Why waterproofing is performed ↑

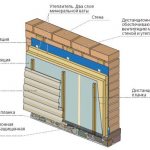

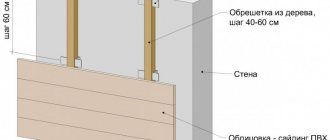

Before sheathing the walls with siding, the sheathing is being installed. A waterproofing film is attached to it from the inside.

A free space is formed between the wall and the siding, which is usually filled with insulation. Despite the fact that vinyl (the material from which the siding is made) is waterproof, the cladding is not airtight: air freely penetrates between the panels and the moisture contained in it permeates the insulation. Mineral wool and glass wool, which are most often used to fill walls, are not afraid of open fire, have a low specific gravity and do an excellent job with their main function of insulation. But, being saturated with moisture, they lose their qualities and become deformed. Wall materials also suffer: drywall swells, wallpaper molds. There is a threat to the safe operation of electrical networks.

How does the protective layer "work"

The task of waterproofing materials is to create a moisture barrier in the form of precipitation and vapors contained in the air. Snow, which is packed under the ridge of the roof, subsequently melts and flows down the surface of the waterproofing film to the ebb of the foundation, and from there into the drainage system. In the absence of this film, moisture would have entered the thermal insulation material.

The same problem occurs with walls. Despite the fact that the siding panels are mounted with an overlap, in case of strong winds, rainwater still gets under the cladding through the cracks. If waterproofing is present, moisture flows down without damaging the structure. Therefore, the external decoration of the building requires a ventilation gap of 20-30 mm for laying the insulating material.

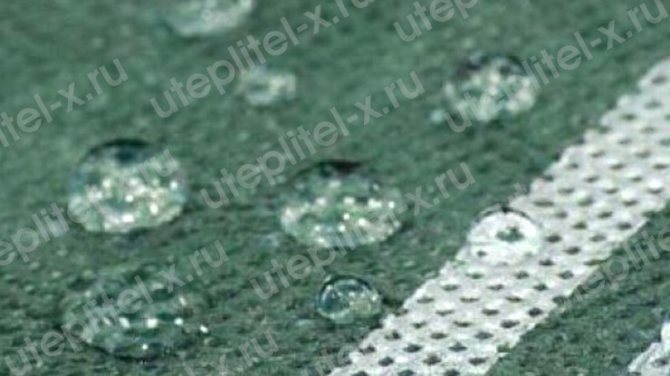

The main difference between a high-quality waterproofing film is its ability to retain moisture, but at the same time not interfere with the natural ventilation of the walls: the film is a membrane and therefore steam can freely pass through the walls, which means that the house will "breathe".

When choosing an insulating material, you should pay attention to the fact that the moisture resistance of each type of film is different: it is assessed by the ability of a unit of area to withstand a certain volume of water without leaks, as well as by the amount of steam passed during the day. The cost of films is also different: it depends on their quality and basic characteristics. The larger the column of water the film can withstand (and let steam through in a large volume), the more expensive it will be. This is explained by the layering of such material, but a cheaper option is enough for laying under siding.

Basic rules for waterproofing device ↑

When installing a waterproofing film, certain rules must be observed:

- When laying the film, the edges should be joined with an overlap of at least 150 mm, gluing the joint with tape. In this case, it is necessary to check the absence of areas not covered with waterproofing in order to avoid the insulation getting wet.

- The film should be fixed in such a way that it cannot be damaged during the installation of the siding.

- The foil is fixed with galvanized wide-headed nails or with staples using a mechanical stapler.

- A gap of about 30 mm is required between the film and the siding in order for natural ventilation to take place.In addition, when installing some types of films, it is required to leave a gap between them and the insulation: this requirement should be indicated in the instructions from the manufacturer.

- It is required to monitor the correct orientation of the film: if you put it on the wrong side, the material will not function correctly.

Installation of hydro and vapor barrier ↑

Roll materials are first freed from packaging, after which they are laid on top of the mounted sheathing from its inner side. This can be done in two ways. The first is more preferable, since it provides a greater degree of tightness. This method consists in unwinding the roll around the perimeter of the house and at the same time fastening the material. It fits from bottom to top: the first row is attached at the very bottom, and the next row is higher, with an overlap on the bottom. In this case, the joints are glued with adhesive tape.

For ease of use, a pole with a round stopper at the bottom is used to prevent the film from slipping. A roll of film is put on the pole: such a device simplifies the unwinding of the waterproofing.

The second method is to unwind the rolls from the upper level of the building downwards: the material is laid in vertical parallel rows. In this case, it is also necessary to observe the overlap and glue the joints of the rows.

Roof waterproofing, carried out using a similar material, should go with its lower edge over the film laid on the walls: this is necessary so that moisture from above can drain from the outside of the material. The vapor barrier material is attached from the inside in the same way, but only after the installation of thermal insulation boards.

After completing the installation of the waterproofing and vapor barrier film, you can start cladding the walls of the building with siding: the entry points of the self-tapping screws will not break the tightness, since they are screwed in from the outside.

Do you need windscreens for siding?

Quite often, a sharp cold snap can be felt inside the room. Most often this happens at a time when there is a strong gusty wind outside the window. This is especially true for the autumn period. To avoid discomfort, it is worth choosing the right insulating material.

A strong gusty wind can cause a cold snap indoors. Not all building materials can hold back the strong flow of cold air. Most often, such unpleasant situations occur in the autumn or spring. To deal with such an unpleasant situation, there is a windbreak film. This isolation is often neglected, but it is not always worth doing.

Windscreen under siding - panels

During restoration work, it is safe to say that wind protection for siding is necessary. Its presence will help protect the quality properties of the thermal insulation layer.

If the insulation layer fully fulfills its functions, then the following indicators are immediately visible on the face:

- while maintaining the quality properties of the insulation, there is no need to constantly heat the premises in the building;

- the atmosphere inside the room cools down more slowly, which makes it much easier to maintain a certain temperature inside the room;

- in the presence of a high-quality insulation layer, you will protect the walls from possible freezing at low temperatures;

- among other things, excellent sound insulation performance is revealed.

Mineral wool is most often used as insulation for external walls. This insulation has remarkable properties, but its use requires high-quality waterproofing. Since the open ingress of moisture has a detrimental effect on the properties of any insulation.

Wind protection scheme for siding panels

Very often, a waterproofing film includes a windproof layer, which eliminates the need to purchase additional material. However, not every waterproofing material differs with such properties.

When windproofing, it is very important that individual pieces of material are overlapped, and the joints are glued with high quality using a special tape.

Windscreen has a short history of use. We can say that this is a new material that was specially developed for new facade materials with high ventilation rates. It should be said right away that in this case, you cannot do without special wind protection, otherwise, with strong gusts of cold wind, temperatures in the room will quickly drop.

Varieties of windproof films

There is a great abundance of insulation materials nowadays. This nuance did not pass by the side of wind protection, which in the modern market is presented in several types of performance, namely:

- Diffuse membranes. With the help of this material, not only waterproofing is performed, but also reliable protection of the insulation from wind load. In this case, the material consists of several layers. For better results, it is recommended to use three or four layer films. It is also worth noting that with the help of such material, vapor barrier for siding is also performed. Diffuse membranes are considered the most popular insulation material today.

- Windproof film. Many companies are engaged in the release of such products. This material is designed to withstand strong wind currents, being a reliable barrier to cold air. Such a film is characterized by resistance to heavy loads, which is why films with increased density are used as wind protection.

Wind bar

When cladding external walls with siding panels, it is important to pay attention to the wind bars. This element helps to contain loads from sudden gusts of wind. When using these elements, the façade siding coating wears out significantly less. This material allows you to significantly redistribute the load.

Using a wind bar will not only significantly extend the life of the cladding, but will also give a complete look to the façade of the building. It is worth noting that, as in many other cases, the mounting of such elements is carried out with accurate calculations, in a strict sequence. Otherwise, the use of wind bars will not give the desired result.

Types of windproof films

Wind protection film for installation is produced by many manufacturers. Such a film for siding can be presented in several types. The most common types of wind insulation are diffusion membranes. The variety of such membranes allows you to choose both the most budgetary and more expensive options.

Diffuse membranes are produced by the largest manufacturers in Europe and the USA. On the territory of our country, the production of such material is currently underdeveloped, which is due to the high cost of equipment. High-quality windproof material for siding walls has a vapor permeability of at least 200 g per square meter. A higher index improves the vapor permeability of the windscreen.

Wind protection film for installation is produced by many manufacturers

Waterproof and windproof films play an important role in the installation process, since such materials are designed for significant wind loads. The traditional version of materials for the installation of waterproofing and vapor barrier has windproof properties that remain up to certain limits.It is for this reason that waterproofing and wind protection do not guarantee complete preservation of the quality and operational parameters of thermal insulation for siding under extreme climatic conditions.

Wind protection and its properties for siding panels

As practice shows, this type of building insulation, such as wind protection, is extremely necessary to create comfortable and cozy conditions inside the building. Very often, it is precisely because of the sharp gusts of strong wind in living quarters that it is impossible to be without warm clothes.

As for siding panels, many people mistakenly think that air currents do not penetrate through it. This opinion is wrong. As practice shows, air flows are everywhere. Because of this, a simple siding cladding will not be enough, and you will need to install high-quality wind protection.

Windproof film attached to the facade of the house

Windscreen is a kind of membrane that acts as a barrier against sharp cold currents. This membrane is designed to contain external air currents, but it allows air from the inside. In the case of installation, the main thing is not to make a mistake and not install the film the other way around. Otherwise, it will be impossible to achieve comfortable conditions inside residential premises.

A well-installed wind insulation must have the following properties:

- Protection of the structure against possible moisture penetration.

- The windproof layer completely covers the entire surface of the walls, while closing possible gaps in the insulation.

- The surface of such a material should facilitate the removal of moisture, while not allowing moisture inside.

The eternal question: what to do?

We support the point of view of those specialists in construction physics and technologists working in the field of wooden housing construction that vapor barrier is not needed when insulating a wooden house. The only case when the placement of a vapor barrier between the load-bearing wall and the insulation can be justified - the house (dacha) is used seasonally, it is rarely heated in winter, or the rooms are kept at a minimum temperature and they are well ventilated. With this operating mode, the temperature difference and, accordingly, the absolute humidity outside and inside is low. For a house where people live permanently, there are internal sources of moisture (breathing of people, steam from kitchen pots and showers, moisture from watering house plants), vapor barrier is more likely to be harmful than beneficial. It is not always possible to do without a film, especially if the logs are uneven, and the insulation is too soft or even backfilled. In this case, wind insulation (with the highest vapor transmission value), building board, craft paper, and even a spunbond that has served its purpose in the garden can be laid as a limiting material between the wall and the insulation structure for siding.

As a counterargument to the lack of vapor barrier, supporters of its placement say that the insulation that is not protected from steam penetration will be moistened and its thermal performance will deteriorate. Alas, they are right. But the ventilation gap facilitates the removal of moisture, and a relatively small (5-15%) drop in heat-shielding properties is a forced victim in the struggle for the durability of the building.

It is important to know: vapor barrier is not needed when insulating a wooden house in which people live all year round.

You cannot do this if the house is inhabited all year round! Walls "wrapped" in glassine will become waterlogged and become defenseless against mold infestation

Mounting the windbreak

When installing a windproof film, as in the case of a waterproofing layer, the film is overlapped. All joints that form must be glued with a special waterproofing tape. In this case, it is required to use just such a tape, this will protect the structure from the penetration of cold air.

When choosing a tape, do not forget that this material must have good vapor permeability. There should be no difficulties with the acquisition of such products, since such a building element is usually produced by the same manufacturer as the wind-waterproof film.

As for the overlap, for best performance, it is recommended to do it at least 15 centimeters.

The film material is sewn onto the finished frame, which makes an indent from the insulation by 2 - 3 centimeters. This gap is required for ventilation.

As it becomes clear, without high-quality wind protection, it is almost impossible to achieve comfortable living conditions. Its use is essential for almost any exterior wall covering. This material is used to isolate only private houses, since its use in multi-apartment buildings is difficult. As for the cladding of the building with siding panels, here you cannot do without the use of a windproof film.

Additional details

To make the process of cladding with vinyl siding even easier, additional components are available for sale:

- Start and finish bars. They will help to install the entire coating evenly and accurately, as well as give the house an even more aesthetic look.

- Corners - constructions that allow you to most accurately hide the ends of the planks and make the corners highlighted.

- Specialized trims for doors and windows. They will complement the image of the house and help to arrange door and window openings without difficulty.

- Profiles for doors and windows. Protect against the possibility of distortions.

- Special profile for lateral fixing of standard panels. If desired, it can also be used as platbands for openings.

- Chamfer for mounting the profile to the roof without any particular problems.

- Ebb tides designed to create drainage to the roof.

- Ceiling panels. These details are required to decorate the ceiling of a veranda or terrace. These elements provide good ventilation and protection from parasites.

Vapor barrier under siding: when and why you need it

When we are asked to calculate the cost of cladding a house with siding, we are often asked the question: “Did you calculate the vapor barrier for siding?”.

At the same time, most often the customer does not understand what he is talking about. But this is fixable.

In this article, you will learn what vapor barrier is, what it is for and when it is necessary to vapor barrier under the siding.

What is vapor barrier

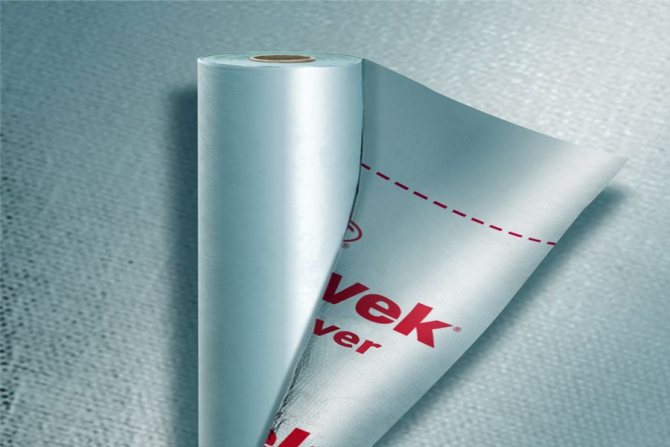

Vapor barrier is a non-woven material in the form of a film rolled into a roll.

In this photo, the first floor of the house is sheathed with a vapor barrier before insulation (click to see all photos from this object)

The simplest and most inexpensive vapor barrier is plastic wrap.

But there are also more advanced types: membranes with limited one-sided vapor transmission, etc.

The purpose of this article is not to describe all types of vapor barrier, but to help you figure out if a vapor barrier is needed when cladding your house with siding, so I will not go deep into the range of membranes and films.

Why do you need a vapor barrier in general and under siding in particular

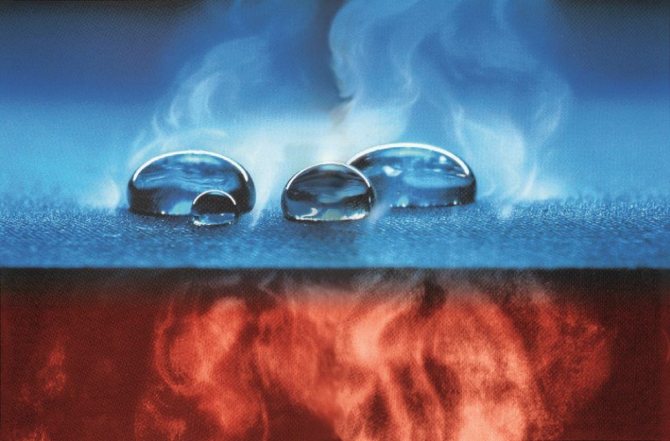

As the name suggests, a vapor barrier isolates the vapor, creating a barrier to its movement from a warmer room to a colder one (outside).

If you allow steam (water in a gaseous state) to pass through the wall of your house, then at some point, the state will change and the gas (steam) will turn into liquid (water).

The place where water vapor condenses and turns into a liquid is called the dew point.

Typically, it is located somewhere inside the wall of your house.

If the steam is not allowed to "crawl" to the dew point, then it will never become moisture (liquid).

The location of the dew point depends on the difference in humidity and temperature between two rooms or between a room in your house and a street.

The warmer the house and the colder it is outside, the closer the dew point moves to the outer surface of the wall.

Once you cut off the outward movement of the vapor in the air inside your home, you protect it from liquidation (condensation) because it does not reach the dew point.

How condensation can damage your home

Residents of panel houses, most likely, faced humidification of the walls inside the house during the cold season.

This humidification occurs due to the dew point shifting into the interior of the house, and the vapor turns into liquid right on the wall.

More often than not, we do not see the condensation process, because the dew point is inside the wall.

But if you decide to insulate the house with siding, then the dew point shifts even further outward and will now be inside the insulation (especially if the insulation is thicker than 50 mm).

In the case of expanded polystyrene (polystyrene), this is not a problem, because it itself is a vapor barrier and does not conduct steam.

But if you insulate the house under siding with mineral wool (mineral wool slabs), which have good vapor permeability, then condensation will form inside such a slab.

In other words, the insulation will get wet inside due to the temperature difference between the room and the outside.

Wet insulation is bad insulation.

Increase the moisture content of the insulation by only 5%, and its thermal insulation capacity becomes two times lower.

It is easy to understand this: the insulation under the siding with a thickness of 100 mm without vapor barrier heats the same way as 50 mm with vapor barrier.

If you do not make a vapor barrier, then you pay for insulation twice as much as you get.

By the way, we have a great article on mistakes when insulating. Click here: 5 mistakes when insulating a house under siding.

When you need a vapor barrier under the siding

As follows from the above, a vapor barrier is needed if you are insulating a house under siding when installing insulated siding.

In this photo you can see the insulation mounted on the vapor barrier (click to see all photos from this object)

In any other case, there is no point in vapor barrier, and you need a similar in appearance, but completely different material: windproofing or, as it is also called, windproofing.

If you insulate the house under siding, then you will still need wind protection.

It will close the insulation outside.

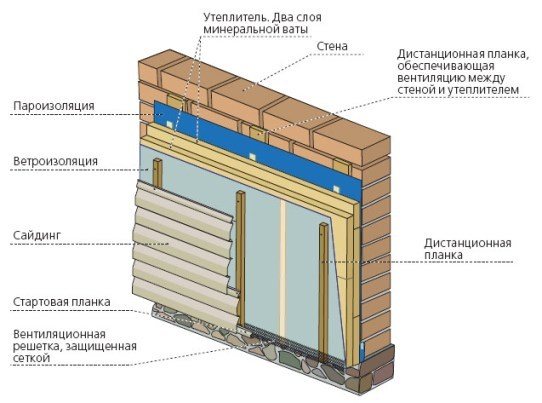

With proper insulation of the house with siding, a multilayer cake is obtained: siding, under it windproofing, under it a heater, under it a vapor barrier attached to the wall of the house.

The order of work when insulating a house with siding

So, you have decided that the walls of your house need to be insulated.

In what order is it done:

Installation of vapor barrier on the wall of the house

First, we protect the insulation from steam, which will penetrate into it from the inside of the house.

To do this, we mount the vapor barrier directly on the wall of the house, always with an overlap:

In this photo you can see a vapor barrier installed on a log house before insulation with siding (see all photos from this object: click here)

By the way, we have a great article on siding log houses. Click here: Timber House Siding.

Installation of insulation over vapor barrier

Next, we mount the insulation, for the sake of which the vapor barrier was started under the siding.

Now we can be calm: the insulation is reliably protected from moisture penetrating in the form of steam from the inside of the house.

In STK Etalon, insulation is carried out without cold bridges, which is one of the many advantages of ordering siding installation from us.

In this photo, the insulation has already been mounted on top of the vapor barrier, and pressed down by the first layer of the crate, but has not yet been closed with windproofing

Installation of windproofing (wind and moisture protection) over the insulation

Now we protect the insulation from moisture that can get into it from the outside and reduce its heat-insulating ability, for which we attached it to the wall.

We need to close the insulation with wind-water protection, it is also wind-water insulation, it is also wind and moisture protection.

In the photo, the insulation is covered with wind protection, which is fixed by the partially mounted second layer of the crate

Installation of siding on top of windproofing

All work on creating a warm “cake” is completed.

Now we cover all this with siding, and the house becomes warm and cozy, while its “subcutaneous fat” (insulation) is reliably protected from moisture on both sides.

See all photos from this property: click here

When is a vapor barrier under siding not needed?

One You already know the answer to these questions: if the house is not insulated, then vapor barrier is not needed (but wind protection is needed).

Second Answer: you will not need a vapor barrier under the siding (or, more precisely, under the insulation) if it is already on the walls of your house inside.

Vapor barrier

The vapor barrier is installed between the wall and the insulation - this is the protection of the insulation from the inside. Such a film does not allow moisture or steam to pass through. Its task is to prevent steam from entering the insulation from inside the house.

How much steam is released from inside the premises? For example, one person releases up to 1.5 liters of water per day in the form of steam. Without a vapor barrier, more or less of this moisture (depending on the ventilation in the room) will be absorbed into the walls and into the insulation.

We offer vapor barrier films:

- Yutafol N96

- three-layer vapor barrier with a reinforcing mesh; - Izospan B, C

- two-layer vapor barrier with a rough reverse side - accelerates the evaporation of moisture; - Izospan D

- high-strength woven vapor barrier.

Waterproofing for siding - materials and stages of work

Siding facade decoration is a popular solution in private low-rise construction. The use of siding allows you to protect from rain, wind, temperature changes and, at the same time, decorate cottages, outbuildings, garages or baths. This finishing material is easy to clean and retains its original appearance for a long time. To increase the heat-saving characteristics of the house, a layer of insulation is often laid under the siding. To protect the thermal insulation layer from getting wet, a waterproofing material is mounted on top of it. In the absence of insulation, waterproofing is still necessary.

Siding successfully imitates popular decorative materials such as facing bricks or natural wood, but costs much less.

Functions of waterproofing under siding

Waterproofing materials laid under the outer skin are used to solve the following tasks:

- Vinyl or metal siding does not get wet, but a leaky connection of the panels causes moisture to enter the gaps, which leads to deformation of the insulation. Most often, mineral or glass wool is used as a heat insulator for siding. These are non-combustible, lightweight materials with excellent heat-saving characteristics. But when wet, they completely lose their performance. The moisture penetrating between the panels also damages the wall materials - drywall and wallpaper; using electrical appliances may become unsafe. When waterproofing is installed, moisture flows down without destroying the thermal insulation material and the wall structure.

- The snow piling up under the ridge of the roof gradually melts and flows down the walls. If a waterproofing material is installed, moisture goes through it to the foundation area, then to the drainage system.

A high-quality waterproofing film retains moisture, but does not interfere with the natural ventilation of the walls, so steam from the house can escape to the outside.

In combination with waterproofing materials, a vapor barrier is often used to protect the insulation from steam coming from the house. Steam condenses and moisture penetrates the insulation.The vapor barrier is placed between the wall and the insulation.

Modern vapor barrier materials do not completely trap steam. To prevent the "greenhouse effect" in the house, a metered amount of air flow passes through the vapor barrier. Excess moisture is retained on the surface of the vapor barrier, and small amounts of dried air do not harm the insulation.

The need for a vapor barrier is determined by the type of thermal insulation material

Why waterproofing is necessary

Vinyl and basement siding provide good protection from rain. But the panels are leaking. Air passes freely through them, the house "breathes", and moisture enters with the air.

Modern heaters made of mineral and glass wool have excellent thermal insulation properties, are fireproof and lightweight. But they are afraid of water. When wet, they lose their qualities, become heavy and deformed.

Even if the facade cladding is carried out without insulation, then waterproofing is still needed - to protect the wall structures from getting wet.

Therefore, the installation of waterproofing is always required when decorating a house with siding.

Insulation under siding - the best options

Thermal insulation material is selected depending on the climate, the purpose of the house (for periodic or permanent residence), the presence of constant winds, and the level of humidity.

The following main types of insulation can be distinguished:

- Roll materials have a small thickness - up to 20 mm, are attached directly to the wall with adhesives, and are used in warm climates.

- The basis of mineral wool insulation is basalt, silicate fibers or fibers of other rocks. One of the varieties of such heat insulators is glass wool. Plates and mats made of such fibers are produced soft, semi-rigid, rigid. The materials have excellent heat-saving, sound-insulating characteristics, but a rather high coefficient of water absorption. Such heaters require packing on the vapor barrier wall before their installation.

For buildings constructed of completely vapor-tight materials, no vapor barrier is required for siding. But in this case, internal insulation is contraindicated, since the thermal insulation will definitely get wet.

- Polyfoam and extruded polystyrene foam have lower absorption than mineral wool.

Types and properties of insulation

Dense slabs of mineral fiber ("basalt wool") are an ideal insulation material for a wooden house for siding. The thermal conductivity is not inferior to either brick or wood. Good air permeability allows cotton wool to "breathe" no worse than wood. Standard sizes allow you to accurately determine the amount and area of insulation.

Plates marked ПЖ-150 (semi-rigid), ПЖ-175 (rigid) and ПЖ-200 (increased rigidity) are intended for insulation of external walls (the numbers indicate the average density of the material in kg / m3). The first and second are more often used in insulation, the second usually go for enhanced fire protection. The dimensions of the slab are 60 × 125 cm and the thickness is from 2 to 12 cm, depending on the density. For a wooden house, a PZh-175 with a thickness of 5–8 cm is suitable. The insulation can be pasted over with paper or fiberglass, stitched with thread. Mineral fiber does not decompose, does not burn, does not shrink. Depending on the binder compressed with the fiber, the hygroscopicity changes. The only drawback of the plates is that when wet, thermal conductivity decreases. Therefore, two types of protection are required: a vapor barrier membrane is laid between the wall and the insulation, and waterproofing (dense film) is laid under the siding.

In Russia, the most, and well-deserved, heaters are "URSA" (URSA) (Izhevsk), "Technonikol" (Nazarovo). For fastening to walls, long nails and round plates with a diameter of 3-4 cm for the caps are required. There are special fasteners on sale.

The procedure for installing siding with laying vapor barrier, insulation and waterproofing

Consider the stages of facade cladding with siding using the example of a wooden house and mineral wool insulation:

Some types of waterproofing materials additionally require compliance with the gap between the thermal insulation and the hydro-barrier.

On top of the fixed waterproofing, a counter-lattice is mounted under the siding from a bar or metal profile, the second option is more durable and reliable

When is vapor barrier and waterproofing needed?

Vapor barrier is required in those structures where the vapor permeability of the wall and heat insulator is high. For example, when insulating a panel house with polyurethane foam, vapor barrier is not needed, and a forced ventilation system is required to remove water vapor, so as not to get high humidity in the house, and with it - mold and mildew. A brick house will already require a vapor barrier device.

Pure waterproofing for siding is not needed at all. In order to prevent moisture vapor from the atmosphere from getting deep into the heat-insulating layer, a vapor barrier is needed. But in order for the condensate accumulated on it to be taken out, a ventilated gap with a width of at least 40 mm is arranged between the cladding and the insulation.