What is it and what is it for

This device is designed to remove smoke and gases from heating devices into the external environment. It is a smoke channel of various shapes and cross-sectional areas.

Another important function of the channel is to provide adequate thrust in the fuel system.

Smoke removal structures are required for stoves, fireplaces, gas boilers.

Previously, with the predominance of stove heating, they were built mainly of bricks. With the advent of gas units, steel chimneys became widespread.

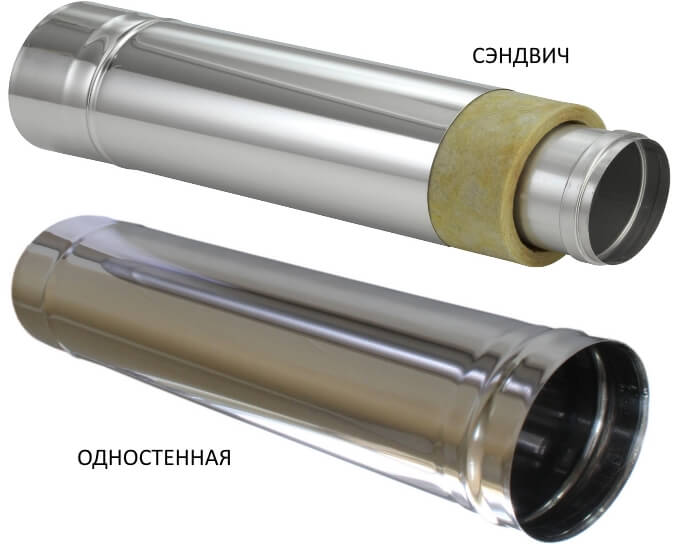

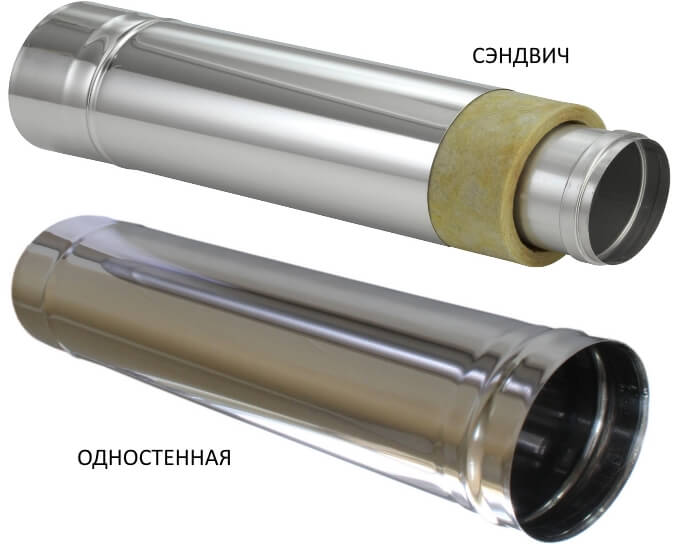

Single-circuit and double-circuit steel chimneys

The cheapest steel chimneys are single-circuit. In fact, it is a sheet of steel rolled into a tube with one welded seam.

Advantages of single-circuit chimneys

- light weight;

- small size;

- affordable price.

There is only one drawback of such pipes - high thermal conductivity. It means that:

- when flue gases pass, the outer surface of the pipe will be very hot. If you touch it, you will definitely get a burn;

- the flue gases will be very cold while driving. In this case, a huge amount of condensate is formed, and the speed of movement of cold gases is lower. Especially a lot of water settles in the chimneys of modern gas boilers with high efficiency;

- you will not be able to install such a chimney outside the building, and with internal installation you will have to make large cuts in each floor and in the roof. It is quite difficult and expensive.

Double-circuit steel chimneys consist of two pipes. Between them is a layer of heat-insulating material. We use basalt fibers - it does not cake, does not change under the influence of high temperatures and retains its properties for many years.

Due to the design features, double-circuit chimneys are often called sandwich chimneys.

Advantages of steel sandwich chimneys

- relatively low temperature of the external circuit: the pipe can be touched without fear of burns;

- all the heat remains inside: therefore, flue gases are removed faster, and the amount of condensate is reduced significantly;

- outdoor installation - you can lead the chimney through the nearest wall using a small horizontal element and then lead it along the outside of the wall. This reduces the cost of installation and makes the operation of the heating system safer;

- smaller size of indentation and cuts when passing through structures made of combustible materials;

- noticeably longer service life.

Disadvantages of steel sandwich chimneys

- larger diameter;

- higher cost;

- somewhat more complex installation.

Can a homemade steel chimney be used?

If you need a pipe for a stove stove outside the house, you can make it yourself, but it doesn't make much sense (today you can buy an excellent steel chimney inexpensively and not waste energy on tin work). If you need pipes for a home or industrial smoke removal system, it is better not to risk it and purchase certified components.

Russdym provides services throughout the entire Moscow region, including the following cities: Istra, Krasnogorsk, Nakhabino, Dedovsk, Dolgoprudny, Korolev, Podolsk, Pushchino, Sergiev Posad, Serpukhov, Chernogolovka, Shchelkovo, Zelenograd, Zvenigorod, Khimki, Solnechnogorsk, Dmitrov, Wedge, Lobnya, Odintsovo, Vnukovo, Volokolamsk, Mozhaisk, Ruza, Skhodnya.

How the chimney works

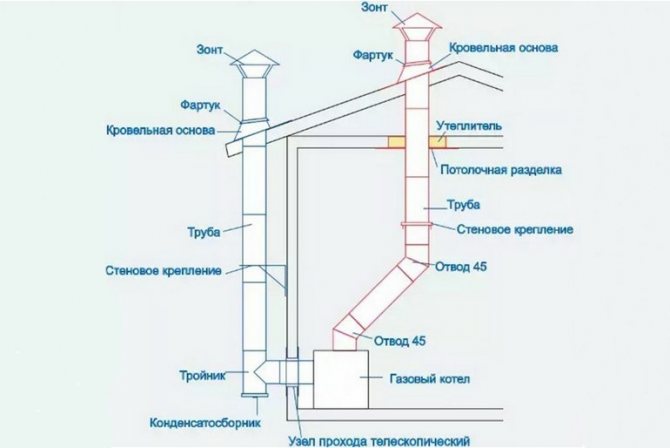

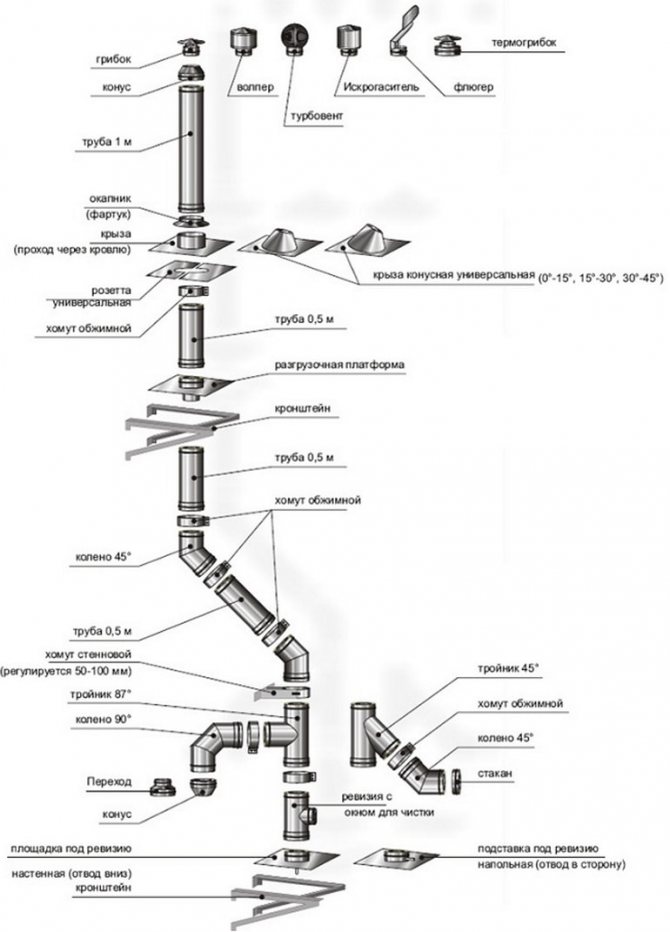

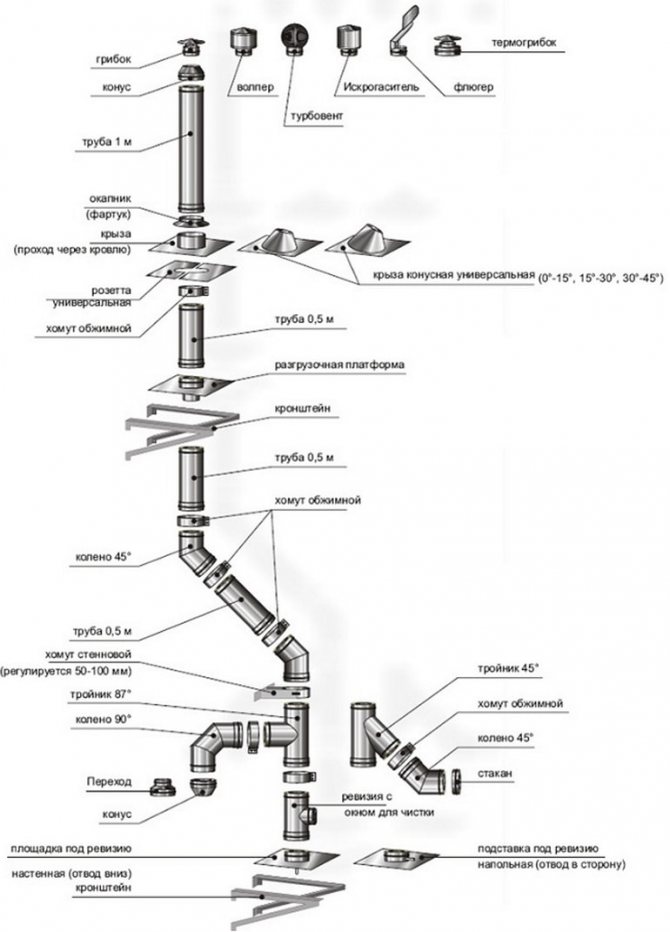

The basis of a metal chimney is made of metal pipes of different lengths.The design makes it easy to connect them by the socket method. Elbows and tees are designed for pipeline bends. Fasteners are crimping clamps, brackets.

A head is installed on top. It protects the drainage from snow and rain, serves to increase traction, decorate the roof.

Supports, nozzles, deflectors, spark arresters and other parts required for the installation of a smoke exhaust device also provide effective operation.

Types and designs

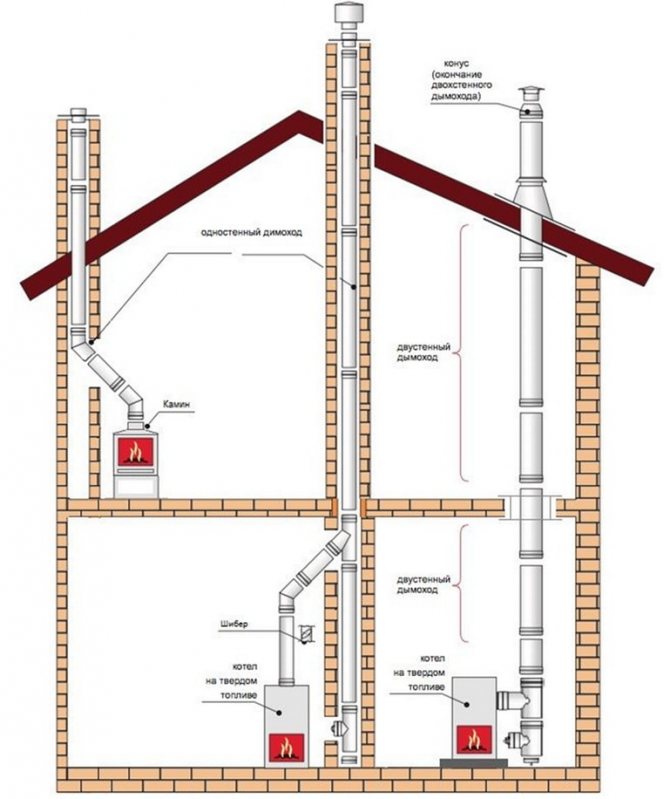

By the type of structures, metal chimneys are divided into:

- single-walled. They are used as temporary branches, for example, for ovens in baths;

- two-layer, called "sandwich". They consist of inner and outer pipes, between which insulation is laid;

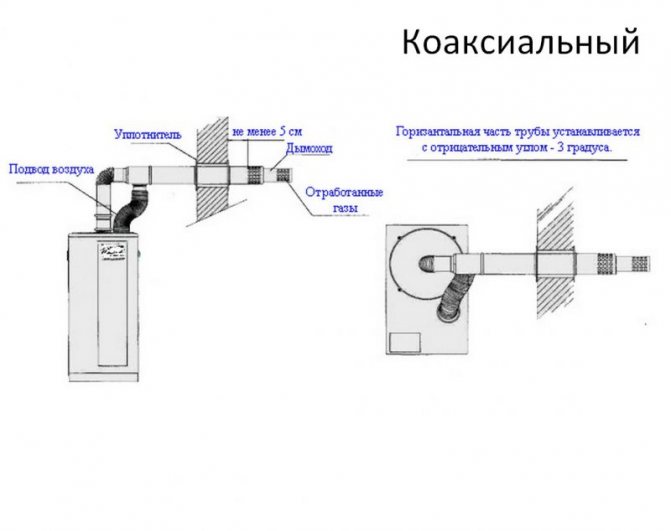

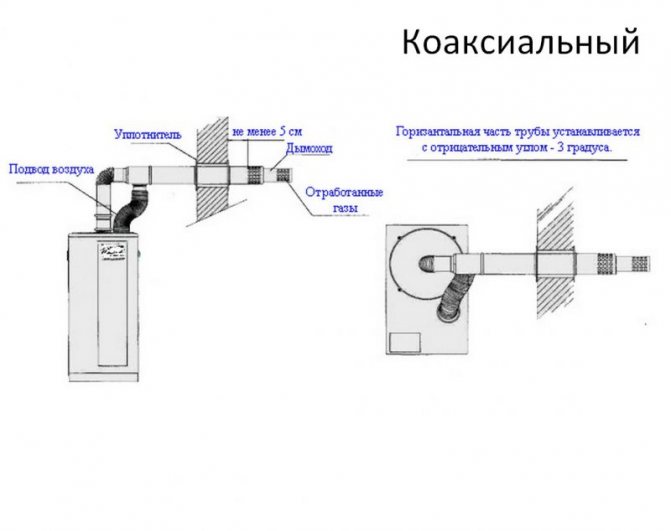

- coaxial chimneys. The design of two channels, simultaneously carrying out smoke and oxygen supply to the furnace. It is used only for heaters with a closed combustion chamber.

Distinguish also:

- straight chimneys. They are installed vertically and led out through the roof;

- lateral attachments. They are brought out with the help of a knee and mounted on the wall of the house;

- the side internal ones go out into the smoke shaft built into the wall, or they themselves are built into the load-bearing wall of the house.

Steel chimneys are made from various metals.

Black steel

Chimneys made of this material are of low cost. They do not have the best strength characteristics, but they can stably withstand temperatures up to 500C.

To increase the service life, enameled products, pipes with thickened walls are used. Chimneys of this type are installed more often in summer cottages, in baths, where heating devices are not used so intensively.

Low alloy steel

Small additions of alloying components give such bends increased corrosion resistance and strength. Able to withstand an operating temperature of 1200 oC. They can be connected to solid fuel foci.

Galvanized iron

Pipes made of this material practically do not rust, the price for them is lower than for stainless steel. However, there are concerns about their negative impact on human health. At a heating temperature above 419C, zinc begins to emit toxic fumes.

In this regard, it is recommended to use galvanized products in systems with low operating temperatures up to 350C. There are no contraindications for their use in sandwich smoke removal devices. Here, the inner channel is filled with stainless steel, the outer one is galvanized.

It should also be noted that a galvanized channel installed without insulation will last only 1-2 heating seasons.

Stainless steel

This type of steel has high heat resistance and resistance to acids and moisture. Chimneys made of stainless steel are made of both single and double-layer types. Withstands temperatures at peak load up to 850 C.

Single structures are used as the inner part of the bends and for casing brick chimneys. The product is inserted inside the old brick channel and connected to the boiler pipe.

Two-layer insulated chimneys have become the most common. They retain heat well, due to which they consistently provide proper traction.

Stages of installation work

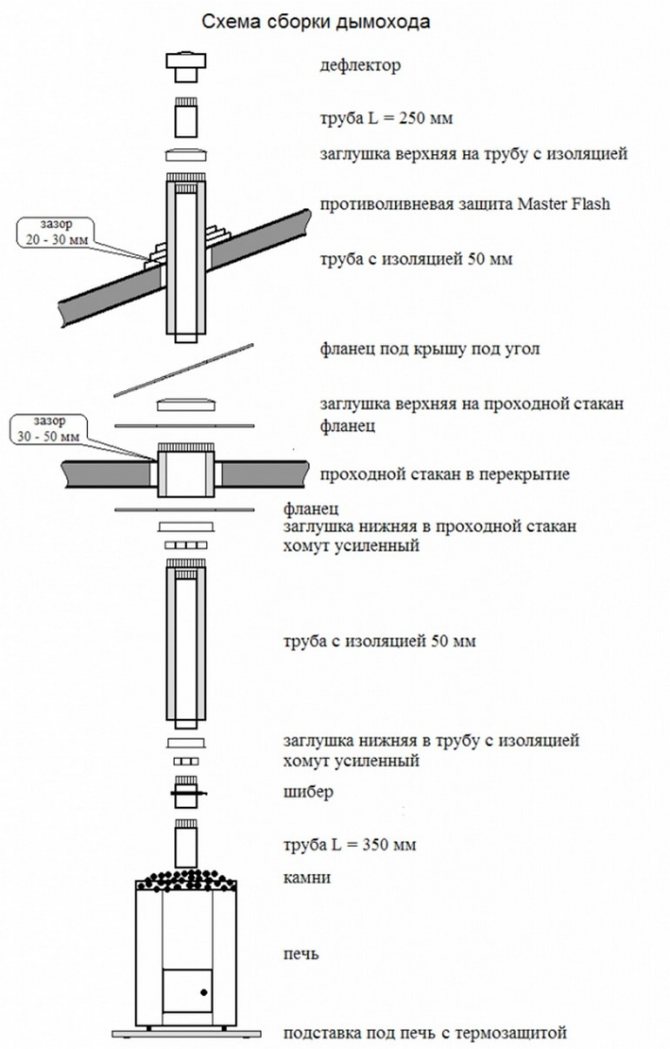

The installation of an internal and external chimney is somewhat different. But before starting work with any kind, it is necessary to check the presence of all the necessary parts and elements according to the drawings. For chimneys you will need:

- bends;

- dampers;

- tees and supports for them;

- brackets, including for a dowel;

- top;

- cap;

- insulation, insulator (if necessary).

An important stage in the installation is the insulation of metal parts.With proper insulation, some problems that arise during the operation of chimneys can be avoided: it will not allow the temperature of the inner walls to drop to the dew point and avoid the appearance of condensation;

- will keep constant draft, as it will not allow flue gases to overcool;

- will not allow the temperature of the outer walls to rise to a temperature that will become fire hazardous to the surrounding structures;

- will protect the roof from the ingress of chemically active combustion products.

The heat insulator can be mineral, basalt wool, glass wool. These materials are fire resistant, easy to install and durable. Thermal insulation can be done with a concrete casing, when materials with low thermal conductivity are added to the mortar.

Chimney protection tube

Advantages and disadvantages

The advantages of metal chimneys compared to brick ones include:

- ease of construction, variability of the assembly configuration;

- optimal ratio of price, quality, ease of installation;

- simple and quick process of assembly and installation of the structure;

- smooth surface of internal walls, on which combustion products do not linger.

Metal chimneys have limitations that should be attributed to their disadvantages:

- the high cost of individual stainless steel structures;

- inability to use at constant operating temperatures above 500C;

- with the exception of certain types of stainless steel, chimneys from other metals are highly susceptible to rust.

Chimney types

A chimney is a system that serves to remove smoke that is formed during the operation of a heating structure of any configuration, and performs the following functions:

- removes all combustion products from the room;

- prevents overheating and fire of building structures;

- insulates the building from the effects of aggressive condensate that forms in the pipes.

Chimneys, according to the material of manufacture, are divided into four types:

- brick, traditional and the most common until recently. Inexpensive, withstands any temperature, but requires the use of refractory, solid ceramic or clinker bricks. It is often used as a design move when creating the exterior of a building. The main disadvantages are destruction under the action of condensate, which forms in winter due to temperature changes, and an uneven inner surface, which reduces the efficiency of traction;

- ceramic, they are chosen for the ease of installation and operation, high traction efficiency, a large assortment of structural blocks. But this is an expensive kind of material and mostly imported;

- plastic has a very narrow field of application - condensing boilers, in which the release products are not higher than 120 ° С;

- metal is the most common in recent years, because it has excellent functional qualities and affordability.

Brick chimneys. An original solution to the exterior design.

Building regulations

The construction of a smoke removal device requires compliance with the building rules set out in SNiP.

Let's list the main ones:

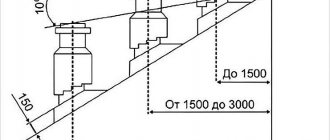

- the height of the straight chimney to ensure normal draft must be at least 5 meters;

- above the ridge of the roof, it should rise by 50 cm, and be at a distance of 150 cm from it;

- connections of pipes in outlet or passage openings of the wall and ceilings are prohibited;

- the diameter of the smoke duct should not be narrower than the Ø of the outlet of the heating unit;

- pull-down chimneys should not have more than three bends along the entire length of the duct.

Internal chimney gasket

The main technological features during the installation of the internal chimney are to ensure tightness when removing its element to the outside and the safety of wiring hot parts through the ceilings.An air gap is mounted between the ceiling and the pipe, the hole is insulated with non-combustible insulation. The same is done for the port and flow.

Non-combustible mineral wool covered with foil is used as insulation. If the chimney is at a distance of 1.5 m from the roof ridge, then the chimney itself should rise 0.5 m above the ridge (taking into account the draft). For a flat roof, this figure does not exceed 50 cm. If the heater is located further than 3 m from the ridge, then the chimney is located at an angle of 10 ° to the ridge. With a pipe height of more than 2 m, it is strengthened with stretch marks.

offers its customers quality steel chimneys and installation services.

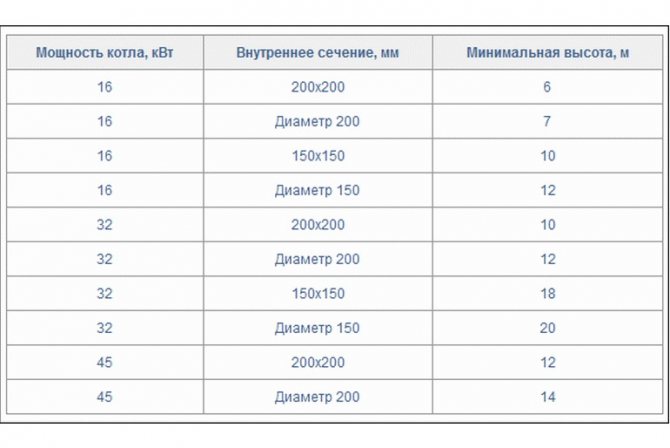

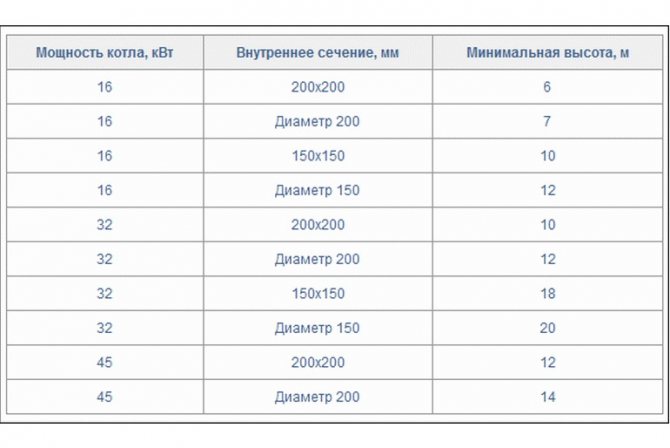

Traction force

The draft of a straight flue duct depends on its diameter and height. For the correct selection of these parameters, a special table is used. A height of 5 m is considered optimal.

For horizontal clamping ducts, the pulling length is 3 meters.

When combining both sections, it is recommended to increase the height of the pipe by one meter for each meter of the horizontal section.

To increase traction, you can apply one of the following options:

- increase the height of the bend above the roof;

- attach a special weather vane to the head;

- use an electric smoke exhauster.

The main parameters of pipes for chimneys

An important parameter that affects the functionality of the entire flue system is the pipe wall thickness.

European standards provide for the following geometrical dimensions of chimneys:

- In heating systems operating on gaseous fuels, pipes made of appropriate steel grades with a wall thickness exceeding 0.5 mm are used.

- For liquid fuel heating units, the pipe wall thickness must be more than 0.8 mm.

- In systems with solid fuel equipment, stainless steel metal smoke pipes with a wall thickness of more than 1 mm can be used.

In addition to the steel grade from which the pipes are made, and the thickness of their walls, other factors also affect the functionality of the smoke exhaust system: the height of the pipe, the size of the chimney diameter and the draft force.

Usually, for chimneys, the following relationship is valid - the higher the pipe, the stronger the draft. In this case, the ratio of the pipe diameter and its height must be calculated by a specialist or independently using special programs that can be found on the Internet. Erroneous calculations can lead to a violation of aerodynamic equilibrium and difficulty in removing combustion products from the pipe.

As for the shape of the chimney, then, as mentioned earlier, a circular cross section is optimal. Any bend or protrusion serves as a site for potential smoke build-up.

When designing a chimney, one more rule must also be observed - the horizontal section should not be more than a meter in length. Otherwise, it can provoke the accumulation of soot in it.

Other structural features of the chimney are determined by the structural and architectural features of the building and the place where the heating unit is installed.

Internal and external chimneys

Internal chimneys are installed inside the building, and only a chimney made of steel or lighter metal is brought out. The installation of the internal chimney provides for a number of additional measures - the device for supporting the chimney and the installation of a protective casing. Insulation in this case is required only for the part that is located above the attic floor.

The design of an internal chimney is more complicated than an external one - in installation, routine maintenance, repair. In addition, the internal chimney poses a potential carbon monoxide poisoning or fire hazard. Therefore, when installing an internal chimney, it is necessary to strictly adhere to all the rules of the corresponding instructions.

External and internal chimney

External attached chimneys are mounted outside the building, they include the following elements: a connecting flue, supporting a wall bracket, revision, main sections. Outdoor t

The steel pipe is safe, easy to install, maintain and repair. The location of the pipe does not depend on the internal structure of the premises. Insulation of external chimneys is mandatory.

Making and installing a chimney with your own hands

The correct choice and competent installation of a ready-made chimney kit is essential for its further functioning. It would be wise to entrust this work to professionals. If you have the appropriate skills and are confident in your abilities, you can assemble and install the smoke extraction device yourself.

The installation process includes the following steps:

- determination of the chimney configuration;

- calculation of the required pipe size depending on the power and size of the outlet pipe of the heater;

- marking of openings on the wall and ceilings;

- drilling these holes;

- laying thermal insulation in them;

- connecting the initial section of the pipe to the heating device;

- assembly and fastening of chimney units, output of the end part to the outside;

- securing the sleeve in the outlet openings;

- installation at the end of the chimney of a wind shield and elements that prevent the formation of condensate and its freezing at the outlet of the pipe;

- finishing the chimney, both on the roof and inside.

Drawing and diagrams

Sizing calculation

We determine the power of the heating device.

We measure the cross-section of the outlet of the boiler or furnace.

Using the table, we calculate the dimensions of the chimney:

Types of industrial metal pipes

Industrial metal chimneys carry a high functional load. They are divided into several types, according to the type of supporting structure and fastening:

- freestanding columnar;

- farm;

- front;

- frameless;

- mast.

They are mounted according to a standard design. Similar projects have also been developed, in which the requirements for metal chimneys of boiler rooms are determined, depending on the type of boiler, for example:

- standard project 907-2-223cm "Metal pipe H = 30 cm for a boiler room with boilers KE-6.5-14S";

- standard project 907-2-247 "Metal pipes for the removal of flue gases with a temperature of 350 0С with an overhead junction of gas ducts at an elevation of +0.5 m."

Such documentation indicates the height, inner diameter, gas temperature at the entrance, the level of possible wind resonance, seismic resistance, weight, scope, design features. All information about the technical and operational data of a particular pipe is contained in its passport, which is drawn up and issued before putting the structure into operation.

To ensure trouble-free operation, in accordance with SP 13-101-99 "Rules for supervision, inspection, maintenance and repair of industrial chimneys and ventilation pipes", industrial inspections are regularly carried out. Based on the results of these examinations, an act is drawn up with an assessment of the condition of the pipe and recommendations for eliminating defects in work.

Installation features

The installation is designed so that most of the chimney is indoors. Thus, heat loss is reduced.

The correct assembly of the chimney begins from the heater. Pipe connections are carried out using the bell-shaped method: the upper part is inserted into the lower one up to the latch, if it is not there, by half the channel diameter.

Wall mounts are spaced at least 1.5 meters apart. Elbows and tees are mounted on separate brackets.

Contact of structural elements with the communications of the house is not allowed.

Installation of stainless steel chimneys: basic steps

Before starting the installation of the steel chimney, it is necessary to treat all internal seams with a special sealant capable of withstanding temperatures up to 10000C. This measure has a positive effect on the functionality of the smoke exhaust system and significantly prolongs its operational period.

Sealant treatment is necessary, since the highest quality rolling or welding does not ensure absolute tightness of the seams. Outside processing is not required as the sealant will not adhere.

Basic rules for installing a metal chimney:

- The installation of chimneys is carried out from the bottom up, that is, the installation of all elements starts from the heating equipment and goes up to the chimney on the roof.

- The chimney links are assembled sequentially. Each subsequent element is inserted into the previous one. This technique of joining parts makes it possible to avoid the ingress of condensate into the insulation.

Fire safety standards regulate the depth of installation of pipes on top of each other. This value should be more than half the outer diameter of the pipe.

- Working channels are laid along walls or internal partitions, which must be made of non-combustible materials.

- The metal chimney is connected to the fixation with special clamps, which are often sold complete with the chimney.

- Every one and a half to two meters, a steel inspection or chimney is attached to the supporting structures using brackets. Each shaped piece - tee or branch - is fixed with a separate bracket.

Horizontal sections of the chimney need constant monitoring. Their contact with electric cables, wires and gas pipes must be excluded. For the convenience of cleaning the chimney with its active use, a door is provided in the lower part of the structure or a removable part is installed.

Chimney protection means

If a metal chimney is placed near the building to be insulated, then its insulation is also necessary. The main purpose of the insulation layer is to ensure rapid heating of pipes and to reduce the amount of condensate falling out.

When chimneys are placed near flammable materials, the insulation layer serves as an additional fire protection. To protect external chimneys from the ingress of pollutants into them, as well as to protect them from moisture and atmospheric phenomena, deflectors, nets and weather vanes are used.

The efficient and safe functioning of the heating system as a whole directly depends on the correct selection of material for chimneys and their competent installation in compliance with all the conditions regulated by regulatory documents.

Frequent errors and problems during installation

Low height of the chimney device. As a result, traction is lost.

The chimney outlet must be higher than the ventilation ducts if they are designed in one block. Otherwise, reverse thrust occurs.

The choice of a chimney, guided only by a low price. Single-wall pipes made of ferrous metal, thin galvanized are suitable only as temporary devices. Even from stainless steel, not all brands are sufficiently heat-resistant. Preference should be given to alloys that can withstand 700 oС and above: AISI 304, 309, 316, 321.

Expert advice

The highest system temperature is observed at the point where the flue duct is connected to the heat generator. Therefore, the initial part of the insulated chimney must be non-insulated, made of heat-resistant material in order to prevent overheating.

It is better to place the condensate trap indoors. On the street in severe frost, it can turn into ice and break the container.

The traditional umbrella fungus does not cope well with extinguishing sparks, wind protection. Instead, it is recommended to install a deflector on the top of a straight pipe, which is fixed with self-tapping screws.

Types of metal chimneys, their area of application

Heating structures are installed together with chimneys, which:

- remove smoke from the room;

- prevent overheating and ignition of structures;

- create a natural draft that removes combustion products from the flow chamber.

For your information! For stoves, fireplaces, gas equipment, smoke removal structures are used.

What are the metal chimneys:

- Single-walled. They are installed as temporary outlets for stoves in a bath. They have no thermal insulation material.

- Two-layer. They have a second name "sandwich". The structure consists of two pipes of different diameters, between which there is a heater.

- Coaxial. They consist of two pipes of different diameters. They do not touch each other. For this, special jumpers are used.

Chimney types

Coaxial view of the chimney

The construction industry produces a wide variety of pipe types:

- Corrugated steel. They are used for chimneys in which the fuel combustion elements have a low temperature. For example, for a gas water heater.

- Steel without alloy additions. With constant operation of heating structures, they are not advised to be used due to their weak strength. However, if the pipe has sufficient thickness, it is installed if there is a reserve boiler.

- Galvanized. The material is poorly affected by corrosion and corrosive acids. It burns out quickly. Installed for intermittent use when gas fumes are at low temperatures.

- Stainless steel. The material with alloying additions - molybdenum, chromium, nickel, titanium and others, has high strength. The chimney made of a steel metal pipe is intended for heating structures with high temperatures.

- Sandwich chimneys. A metal chimney pipe consists of elements wrapped in a heat insulator (basalt wool) and enclosed in a galvanized steel casing or inexpensive stainless steel. The whole structure is reliably connected into a socket, baguette or flange method.

- Seamless heat resistant. They are used in industrial or chemical plants. Such pipes are able to withstand temperatures in excess of 1200 ℃ with corrosive smoke. The grade of this steel is 20x23H18. For household chimneys, it is desirable that the steel contains a nickel alloying addition. It will protect the structure from sulfur compounds.

Chimneys made of stainless steel

A metal chimney pipe made of stainless steel is not cheap, but it has excellent qualities for operation.

How to insulate

Chimney insulation is an urgent task in the Russian climate.

For this, a sandwich system has already been invented, when a pipe made of insulation is put on the outlet channel, and an external pipe acting as a protective box is put on it.

The so-called two-layer system with insulation is now widespread.

You can make a similar design yourself. Basalt wool is used as a heater, which is applied to the inner part, wrapped with a reinforced mesh and an outer pipe is put on top.

Our chimneys

For quite a long time, we were engaged only in the design and installation of smoke removal systems, using third-party components for this, it provides these services today - so, by contacting us, you can order the installation of Vulcan chimneys.

However, we noticed that:

- inexpensive third-party components were often substandard. We could not guarantee the long life of the chimney using these elements;

- quality components were often unjustifiably expensive. As a result, the total budget turned out to be very large. This, of course, was not to our customers' liking.

The solution to the problem was found quickly: we opened our own production of steel chimneys. It turned out that high-quality steel chimneys can be quite affordable.

Steel chimneys "Russdym" - the main features

- thick stainless steel - thickness from 0.55 to 1 mm;

- basalt fiber as insulation;

- high quality welded seams;

- verified geometry of all elements - no hammer fitting.

Advantages of steel chimneys for boilers and furnaces

- round cross-section - in such chimneys, the speed of movement of flue gases is maximum;

- Smooth inner surface - improves traction and reduces soot and condensation;

- resistance to aggressive components of soot and creosote - this is why we use high-quality stainless steel;

- small dimensions - steel chimneys can be mounted inside old brick ones;

- low weight - the elements can be simply attached with brackets to the walls of the building;

- affordable price - a steel chimney will cost significantly less than a Schiedel ceramic chimney and even cheaper than a brick one (however, brick ones are rarely used today);

- affordable price;

- ease of maintenance and cleaning;

- sufficiently long service life.

Disadvantages of steel chimneys for stoves and fireplaces

- restrictions on the maximum temperature of flue gases. According to SP 7.13130.2013 “Heating, ventilation and air conditioning. Fire safety requirements ", the temperature of flue gases in steel smoke removal systems should not exceed 400 degrees Celsius. This is enough if you are going to heat with wood, but for coal stoves you will need a more heat-resistant chimney;

- for all its advantages, steel pipes are inferior to ceramics in terms of durability. True, they are much cheaper.