performed on the manifold.The three-way valve does not allow the entire coolant to pass through itself, but only a small amount. The rest flows through the bypass. There it mixes with cold water coming from the collector, and then moves to the water heating unit. Normal operation of the underfloor heating is impossible without a bypass line.

With an unconventional method, installing a thermostatic relay on the return line will help to set the required temperature in the circuit. It is installed on the manifold. The operation of the circulation pump (switching on and off) installed on the collector (in the supply or return line) occurs when the set temperature is reached or when it drops below the required value. The temperature is set on the relay using the handle within the range of 30-35 0С.

The pump delivers liquid heated to 70 ° C and higher into the pipe system, heat is transferred to the base of the warm floor, as a result, after passing through the pipe circuit, the thermal relay is triggered and the pump is turned off. Cooling of the liquid also occurs in the manifold. Upon reaching a temperature lower than the set one, the reverse process will occur: the pump will turn on, and the coolant will be heated.

The simplest and cheapest way is to install a circulation pump and a valve in the coolant supply system, and a patch thermostat is installed on the return pipe on the collector. When the room heats up (this will be indicated by the temperature rise in the pipe system above the set value), the thermostat will stop the supply of warm liquid and turn off the pump. When the temperature drops, it will turn on the pump again and feed a hot heat carrier into the pipe system. The work is carried out in 2 modes - working and waiting.

The warm floor is also regulated by installing a mixing valve. Usually, this is how the temperature of a water-heated floor is regulated in an apartment located in a multi-storey building. It is connected to the central heating system of the house. Here, a circulation pump is installed on the supply; in front of it, either a three-way valve or a mixing valve can be installed.

There is a mixing of hot and cold heat carrier to the desired temperature. In this case, attention must be paid to the setting of the mixing valve, in contrast to the three-way valve, which can be turned as desired.

The most expensive and rational method is to regulate the temperature by installing a special actuator, called a servo drive, on the valve, and a thermostat in the room. The latter device is controlled by the operation of the servo. It opens and closes automatically as the temperature drops or rises.

Servos