Among the huge range of insulation materials for baths, consumers increasingly prefer aluminum foil. This coating is affordable and simple. It perfectly retains heat inside the premises, excluding the rapid cooling of the building. This saves energy and guarantees a comfortable stay inside.

Among the main advantages of this material are:

- high refractory qualities;

- good steam and moisture resistance;

- high reflectivity;

- excellent anti-corrosion properties.

Vapor barrier properties allow eliminating the leakage of hot steam, which then does not accumulate in the coating. Aluminum foil does not deform, does not emit harmful substances and vapors, is durable and hygienic. The canvases are highly plastic, they are UV resistant and are easy to install. They are immune to chemicals and can withstand high temperatures for a long time.

Foil perfectly protects adjacent adjoining rooms if the bath is located inside the house. With proper installation, even thin sheets will not tear and deform. However, this material must be purchased with a margin of 7%. Foil for a bath is good because it can withstand temperatures up to 145 ° C. In combination with high reflectivity, this property allows you to keep warm inside the steam room for 2.5 hours longer than other heaters. This provides a thermos effect. Thermal insulation is universal in use and is suitable for surfaces that do not require special treatment with fungicidal substances.

Which foil to choose

If you want to decide which foil to choose for the bath, you must consider several options. Different types of such coatings have special characteristics and properties. For example, "Folgoizolon" is a foil that is applied to foamed polyethylene. Thermal insulation is offered in rolls or sheets. Among the advantages should be highlighted:

- high noise insulation properties;

- excellent strength;

- amortization qualities;

- the possibility of laying the material on a surface without thermal insulation.

"Folgoizolon" is suitable for log walls and surfaces with lathing battens. The bases can be sheathed with clapboard. The thickness of the material reaches 100 mm, and the length and width of the web can be equal to 120 cm and 600 mm, respectively. This is true for sheet material, whereas when it comes to rolls, the thickness varies from 20 to 110 mm, and the length is standard and is equal to 25 or 30 m.The width of the roll is also fixed and can be equivalent to 100 or 120 cm.

Such insulation for a bath with foil can withstand up to 125 ° C. Another variety is paper-based foil. This material is also called kraft foil. It is environmentally friendly and can be used on any surface, but the material should be combined with insulation. Sheets can have a thickness of 0.03 to 1 mm. The temperature range here is somewhat narrower and varies from 50 to 85 ° C.

Reviews of laminated foil

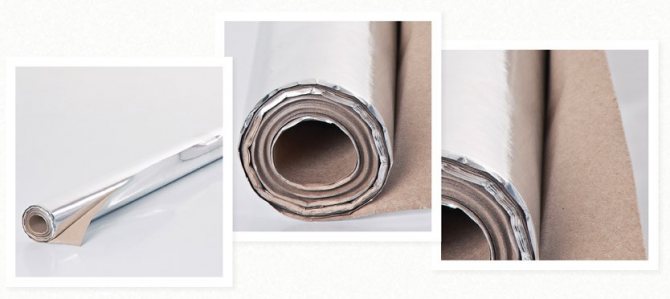

Another type of foil is laminated aluminum material, which is made by combining polyethylene, paper and foil. As a result, it is possible to obtain a layer that, according to consumers, has high barrier properties.

The canvases have impressive indicators of impermeability to steam and gases.If we compare it with a film, then with its thickness of 9 microns, it will have a water vapor transmission capacity of 0.1 g per m2 per day. Customers like the high hygiene performance of laminated foil. In humid conditions, the surface will not create a nutrient medium for the development of mitoxins and microflora. It is impossible not to mention also the elasticity. This material resists compressive loads while maintaining its original shape.

Among the main types of laminated foil, Kraft paper with foil should be distinguished, which is a three-layer laminating material. The first layer is kraft paper, the second is thin polyethylene, while the third is the aluminum foil itself. Kraft paper is made from long-fiber cellulose using a leveling method and the use of chemical salts.

According to users, kraft paper is characterized by its density, wear resistance and mechanical strength. As for polyethylene, it has impressive thermoplastic, vapor barrier and water-repellent properties. Foil fulfills its main function - it reflects heat into the room.

If you purchase material made in China, then you will have to pay $ 26 for the sheet. Laminated foil from European manufacturers is more expensive - $ 45 per sheet. A domestic manufacturer offers foil on kraft paper for $ 20 per sheet.

Foil characteristics at 100 microns

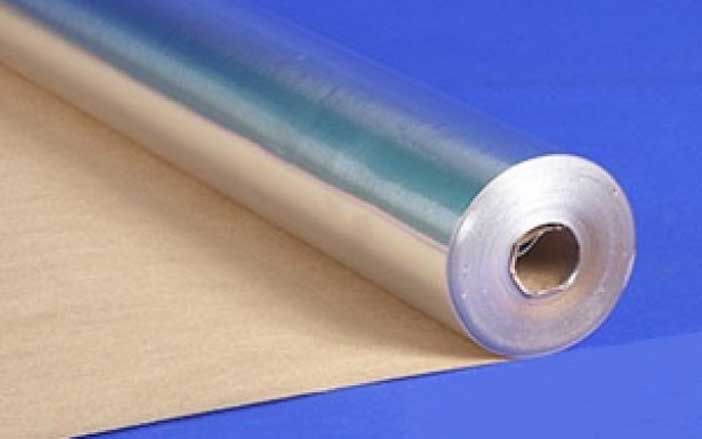

On sale today is a foil for a bath 100 mkr, which is polished and looks like a roll. Its width is 1 m when it comes to the hard variety. The annealed foil has a width of 0.5 m. The length reaches 10 m. One roll weighs 2.5 kg.

This foil for a bath, the thickness of which is 0.1 mm, can be used at temperatures up to 650 ° C. Its reflectivity is 97%. The material has a smooth surface and can be used in the construction of underfloor heating, air ducts, stoves, boilers, as well as for insulation for various purposes. The layer effectively protects against fire, it is resistant to corrosion and retains heat in the coolant.

Such foil in rolls is an excellent vapor barrier. It can replace materials such as:

- glassine;

- roofing material;

- bituminous paper.

The latter emit harmful substances when exposed to temperature. Foil can be used as an independent reflective insulator and in combination with other heat-insulating materials. The polished surface is an ideal reflector, increasing the efficiency of thermal insulation.

Operation is possible not only inside, but also outside the premises. This area of use includes the insulation of roofs, attics, attics, floors, walls, pipes, ceilings, ventilation, ceilings, water heaters, vans and wall sections behind radiators. This foil acts as sun-reflecting panels on windows.

Overview of foil insulation

From the information above, it became clear that aluminum foil is used both with and without insulation. In the first case, the foil is applied to the insulation, and in the second - to the timber or log.

On sale you can find:

- Polished aluminum foil in accordance with GOST 618-73 in rolls or sheets

- Foil Kraft Paper

- Insulation with a foil layer

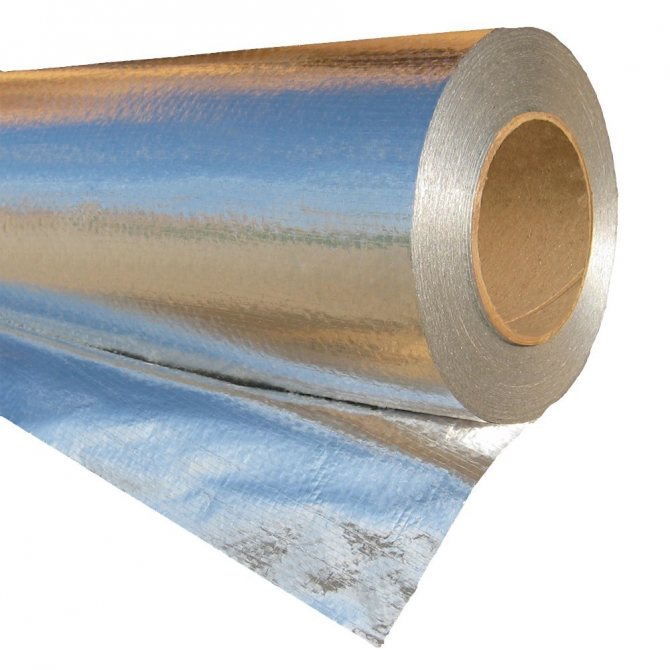

Let's consider all the varieties separately, in more detail. The picture shows foil rolls.

1. Depending on the thickness, the foil is sold in sheets or in rolls. Annealed (soft) foil is marked with the letter M, and unannealed foil is designated with the letter T. The thickness of the foil is from 0.007 to 0.2 mm and more, the width is usually 1 to 1.5 m.

Rolls of thin foil often consist of five pieces of linen, and thicker ones of three.

In stores, it has a specific purpose - for baths and saunas.

2.Foil paper is a high tenacity paper with added cellulose and a thin aluminum coating. The product is attached to the walls using nails, screws or construction brackets.

It is ideal for thermal insulation of building structures in hard-to-reach places.

A roll with a width of 1 m consists of 30 m of linen. Price for 1 m2 = 420 rubles.

This type of coating can withstand temperatures from - 50 to + 120 degrees. WITH

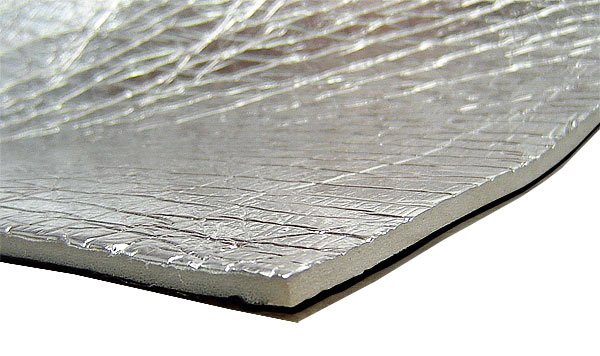

3. This foil insulation is specially designed for the decoration of rooms with high humidity.

Penotherm NPP LF is a heat-insulating material made of expanded polypropylene with aluminum foil. It is reflective thermal insulation as it uses polished aluminum foil. It is mainly used for thermal insulation of walls and ceilings in baths and saunas.

Penotherm NPP LF can be easily cut with a clerical knife, can be mounted using a furniture stapler, glued with tape.

Main characteristics: application temperature from - 50 to + 150 degrees. C, good thermal insulation, good vapor barrier, good sound insulation, does not rot and corrosion, environmentally friendly material.

In brick or block saunas, it is recommended to insulate not only the steam room, but also the sink.

Penotherm NPP LF is produced in different thicknesses and therefore prices will also be different:

- thickness = 2 mm costs 134 rubles / m2

- thickness = 3 mm costs 145 rubles / m2

- thickness = 4 mm costs 154 rubles / m2

- thickness = 8 mm costs 244 rubles / m2

- thickness = 10 mm costs 278 rubles / m2 (prices are indicated for the city of Perm)

Let's go back to point 1 - to aluminum foil in rolls to get acquainted with the prices:

- thickness = 0.04 mm costs 570 rubles / roll

- thickness = 0.08 mm costs RUB 950 / roll

- thickness = 0.1 mm costs 200 rubles / m2

- thickness = 0.2 mm costs 300 rubles / m2

- thickness = 0.8 mm costs 450 rubles / m2

Knowing the prices of foil insulation and the material of the walls of your bath, you can compare them with your money and it is already better to choose it and buy it.

And when the material is purchased and delivered, you can edit it the way the author of this video did.

Thanks to the foil insulation, bathing procedures will be a joy and pleasure. Good luck!

willcomfort.ru

Reviews of foil mineral wool

Foil mineral wool can be represented by soft roll and hard mats. According to experts, this expands the area of use. Among the main advantages of the first of these types, according to consumers, a high degree of moisture and vapor barrier should be highlighted.

Foil wool in the form of rigid mats has excellent insulating properties and is easy to install. The thickness of soft rolls can reach 10 mm, and the maximum exposure temperature, as home craftsmen emphasize, is quite high and reaches 125 ° C.

Reviews about foil rolls

This material is sold not only in the form of panels. If you want to purchase bath foil, you can choose the material in rolls. It is distinguished by its low cost, which is complemented by ease of installation. Installation of such a foil is possible only on a refractory heat-insulating material with fastening with metal brackets.

Customers like that the sheet thickness is minimal and can be 0.5 mm. The roll width is 1500 mm. According to consumers, the temperature range is wide enough and varies from -50 to +75 ° C.

What is the main thing in a good bath?

A good bath is one that heats up quickly and does not cool down for a long time. If the first problem is solved by a high-quality stove, then the insulation system is responsible for the problem of keeping heat. The material of the building does not matter much here. Do not close up the cracks and holes - there will still be loopholes for the formation of cold bridges. Proper insulation should create the effect of a thermos, this function is performed by foil.

Foil for a bath, without touching the walls lined with clapboard, blockhouse, reflects heat, not allowing it to go outside the steam room, works like a mirror. The material, in fact, serves as a heat reflector and more. Another important function is to ensure the tightness of the room, does not allow water and steam to pass through. The steam, while remaining hot, does not condense, it remains inside the room, which also contributes to the retention of heat. The steam room, in which insulation is foil, heats up much faster and accumulates heat.

Such functions are relevant for all other premises of the bath. It is also important to maintain heat and tightness in the shower, pool, recreation room.

Additional properties of expanded polystyrene with a foil layer

This material is combined and consists of closed cell polyethylene foam. It is supplemented with aluminum foil. Canvases are used as sound insulation and heat-shielding material for indoor and outdoor work. The combination of these layers makes it possible to economically and efficiently decorate baths and saunas. Among the main properties should be highlighted:

- shock-absorbing qualities;

- health safety;

- vapor barrier properties;

- ability to reflect heat up to 98%;

- long working life;

- chemical resistance.

Selection of foil coating according to the recommended layer

In order to achieve a high-quality coating during laying work, you should adhere to the thickness of the foil thermal insulation. It will depend on the material and wall thickness. If the base is brick, and the wall thickness of the steam room reaches 37 cm, then the recommended layer should be from 8 to 10 mm. If the base is concrete or brick, and the wall thickness varies from 25 to 35 cm, then the foil insulation should have a thickness of 10 to 12 mm. In the case of a wooden frame from 10 to 15 cm, you should use foil insulation, the thickness of which varies from 6 to 8 mm.

When using the same material, but with an increase in wall thickness up to 20 cm, a foil layer from 4 to 6 mm in thickness should be used. Foil for a bath will be with a layer of 2 to 4 mm, if the wooden frame is more than 20 cm thick.

Glass wool or basalt wool can be used as an additional insulating layer. Similar mineral heat insulators are also suitable. Aluminum foil or similar coatings will reflect heat inside the room, so it is better to install such a layer in a steam room, insulated according to the principle of a pie. This recommendation is relevant for saunas and baths made of concrete or brick. The advice is also suitable for frame buildings. With a sufficient thickness of the external walls of wooden log cabins, a layer of additional thermal insulation can be neglected, but when choosing a foil material, you should not give preference to thin sheets of kraft paper in foil.

Installation technology

When installing foil for a bath, you must adhere to the tips that will allow you to achieve the effectiveness of the coating and a comfortable stay in the steam room. When it has an impressive area, you can use basalt or mineral foil. When laying the material in a non-commercial bath, it is sufficient to use kraft paper in foil or roll foil. The thickness of the material must be 3 mm or more.

When locating a sauna inside a house or in a basement, you need to take into account the central heating and the location of its sources. In this case, such a system will act as additional air heating.

When finishing the bath with foil, it is important to provide for condensate drainage. In this case, the canvas is displayed on the walls and floor. Foil material should be laid with an overlap of 20 cm and glued with foil tape. In order to provide a thermos effect, a 15 mm gap must be placed between the foil coating and the decorative cladding.It will provide ventilation and guarantee a healthy microclimate.

How to properly apply foil for a bath

And if you properly insulate your bath with foil, you will get the "thermos effect" - this is the way to quickly accumulate heat and maintain the desired temperature for a long time. The use of foil is especially necessary in the sauna room. Where the foil is applied to the ceiling and walls.

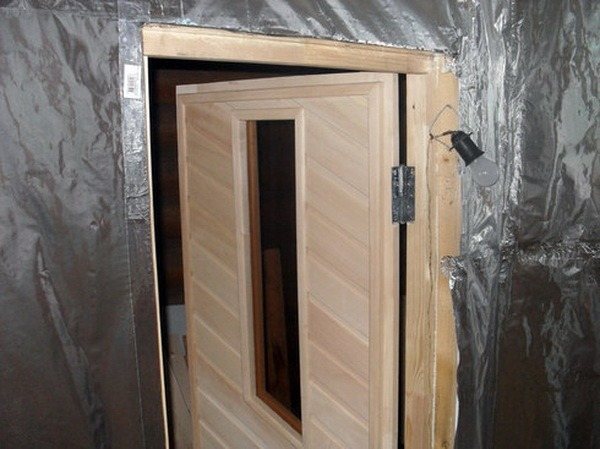

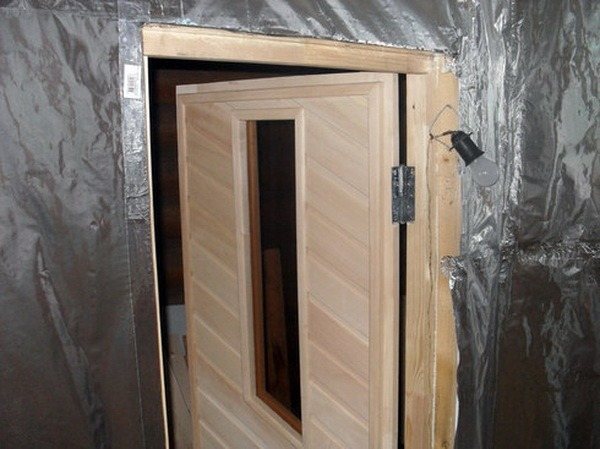

The pictures show that there must be an air gap between the clapboard and the foil layer, which means that the insulation system and the walls of the bath must breathe.

First, the ceiling is insulated in the steam room and only then they move on to decorating the walls of the room. If the insulation is mineral wool, then paper is first glued to the ceiling, then a crate of wooden bars is nailed and mats are inserted between them. To prevent the mats from falling, they are fixed with slats.

Then, neatly, or better together, they overlap the foil. Try not to tear it.

If broken, cover with aluminum duct tape. All foil overlaps, also glue with tape. The main loss of heat goes through the ceiling, so the insulation process must be thorough and the use of foil for the bath has had a positive effect. Watch the video about the use of foil

So that there is no leakage of heat and steam, the foil is laid down to the walls and ceiling by 5-10 cm. On top of the foil layer, more bars are nailed to create an air gap of up to 2 cm for air convection. And already the last finishing layer or linden paneling.

To use foil with insulation in the bath or without it, until now, different people have their own opinions, here's a look at how the author discusses this topic

Thus, all the steam remains in the steam room, does not accumulate in the insulation and does not condense on the inner surface of the load-bearing walls. The bath will stand for a long time without repair.

Foil mounting algorithm

If you are interested in how to fix the foil in the bath, then you should know that the process is divided into several stages. The most convenient to work will be sheets or rolls, the width of which is 60 cm or 1.2 m. It is necessary to make a crate on the walls. For this, square beams with a side of 5 cm are used.

A distance is maintained between adjacent strips, which depends on the width of the material. If rolls of 600 and 1200 mm are used in the work, then the step will be 60 cm. For foil materials with a width of 1000 and 1500 mm, the distance between the bars will be 50 cm. The bars are fastened with self-tapping screws of a suitable length. A layer of mineral insulation is located between the planks so that it does not protrude beyond the level of the beams.

After you have decided which foil is best for the bath in your case, it should be strengthened over the thermal insulation with the obligatory placement of a reflective layer inside the steam room. The joints of sheets and canvases are glued with metal tape. But it is important to take into account that under the influence of temperatures, the glue can soften, which will contribute to the divergence of the sheets and the violation of the seal. It is better to fix it with nails or staples, nailing them onto the uneven bars.

With an impressive width, the foil material is attached not only at the edges, but also in the center. The foil for the walls of the bath is sewn up with clapboard. An air pocket of 0.5 cm should be left between these layers. Its main function is to reduce the heat-conducting properties of the foil and reflect the rays that hit its surface. The air gap will be created by the lathing under the lining. For this, 20 mm strips are selected, which are attached with self-tapping screws.

In some cases, the order of the materials is changed. At the same time, a layer of foil is stuffed onto the layer of thermal insulation between the beams of the sheathing with nails or staples, which is attached from above with thin slats. They should sit on top of the lathing.

Sometimes the frame is stuffed over the thermal insulation.In this case, the foil is laid over the entire area of the wall, as well as on the beams. Leaving an air gap in this case is impractical. Fastening the lining using this technology is carried out on the crate. Practice shows that the use of heat-insulating materials with a foil layer saves money and simplifies the installation process.

How to sew correctly?

The main installation condition is an overlap fastening with a grip of 10-20 cm, the joints should be glued with special tape, then there will be no loopholes for steam, condensate will fall to the floor without penetrating into the insulation layer.

Aluminum tape - a guarantee of tightness

The use of foil in a log bath differs from the technology of insulating a building made of brick and concrete. Walls made of logs should be carefully dug. If the tree looks aesthetically pleasing, the frame is well-built and the rooms (except for the steam room) are not supposed to be clad with clapboard, then the use of foil for the walls is not necessary. The ceiling is sheathed with a heat reflector without fail.

On a note! To get the effect of a thermos - it is necessary to sheathe the steam room with foil, walls, floor, ceiling.

- It is necessary to sheathe the wall around the stove with thick ordinary foil, the heat will not get behind the wall with the stove.

- On the ceiling, installation is carried out with a reflective layer downward, with an overlap and an allowance of 5-15 cm on the wall.

- Walls are also sheathed, floor overlap is required.

- The floor is set up last.

Work with the floor is carried out after the lining is sewn onto the ceiling and walls, the correct installation of which assumes the presence of a gap between the frame and the heat reflector layer.

Air gap is required

The same procedure for installing a foil layer of brick-concrete structures. The only difference is that all rooms (walls, floors and ceilings) are sheathed there, without exception.

On a note! The joints with window and door openings should be especially carefully upholstered. Nail the foil with tape, glue it with tape, checking for cracks.

Correct cladding of a window opening

In conclusion, a few words about ideal insulation. Foil materials perform the function of a heat reflector, in fact, they are not insulation. For high-quality insulation, the installation of a pie is required, the top layer of which is the material for vapor barrier, then the insulation itself, and only then a layer of foil-clad material. In this form, the bath will be functional, healthy, pleasant for the body and soul.

Installation of foil on the ceiling

After reading reviews about bath foil, you can understand that it has a wide range of uses. It can be installed not only on the walls, but also on the ceiling. To do this, it is covered with a roll of paper with a wide overlap. At the next stage, the paper is fixed with square bars with a side of 5 cm. Insulation is installed between them.

The next step is to install the foil. It will block the isolation ward. It is important to ensure one hundred percent solidity. Fastening is carried out with adhesive tape, which can be purchased at a hardware store. Quite often, it is sold together with foil.

Among such tapes there are substandard ones. It is quite simple to check this: a piece of material must be glued to a piece of foil and try to tear it off. If you have ordinary tape in your hands, then it will not be so easy to cope with the task. If you want to know in detail how to sheathe a bath from the inside with foil, then the extreme sections and joints must be carefully fixed. This is necessary to exclude moisture penetration. It is important to achieve tightness.

Wax paper or heavy cardboard can be used instead of aluminum foil. It is pre-soaked with linseed oil. But on such a vapor barrier it will be necessary to lay a layer of clay, only after that you can start warming. The foil is fixed with 2 x 3 cm bars. This will preserve air exchange, and in the future you can install decorative trim on the bars.

Performing a simple planking of a bath

In order for the foil for the bath to clearly perform the functions assigned to it, it is necessary to follow the rules for its installation, because if you stuff it on bare brick or concrete, then due to its high thermal conductivity, the material will release all the heat outside. The reflectivity of aluminum in rolls reaches 96%. This helps to retain a significant amount of heat energy released by the stove.

Manufacturers offer various sheet thicknesses. In hardware stores, there are parameters of 30-300 microns. Various bases help to enhance the positive effect. Its role can be played by:

- kraft paper;

- prepared fabric;

- fiberglass;

- polyethylene;

- mineral wool.

There are rolls on sale without any base, but the use of such material is not recommended.

Foil is selected for insulation according to its basic properties. In addition to durability and ease of installation, which can be achieved with thicker sheets, there are the following selection criteria:

- the presence of a different base makes it faster and easier to fix the material on any surface, because it becomes more difficult to break it, even involuntarily;

- due to the fact that the foil for the bath is able to withstand high temperatures (the values in the room reach 100 0 C), it is practically irreplaceable as an additional barrier between the room and the external environment;

- its surface is highly reflective, practically not absorbing any radiation;

- the vapor permeability coefficient should be no more than 0.01 g / m 2 per day;

- strength characteristics will ensure ease of installation;

- the foil does not emit any toxic fumes even with significant heating in the steam room;

- the minimum parameters of the formation of corrosion foci allow its effective operation for a long period.

Foil heaters have different names. It depends on the backing fastened to the sheets. So, foil is called foil applied to a foamed polyethylene base. It is offered to customers in roll form or as rigid plates.

In the first case, the thickness varies in the range of 2-10 mm, and in the second, the interval will be 20-110 mm. The kit can withstand temperatures up to 120 0 С.

Folar is a vapor barrier made of 4x4 mm fine-mesh fiberglass mesh, which acts as a reinforcing layer between two sheets of foil. It is based on no harmful substances. Depending on the brand, it can withstand thermal loads in the range of 150-300 0 С.

Izolar - paper-based foil for a bath. It has three layers, in addition to the metal one, there is a polyethylene ball and an interlayer of kraft paper. In hardware stores, it is presented in the range of 0.03-1.0 mm. He must withstand temperatures of 100 0 C, as this value is indicated in his instructions for use.

You can even find foil-clad mineral wool on the shelves, the operating temperature of which is -60-300 0 C. It is this that a large number of specialists who are engaged in the conversion, construction or modernization of baths have fallen in love with.

Although the principle of operation of the foil coating is based on the reflection of heat into the room, it will not be possible to cope with its entire volume. In order to maintain a constant temperature in the room, it is necessary to make a "cake" of insulation, where insulation, steam and waterproofing should be used as the main material.

It will be possible to obtain the highest quality result at a relatively low cost with proper installation. To do this, you must follow certain rules.

It will be possible to create comfortable conditions using foil on craft paper for a bath with a thickness of at least 3 mm. Basalt based material has an excellent reflective effect.During the development of the installation scheme, you will need to prepare a place for condensate drainage. The obligatory overlap of 150-200 mm will increase the productivity of the steam room, because in this way all the seams are sealed.

The use of a foil backing will give the maximum benefit in forming an air layer separating the foil sheet from the wood finish. This rule applies not only to the walls, but also to the ceiling.

It will be possible to create a cozy microclimate with well-organized ventilation. If this condition is neglected, the layers will immediately become saturated with a large amount of moisture, losing their thermal insulation properties and making the foil layer useless.

In the steam room, the "thermos" effect is especially important, when all the heat is concentrated inside. A 1.5-2 cm wide ventilation gap between the foil layer and decorative trim will help to cope with this.

It is necessary to take into account the proportions of the insulation and the material from which the walls of the bath are taken out. The thickness of the substrate should be different for wood and brick steam rooms.

We suggest that you familiarize yourself with: Door to the steam room: glass, wooden, dimensions, drawings, photos

Work with sheets or rolls, which have a width of 0.6-1.0 m, will provide a quick and reliable result. For their installation, the inner space of the bath room is wrapped vertically with 50x50 mm strips. Self-tapping screws are used to fasten the timber. The most convenient insulation in this situation, for example, mineral or basalt wool, is placed in the grooves of such a flooring. It is advisable to avoid the appearance of gaps.

After laying the cotton wool, we proceed to the installation of the foil layer. It needs to be turned inside the room. Fixation is carried out in the most convenient way in this situation: brackets or self-tapping screws. It is advisable to process not only the edges, but also to grab the layer in some central zones. The seams must be sealed with foil tape. It will also maintain the integrity of the structure.

For fixing the material, staples are perfect, with which it is nailed along the perimeter and center. The foil is very tear-resistant, so do not be afraid that a torn hole will appear in the place of the staple.

Body preservation will be significantly improved during the formation of an air gap after the foil. To do this, we punch a row of slats 10-20 mm high in increments of up to half a meter. The final layer is a lining, which we fill on the resulting crate.

Wall and ceiling lined with wooden clapboard

Installation of foil-clad walls and ceilings in the steam room will not only save 20-30% of funds for heating the bath, but also save the wooden frame of the building from the development of mold, fungi and other undesirable microorganisms in it.

When cladding the walls of bath buildings, the foil sheet is attached to the surface or over the thermal insulation layer. Such work will take little time and will not require much effort.

The process looks like this:

- Before sheathing the bath with foil, a frame made of wooden planks is fixed on the wall.

- Insulation is placed between the slats.

- The top of the insulating material is covered with an overlap foil, the joints between the strips are glued using aluminum tape.

- The foil is sheathed with clapboard and a 15-20 cm air gap is made between it and the surface of the foil. This is a prerequisite for efficient heat transfer.

The air gap will reduce the thermal conductivity of aluminum, and since the hot lining will not come into contact with the foil, due to the insulating qualities of the air, direct heat transfer will become impossible. At the same time, infrared rays falling on the surface of the foil sheet will be reflected towards the steam room.

Aluminum foil, GOST 618-73, is a rather fragile material that is necessary to create an insulating cake for baths and saunas; it is used either in the form of a conventional aluminum film or in conjunction with a substrate.

A heat insulator is necessary to improve the efficiency of the bath. The benefits of its use are as follows:

- promotes rapid heating of the room;

- retains heat, not allowing it to go outside;

- protects walls, a layer of insulation from the destructive effects of moisture and steam;

- protects against the formation of mold, mildew;

- withstands high temperatures and their drops;

- extends the life of the building as a whole.

Environmentally friendly foil is non-corrosive, non-toxic, ecologically perfect, meets all sanitary and hygienic requirements.

On a note! The use of foil is useful, the consumption of energy (electricity, wood) is reduced by at least a third! The life of the bath is extended twice! The material is inexpensive, easy to install.

The benefits of the application are obvious, it is only important to choose the right material for the steam room and other premises of the bath, sauna.